Adjustable full-automatic tilter and method thereof

A turning machine and fully automatic technology, which is applied in the field of turning machines, to achieve the effect of avoiding paper stack misalignment and waste products, improving work efficiency and saving manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

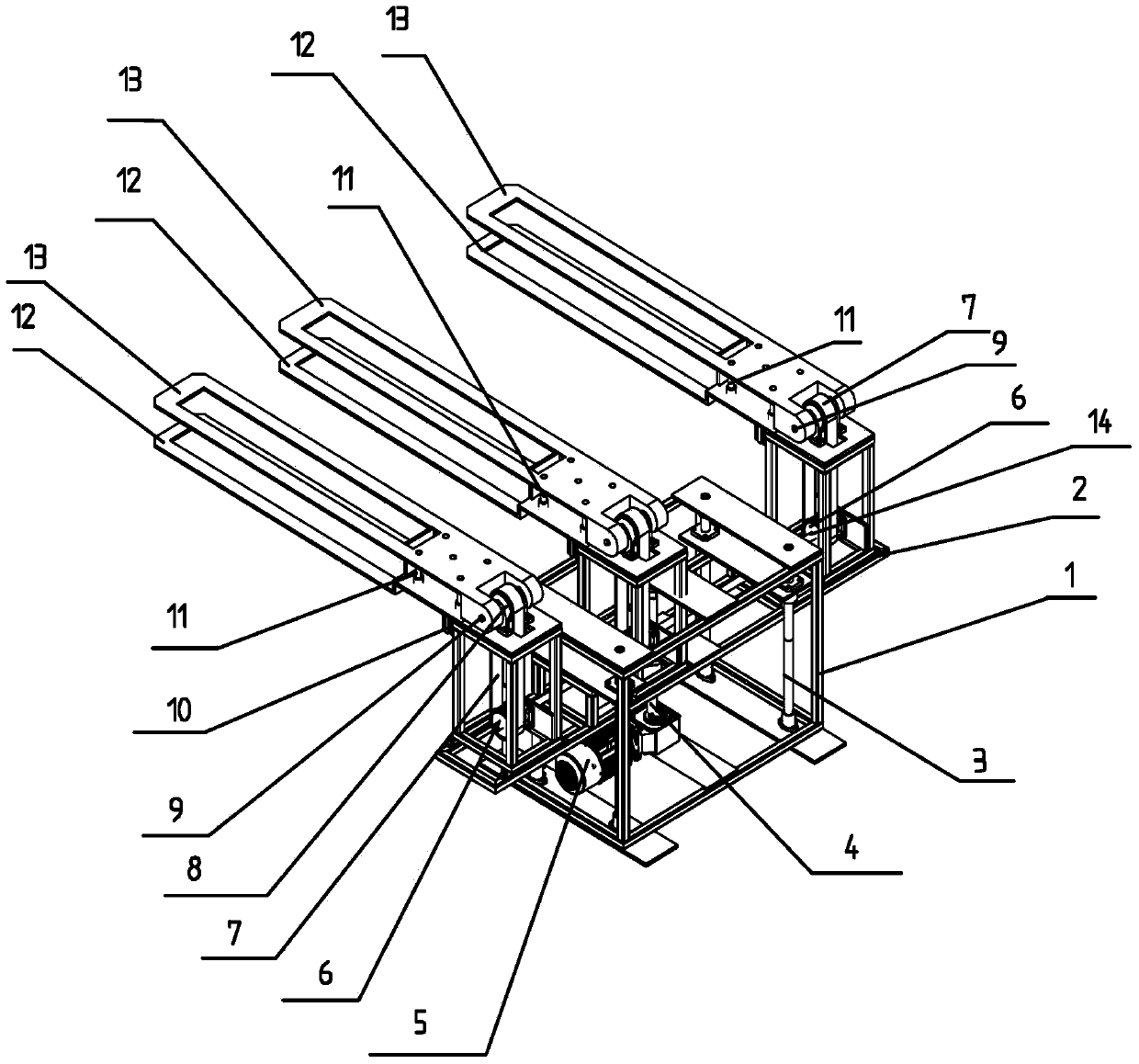

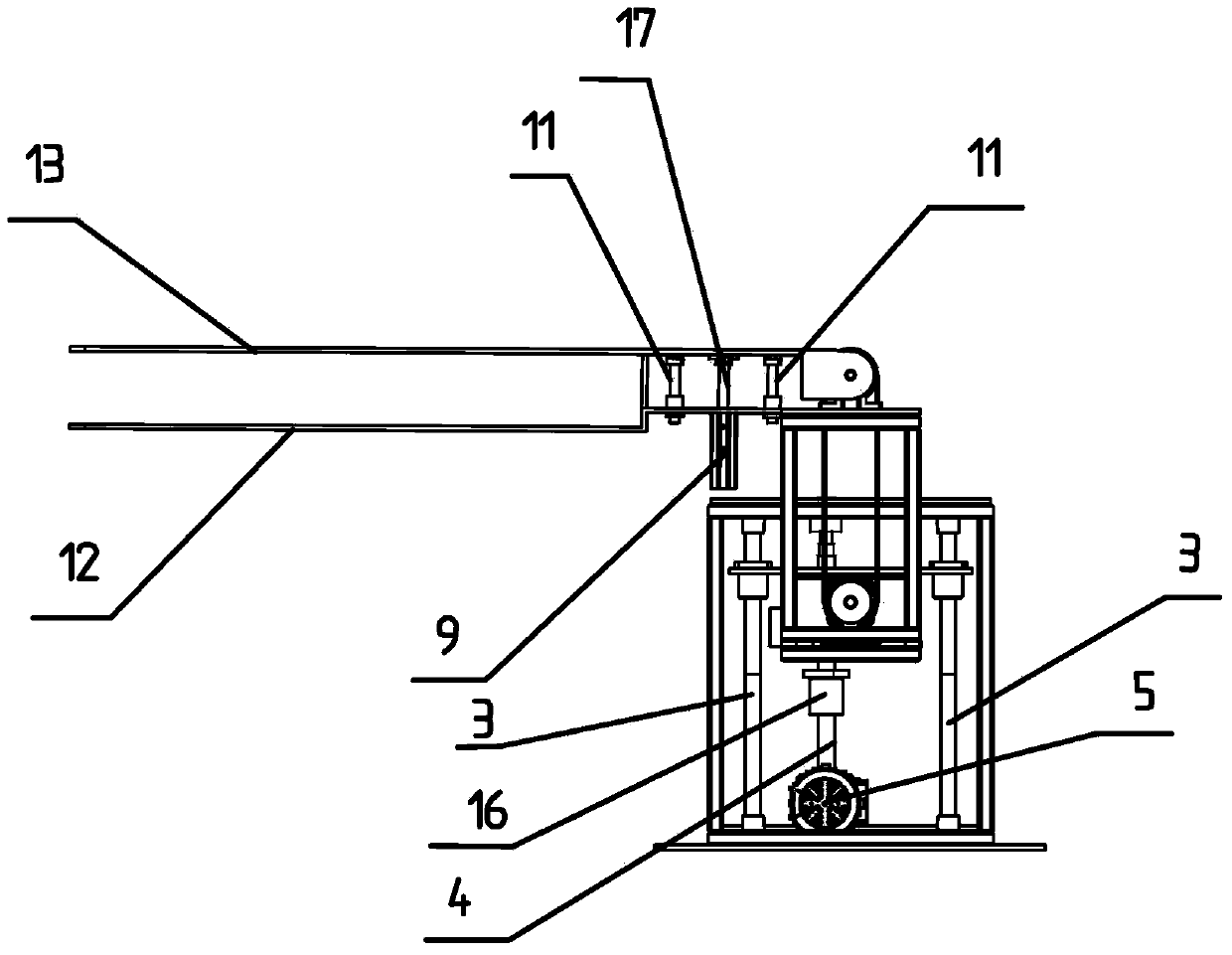

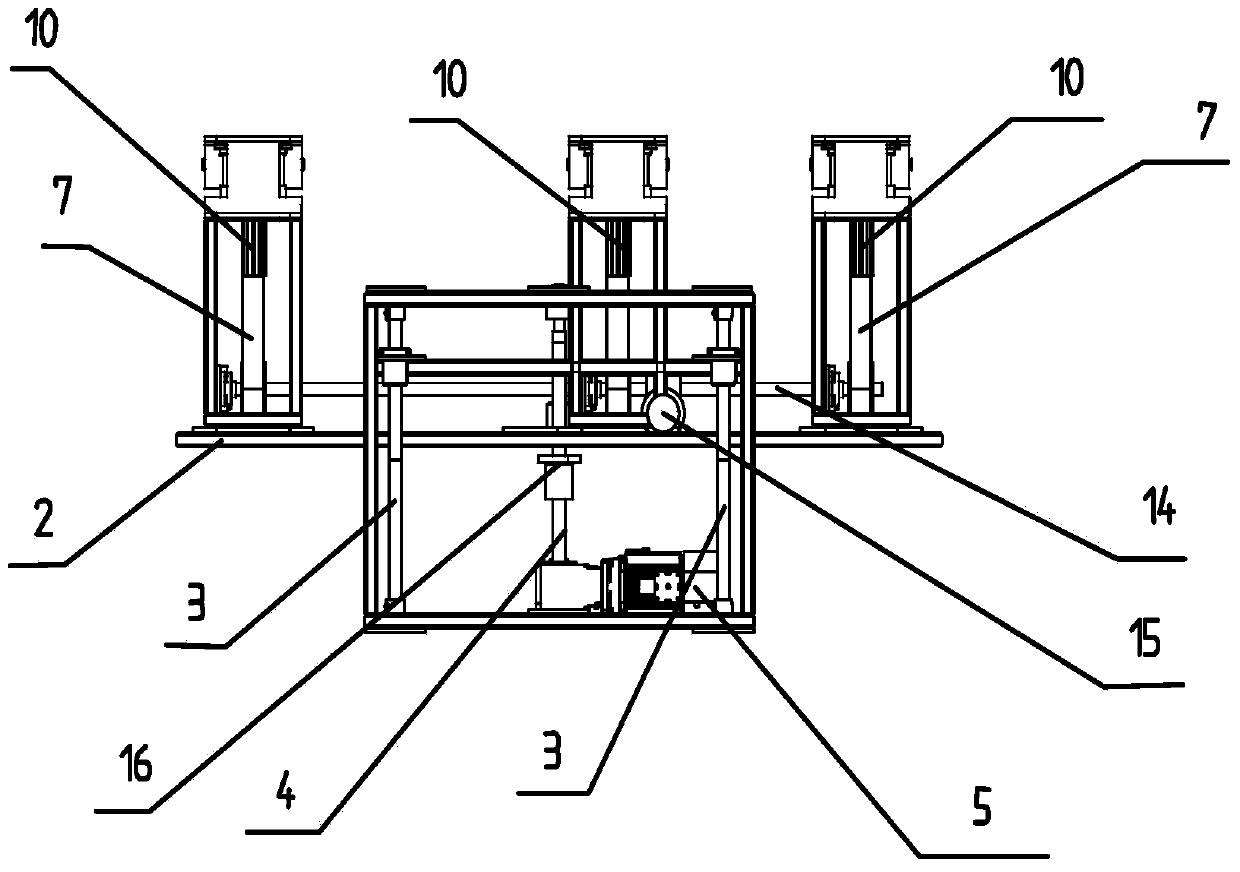

[0033] This embodiment provides an adjustable fully automatic turning machine. The turning machine adopts a multi-set splint structure. Each set of splints is composed of a fixed splint and a movable splint. The product is sandwiched between the fixed splint and the movable splint. The splint group passes through Rotate around the axis of rotation to achieve product flipping.

[0034] Such as figure 1 , figure 2 , image 3 As shown, a kind of adjustable fully automatic turning machine of the present embodiment comprises: base 1, lifting table 2, guide shaft 3, screw rod 4, lifting motor 5, driving wheel 6, synchronous belt 7, driven wheel 8, Rotary shaft 9, cylinder 10, guide rod 11, movable splint 12, fixed splint 13, main shaft 14, overturning motor 15, nut 16, cylinder push rod 17.

[0035] The base 1 is a rectangular frame structure, the bottom of the base is equipped with two rectangular feet, the bottom of the guide shaft 3 is fixed on the feet of the base 1, there a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com