Novel adjustable multistage hotpot seasoning stir-frying and stirring device

A hot pot bottom material and stirring device technology, which is applied in food forming, food science, application, etc., can solve the problems of low processing speed and efficiency of hot pot ingredients, lack of fragrance between materials, and limit the taste of hot pot ingredients, so as to achieve simple structure and easy use Flexible and convenient, quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means realized by the present invention, creation feature, purpose and effect be easy to understand, the following

[0013] The present invention will be further elaborated in combination with specific embodiments.

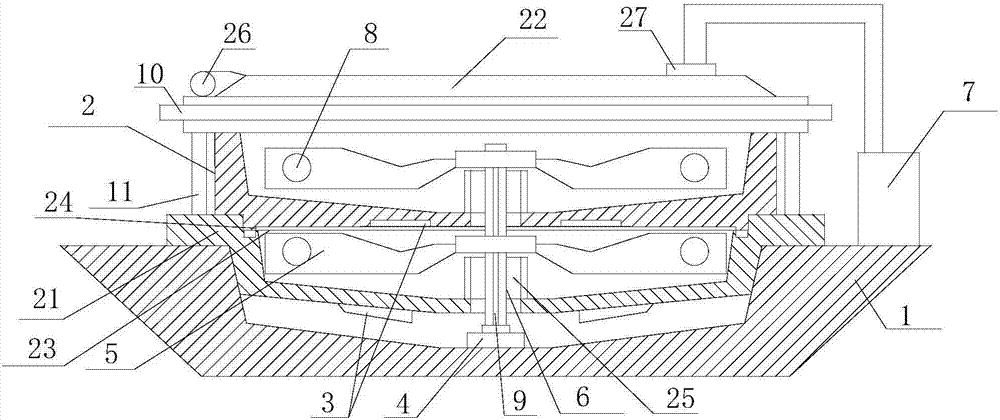

[0014] Such as figure 1 The novel adjustable multi-stage chafing dish bottom material frying stirring device comprises a support frame 1, a frying pan 2, a heating device 3, a frying drive motor 4, a frying stirring paddle 5, a frying drive shaft 6 and Exhaust gas recovery device 7, frying pan 2, frying drive motor 4 and exhaust gas recovery device 7 are all installed on support frame 1, and frying pan 2 includes pot body 21 and sealing cover 22, wherein at least two pot bodies 21, the bottom of pot body 21 Positioning groove 23 is set on the outer surface, connecting groove 24 is set on the top, driving hole 25 is set at the axis of pot body 21, two adjacent pot bodies 21 are connected by positioning groove 23 and connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com