Bearing insert to be inserted in inner hole part of plastic flow deflector shell of engineering plastic well pump

A technology of engineering plastics and guide shells, applied in the components, pump components, pumps and other directions of pumping devices for elastic fluids, can solve problems such as increased manufacturing costs, motor damage, inability to withstand radial forces, etc., and achieves low Production cost, effect of high bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

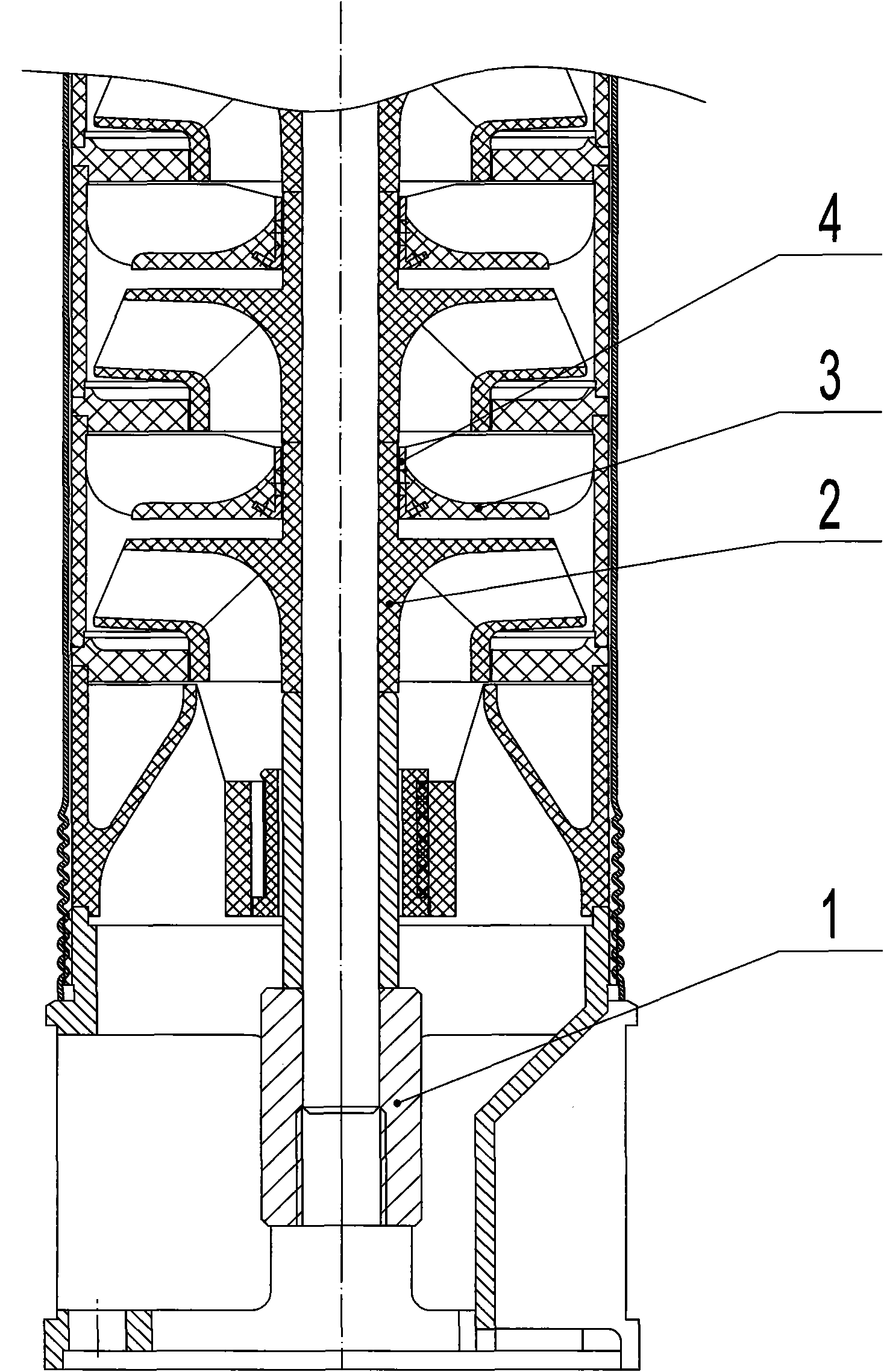

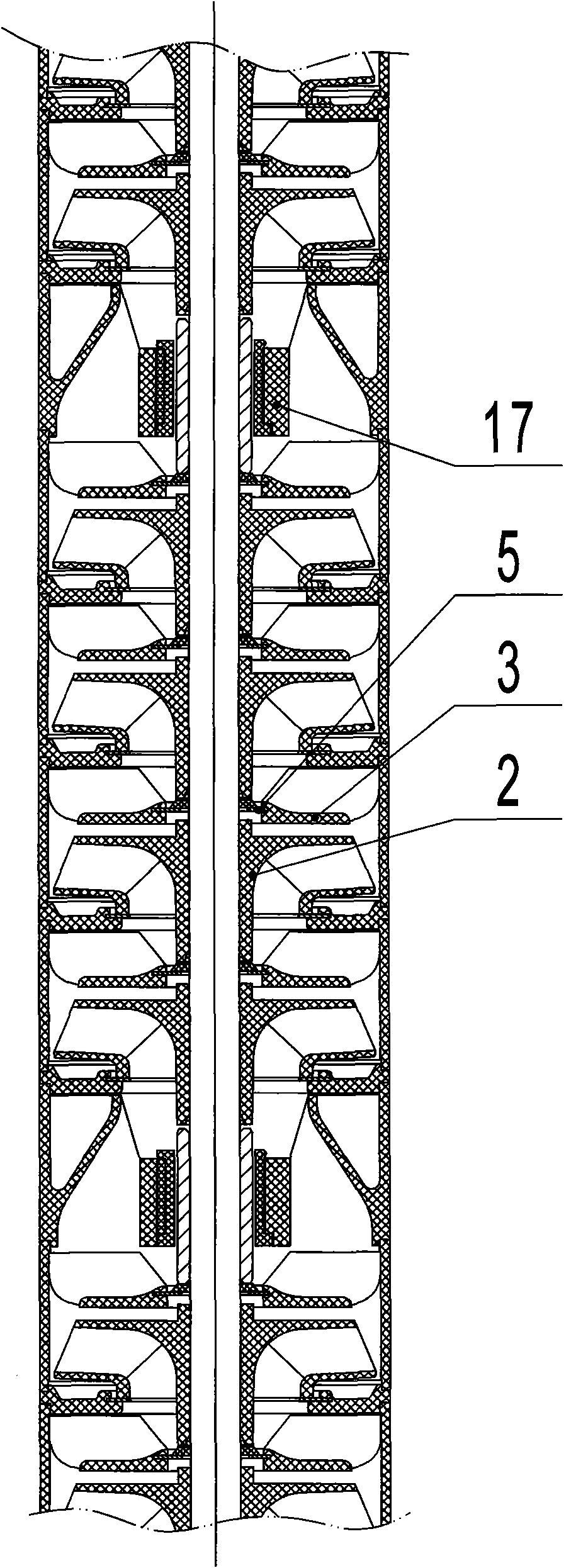

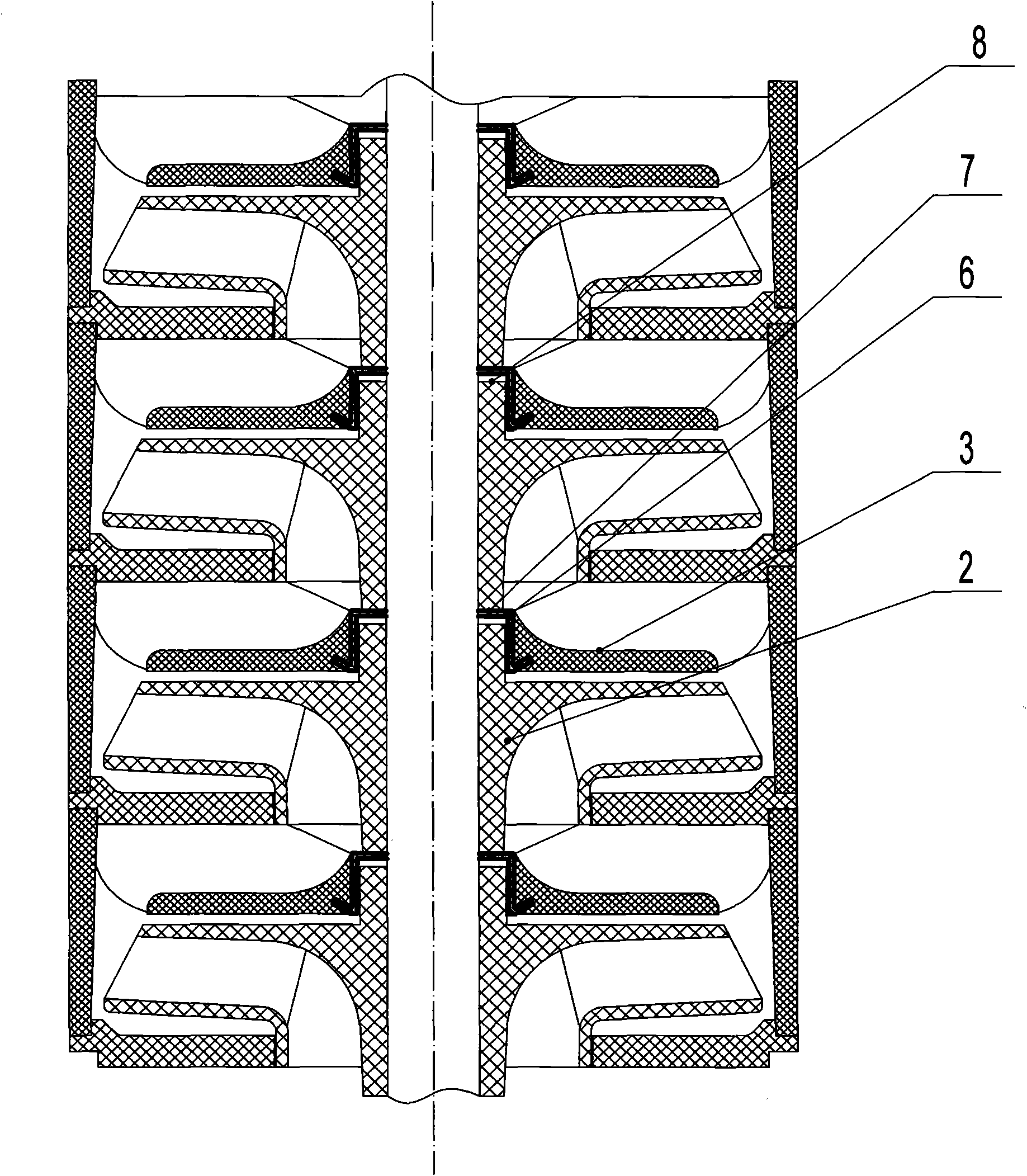

[0018] image 3 The illustrated embodiment is a part of a multistage well pump in which both the impeller 2 and the diversion casing 3 are made of engineering plastics. In the plastic diversion casing 3, a radial thrust bearing insert 6 is inlaid, and the whole of the insert Shaped like the shape of a top hat, such as Figure 5 As shown, its top 9 is a plane ring, its middle part 10 is a cylinder, and its lower part 12 is a uniformly distributed flange. After the plastic guide shell 3 is injected, the insert top 9 and the inner wall of the cylinder 10 are exposed outside, such as Figure 4 shown.

[0019] The insert has some through holes 11 evenly distributed on the wall of the middle cylinder, and some through holes 13 are also evenly distributed on the plate surface of the lower flange. These through holes are filled with plastic after the plastic diversion shell is injected, so that the bearing The insert is firmly integrated with the plastic diversion shell, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com