Turning device, base plate box aligning system and base plate box aligning method

A flipping device and substrate pair technology, which is applied in the direction of flipping objects, transportation and packaging, optics, etc., can solve the problem of low working efficiency of the flipping device, achieve the effect of saving power consumption and improving flipping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

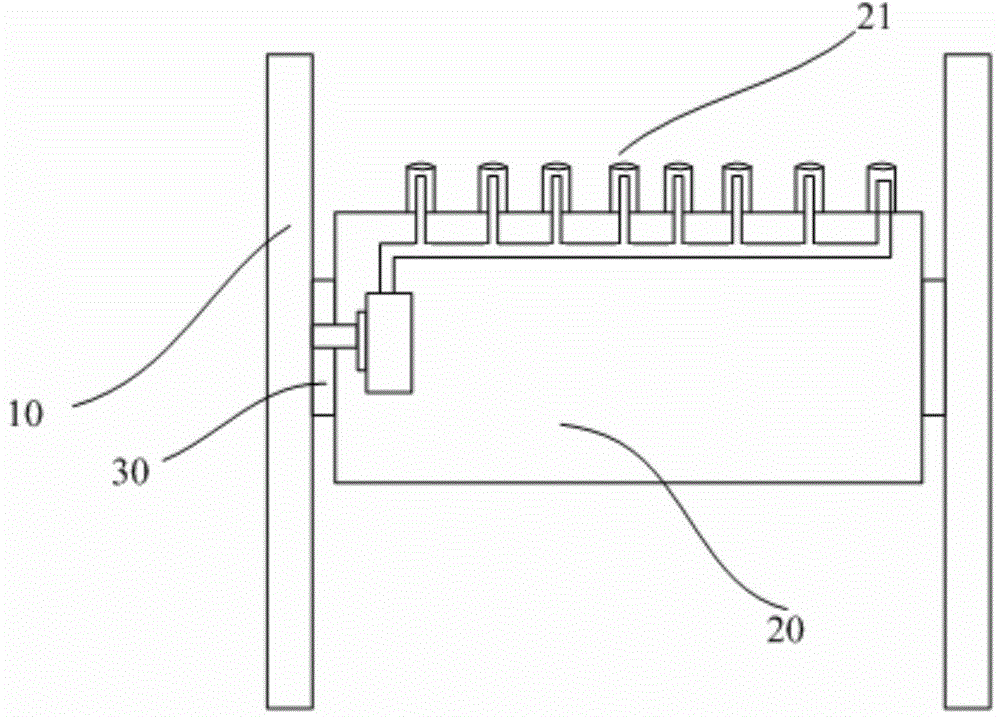

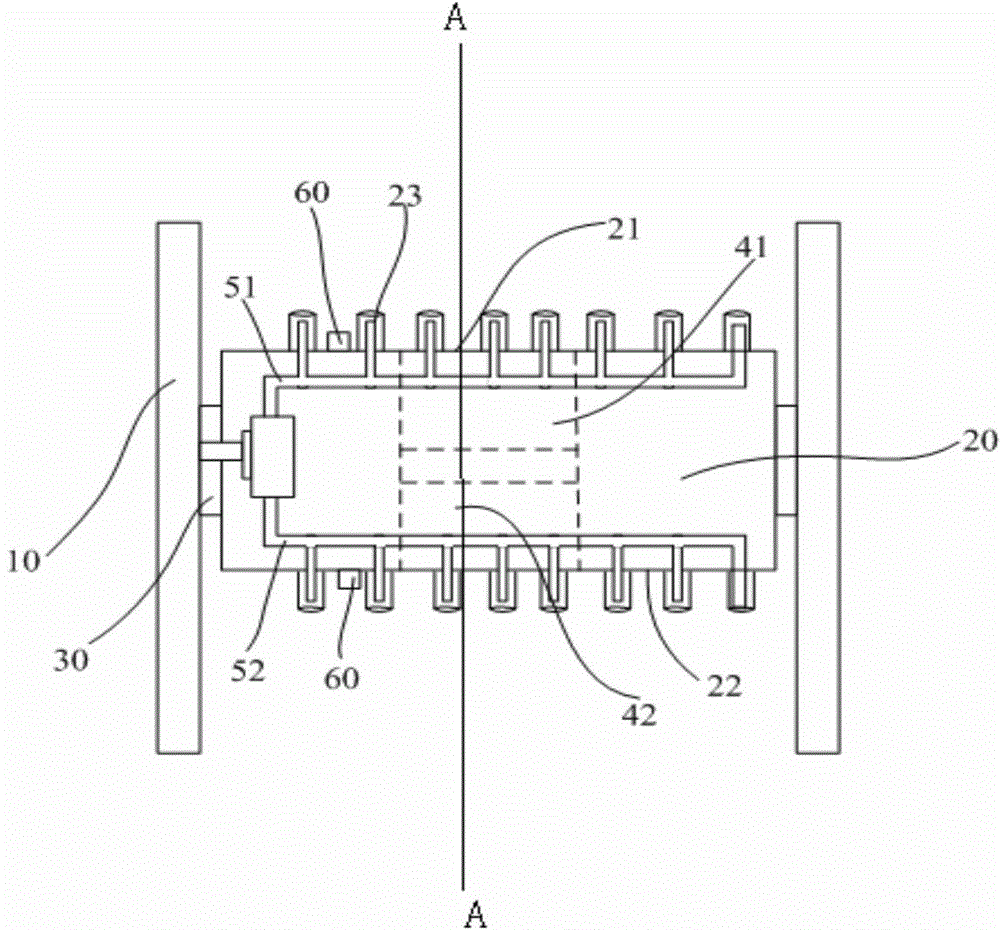

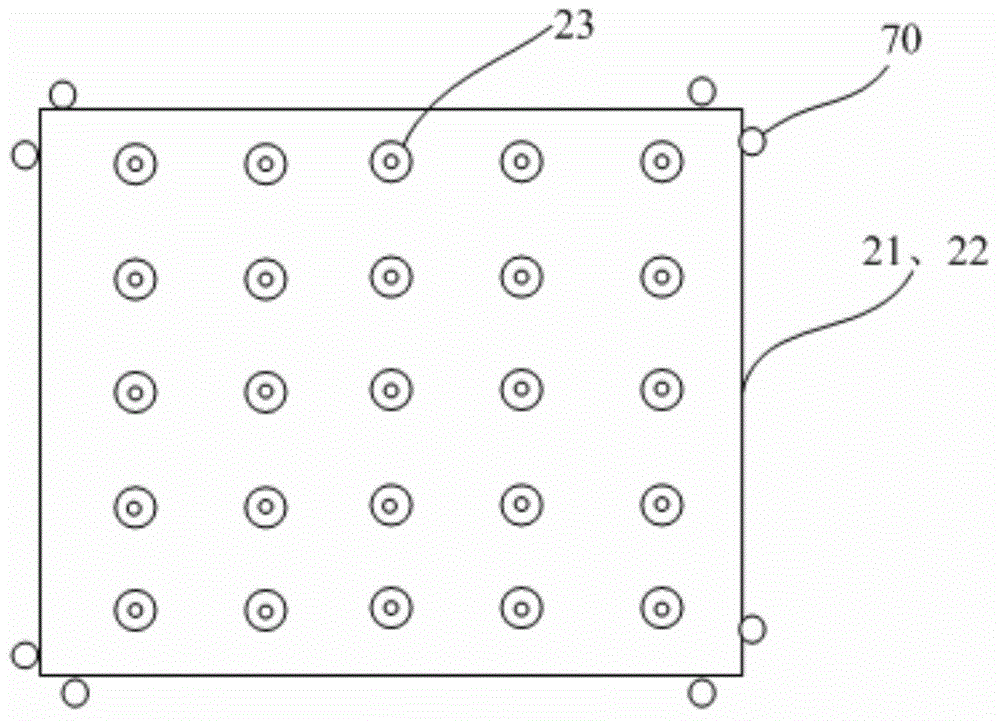

[0034] Such as Figure 2-5 As shown, the present embodiment provides a turning device, including a fixed bracket 10, and a turning platform 20 connected to the fixed bracket 10 through a vertical rotating shaft 30, respectively used to drive the first adsorption surface 21 and the second adsorption surface 22 in the horizontal The first horizontal rotation shaft 41 and the second horizontal rotation shaft 42 that rotate in the direction, as well as the vacuum adsorption unit and the control unit; wherein, the turnover platform 20 has a first adsorption surface 21 and a second adsorption surface 21 that are relatively arranged for adsorption of the substrate The adsorption surface 22 ; the control unit is used to control the vacuum adsorption unit to adsorb the substrate through the first adsorption surface 21 or the second adsorption surface 22 , and the inversion platform 20 inverts the adsorbed substrate through the vertical rotation axis 30 .

[0035] In the overturning dev...

Embodiment 2

[0045] This embodiment provides a substrate-to-cassette system, and the substrate-to-cassette system includes the turning device described in Embodiment 1. Of course, the substrate cassette alignment device of this embodiment also includes a position alignment device carrying the cassette alignment substrate.

[0046] Since the overturning device in this embodiment can pre-align with the box-matching substrate before the box-matching substrate is aligned, the alignment is more accurate and the alignment time is saved.

[0047] It should be noted that, at present, in the field of display technology, traditional flat-panel display substrates with double-layer substrates are usually manufactured through precise cell alignment processes, such as TFT-LCD liquid crystal display substrates or TFT-LCD liquid crystal display substrates. The liquid crystal cells that are used together to achieve 3D effects require strict control of the pre-alignment accuracy of the two substrates. At p...

Embodiment 3

[0050] This embodiment provides a substrate-to-cassette method, which includes the following steps:

[0051] Step 1. A substrate is sucked by the first suction surface 21 or the second suction surface 22 of the turning device, and the substrate is turned over to the alignment platform facing the alignment device carrying the alignment substrate.

[0052] Step 2: Detect the positional relationship between the substrate adsorbed by the first adsorption surface 21 or the second adsorption surface 22 of the turning device and the alignment substrate carried on the alignment platform, and align the adsorbed substrate with the alignment substrate.

[0053] Step 3: Align the adsorbed substrate with the alignment substrate, detect the positional relationship between the adsorbed substrate and the alignment substrate again, and align the adsorbed substrate with the alignment substrate.

[0054] When the fixed position of the substrate is defective after the box is aligned, step 4 may a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com