Automatic shearing and stacking equipment that can be moved and lifted

A stacking and equipment technology, which is applied in the field of automatic shearing and stacking equipment, can solve the problems of large drop between the workpiece and the receiving trolley, high labor intensity of the operator, and affecting the stacking of workpieces, and achieves convenient operation, ingenious structure, and reduced labor. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific drawings and embodiments.

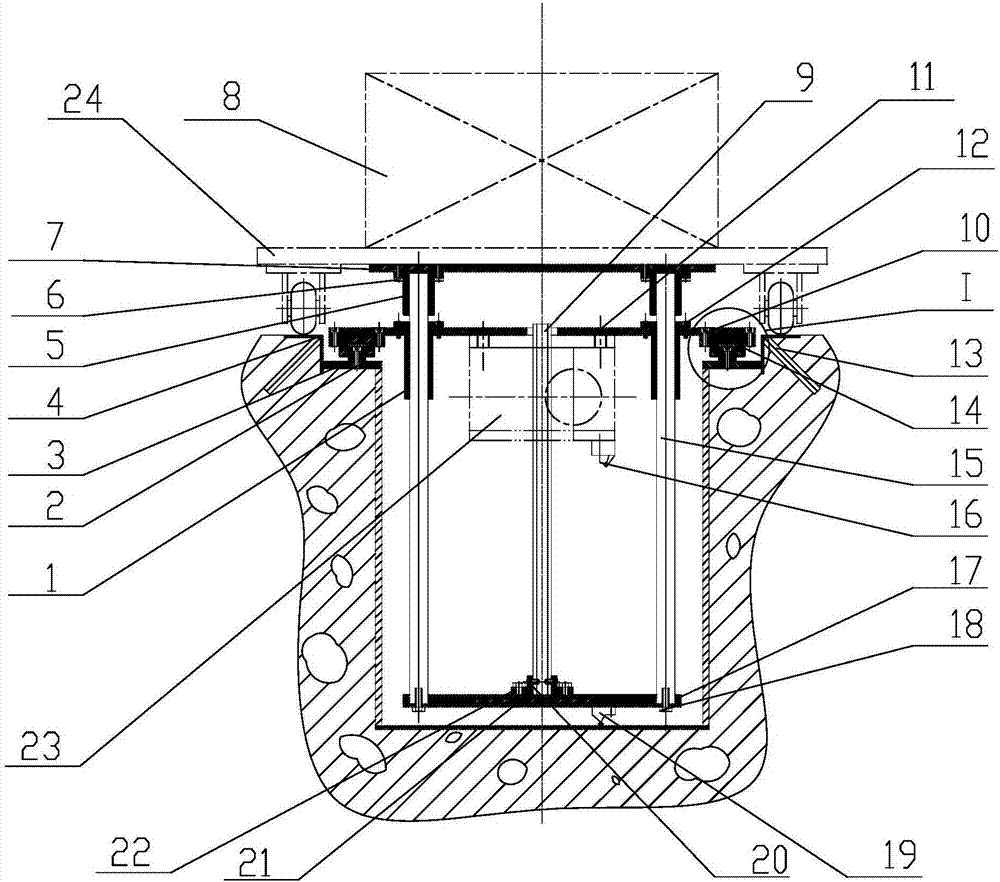

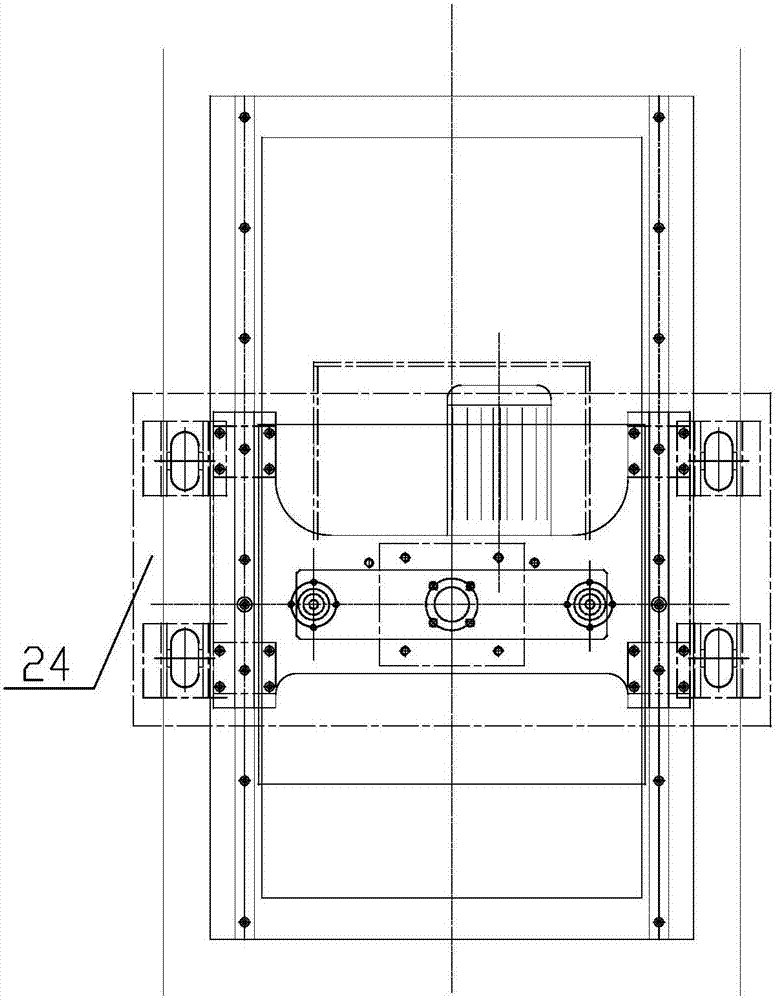

[0019] As shown in the figure: the movable lifting automatic shearing and stacking equipment in the embodiment is mainly composed of a lifting and moving device and a position adjustment mechanism.

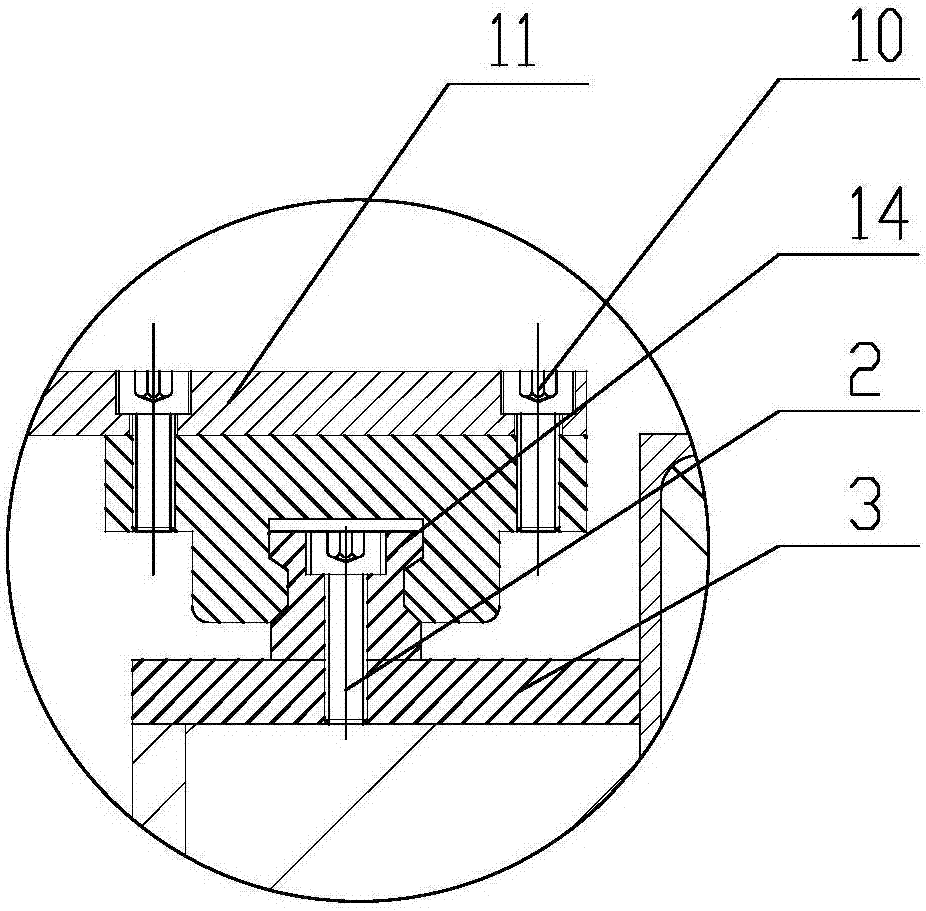

[0020] Such as Figure 1~Figure 3 As shown, the lifting and moving device is mainly composed of a long ball sliding sleeve 1, an upper supporting plate 7, a fixed middle plate 11, a guide column 15, a lower connecting plate 17 and a worm elevator 23; the worm elevator 23 is fixedly installed in the fixed The bottom of the plate 11, the center of the fixed middle plate 11 is provided with a through hole, the lifting screw 9 of the worm lifter 23 can pass through the through hole and move freely; A long ball sliding sleeve 1 is installed in each mounting hole, and the long ball sliding sleeve 1 is fastened on the fixed middle plate 11 with the fourth screw, and each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com