Dry-powder pulping method of lithium-ion battery

A lithium-ion battery, dry powder technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of cumbersome operation, affecting battery consistency, and high energy consumption, avoiding agglomeration, saving money, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A kind of lithium ion battery negative electrode dry powder pulping method, comprises steps as follows:

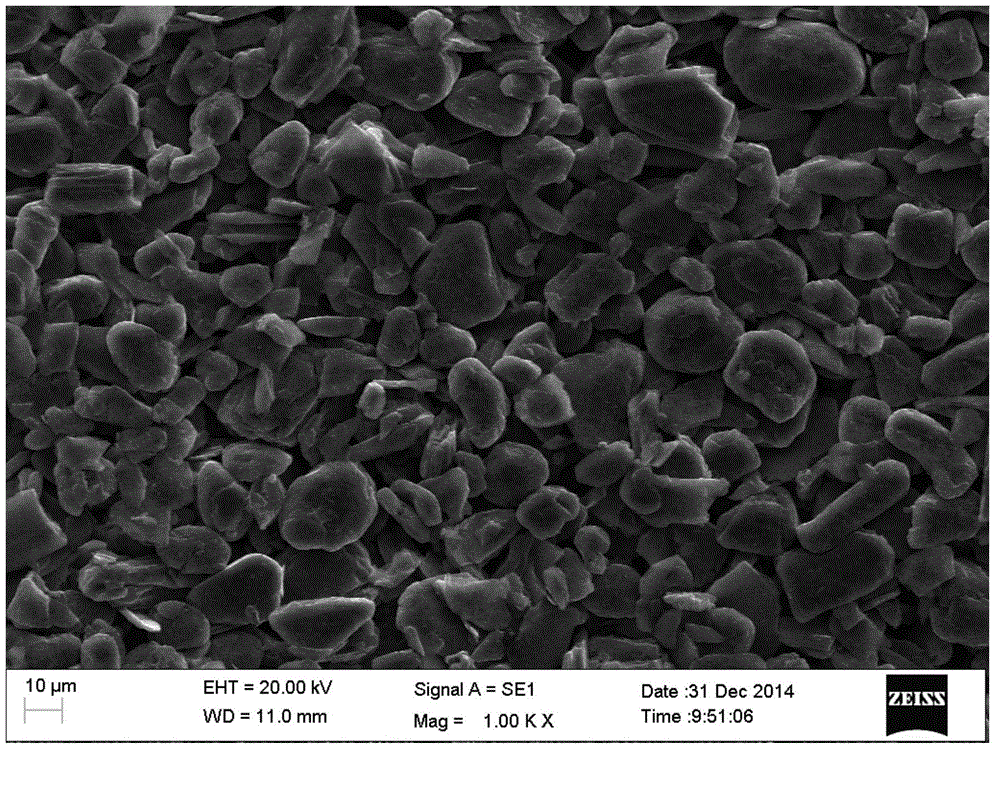

[0050] 1. Clean up the pulping machine, add the above-mentioned powdery materials into the pulping machine in the order of 1 / 2 active material, conductive agent, thickener, and 1 / 2 active material and stir, active material, conductive agent, thickener The weight ratios of the agent and the binder are respectively: 95.0%, 1.0%, 2.0%, 2.0%; adjust the revolution speed of the pulping machine to be 10r / min, the rotation speed to be 500r / min, and stir for 1h to obtain the mixed powder The active substance is graphite, the conductive agent is carbon black conductive agent (SP), the binder is styrene-butadiene rubber (SBR), the thickener is carboxymethyl cellulose (CMC), and the solvent is deionized water.

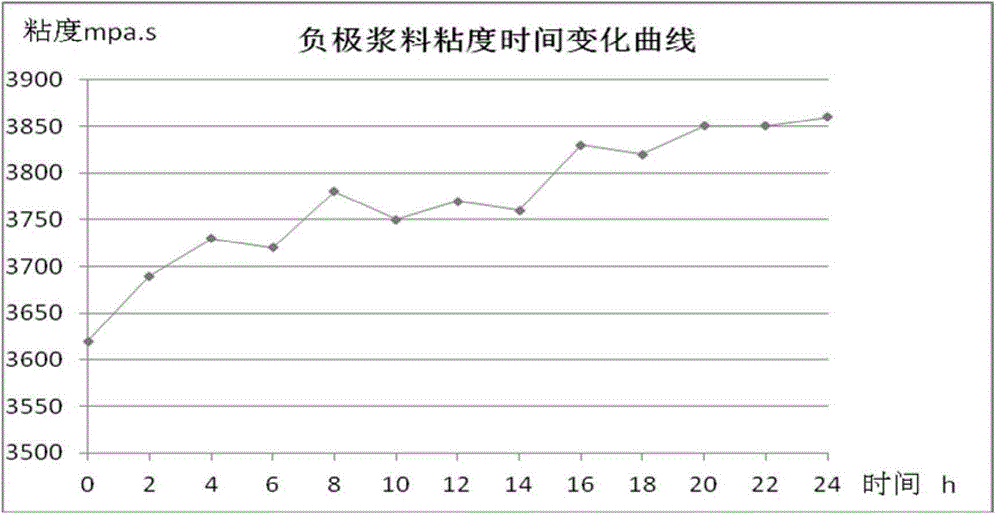

[0051] 2. Add the solvent in three times, add the solvent accounting for 70% of the total amount of solvent for the first time, adjust the revolution speed of the pulp...

Embodiment 2

[0063] A method for making slurry of lithium ion battery negative electrode dry powder, as described in Example 1, the difference is:

[0064] Step 2, add the solvent in 4 times, add the solvent accounting for 60% of the total amount of solvent for the first time, adjust the revolution speed of the pulping machine to 40r / min, the rotation speed to 2000r / min, stir for 1h, and control the temperature at 48°C during this process. Obtain viscous slurry;

[0065] Step 3, carry out scraping and bottom turning, scrape off the viscous slurry on the stirring paddle and turn up the slurry at the bottom of the mixing tank, without leaving a dead corner of stirring; after scraping and turning the bottom, add the solvent for the second time The total amount of solvent is 20%, adjust the revolution speed of the pulping machine to 50r / min, the rotation speed to 2500r / min, and stir for 1.5h to further dilute the viscous slurry. The process controls the temperature to 50°C and the vacuum degre...

Embodiment 3

[0069] A method for pulping positive electrode dry powder of lithium-ion batteries, comprising the following steps:

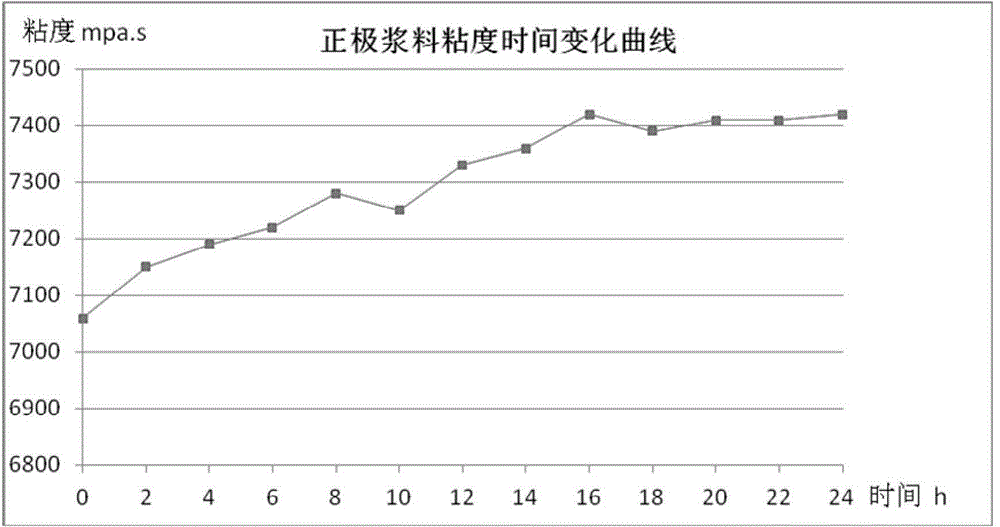

[0070] 1. Clean up the pulping machine, add the above-mentioned powdery materials into the pulping machine according to the feeding order of 1 / 2 active material, conductive agent, binder, and 1 / 2 active material, and stir. Active material, conductive agent, thickener The weight ratios of the agent and the binder added are respectively: 96.0%, 2.0%, and 2.0%; adjust the revolution speed of the pulping machine to be 15r / min, the rotation speed to be 1200r / min, and stir for 0.5h to obtain the mixed powder;

[0071] The active material is lithium cobaltate, the conductive agent is carbon nanotubes (CNTs), the binder is polyvinylidene fluoride (PVDF), and the solvent is N-methylpyrrolidone (NMP).

[0072] 2. Add the solvent accounting for 75% of the total amount of solvent for the first time, adjust the revolution speed of the pulping machine to 15r / min, the rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com