Four-bit embedded glass curtain window system

A glass curtain wall, built-in technology, applied in the direction of wall, wing fan layout, building components, etc., can solve the problems of strong dependence on construction measures, many cross operations, hidden dangers in construction safety, etc., to improve construction quality and appearance. , The operation is convenient and fast, and the effect of reducing engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

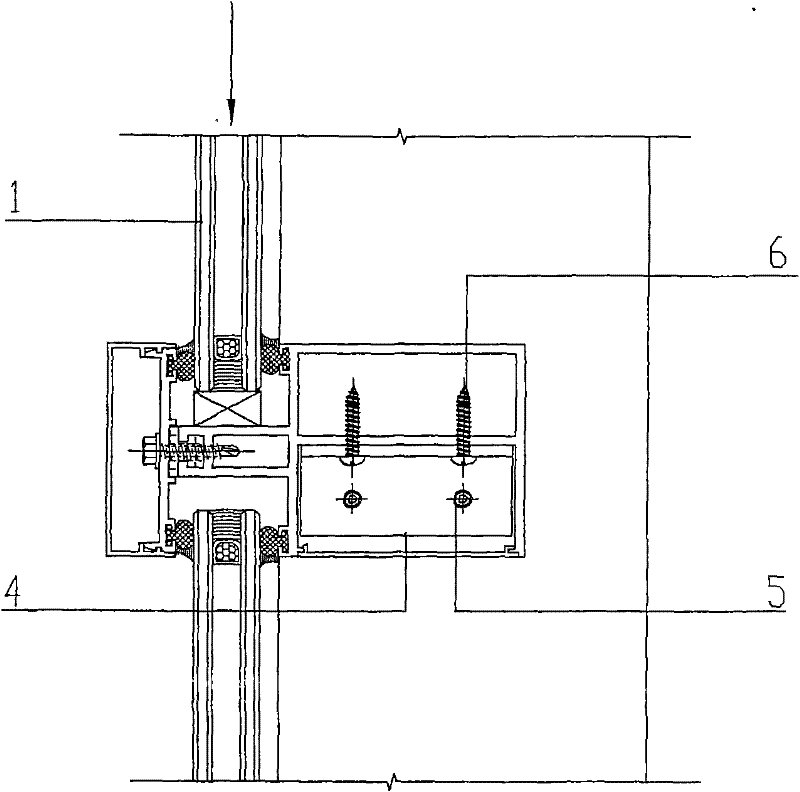

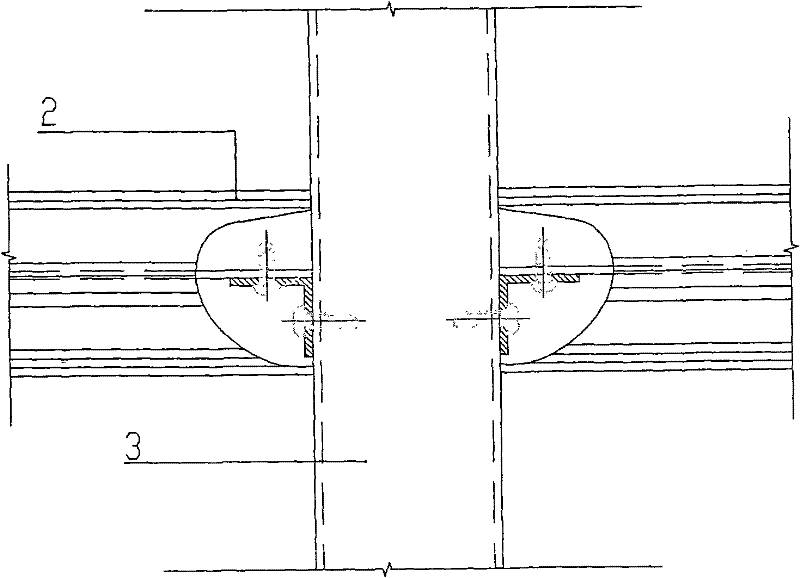

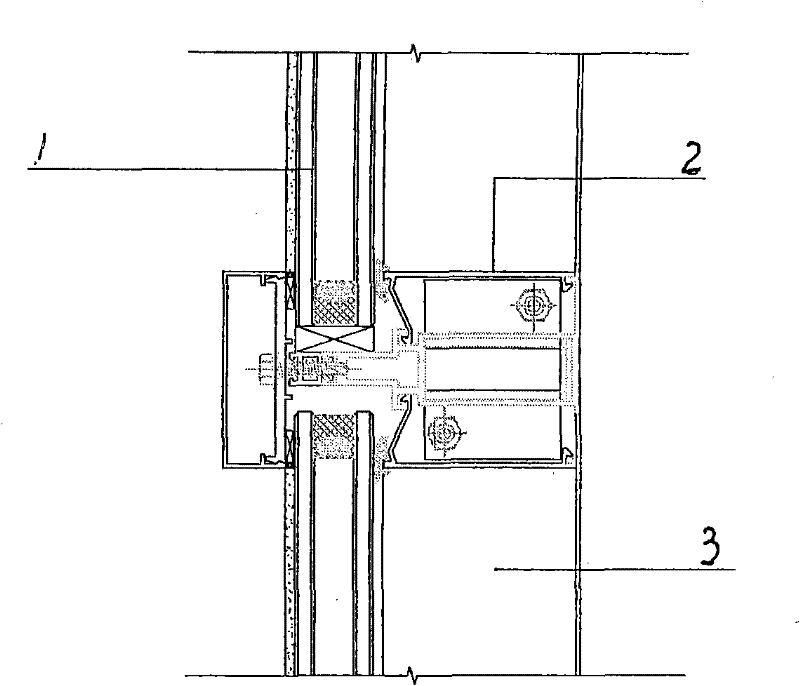

[0032] Such as Figure 2-a , Figure 2-b , Figure 4 , Figure 6 Shown: a four-position embedded glass curtain wall window system, which is composed of profile frame, glass and opening fan; column 3 and beam 2 double T-shaped embedded support beam corner code 7 is embedded in the cavity of the beam, and Through the penetrating screw 8, it is fixed on the column and assembled to form the profile skeleton of the curtain wall. The profile skeleton is connected to the main structure through steel adapters. The corner code 7 of the double T-shaped embedded support beam can realize the constraints on the upper and lower directions of the beam, and the force transmitted to the beam is a uniform load, and the action per unit area of the beam is much smaller than the concentrated force. Deformation will occur; under the action of this close-fitting structural form, the turning of the beam is greatly improved, and the construction quality and appearance effect are significantly impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com