Panel turnover machine

A technology of flipping machine and flipping board, which is applied in the field of PCB manufacturing, and can solve problems such as impracticability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

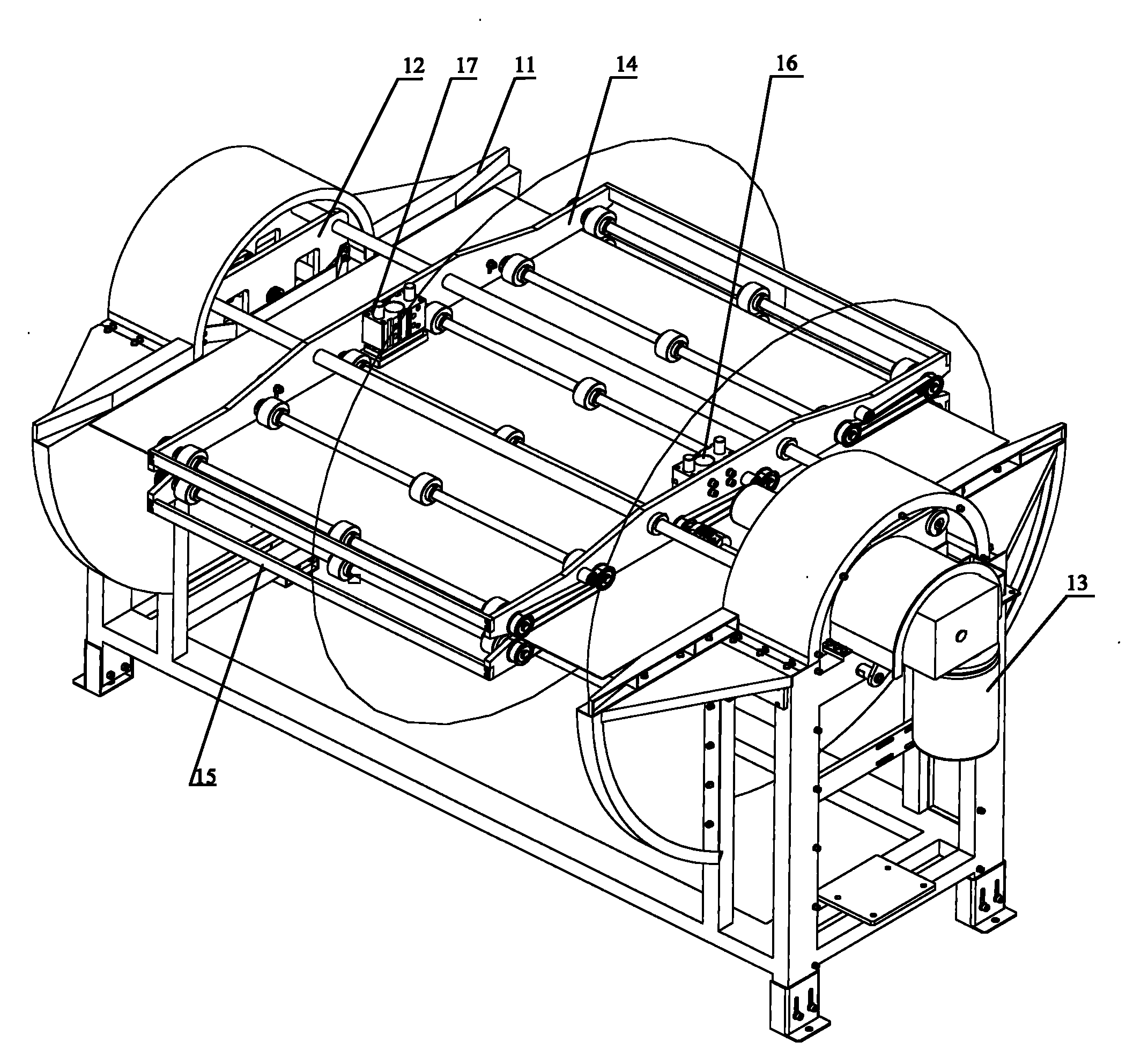

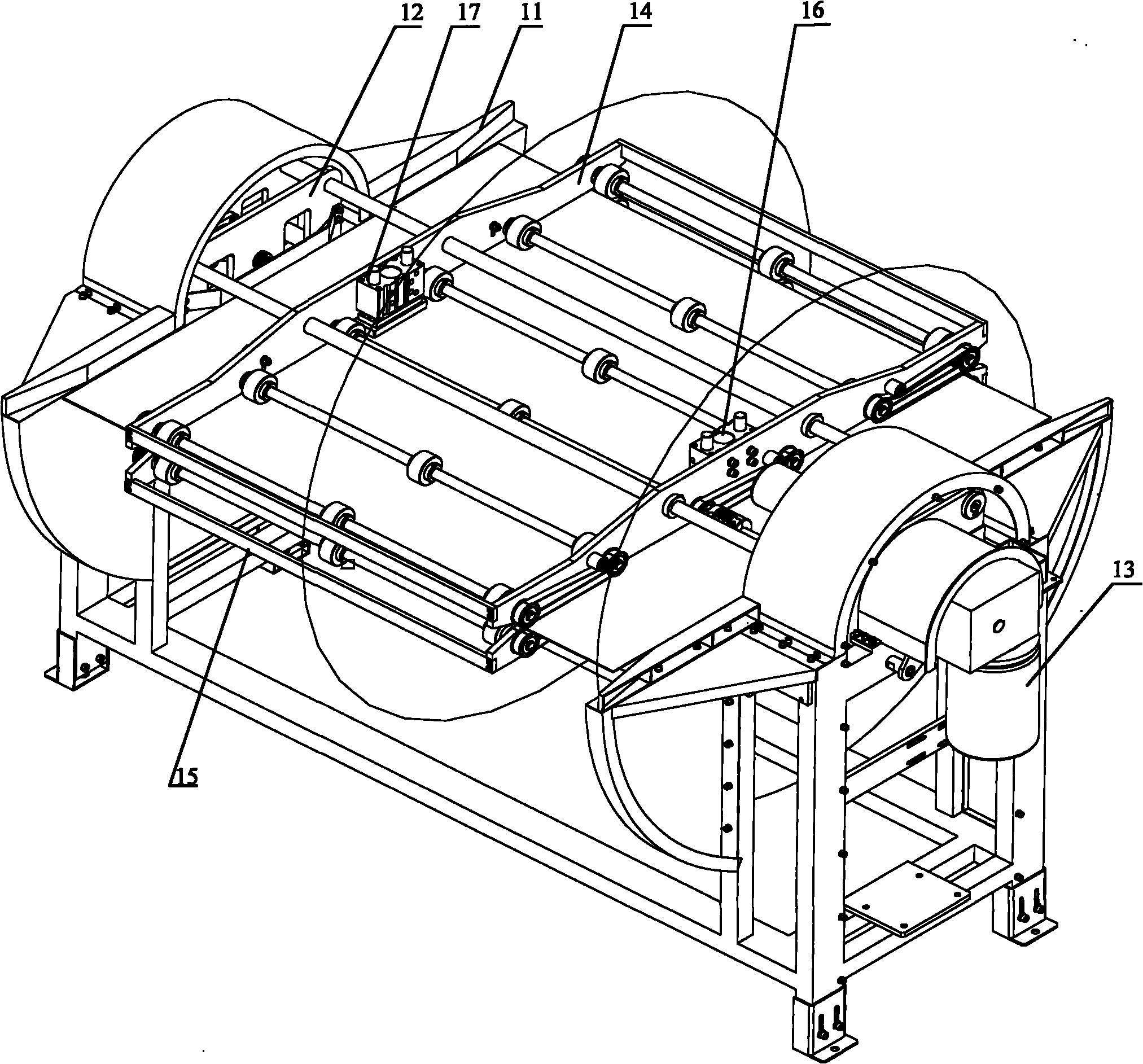

[0027] Such as figure 1 As shown, a turning machine includes: a frame 11 , a motor 13 , a mounting plate 11 , transmission components 14 and 15 and anti-falling components 17 and 16 .

[0028] The frame 11 is used to support the motor 13, the mounting plate 11, the transmission parts 14 and 15 and the anti-falling parts 17 and 16;

[0029] The motor 13 is fixed on one end of the frame 11, and the output shaft of the motor 13 is fixed with a first mounting plate (not marked in the figure), and the first mounting plate can rotate under the drive of the motor 13;

[0030] The second mounting plate 12 hinged on the other end of the frame 11 and rotates in the same direction as the motor 13;

[0031] Be installed in between described first installation board and the second installation board 12 and be used to transfer the transfer member 14 and 15 of turnover board, the distance between described transfer member 14 and 15 is greater than the thickness of transfer board; Transfer m...

Embodiment 2

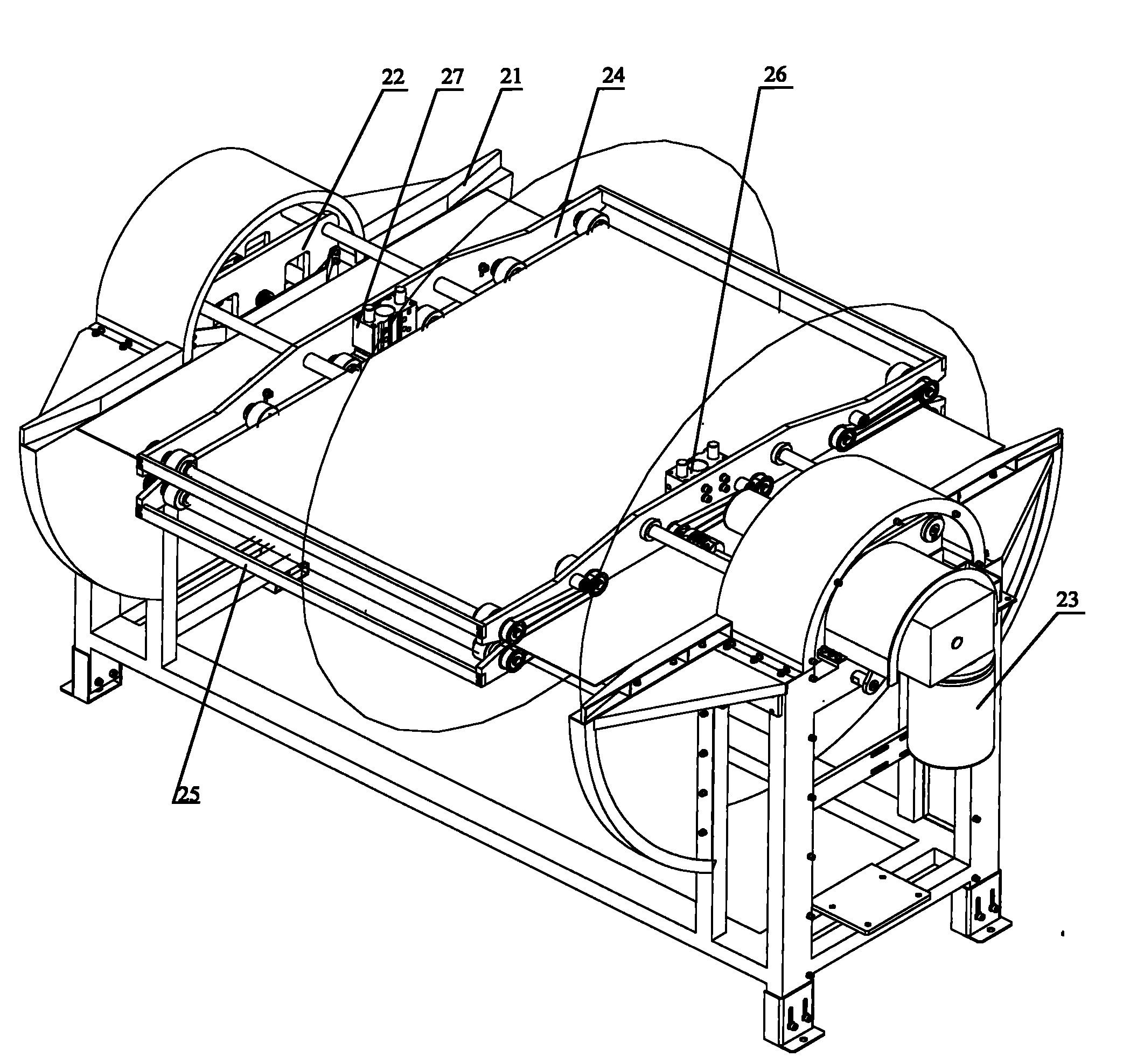

[0038] Such as figure 2 As shown, a turning machine includes: a frame 21 , a motor 23 , a mounting plate 21 , transmission components 24 and 25 and anti-falling components 27 and 26 .

[0039] The frame 21 is used to support the motor 23, the mounting plate 21, the transmission parts 24 and 25 and the anti-falling parts 27 and 26;

[0040] The motor 23 is fixed on one end of the frame 21, and the output shaft of the motor 23 is fixed with a first mounting plate (not marked in the figure), and the first mounting plate can rotate under the drive of the motor 23;

[0041] The second mounting plate 22 hinged on the other end of the frame 21 and rotates in the same direction as the motor 23;

[0042] Be installed in between described first mounting plate and the second mounting plate 22 and be used for transmitting the transmission parts 24 and 25 of flipping board, the distance between described transmission parts 24 and 25 is greater than the thickness of flipping board; Transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com