Compound hard paperboard production line with automatic overturning and paper collecting functions

An automatic flipping and cardboard technology, which is applied in the direction of flipping objects, stacking receiving devices, sending objects, etc., can solve problems such as unevenness, serious bulging (severe bulging at both ends), and automatic stacking and collection of cardboards. Improve work efficiency and reduce the labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

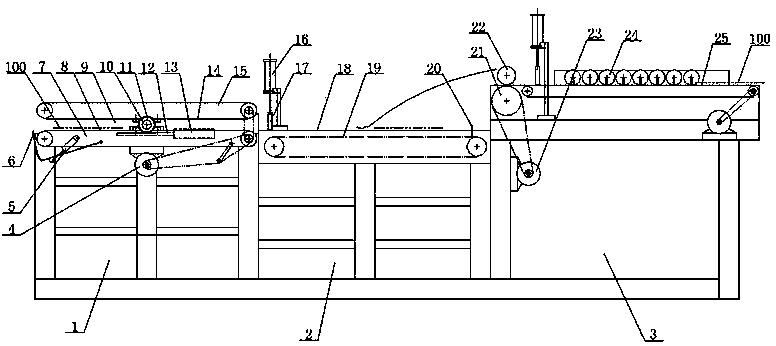

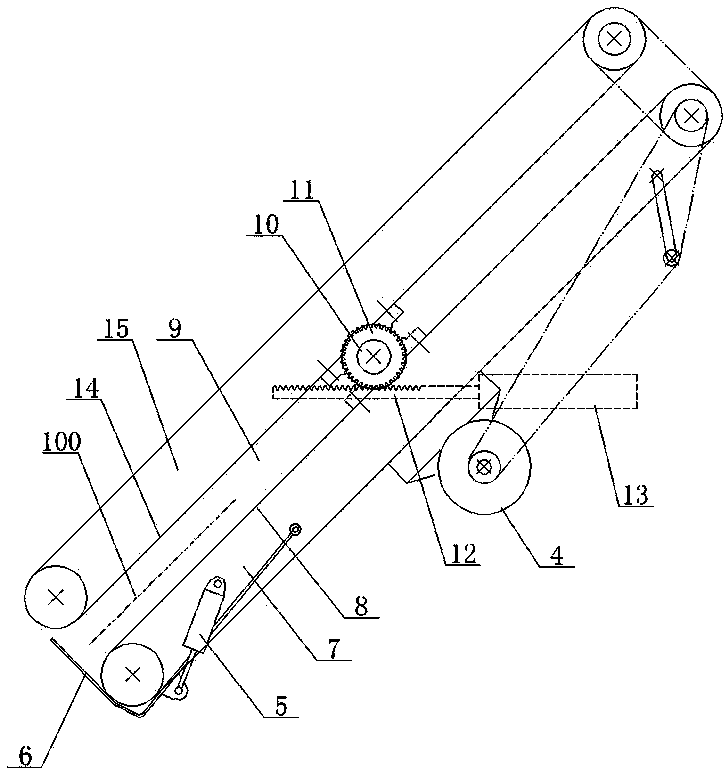

[0018] The accompanying drawings show the technical solution of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

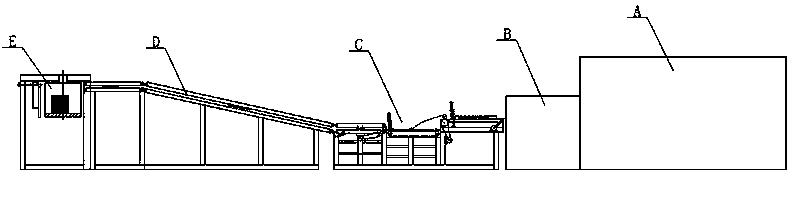

[0019] As shown in the figure, the cardboard composite production line with the function of automatic reversing and delivery of the present invention includes a composite machine A for composite cardboard, a rolling paper cutter B for transversely cutting composite cardboard, a paper feeding platform D for transporting cut cardboard, and a stacking machine. The automatic lifting delivery table E for collecting cardboard, the cardboard turning mechanism C is set between the paper cutter B and the paper feeding platform D, the cardboard turning mechanism C includes the cardboard alignment conveying part 3, the cardboard stacking conveying part 2 and the cardboard turning conveying part 1 , the paper feeding platform D is set at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com