Patents

Literature

51results about How to "Improve bearing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

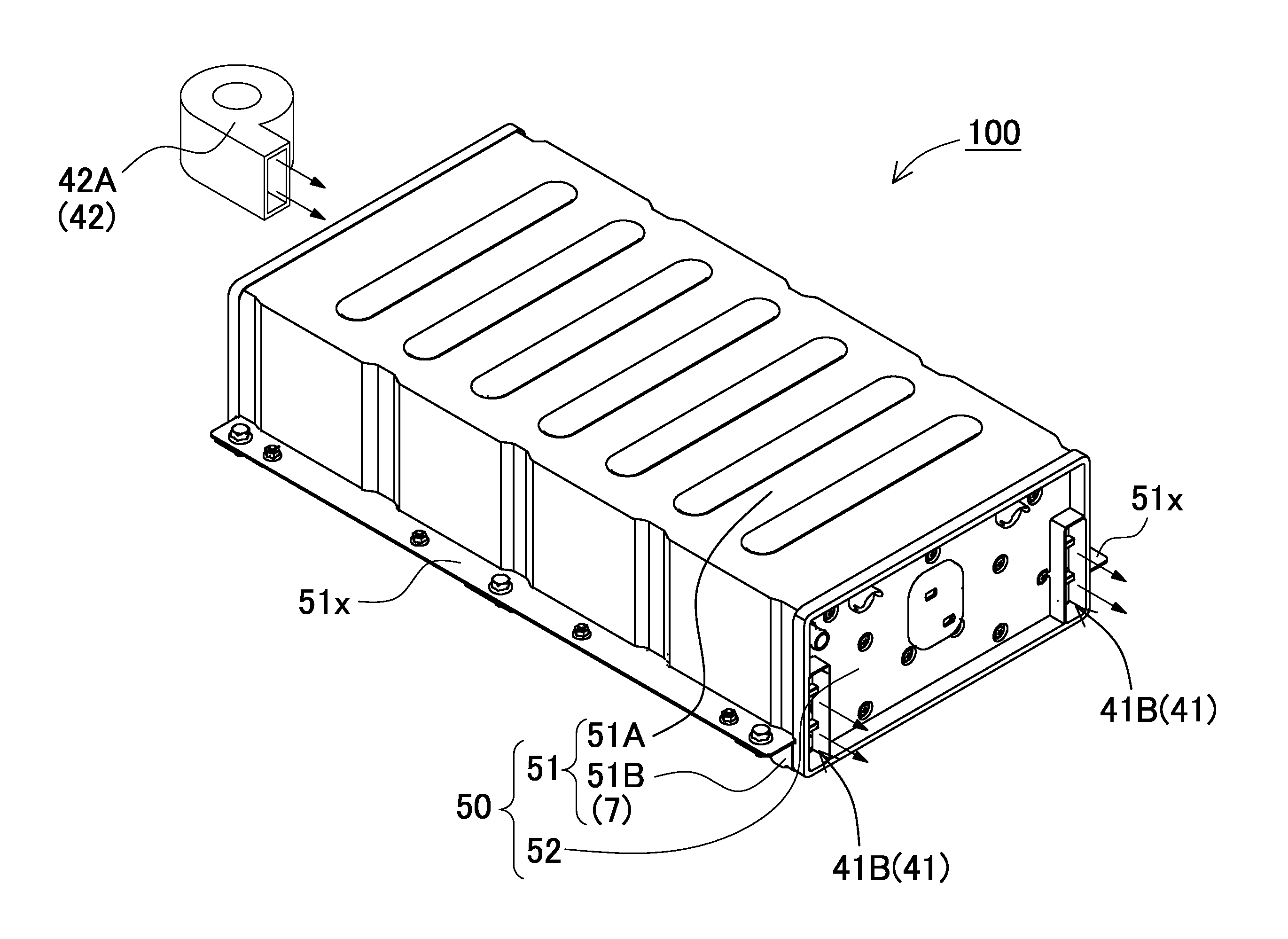

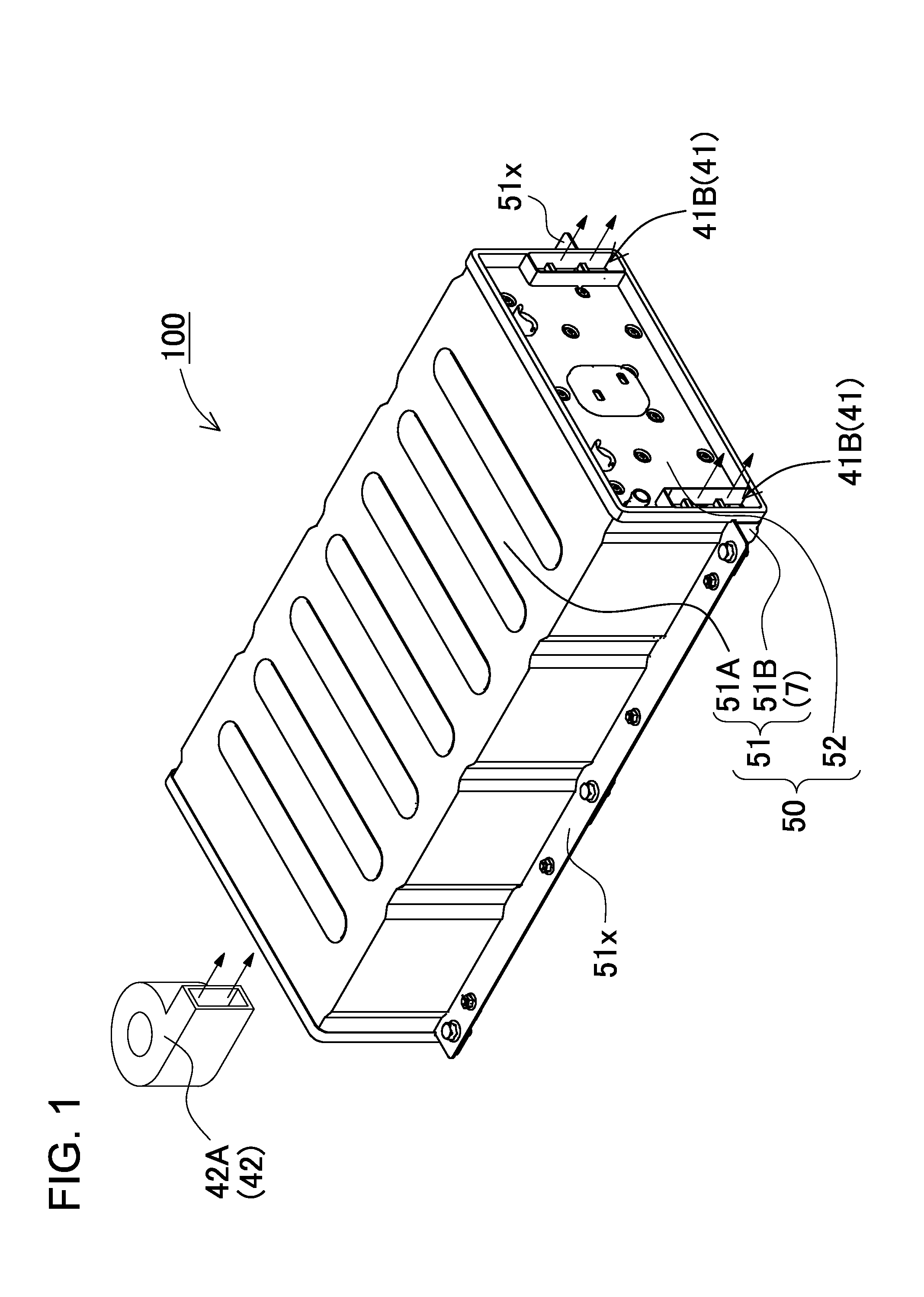

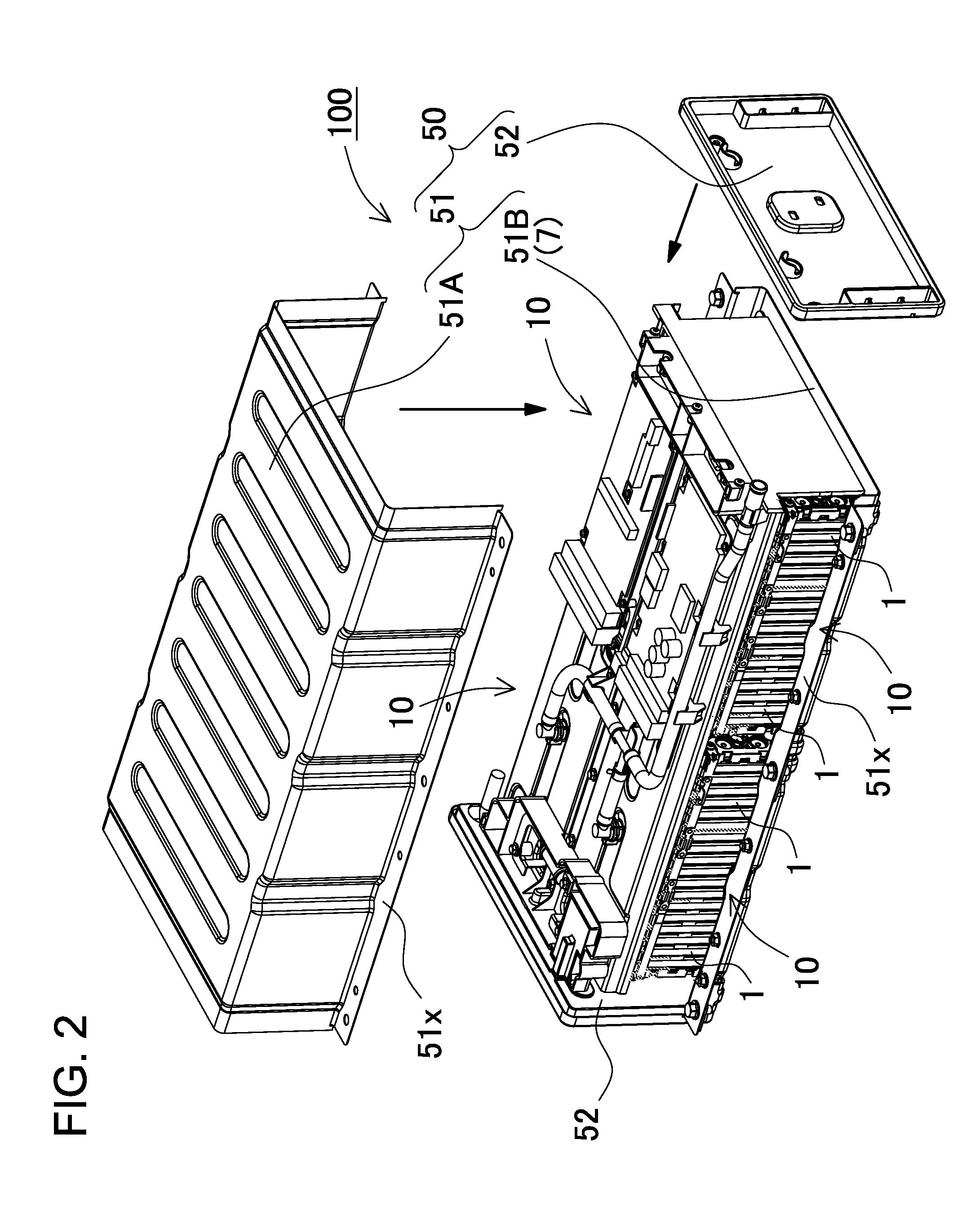

Power supply device, power-supply-device separator, and power-supply-device-equipped vehicle

InactiveUS20140014418A1Fast heat conductionImprove bearing performanceElectric propulsion mountingSecondary cellsForming gasProduct gas

Owner:SANYO ELECTRIC CO LTD

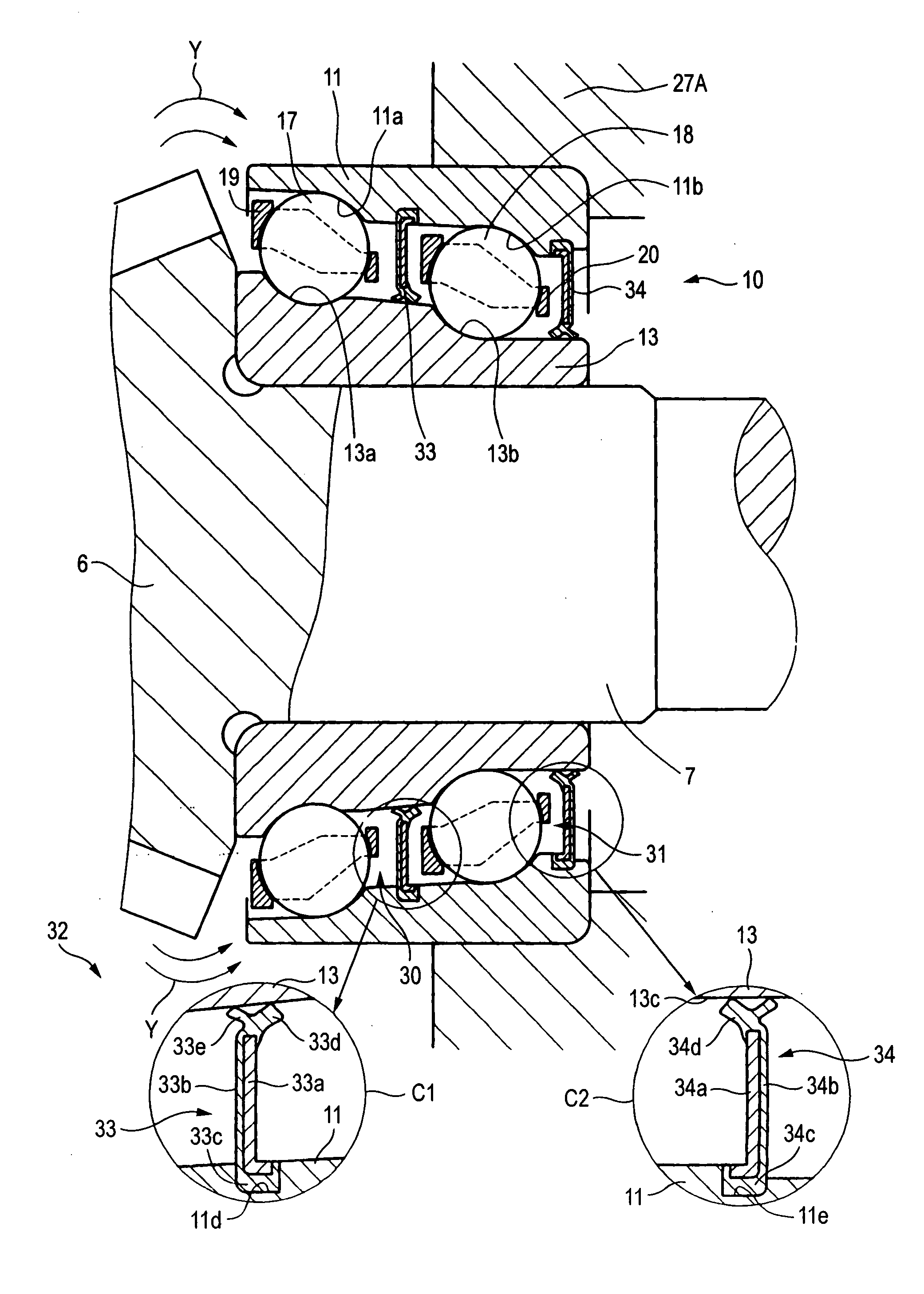

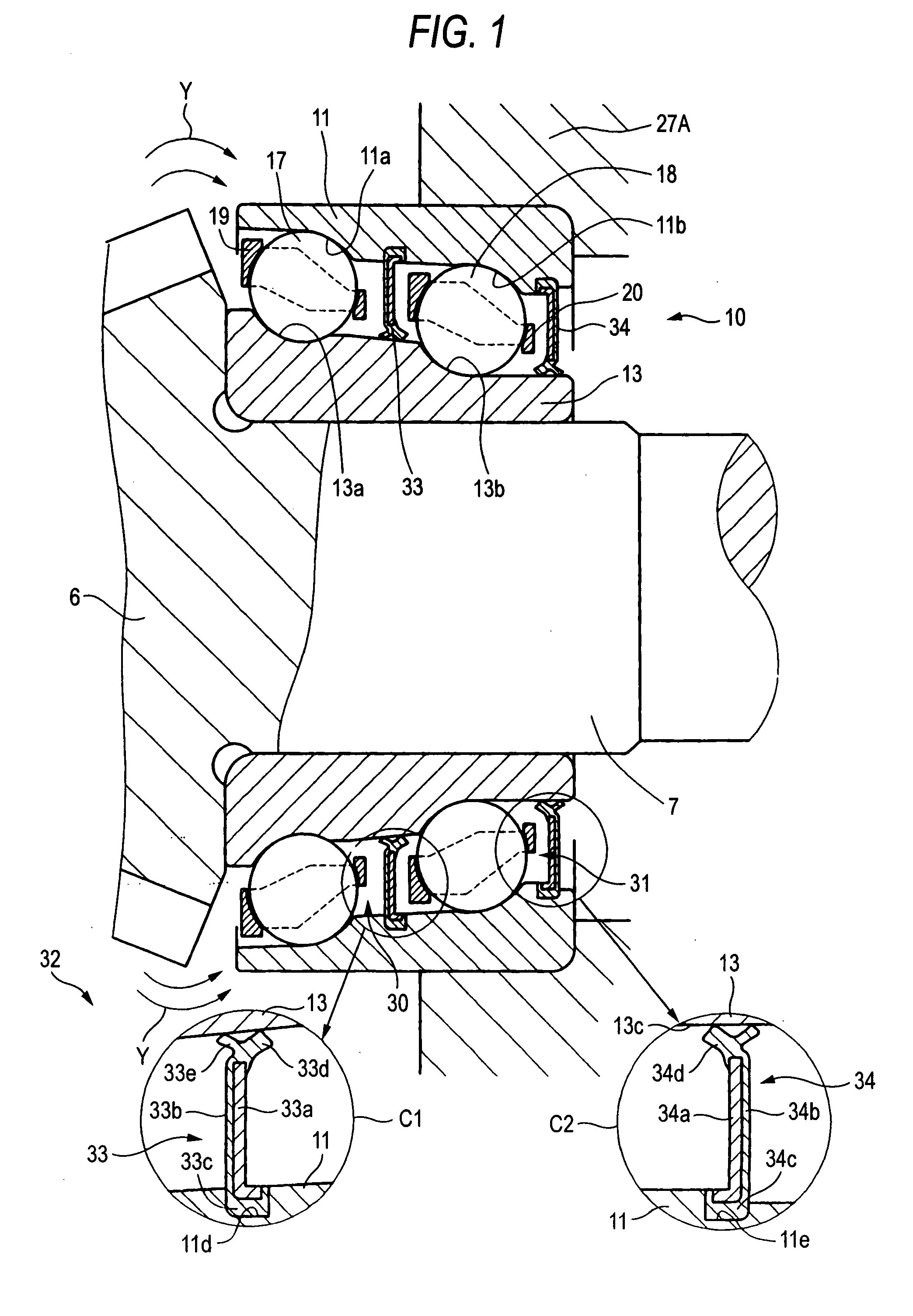

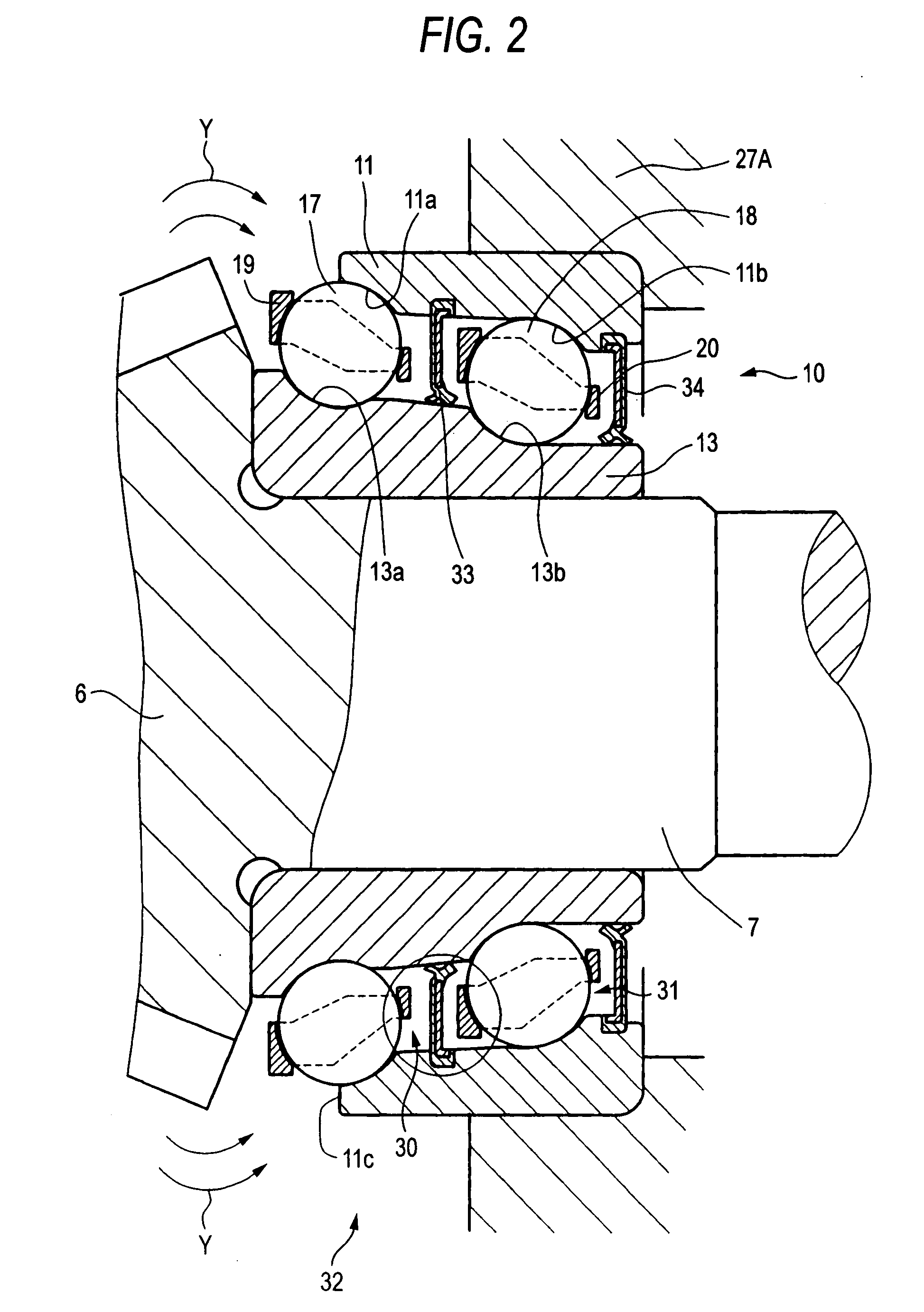

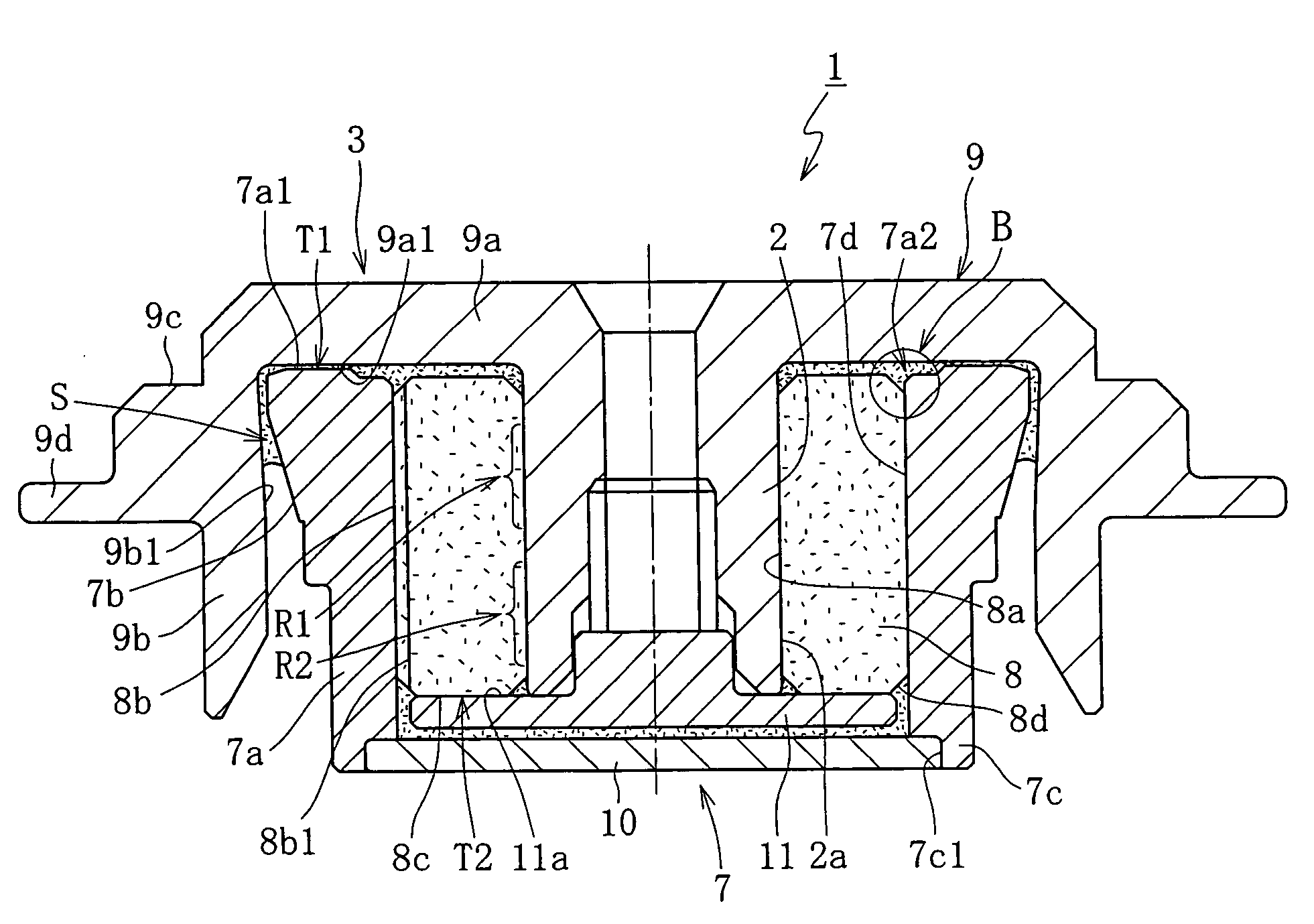

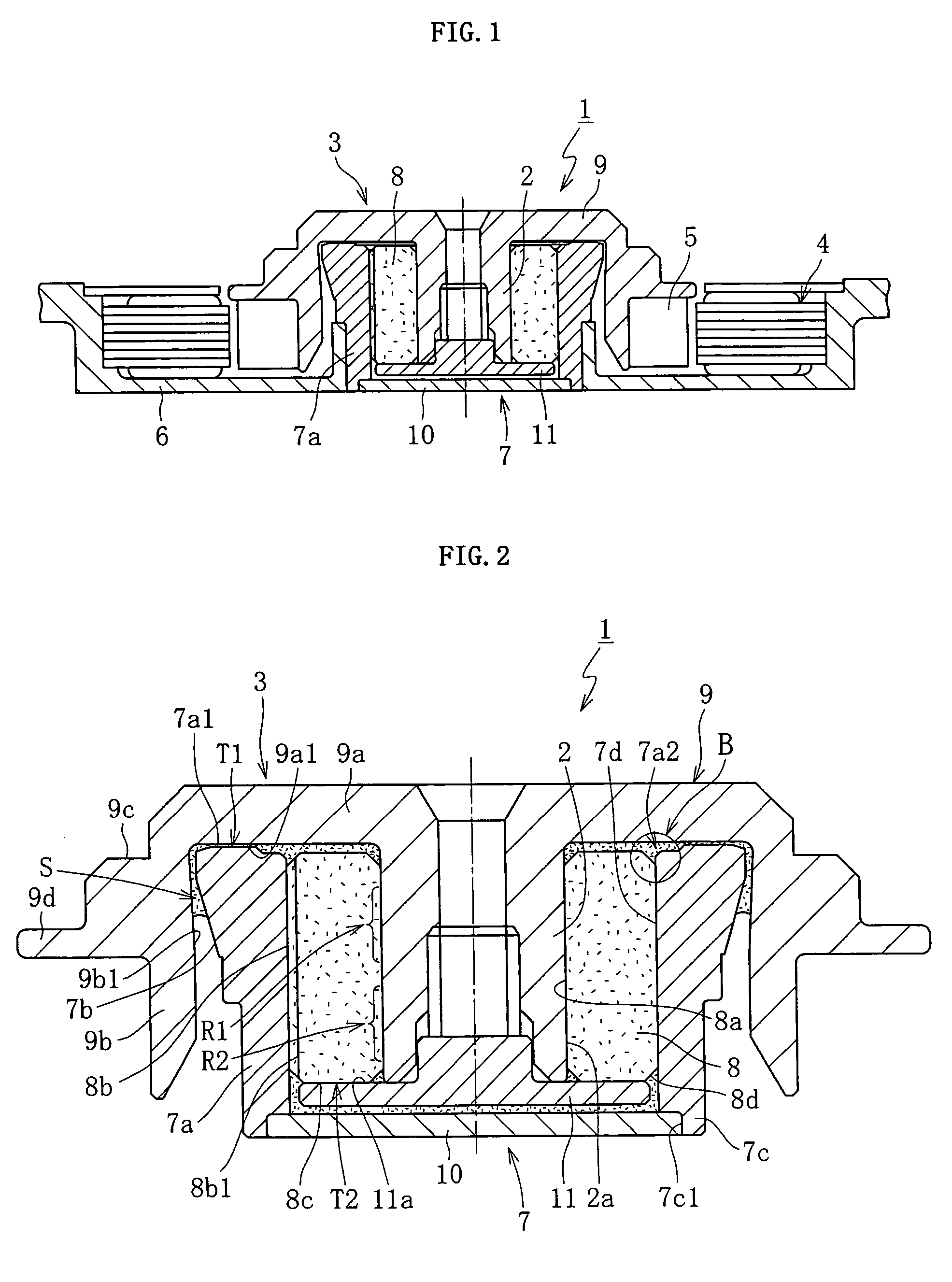

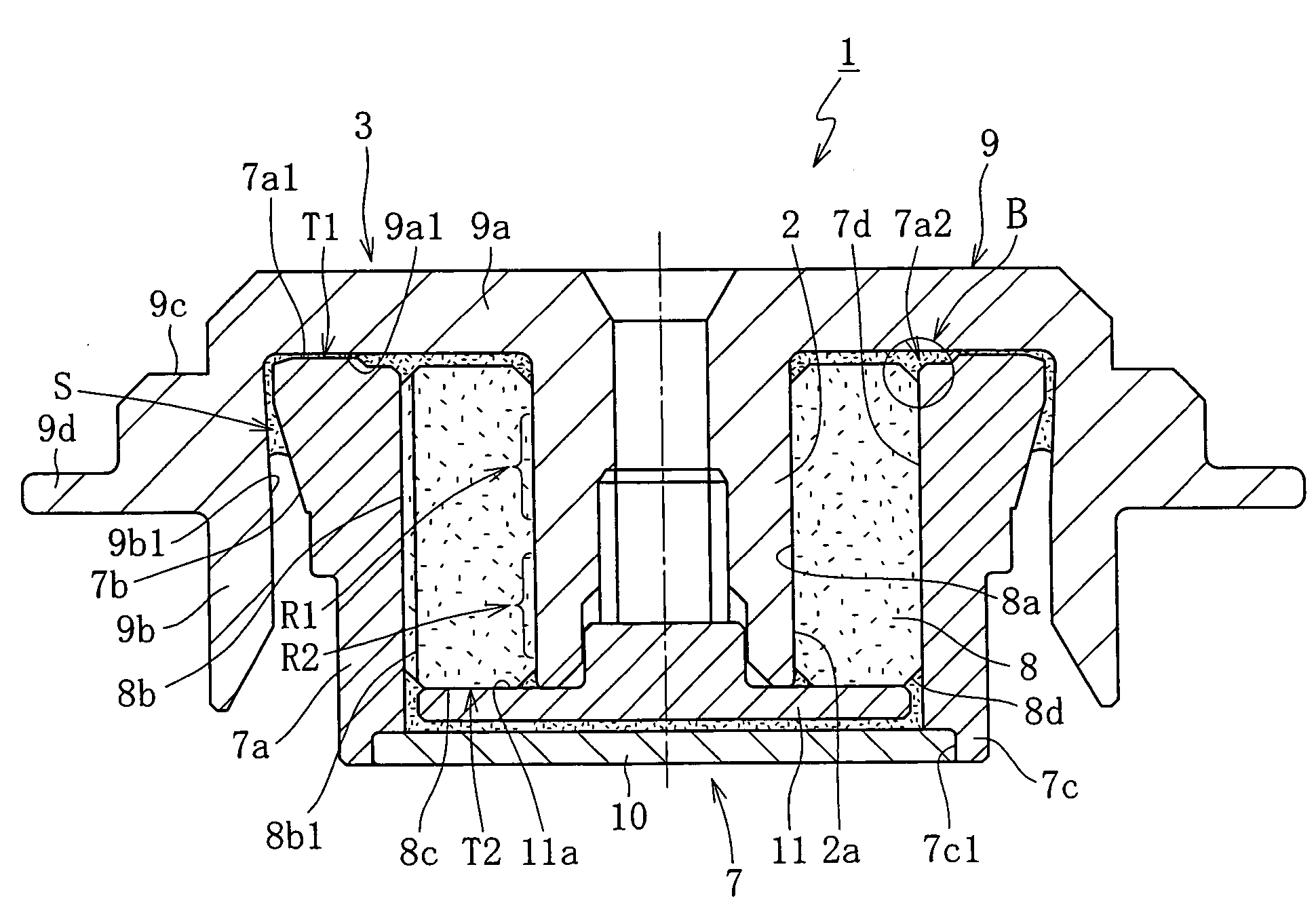

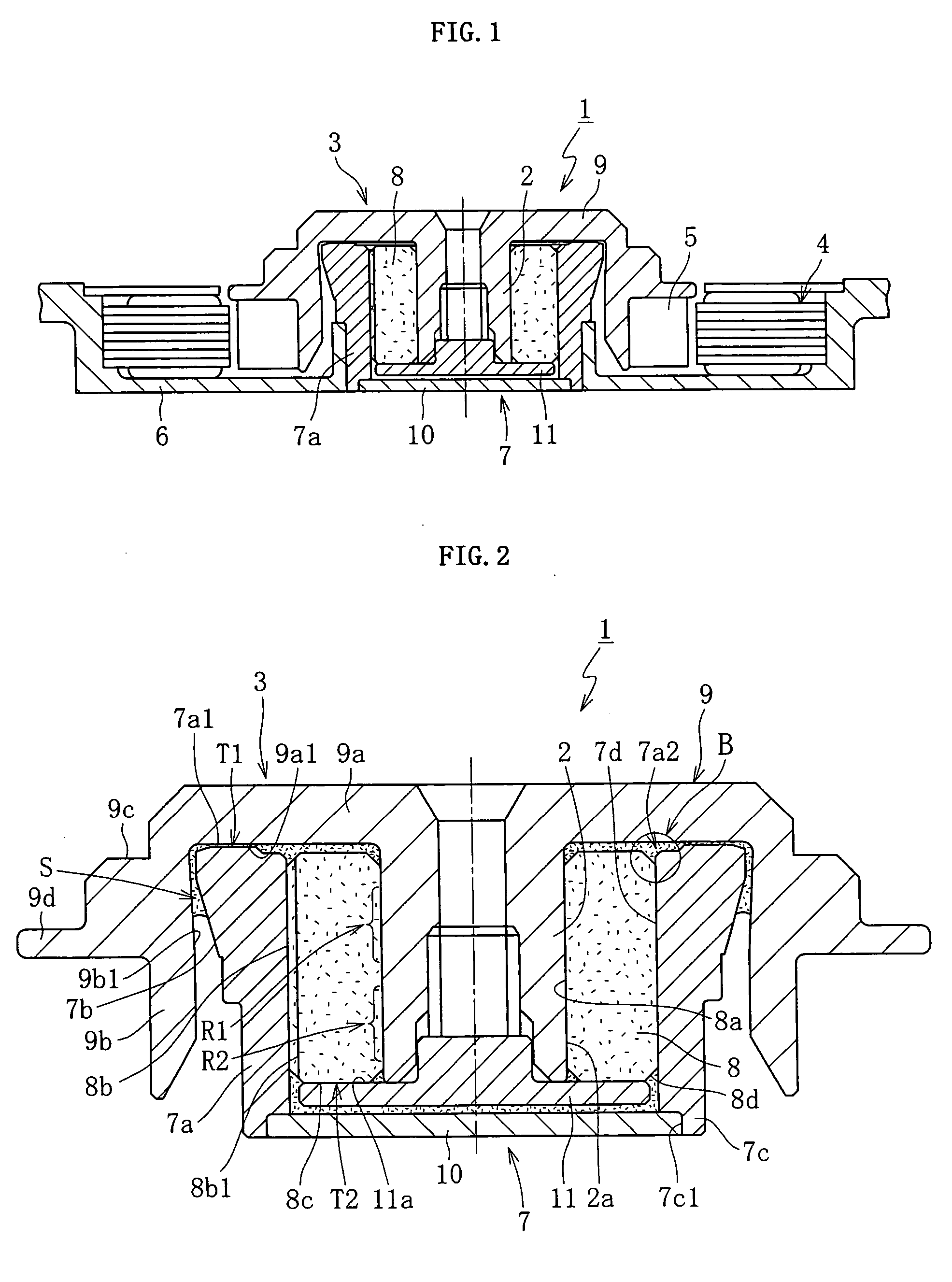

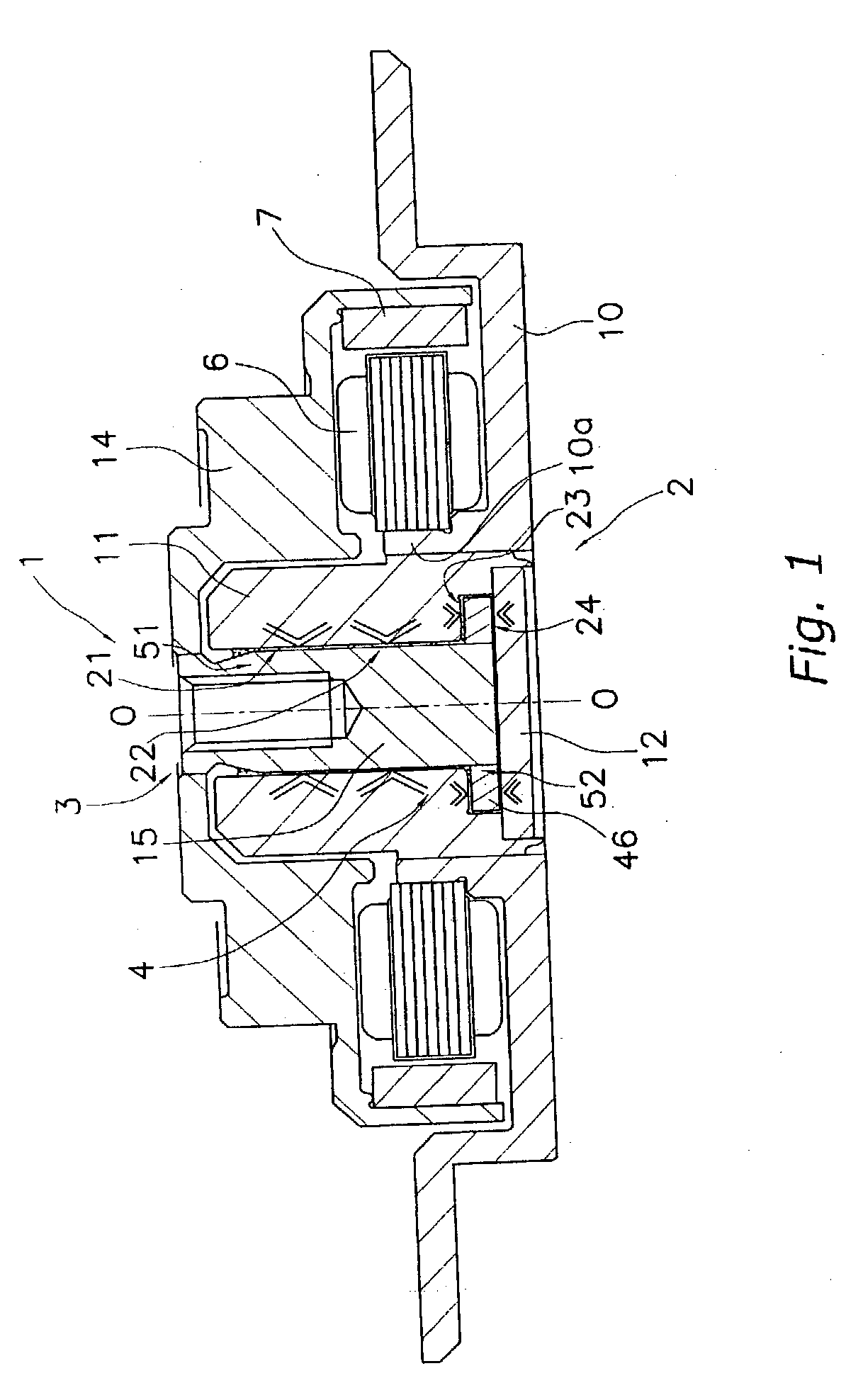

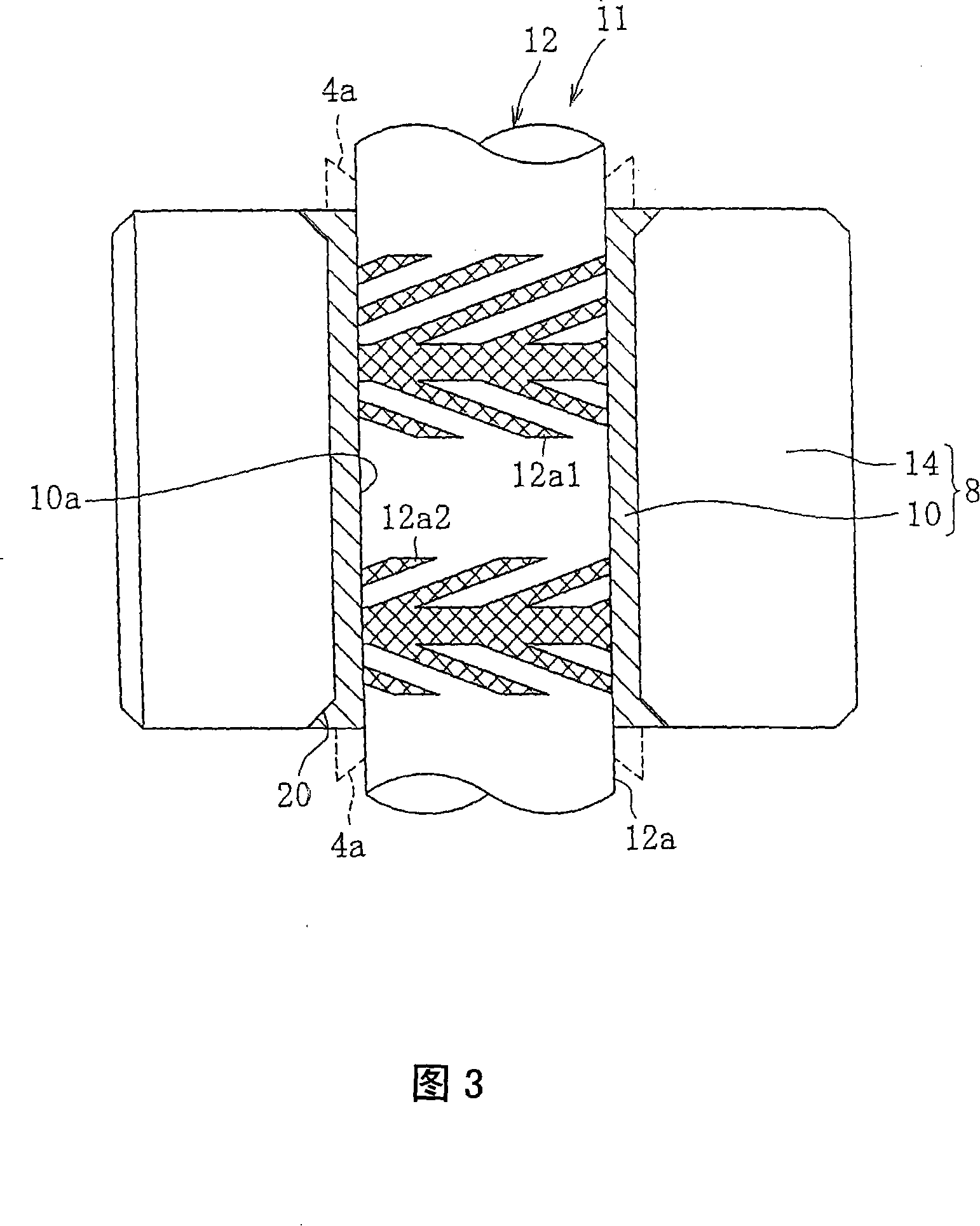

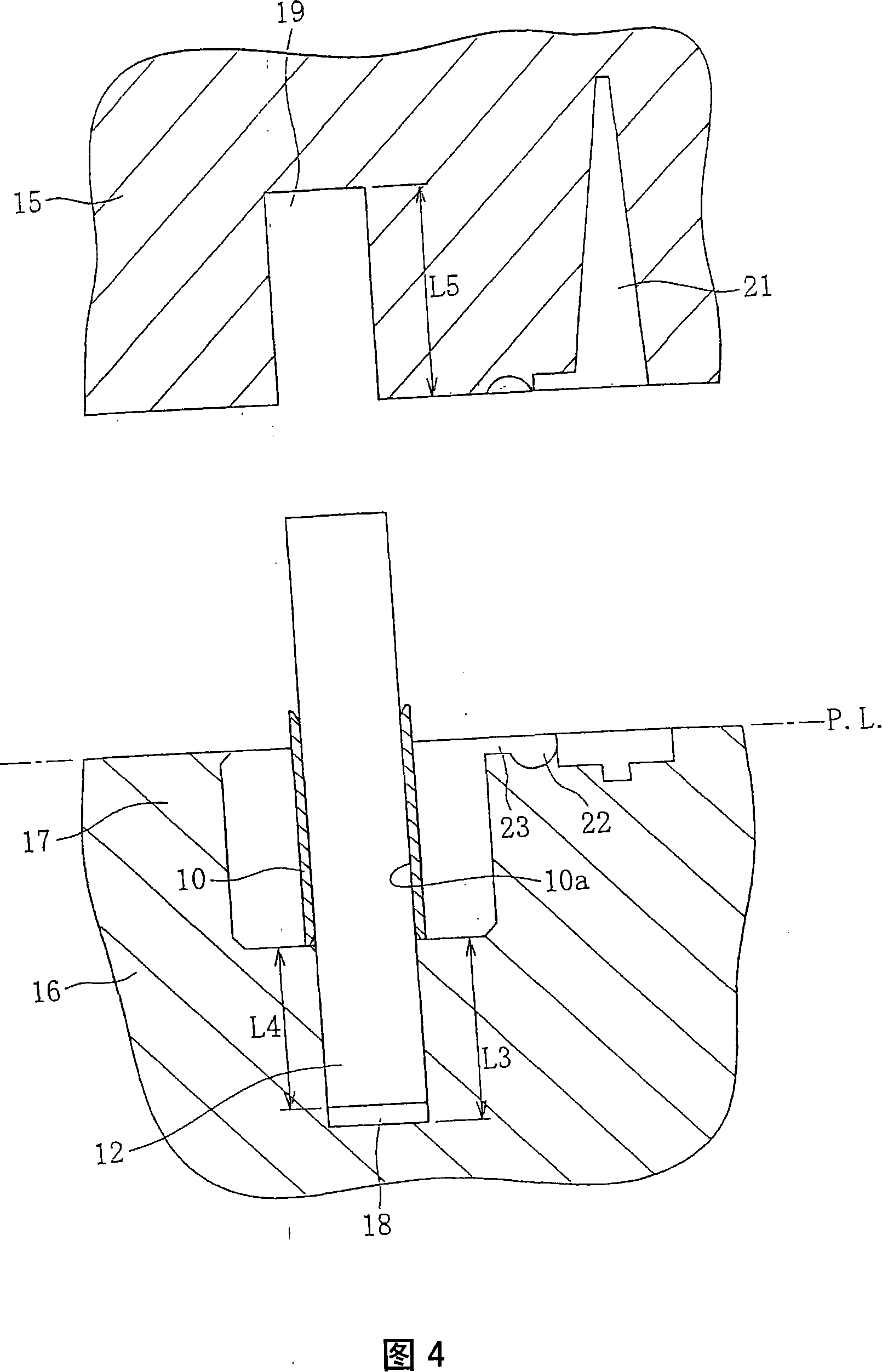

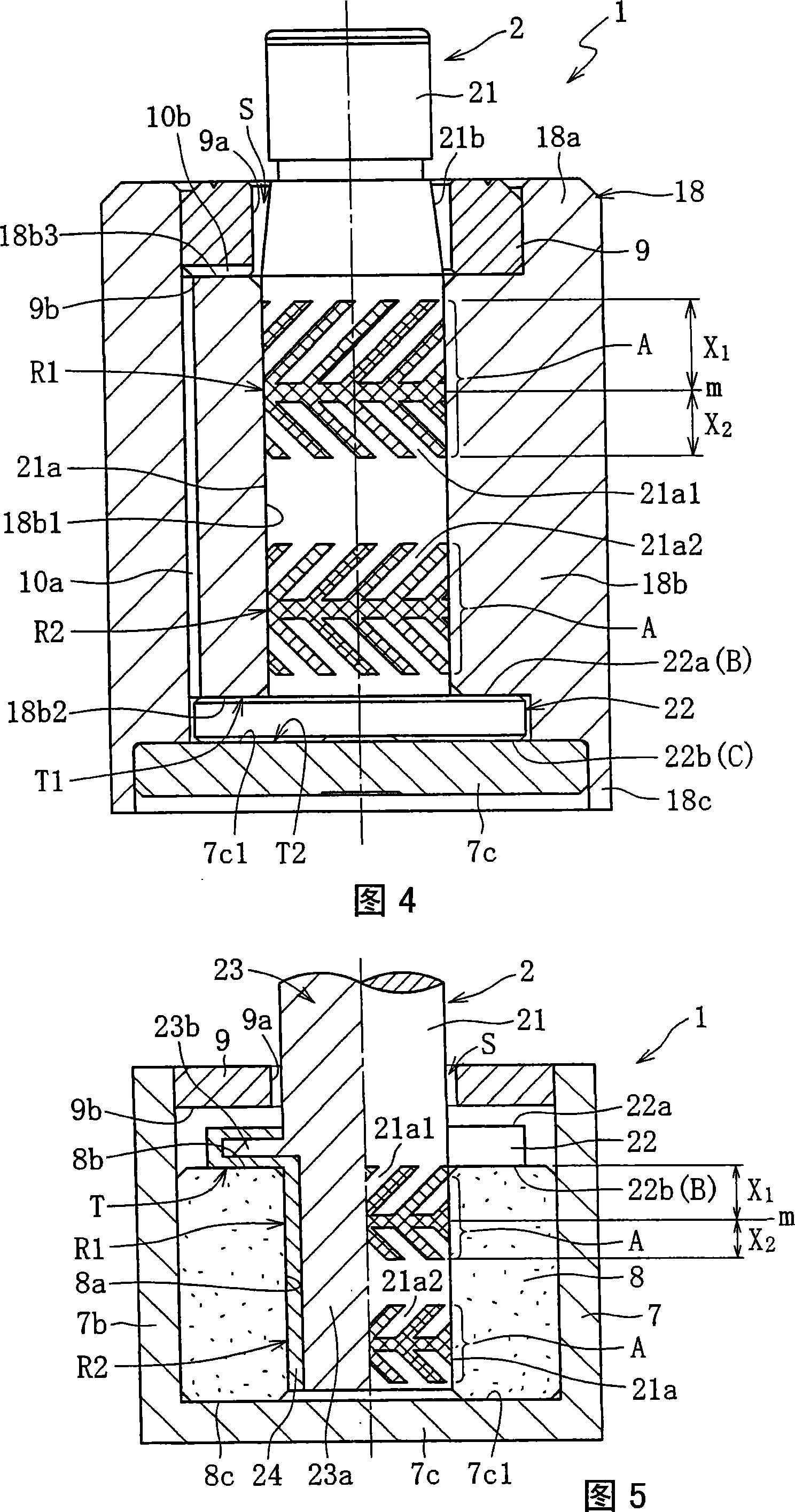

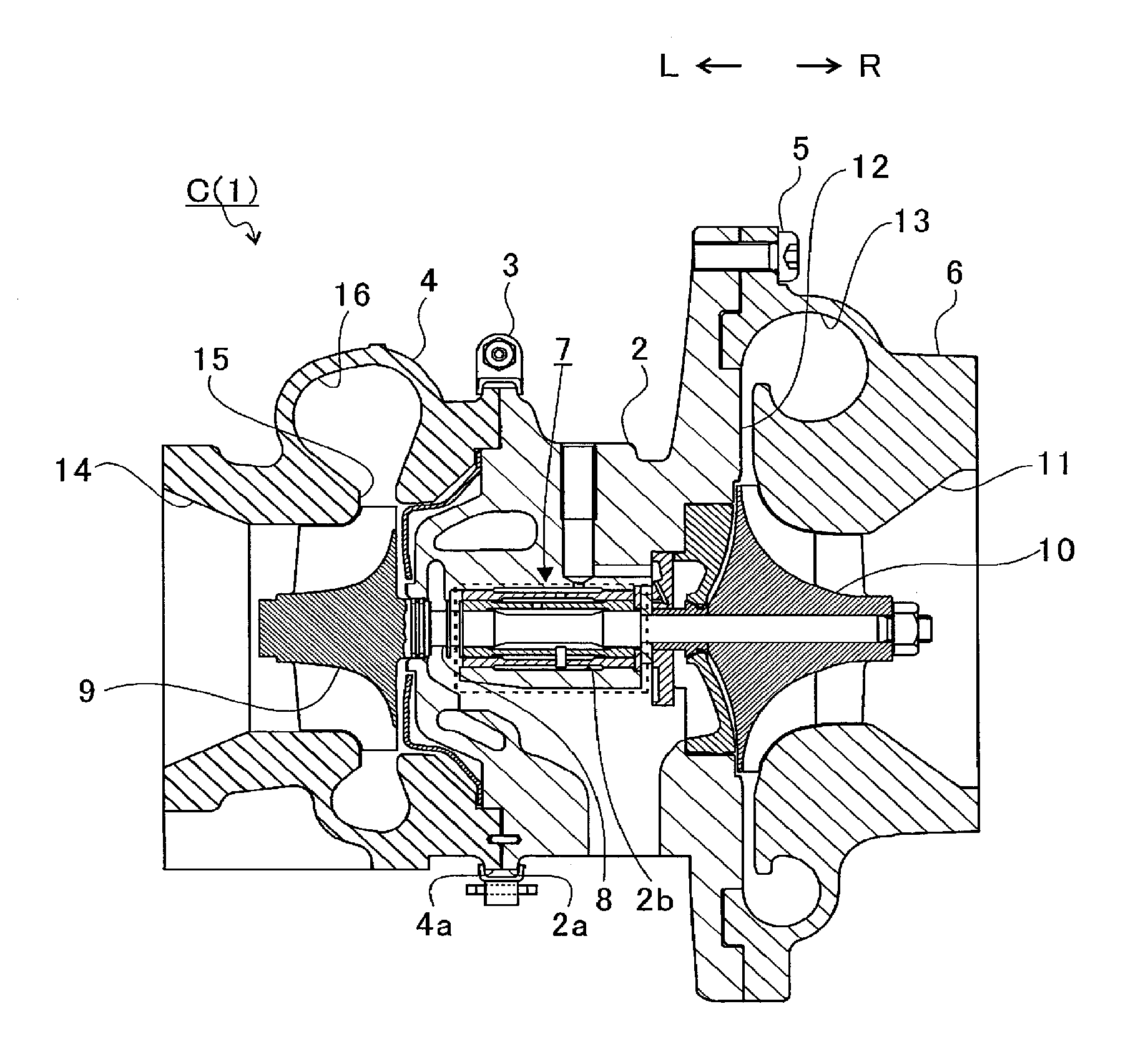

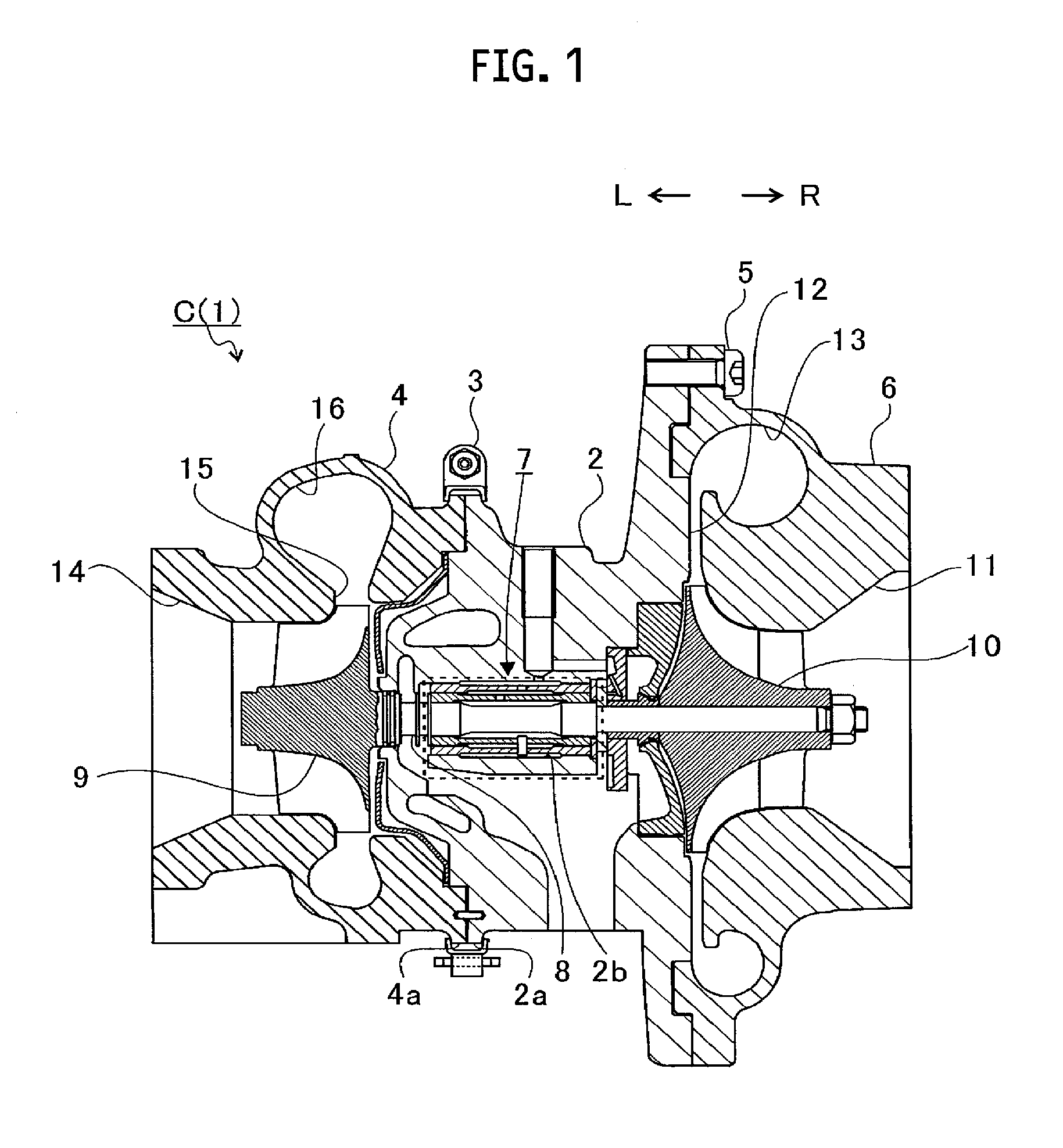

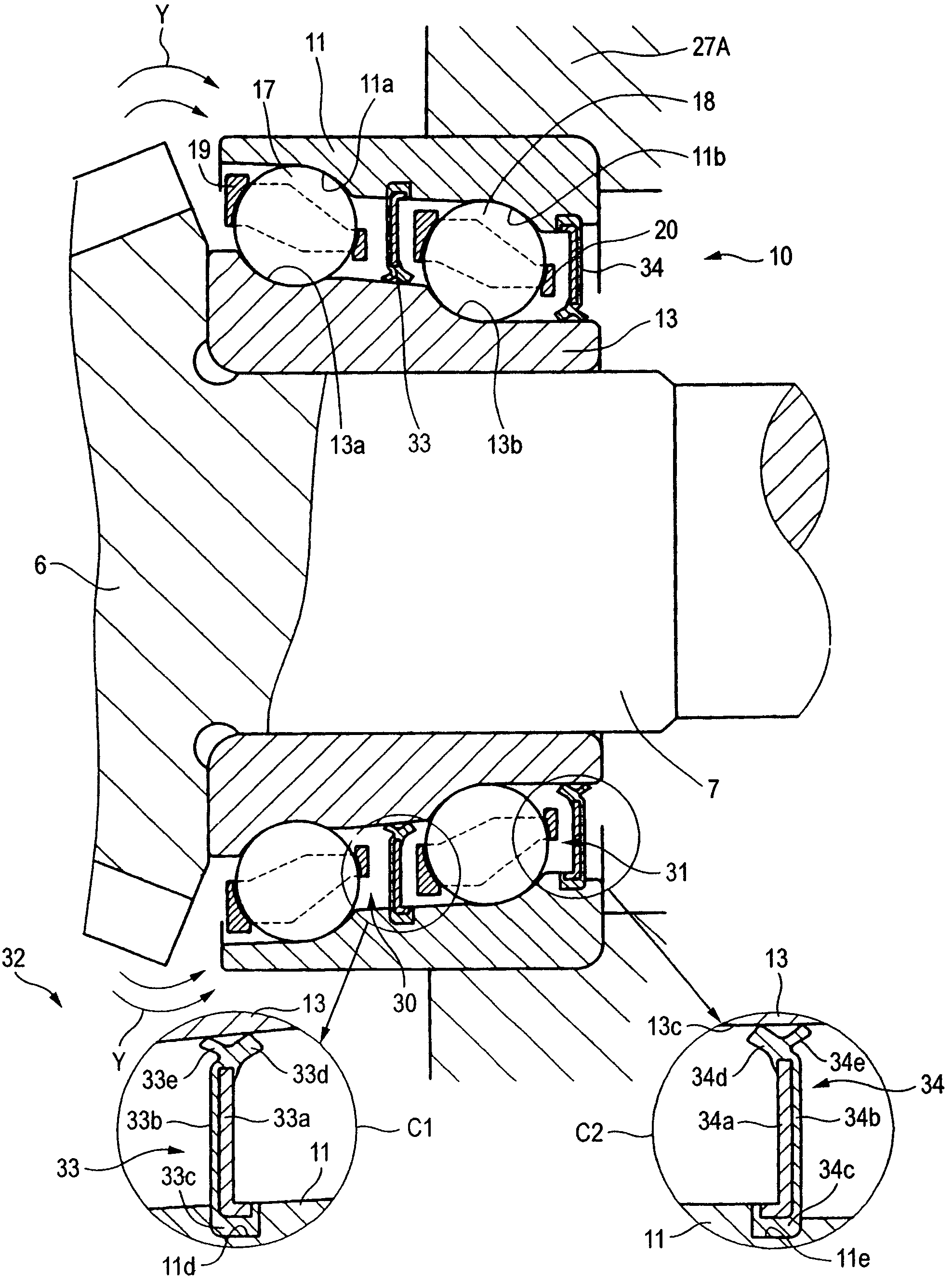

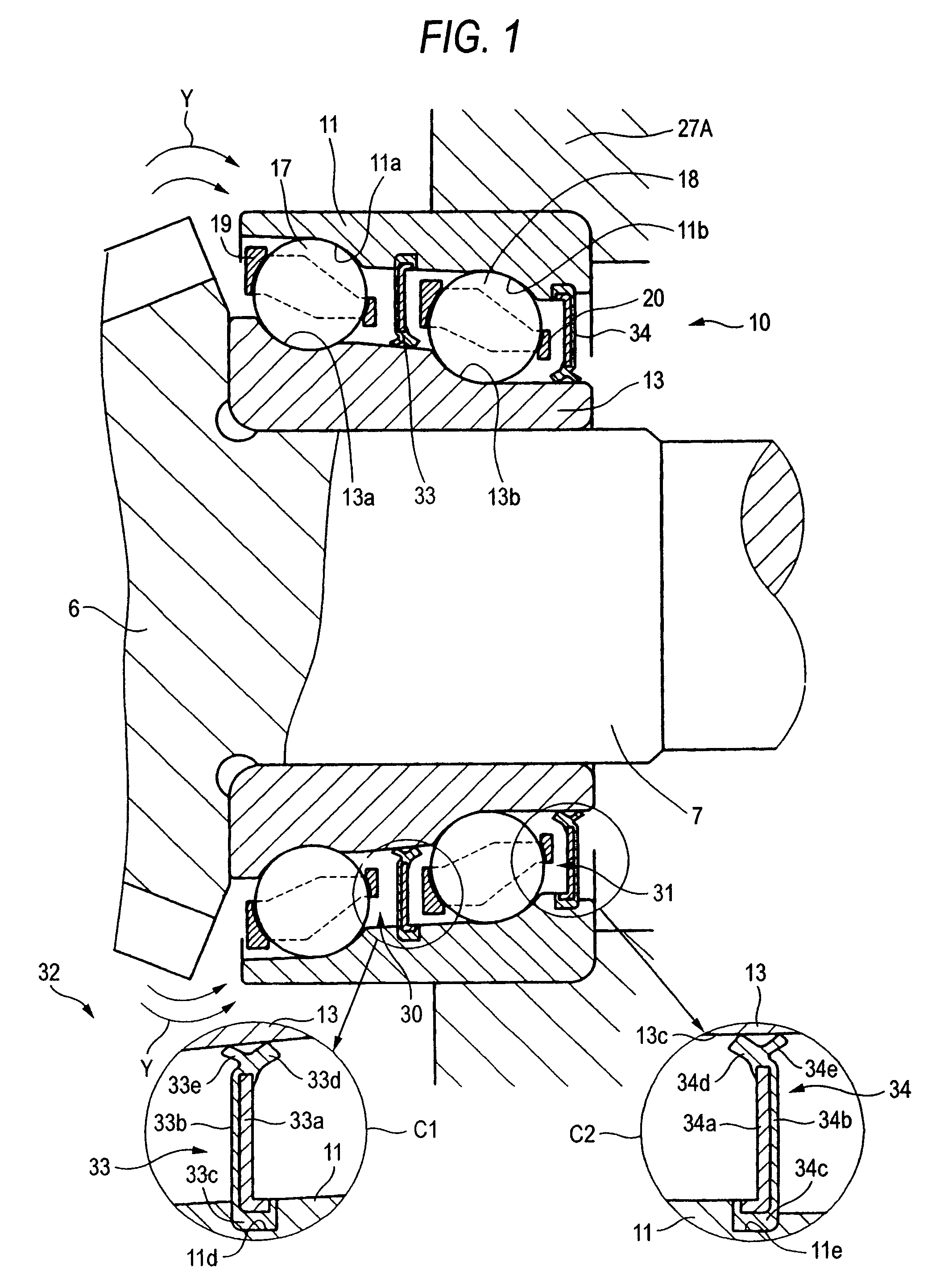

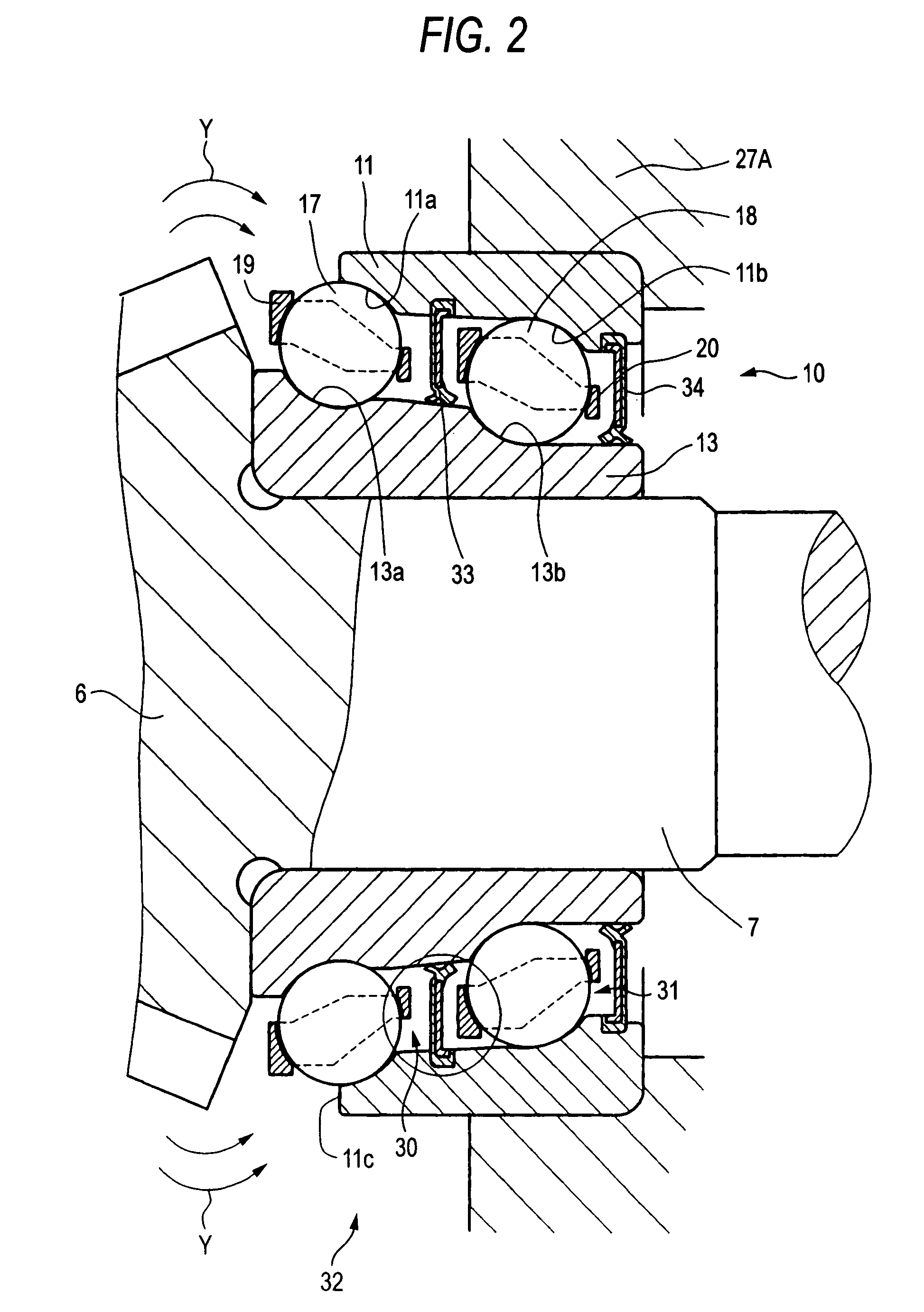

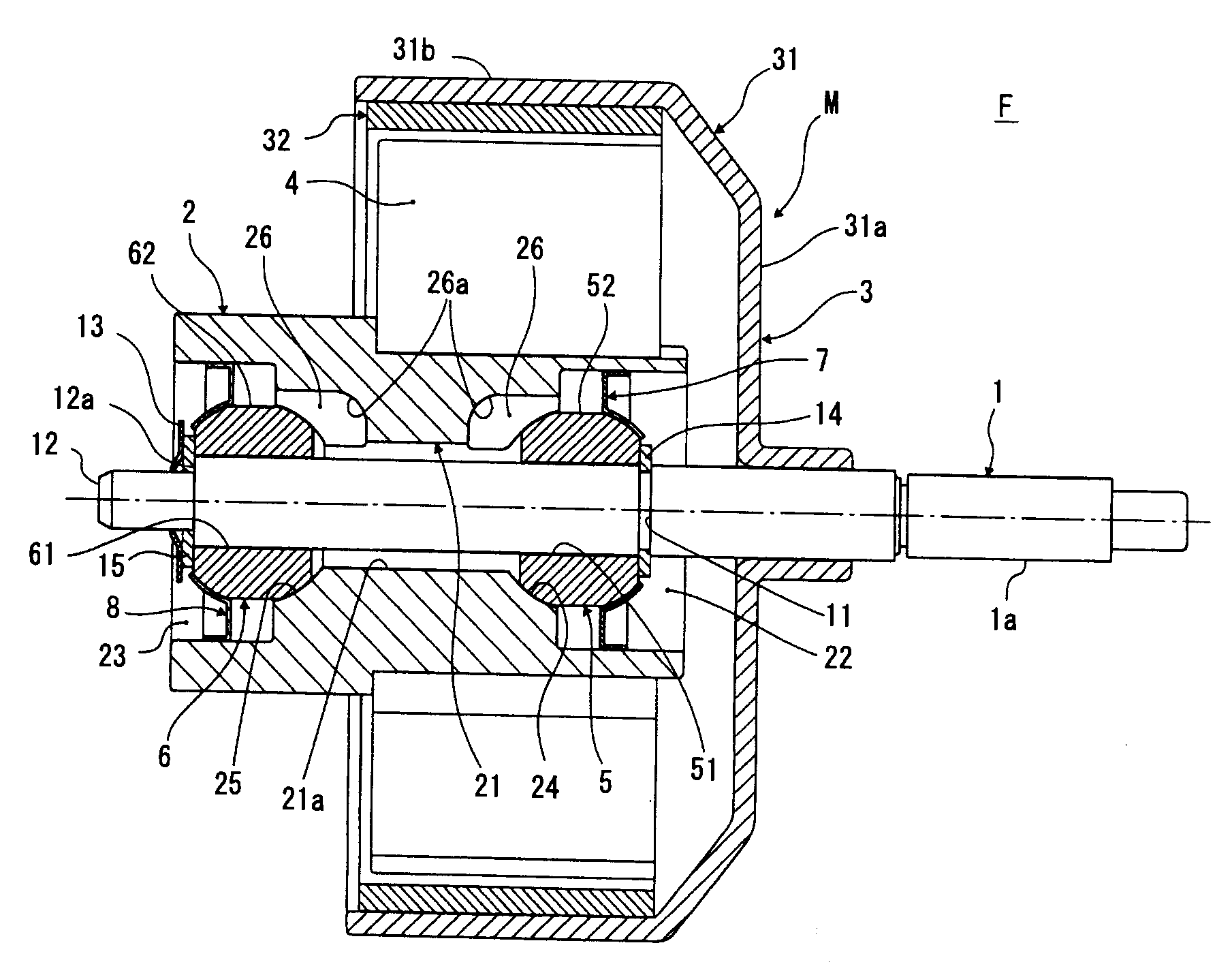

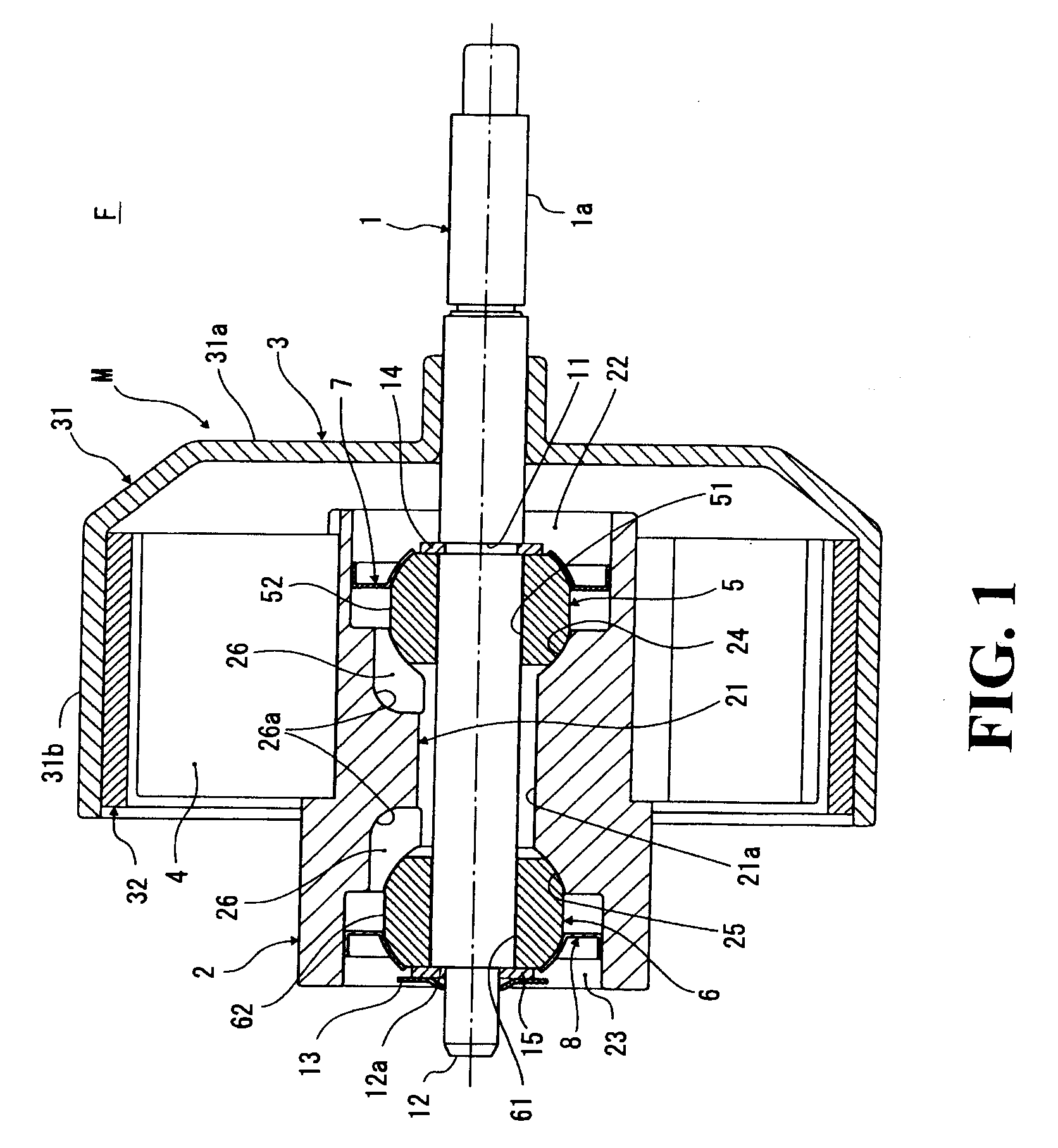

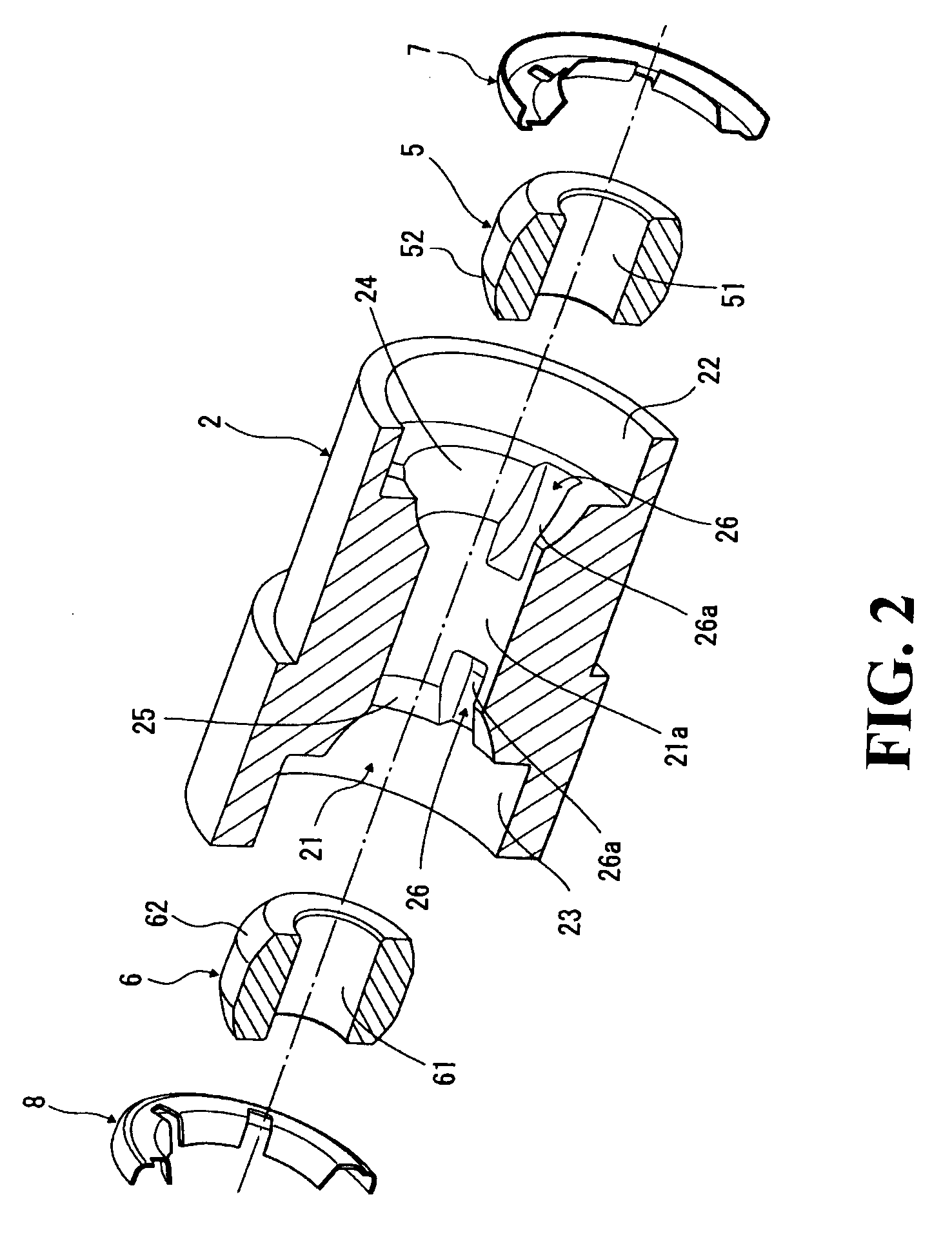

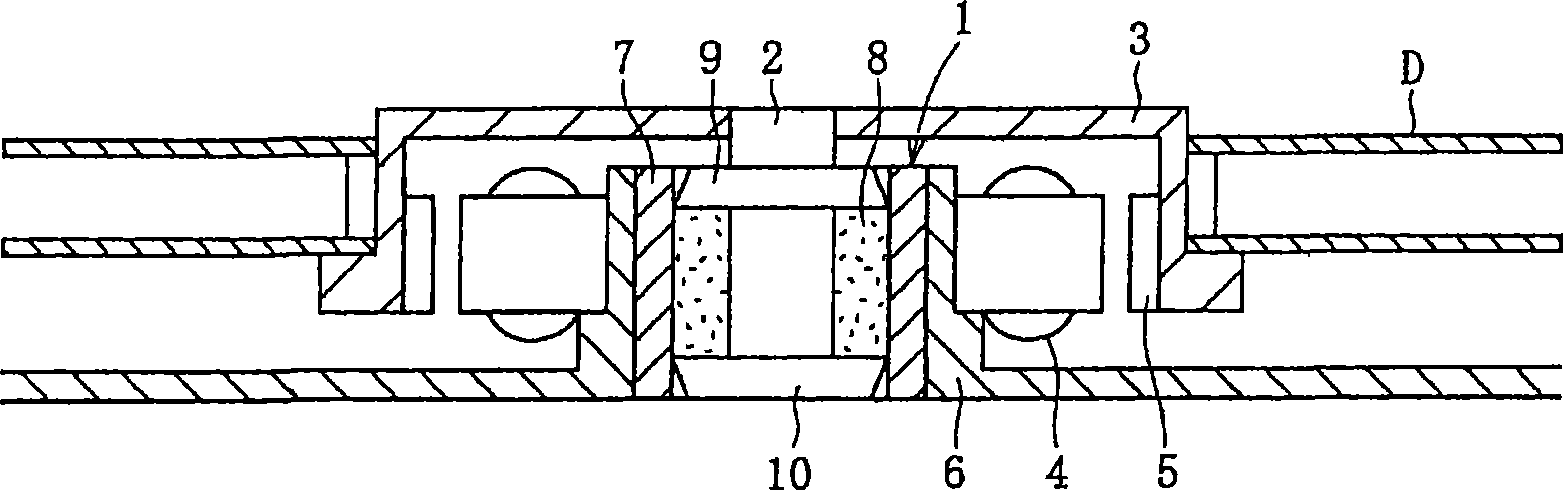

Rolling bearing device for supporting pinion shaft

InactiveUS20070242913A1Improve the rotation effectReducing a torque lossGearboxesShaftsInterior spaceBall bearing

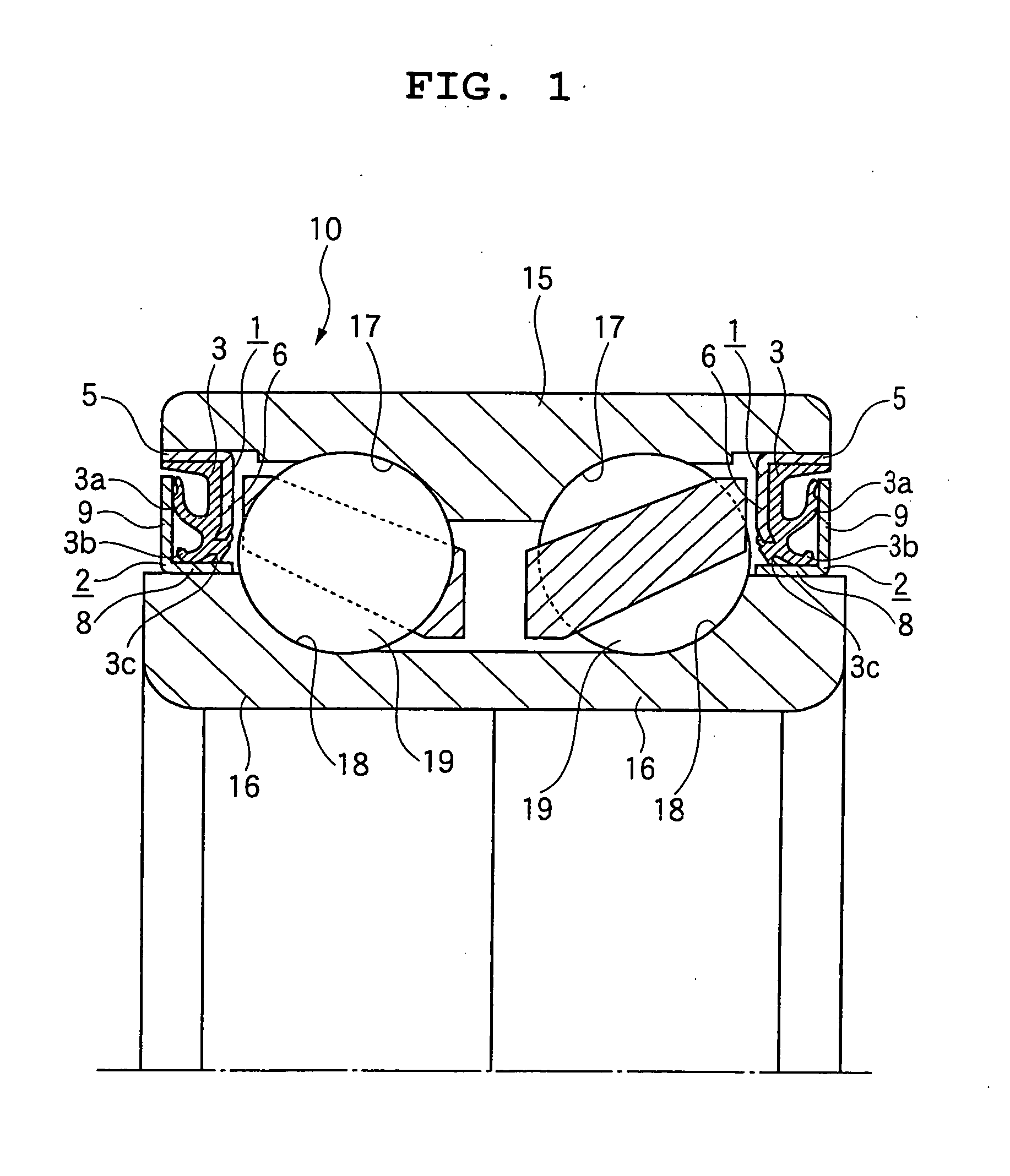

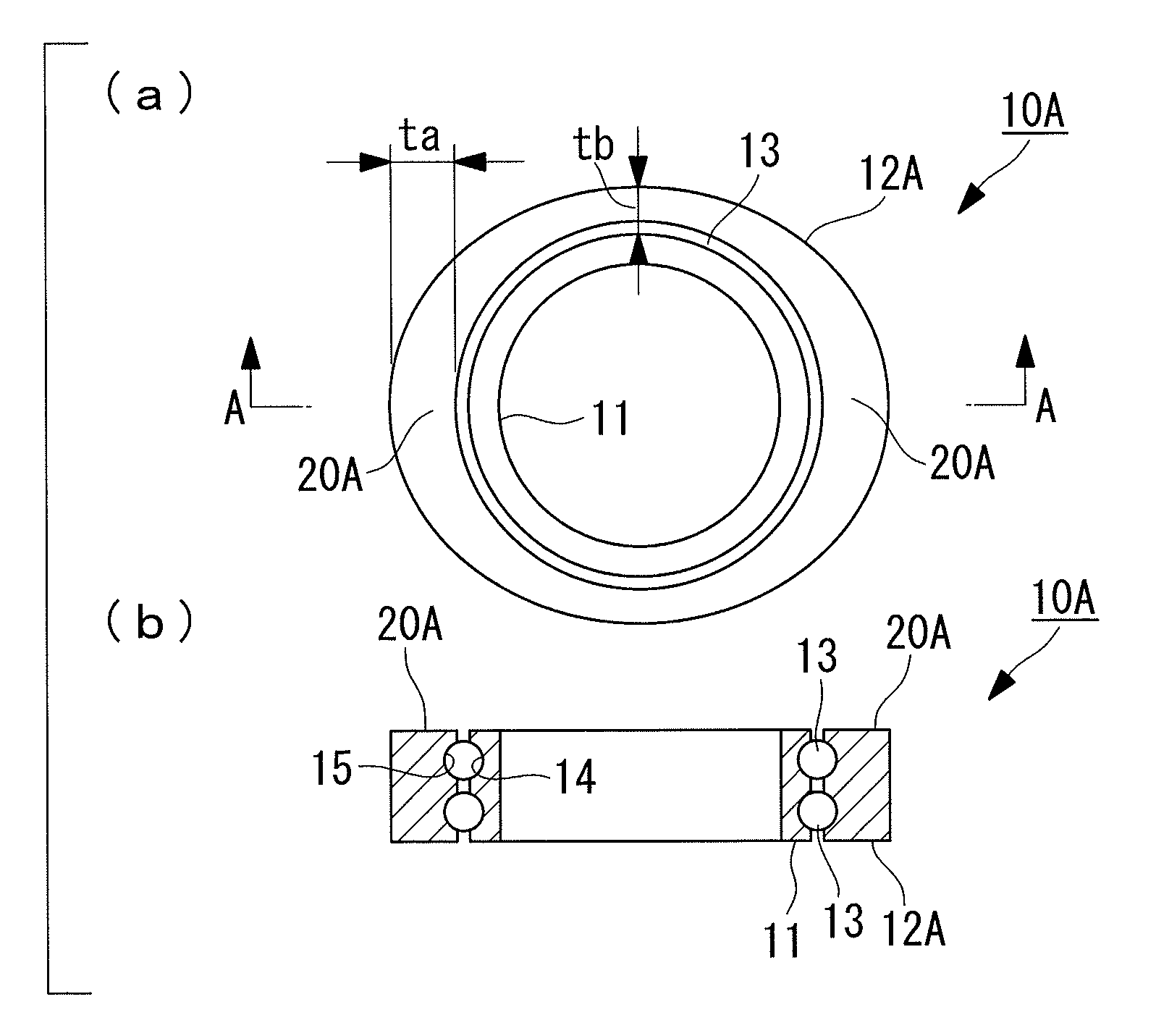

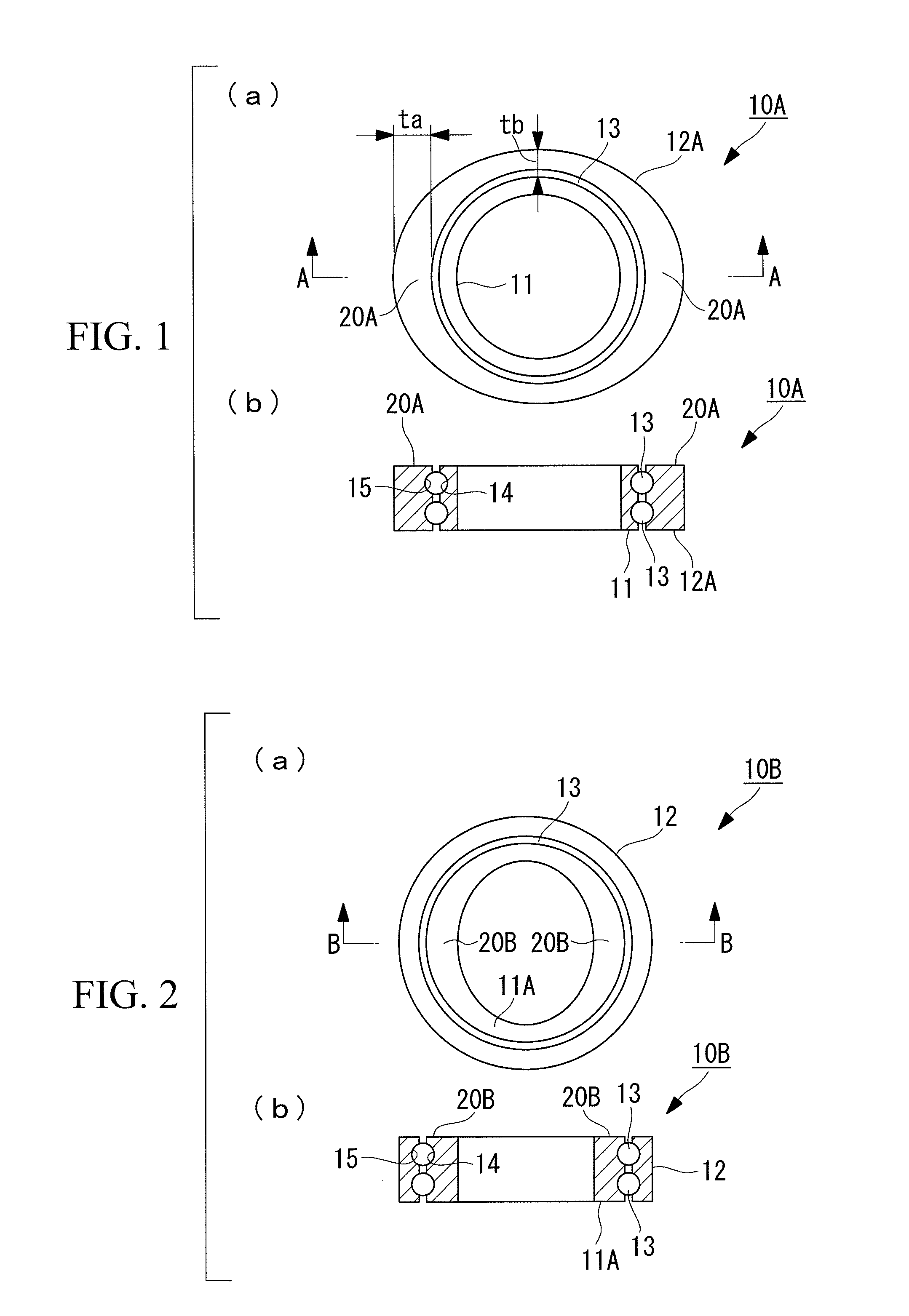

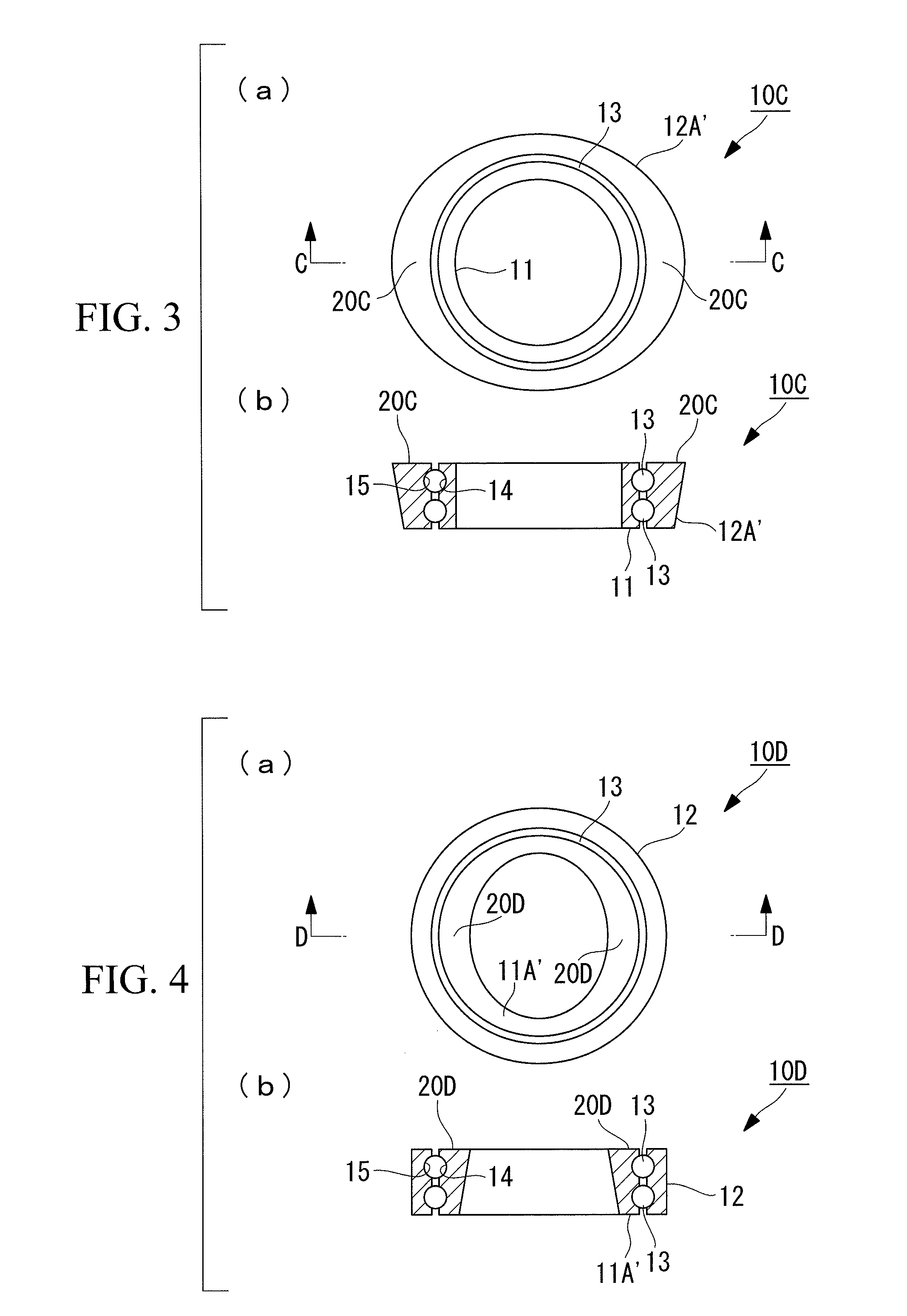

In a bearing device, a double row rolling bearing for supporting a pinion gear-side portion of a pinion shaft on a case (annular wall) is formed by a tandem-type double row angular contact ball bearing. A first row of balls having a larger pitch circle diameter are disposed between inner and outer rings of the double row angular contact ball bearing at a region near to the pinion gear, and a second row of balls having a smaller pitch circle diameter are disposed between the inner and outer rings at a region remote from the pinion gear. A bearing internal space is divided into a first bearing internal space containing the first ball row and open toward the pinion gear and a second bearing internal space containing the second ball row and sealed by partition walls formed respectively by bearing seals, lubricating grease being sealed in the second bearing internal space.

Owner:JTEKT CORP

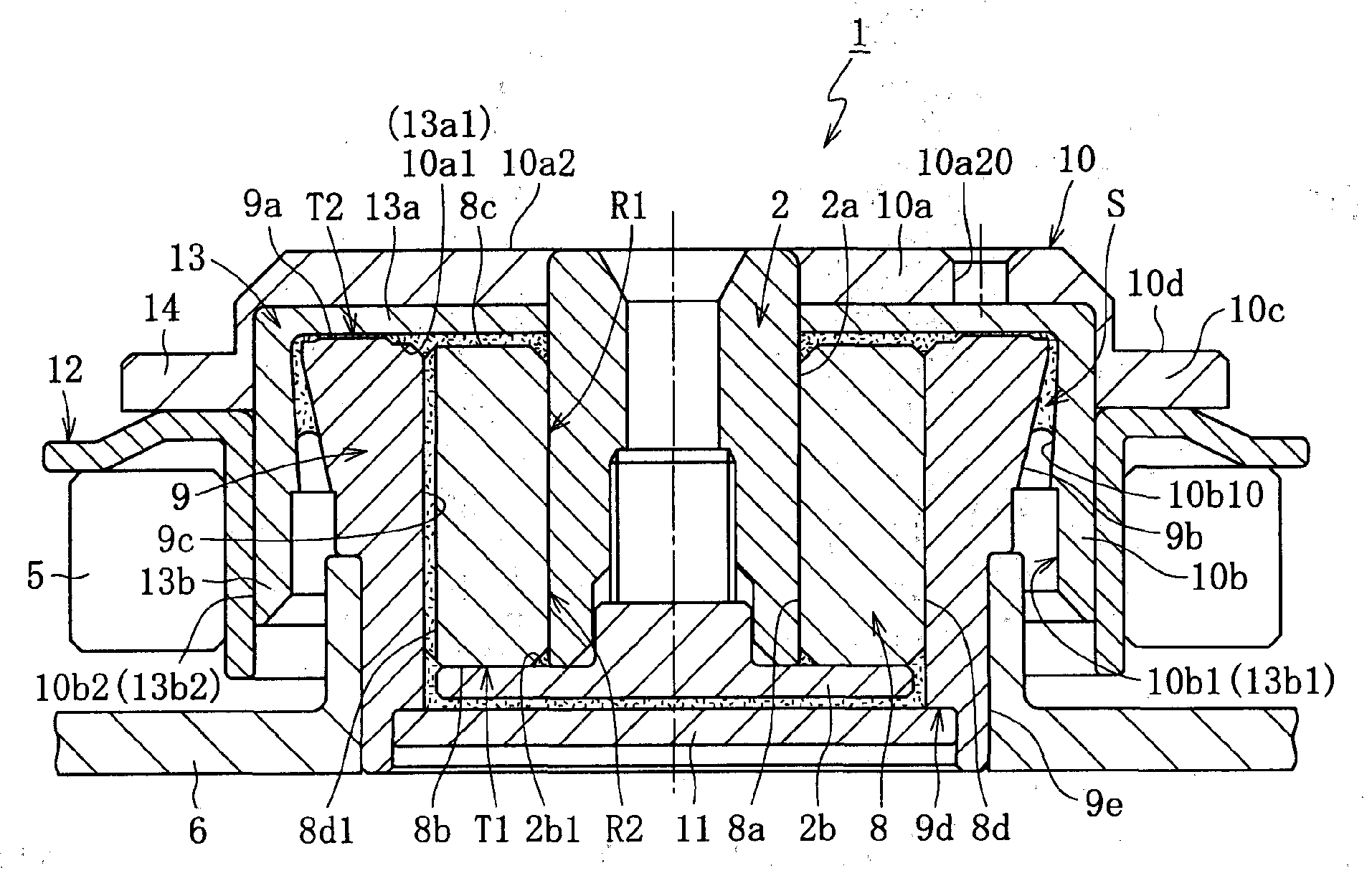

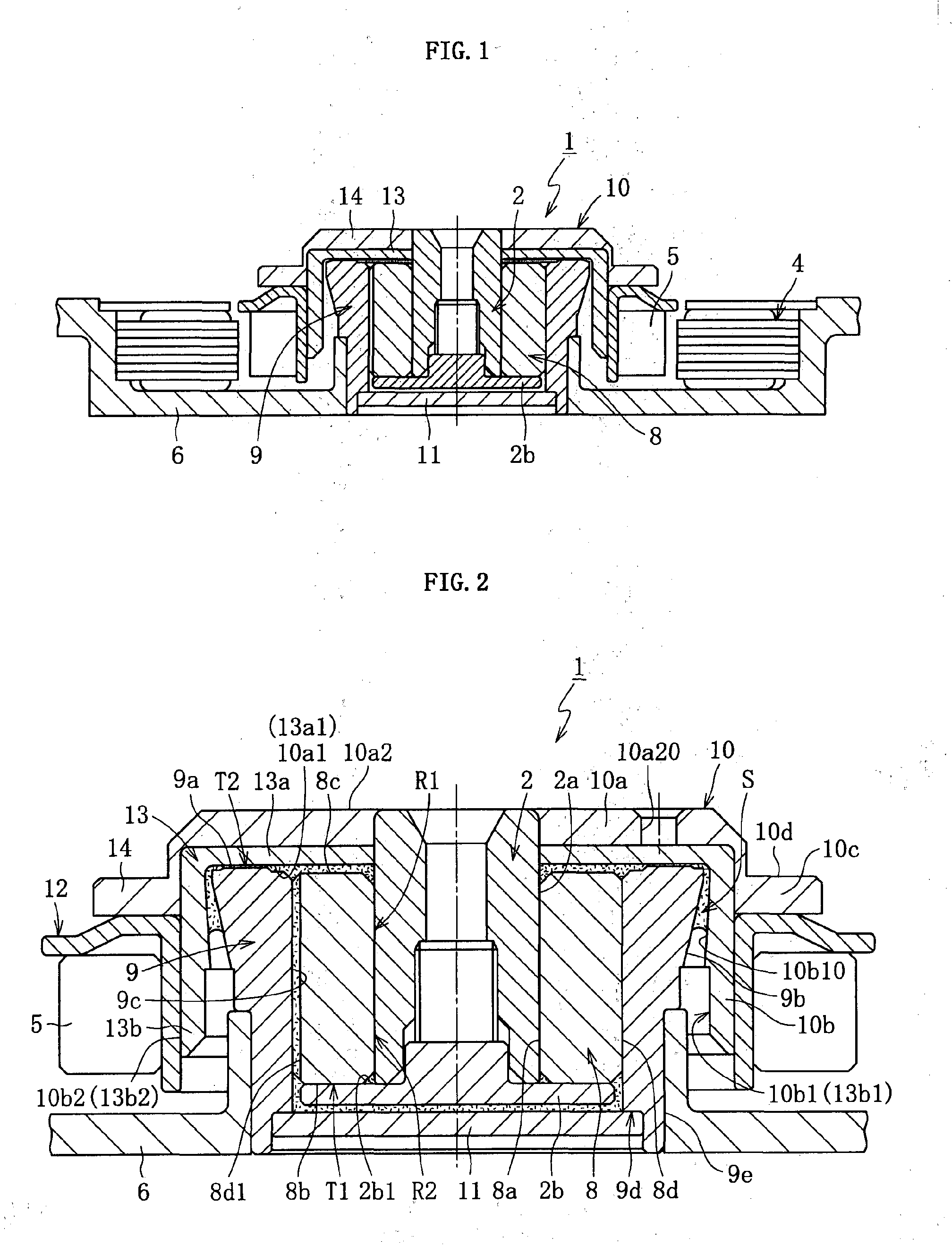

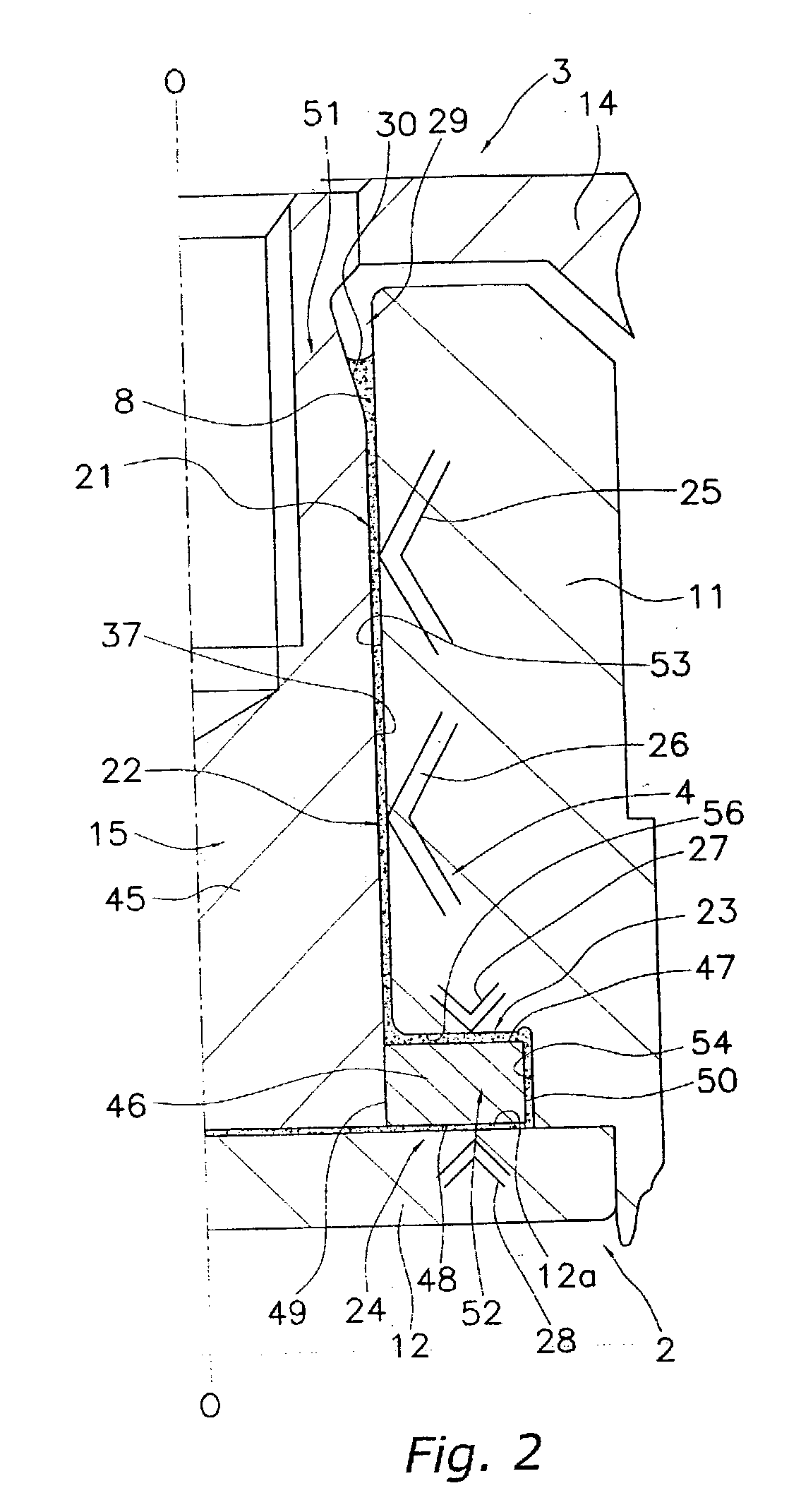

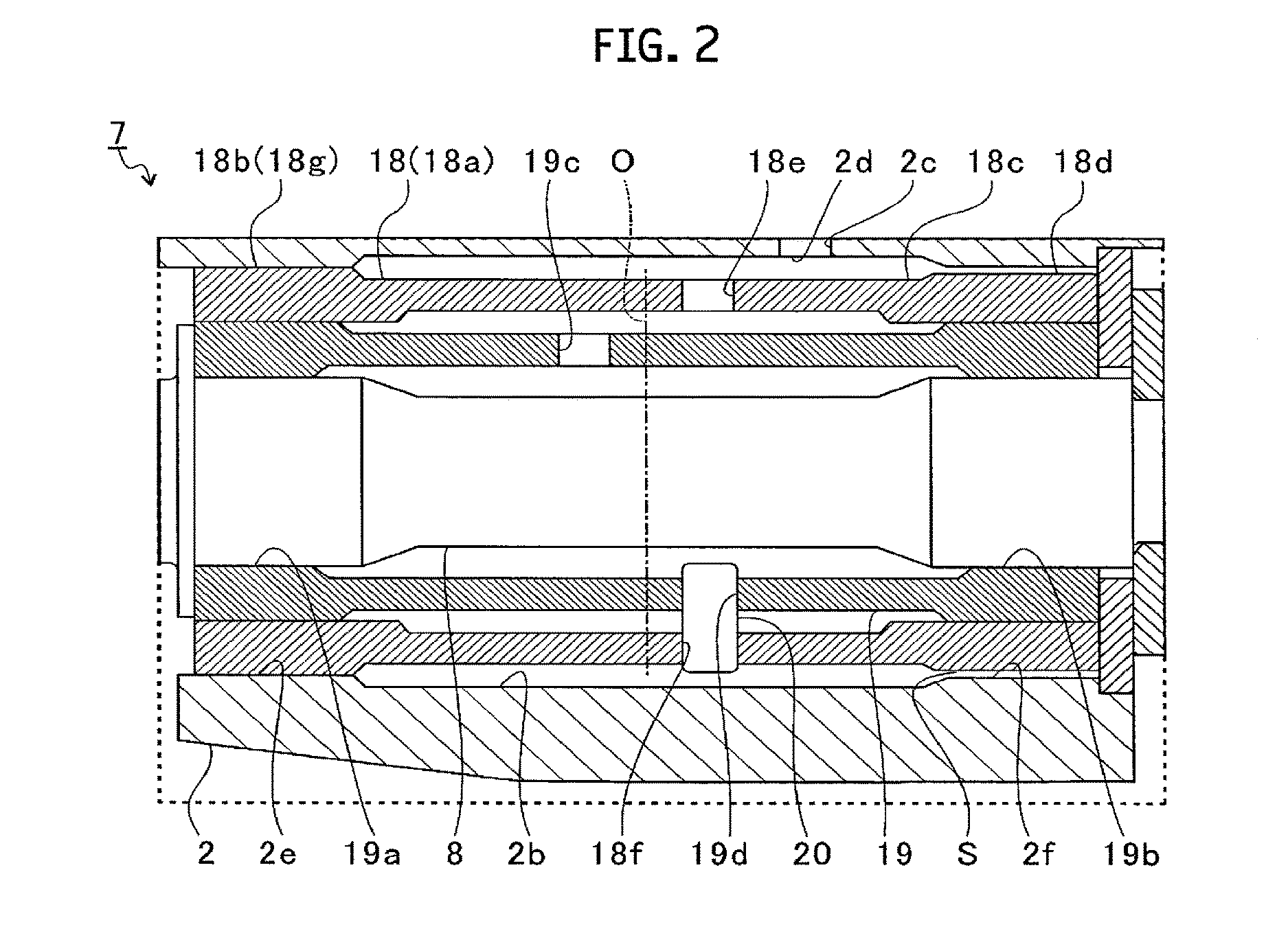

Fluid dynamic bearing device

InactiveUS20100226601A1High riskImprove fixation accuracyShaftsRecord information storageEngineeringFluid power

A hub (10) is a product formed by injection molding of a resin together with a core metal (13) as an inserted component, and the core metal (13) is exposed on a surface of the hub (10). With this configuration, a cavity of a die for molding the hub (10) is not divided by the core metal (13), and hence it is possible to suppress deterioration in fluidity of a resin due to arrangement of the core metal (13) in the cavity.

Owner:NTN CORP

Grease compostion for automobile electrical equipment auxiliary device and prelubricated rolling using the grease composition

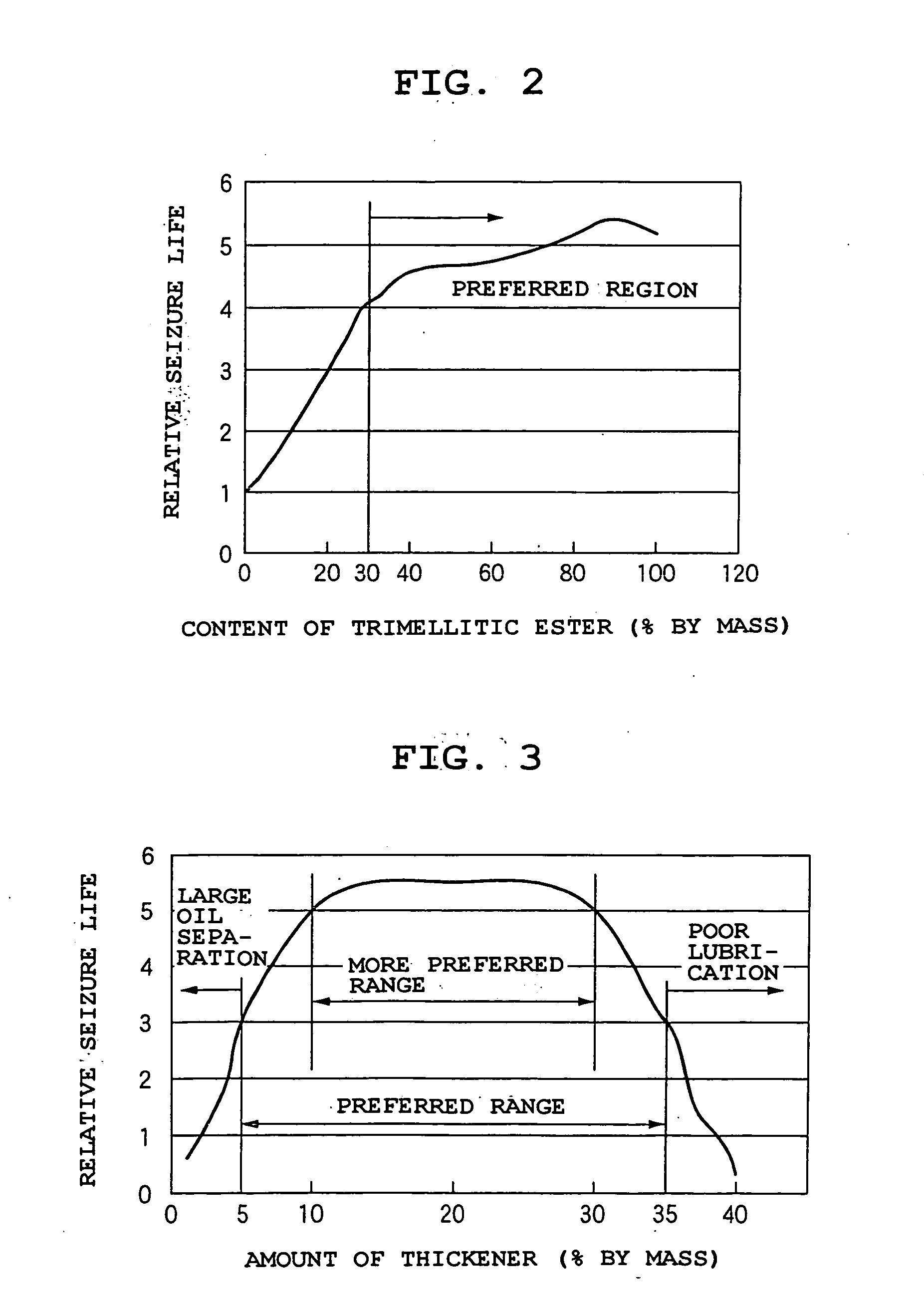

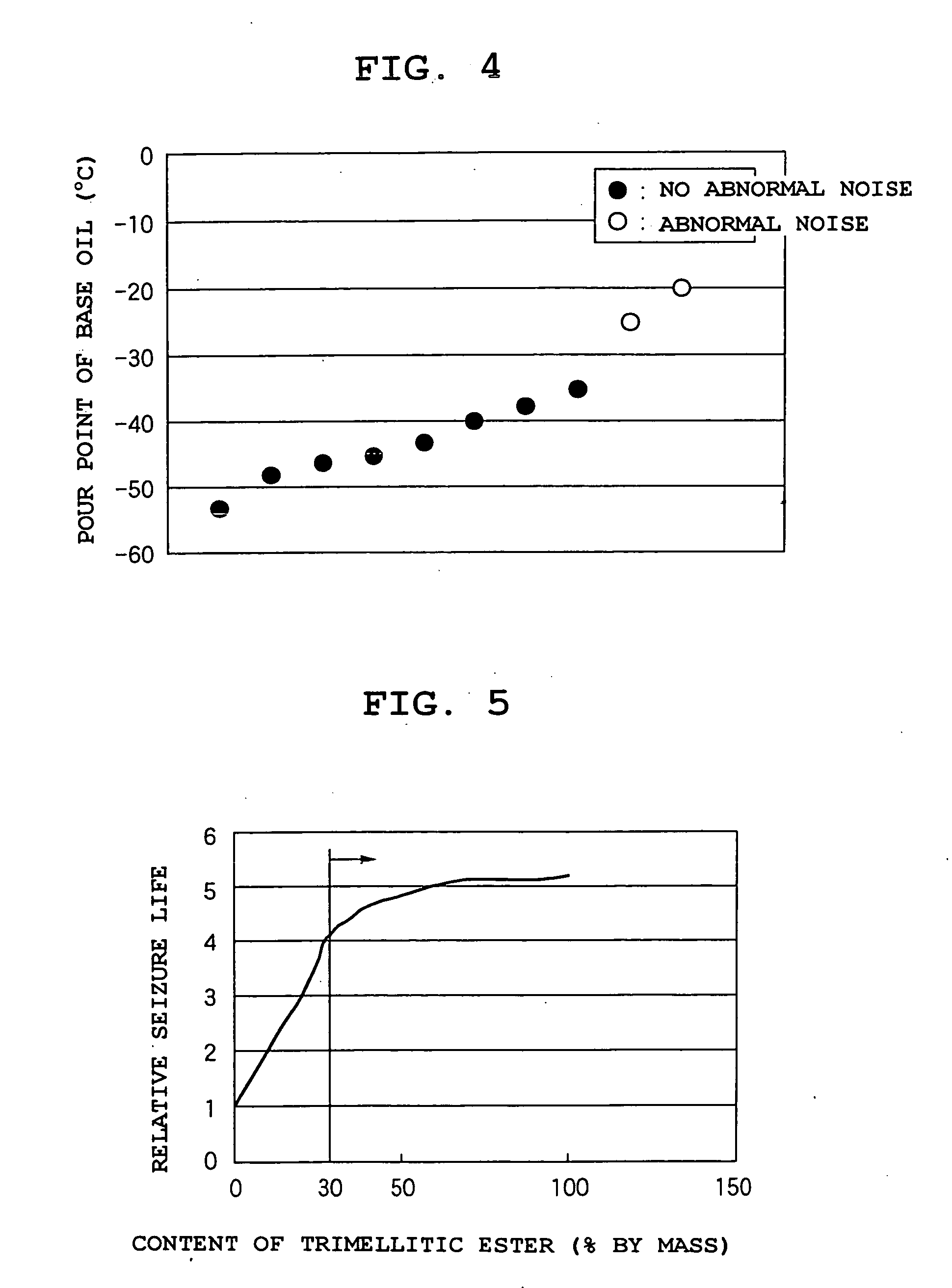

InactiveUS20060073989A1Improve bearing performanceImprove performanceMaterial nanotechnologyRolling contact bearingsEngineeringBase oil

To provide a grease composition for auxiliary machinery of automobile electrical component containing an aromatic ester oil-containing base oil having a specific diurea compound as a thickener blended therewith and a rolling bearing having the foregoing grease composition packed therein. The foregoing grease composition and rolling bearing do not generate abnormal noises even at an extremely low temperature of −40° C., have excellent seizure resistance even under a high temperature closed to 180° C., have excellent rust preventing performance, and are suitable especially for electrical parts and auxiliary machineries of engines, etc.

Owner:NSK LTD

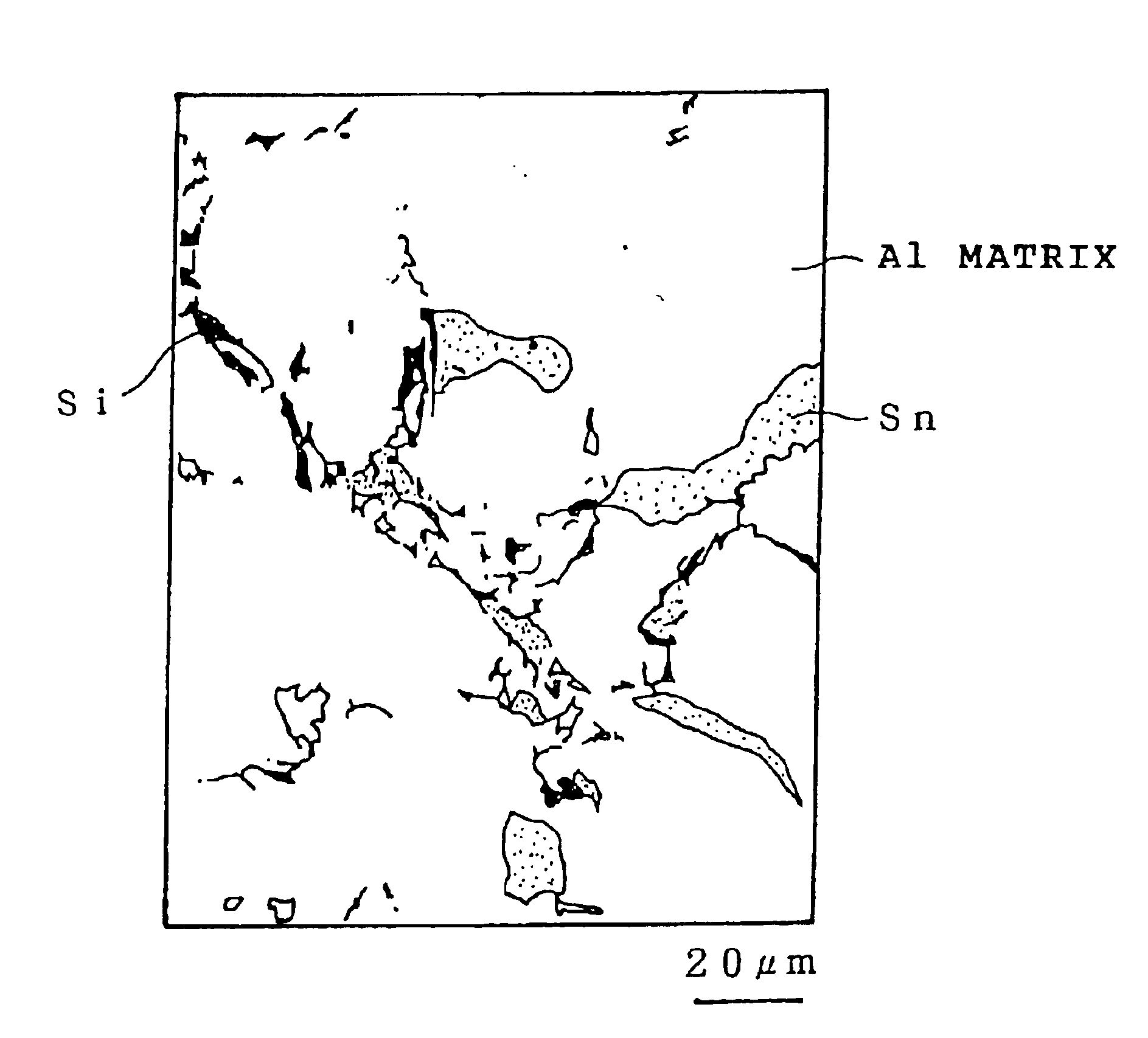

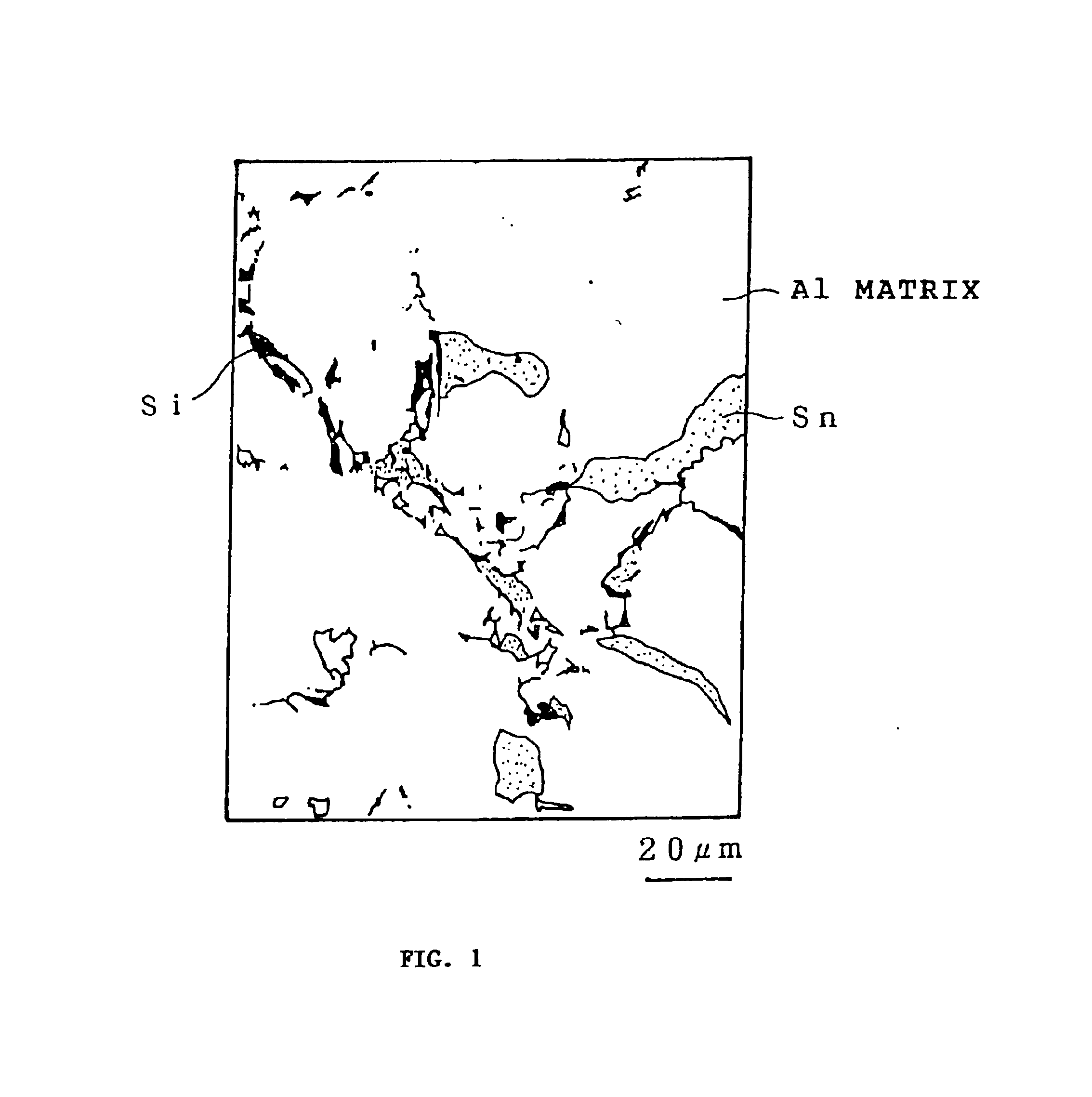

Aluminum bearing-alloy

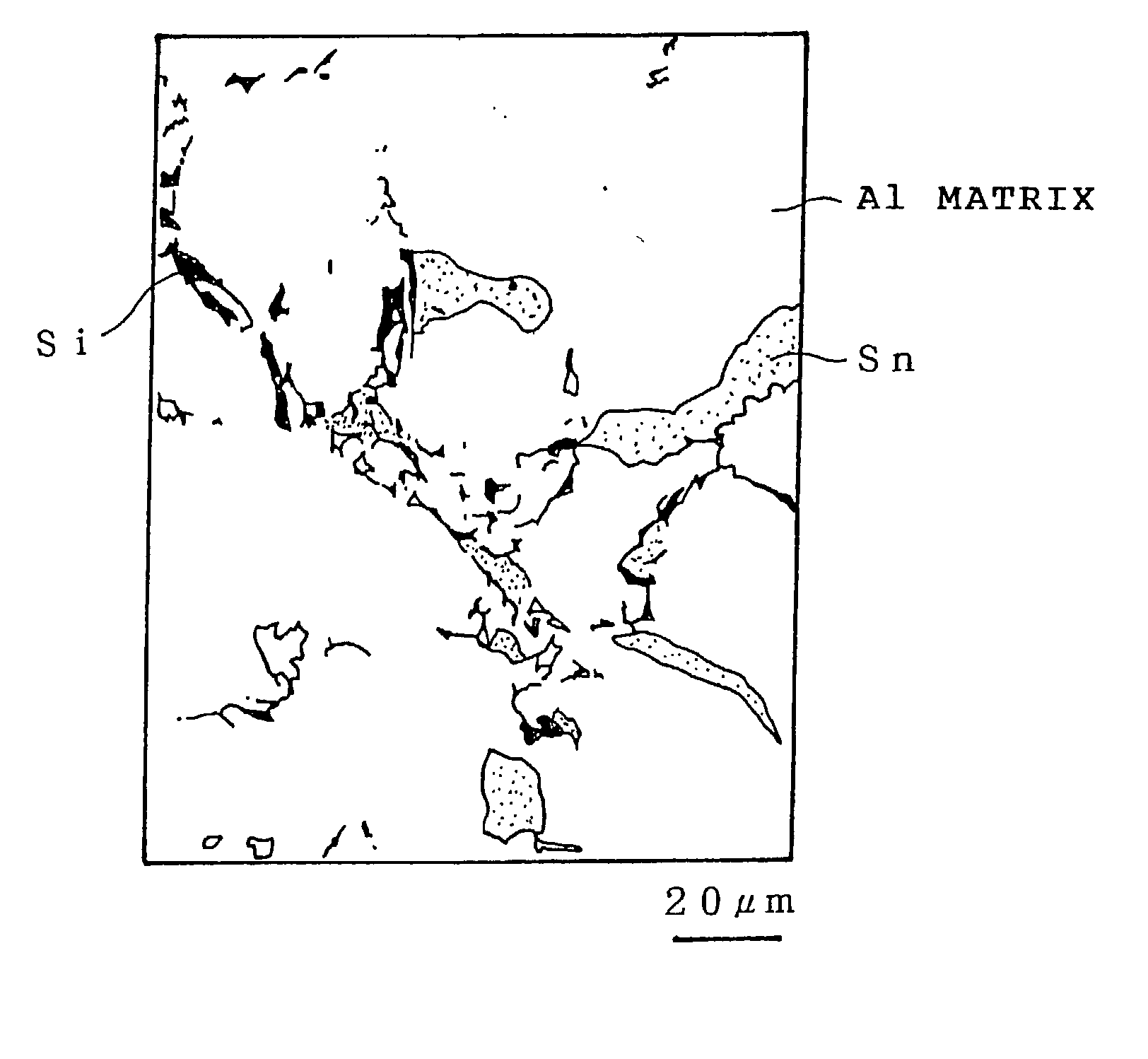

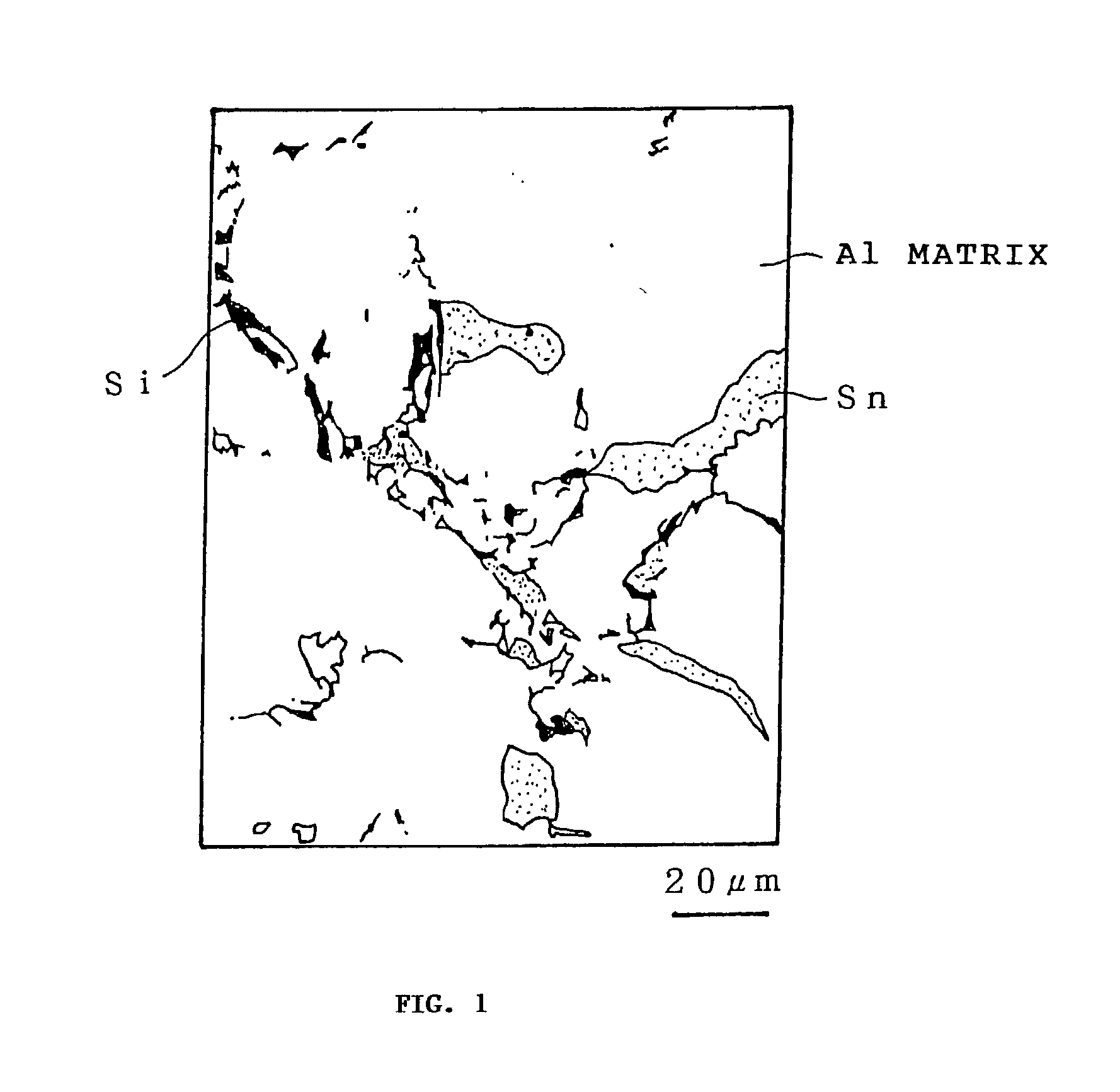

InactiveUS20030102059A1Excellent in wear and fatigue resistance propertyImprove bearing performanceShaftsBearing componentsMaterials scienceAluminium alloy

An aluminum bearing-alloy containing 1.5 to 8 mass % of Si is provided, in which there can be observed Si grains on the sliding surface of the aluminum bearing-alloy. A fractional area of the observed Si grains having a grain size of less than 4 mum is 20 to 60% of a total area of all the observed Si grains. Another fractional area of the observed Si grains having a grain size of from 4 to 20 mum is not less than 40% of the total area of all the observed Si grains.

Owner:DAIDO METAL CO LTD

Fluid dynamic bearing device and motor equipped with the same

InactiveUS7556433B2Low production costLess expensiveShaftsMetal-working apparatusEngineeringInjection moulding

Owner:NTN CORP +1

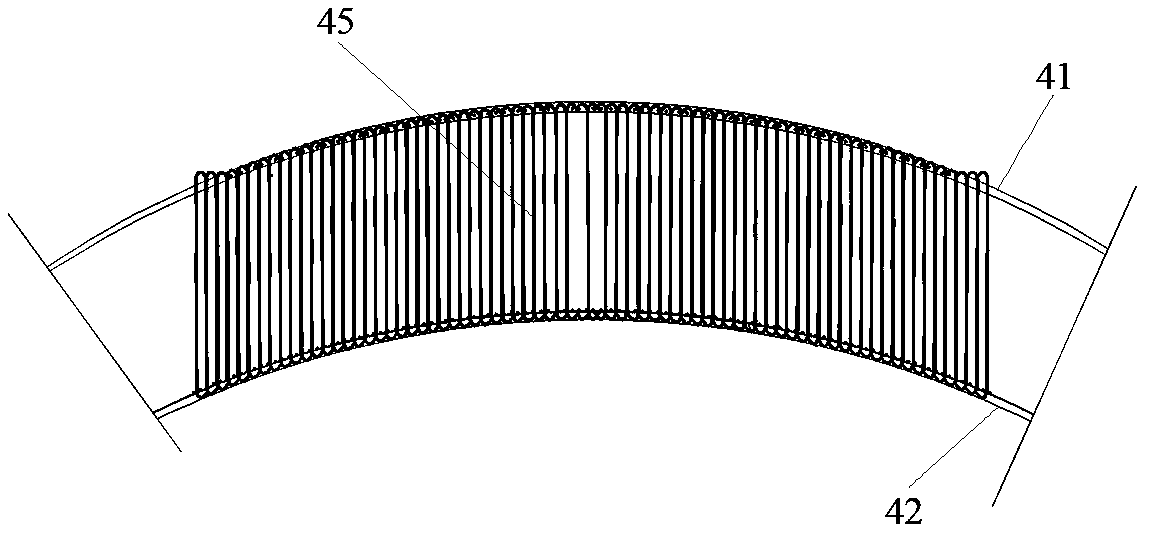

Slewing bearing structure

InactiveUS20130202234A1Simple structureInhibit transferRoller bearingsShaftsStructural deformationContact pressure

There is provided a slewing bearing structure capable of maintaining favorable bearing performance by adjusting and changing rigidity thereof while minimizing the increase in the weight thereof for preventing distortion of a pressure pattern caused by structural deformation from unfavorably affecting the bearing performance. A slewing bearing of a rolling bearing, in which a rolling element is put between bearing rings and formed on an inner ring and an outer ring, has a slewing bearing structure in which a rigidity strengthening portion, at which rigidity of the inner ring and / or the outer ring is increased more than that at peripheral portions, is formed at a circumferential area where a bearing contact pressure is high.

Owner:MITSUBISHI HEAVY IND LTD

Fluid dynamic bearing device and motor equipped with the same

InactiveUS20060188187A1Low production costGood fluid performanceShaftsRecord information storageEngineeringElectric motor

Owner:NTN CORP +1

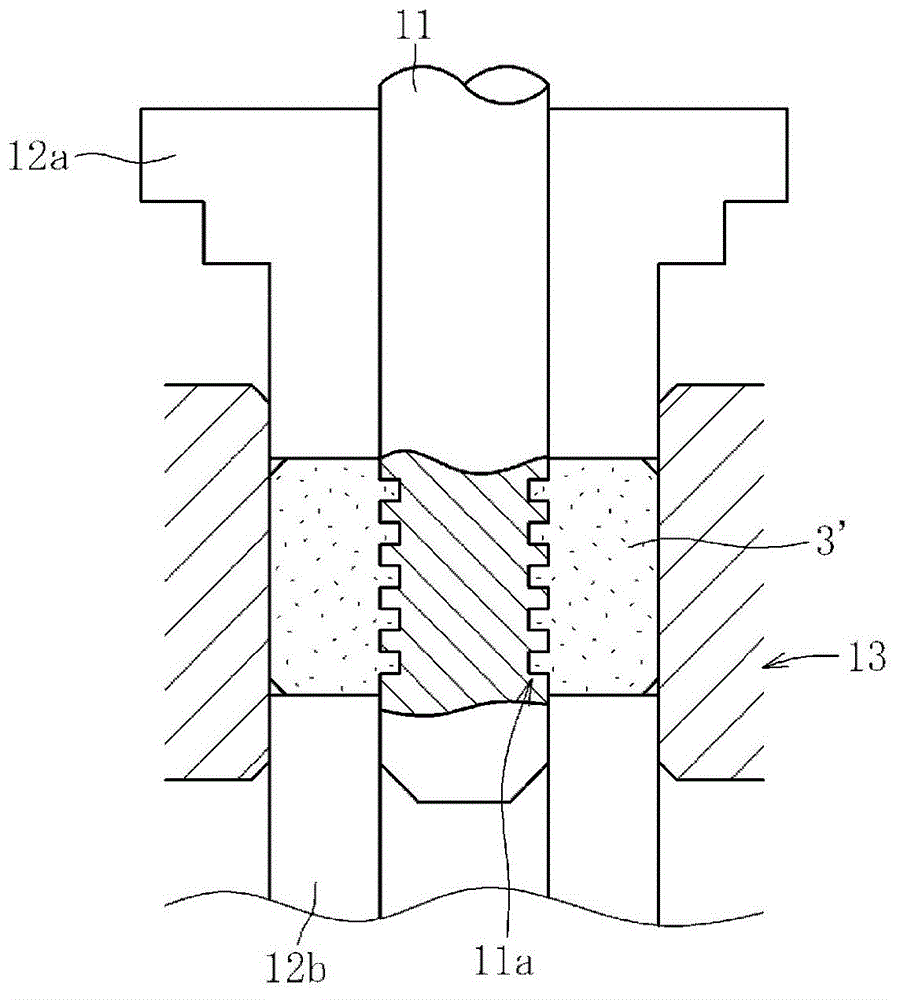

Method of manufacturing a thrust plate, method of manufacturing a shaft for a hydrodynamic bearing, hydrodynamic bearing, spindle motor, and recording disk drive device

InactiveUS20030184911A1Reliable and highly precise degree of run-out precisionImprove bearing performanceShaftsMetal-working apparatusThrust bearingDynamic pressure

A method of manufacturing a thrust plate for a dynamic pressure bearing in which the upper and lower end surfaces thereof have a highly precise perpendicular angle relative to the central axis thereof. The thrust plate has an annular shape, and a central hole is formed therein in which is fitted a shaft body. Thrust surfaces that form a portion of thrust bearing units are formed at both end surfaces of the thrust plate. The method of manufacturing the thrust plate includes a blanking step in which a plate-like work piece is press-cut to obtain an annular blank intermediate, an end surface polishing step in which both end surfaces of the blank intermediate are polished, and a shaving step in which an inner hole and an outer periphery of the polished blank intermediate are simultaneously press-cut to shave off surfaces thereof.

Owner:SOODE NAGANO +1

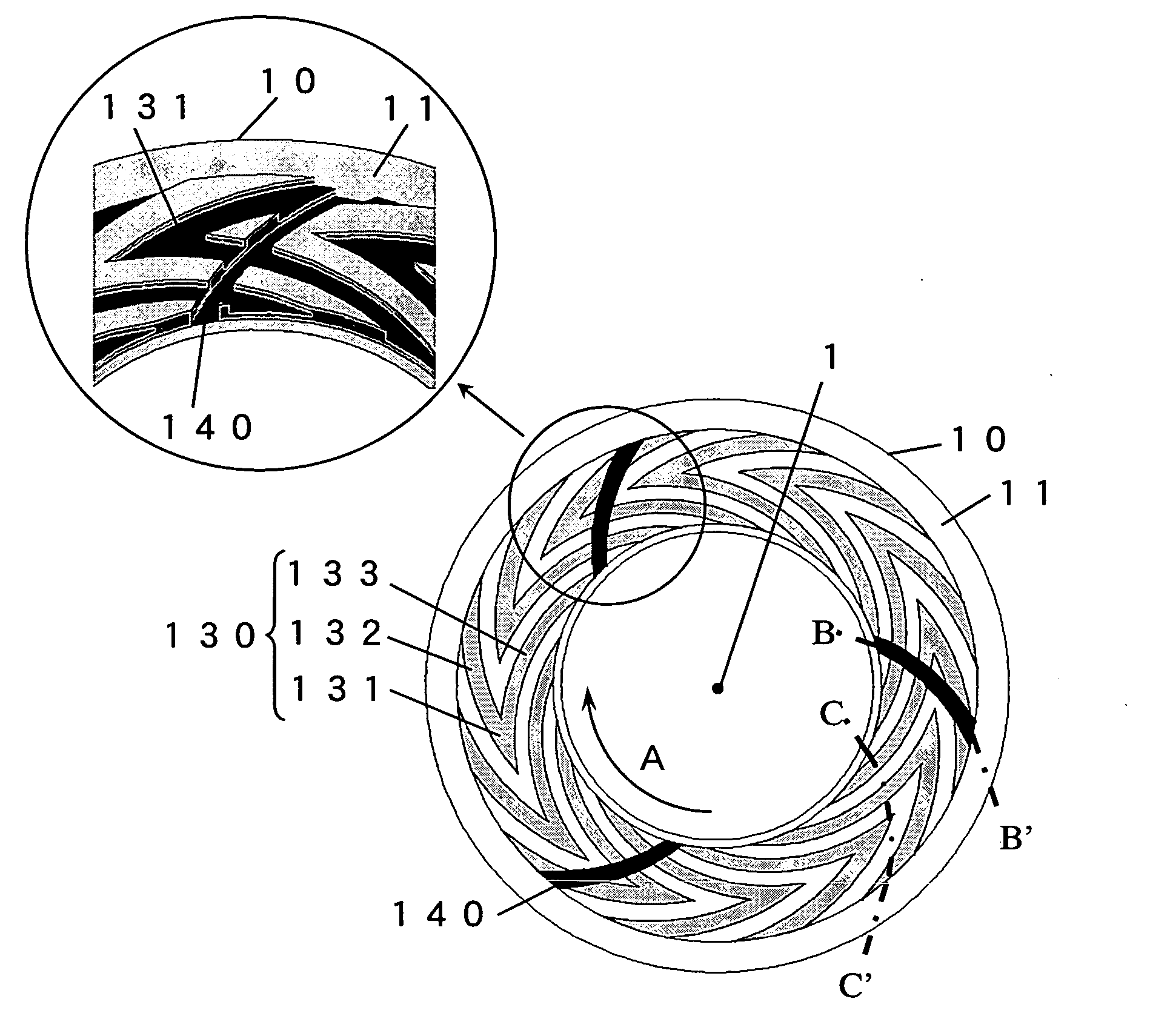

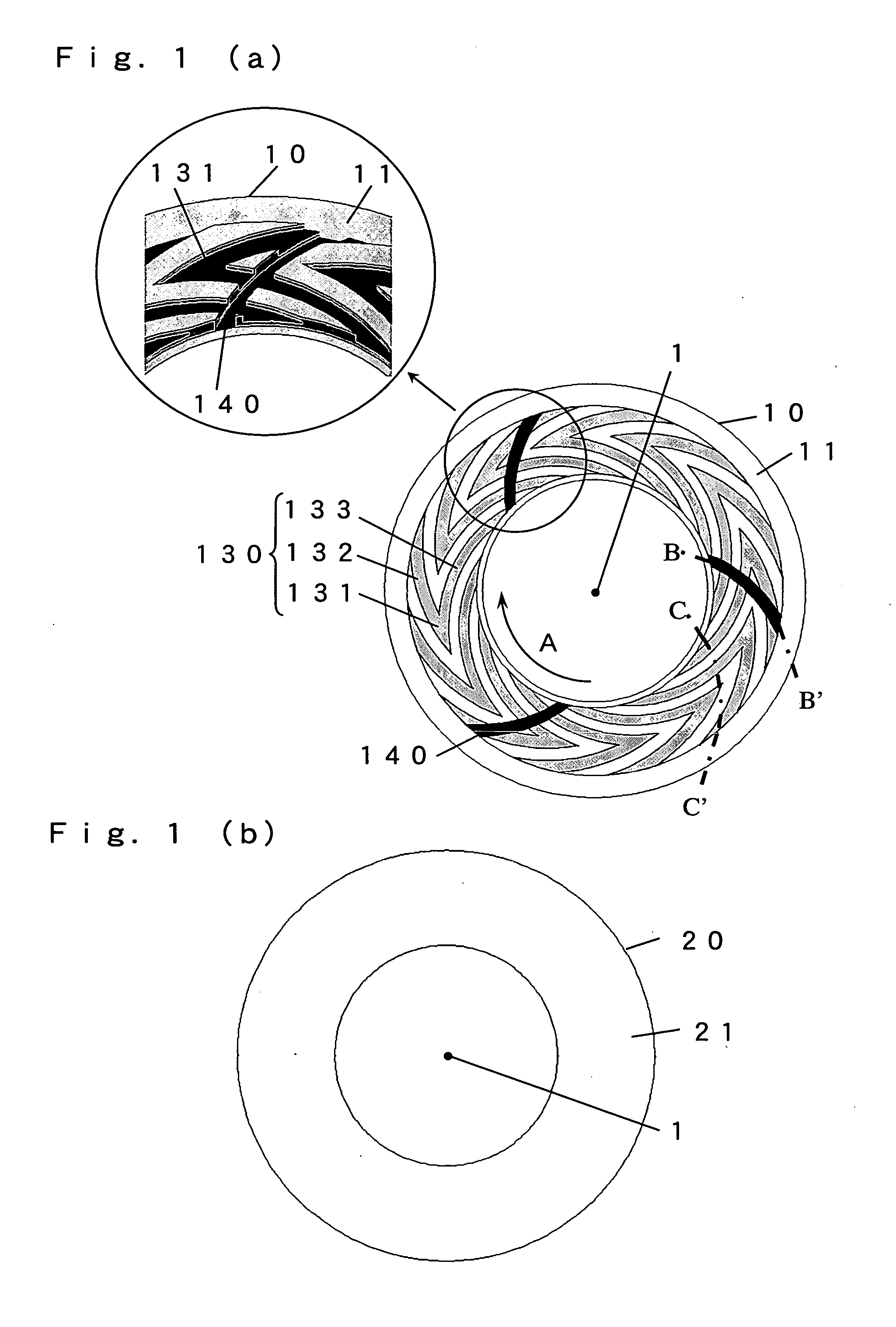

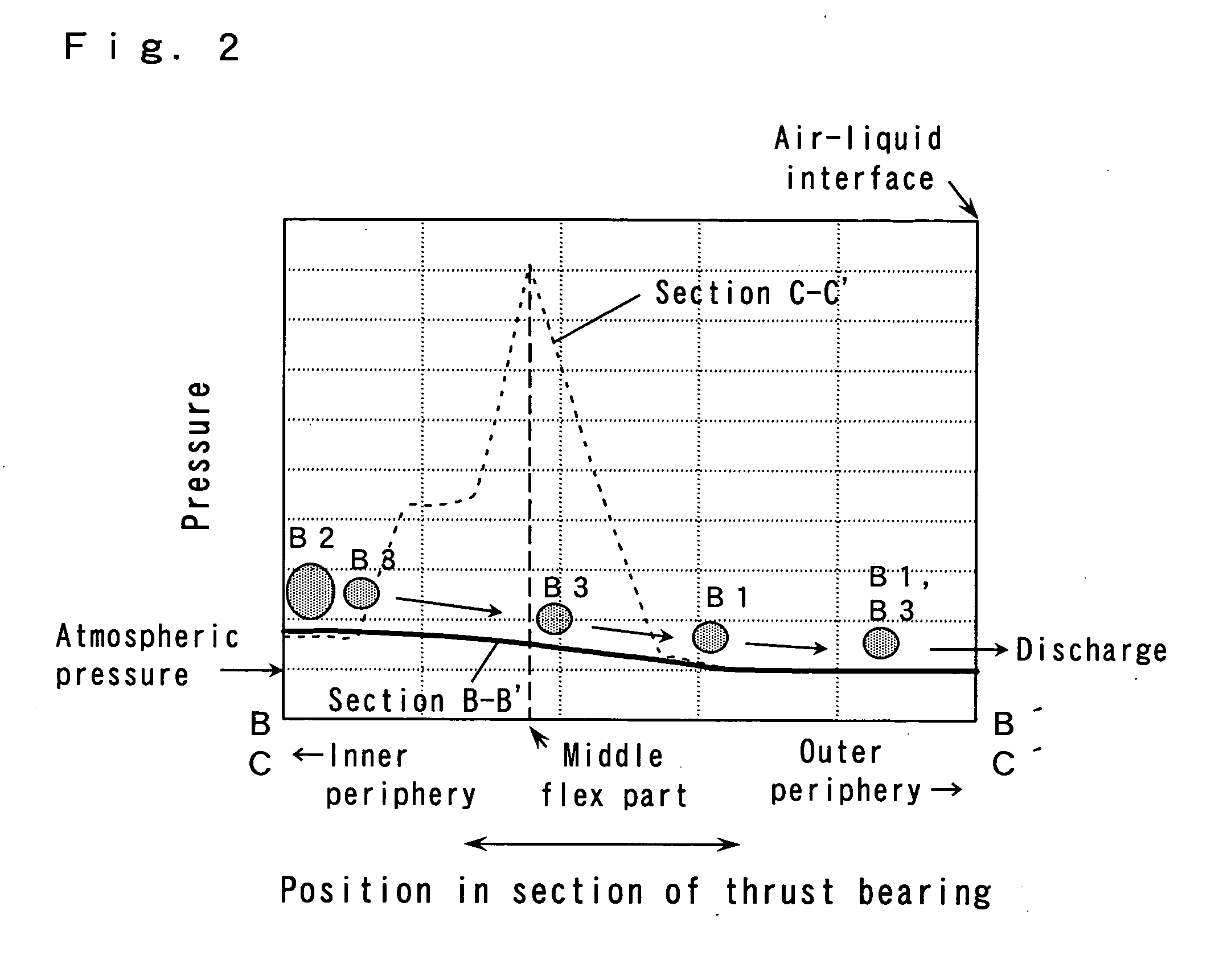

Thrust dynamic pressure bearing, spindle motor using the same, and information recording and reproducing apparatus using them

InactiveUS20050141789A1Improve reliabilityIncreased durabilityShaftsRecord information storageAir liquid interfaceDynamic pressure

In order to prevent lubricating oil leak due to bubbles in thrust dynamic pressure bearing of herringbone grooves, stabilize the bearing performance, and enhance the reliability and durability, auxiliary grooves deeper than pump-in type herringbone grooves for generating dynamic pressure are provided, and the bearing inner periphery and bearing outer periphery are linked by a pressure gradient descending slowly, and therefore bubbles present in bearing inner periphery can be guided into the bearing outer periphery through auxiliary grooves, and discharged to outside of the bearing from the air-liquid interface, so that lubricating oil leak due to bubbles can be prevented.

Owner:PANASONIC CORP

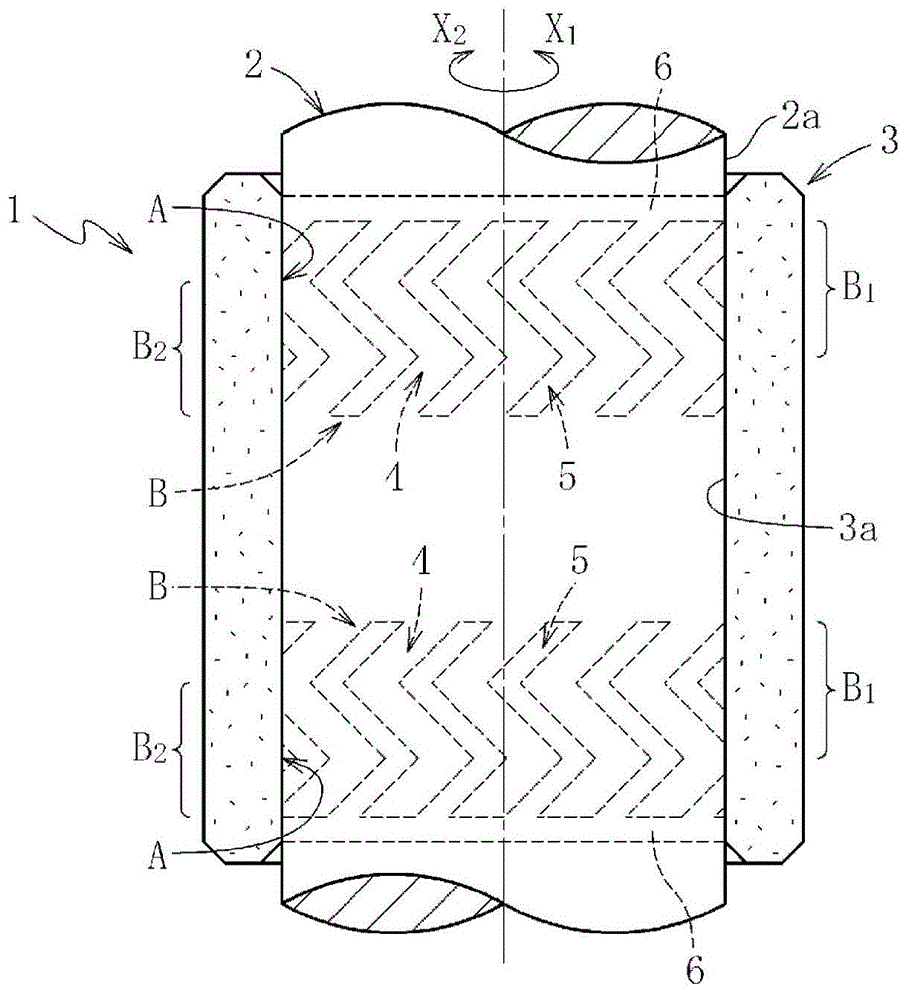

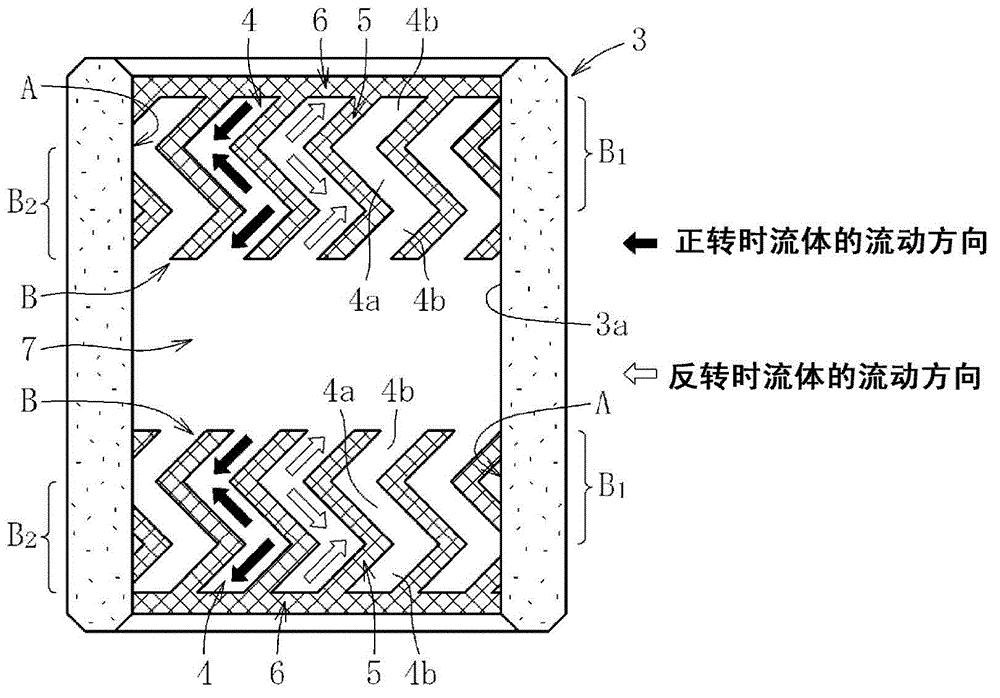

Fluid dynamic pressure bearing device

InactiveCN103339393AImprove bearing performanceImprove performanceBearing componentsSliding contact bearingsEngineeringDynamic pressure

Owner:NTN CORP

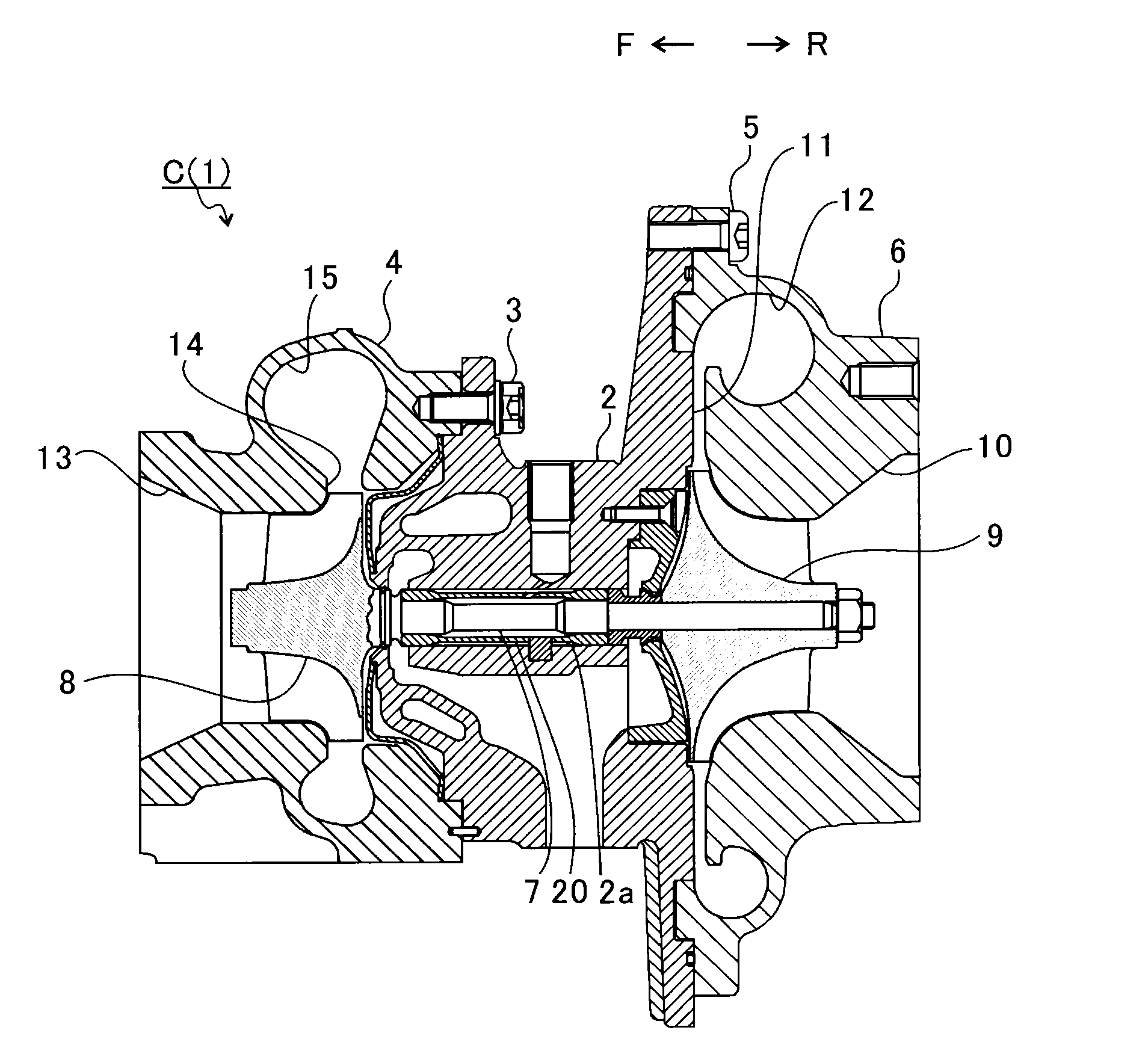

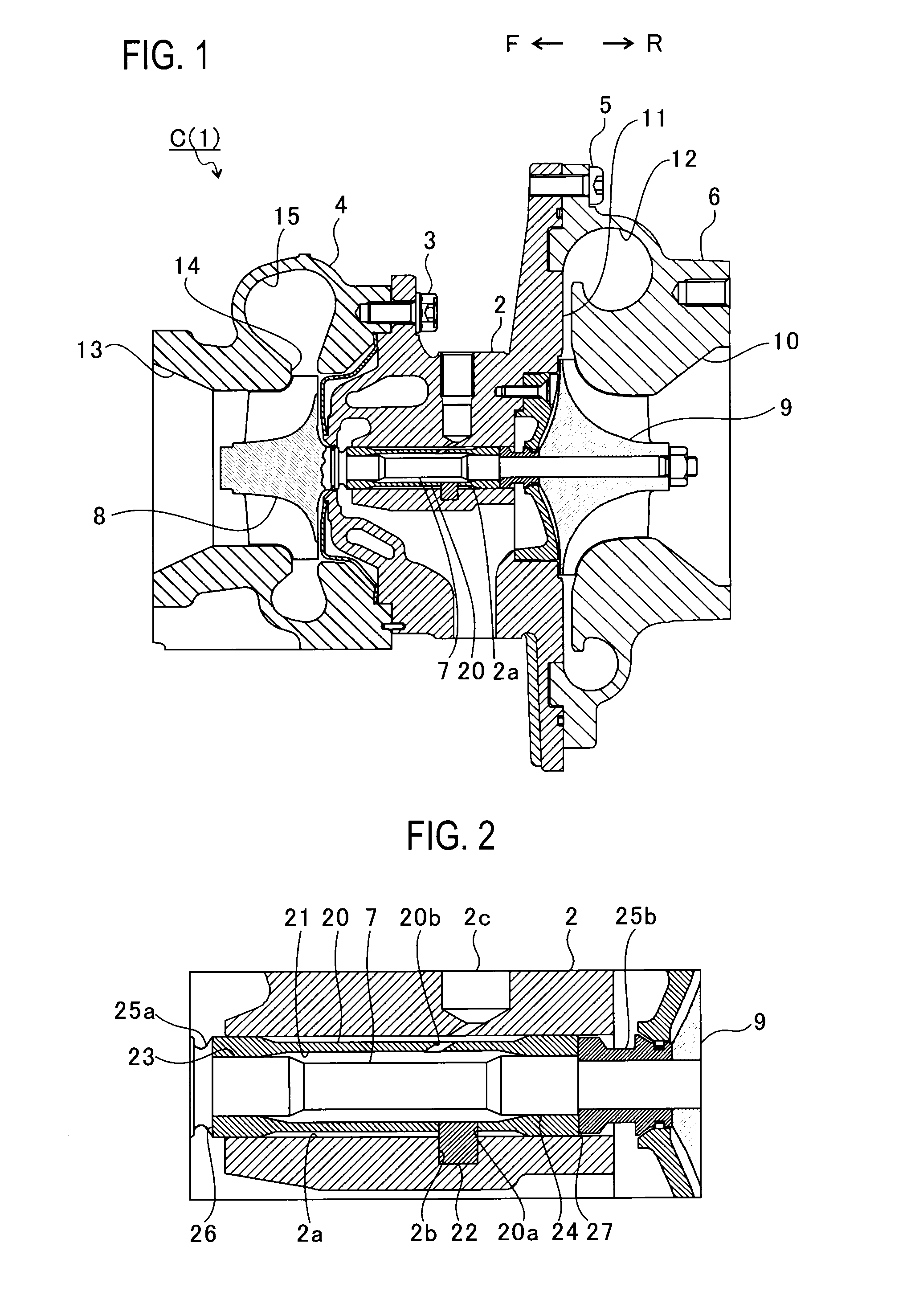

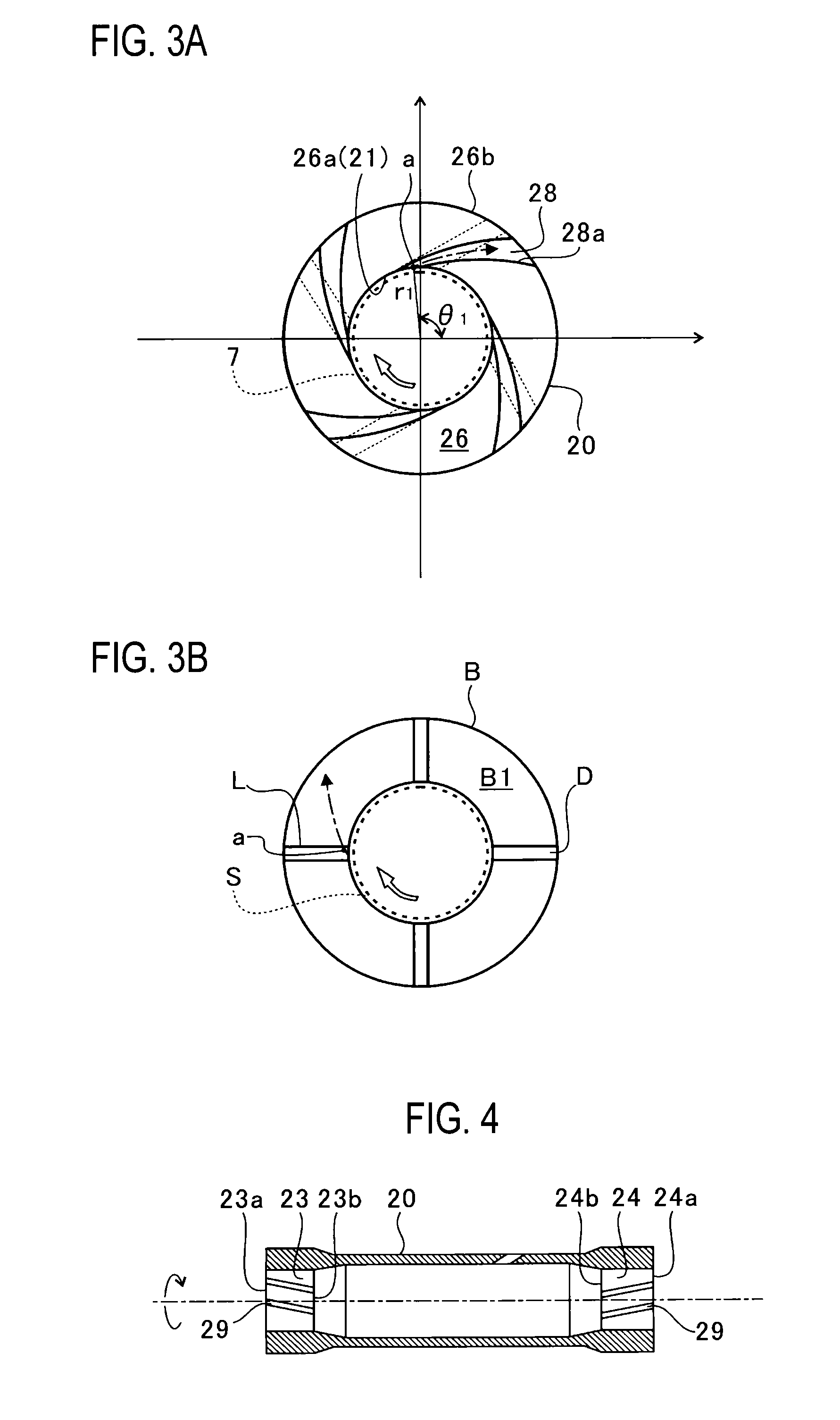

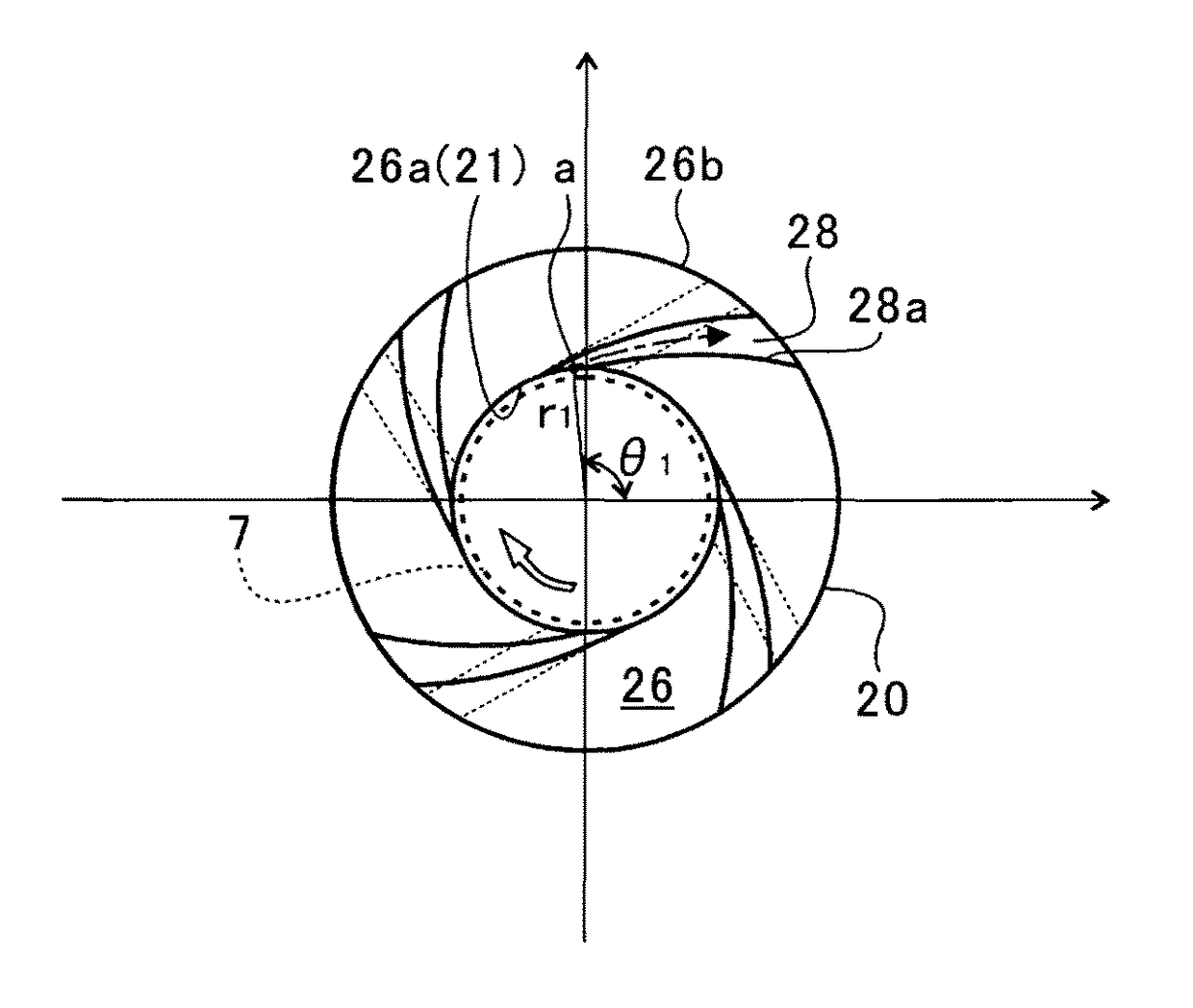

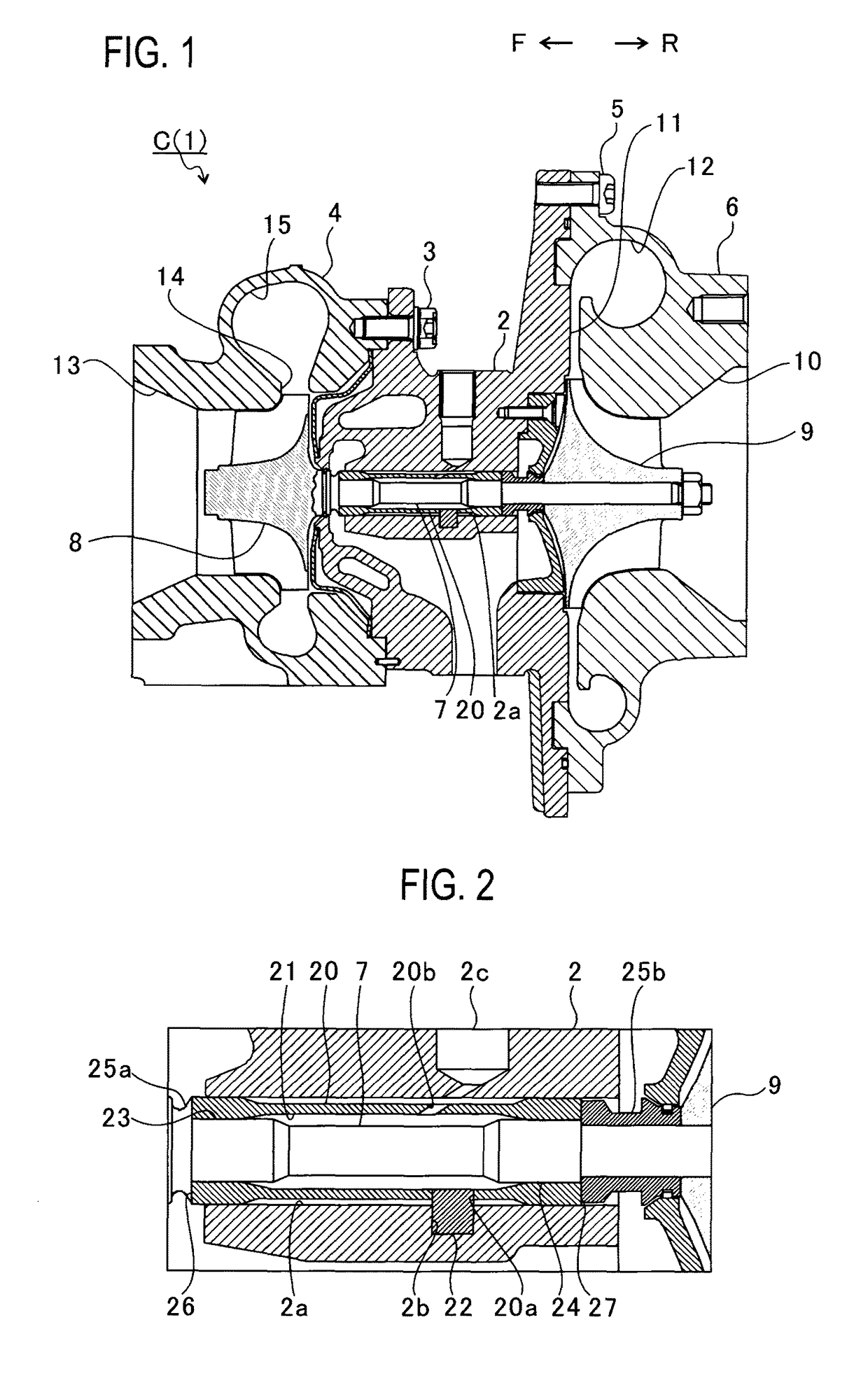

Turbocharger

ActiveUS20150078884A1Reduce harmImprove the lubrication effectEngine manufacturePump componentsTurbochargerEngineering

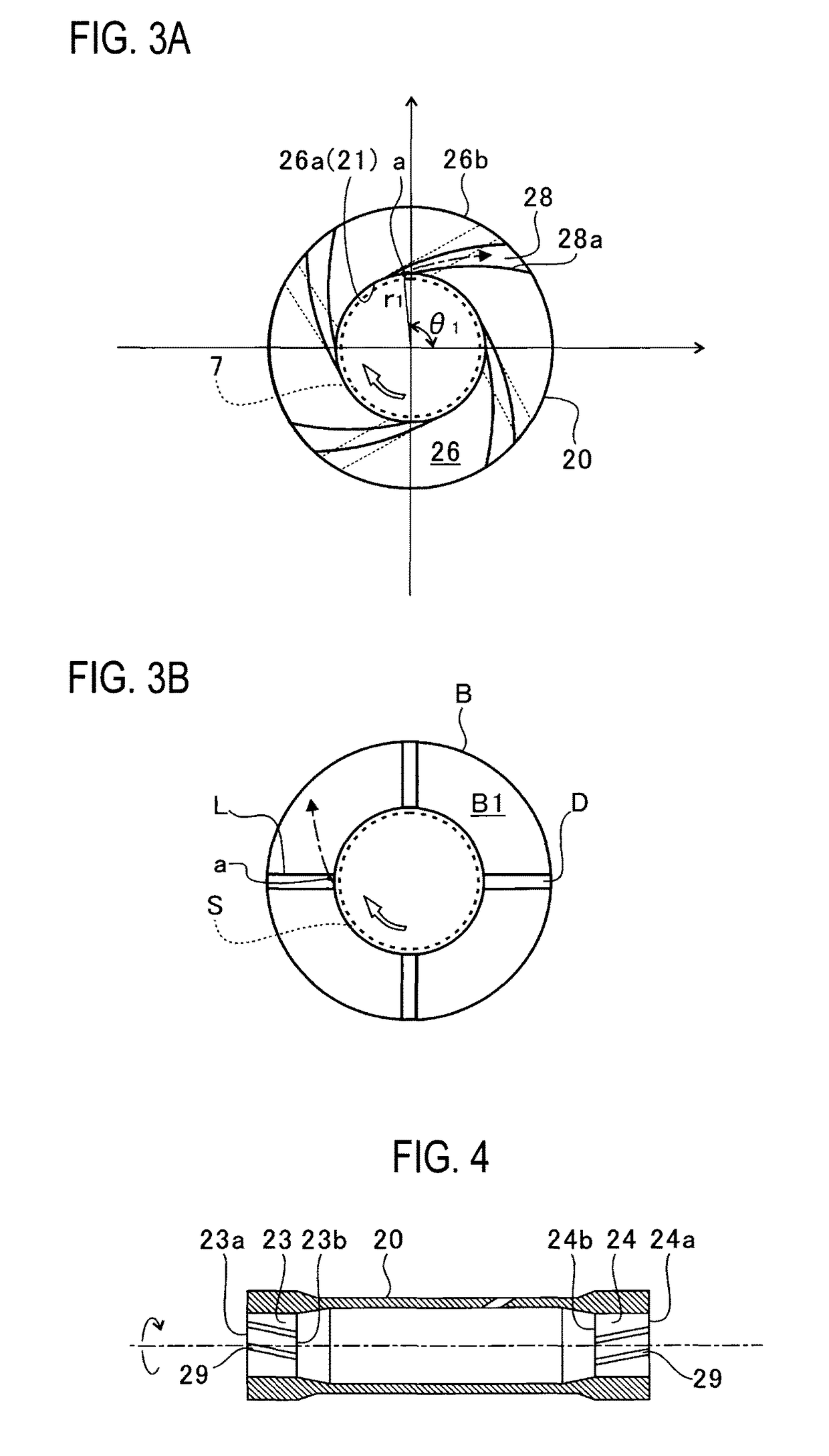

A turbocharger includes: a bearing provided in a turbocharger body, and configured to rotatably support a turbine shaft in an insertion hole formed in the bearing; and an opposing portion which faces an end surface of the bearing in an axial direction of the turbine shaft. An end-surface guide portion is provided to any one of an opposing surface of the bearing which faces the opposing portion, and an opposing surface of the opposing portion which faces the bearing. The end-surface guide portion configured to make the insertion hole and an outer peripheral edge of the end surface of the bearing in radial directions of the turbine shaft communicate with each other extends forward in a rotational direction of the turbine shaft from a part of the end surface of the bearing which communicates with the insertion hole.

Owner:IHI CORP

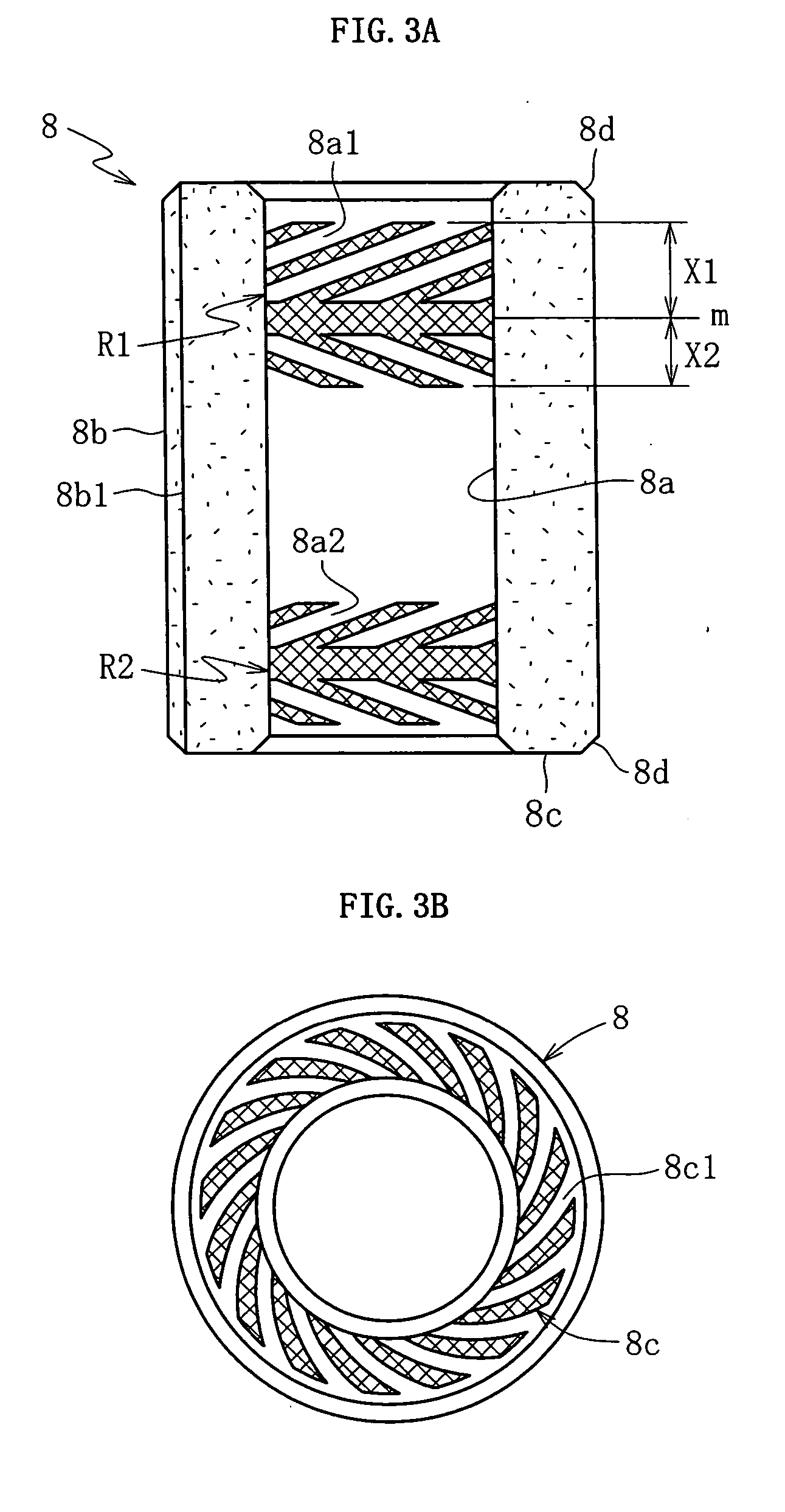

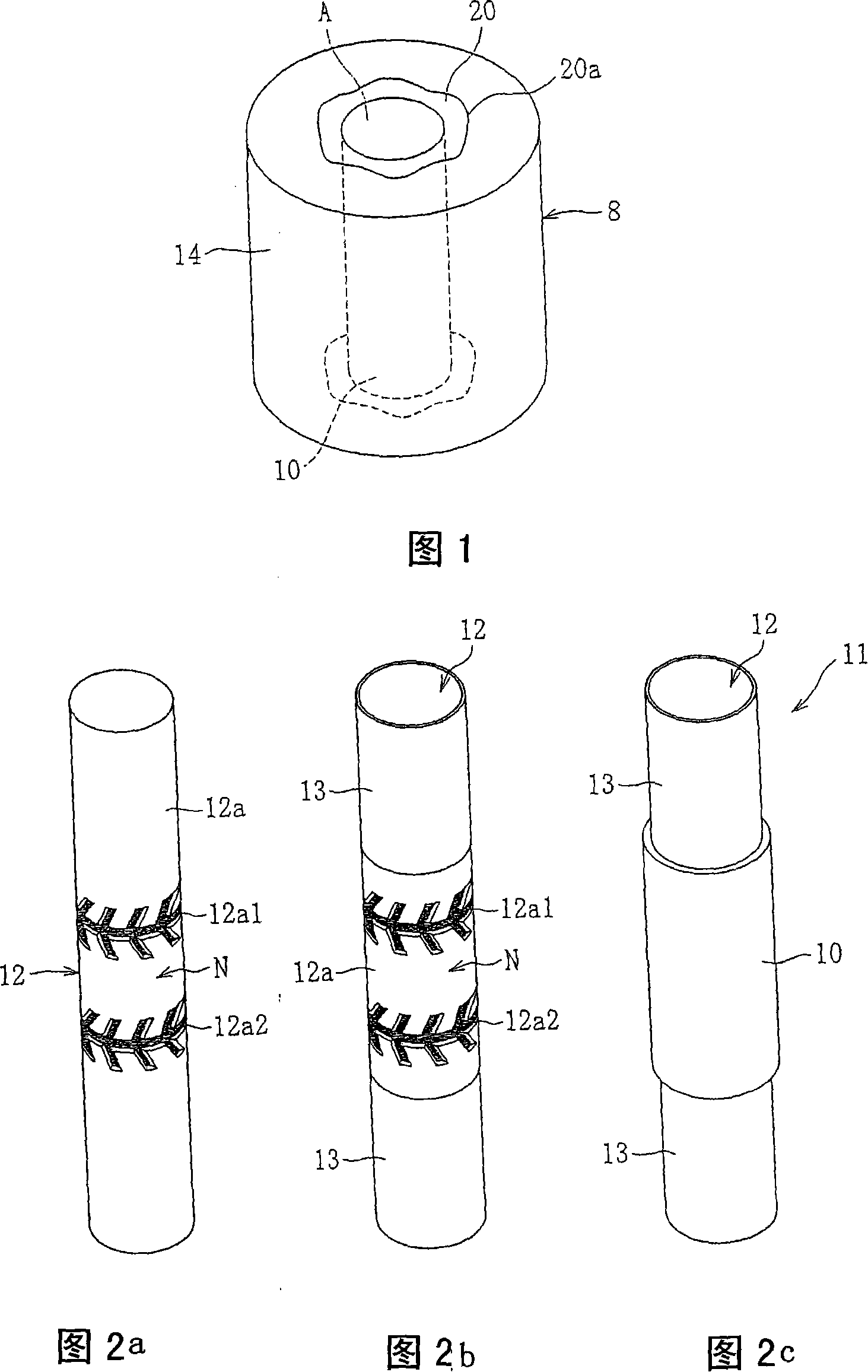

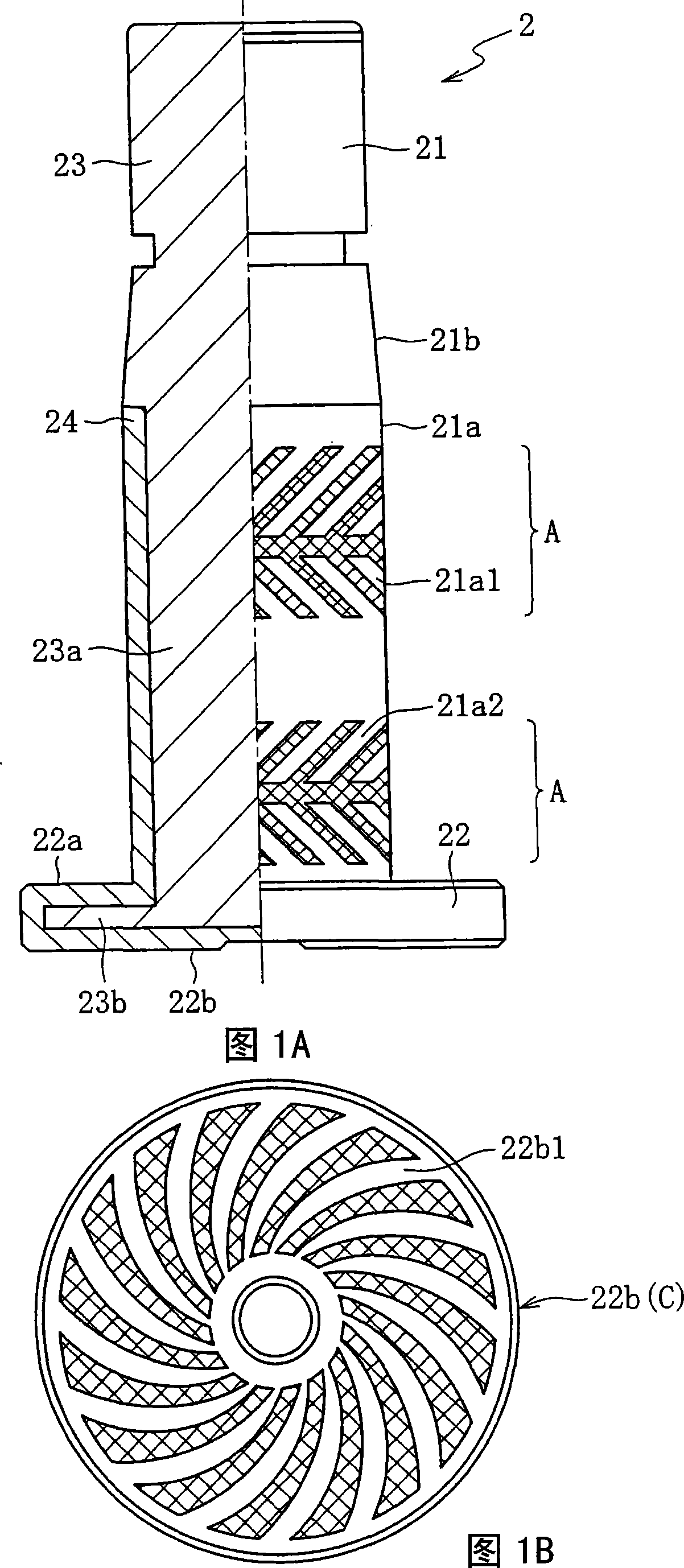

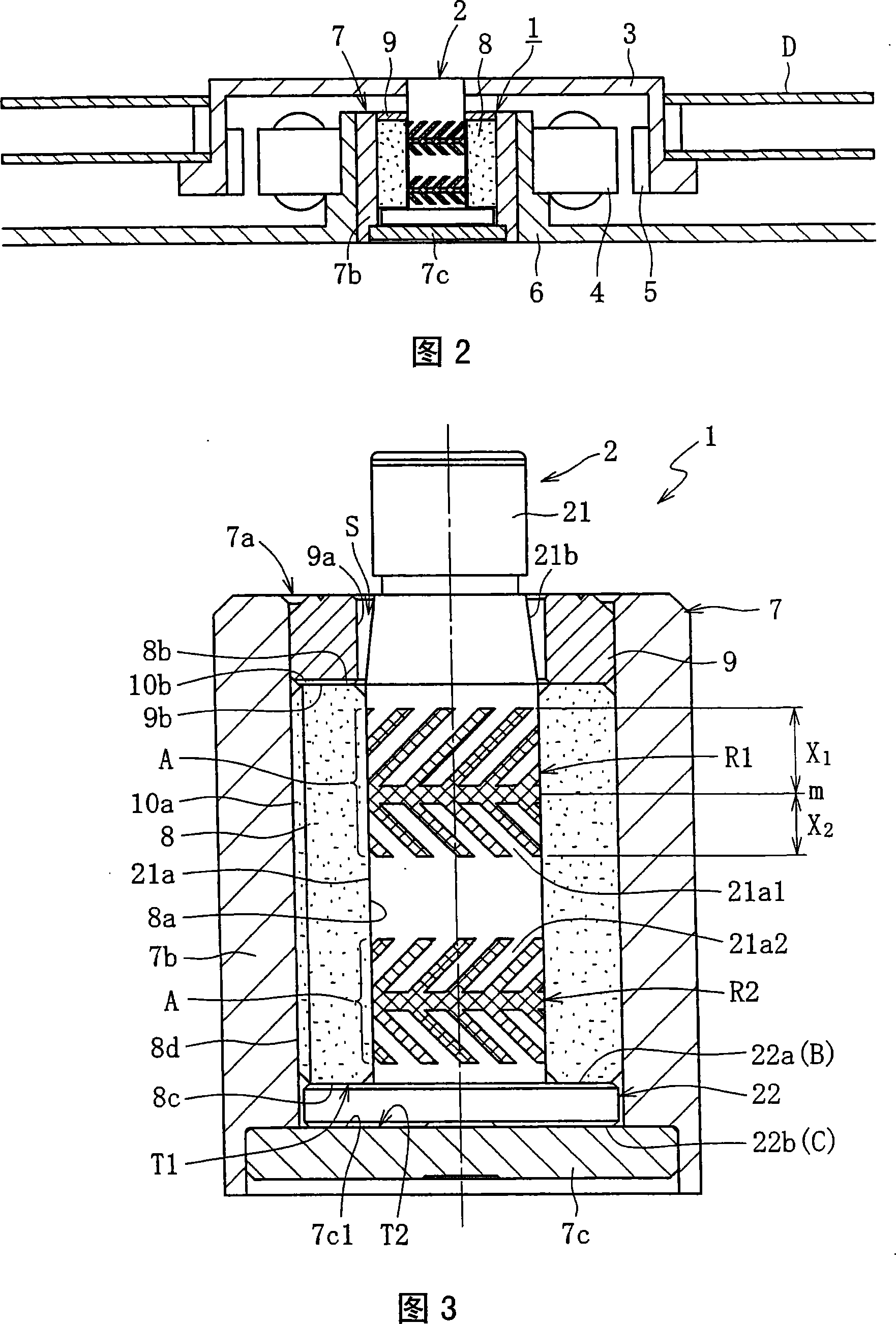

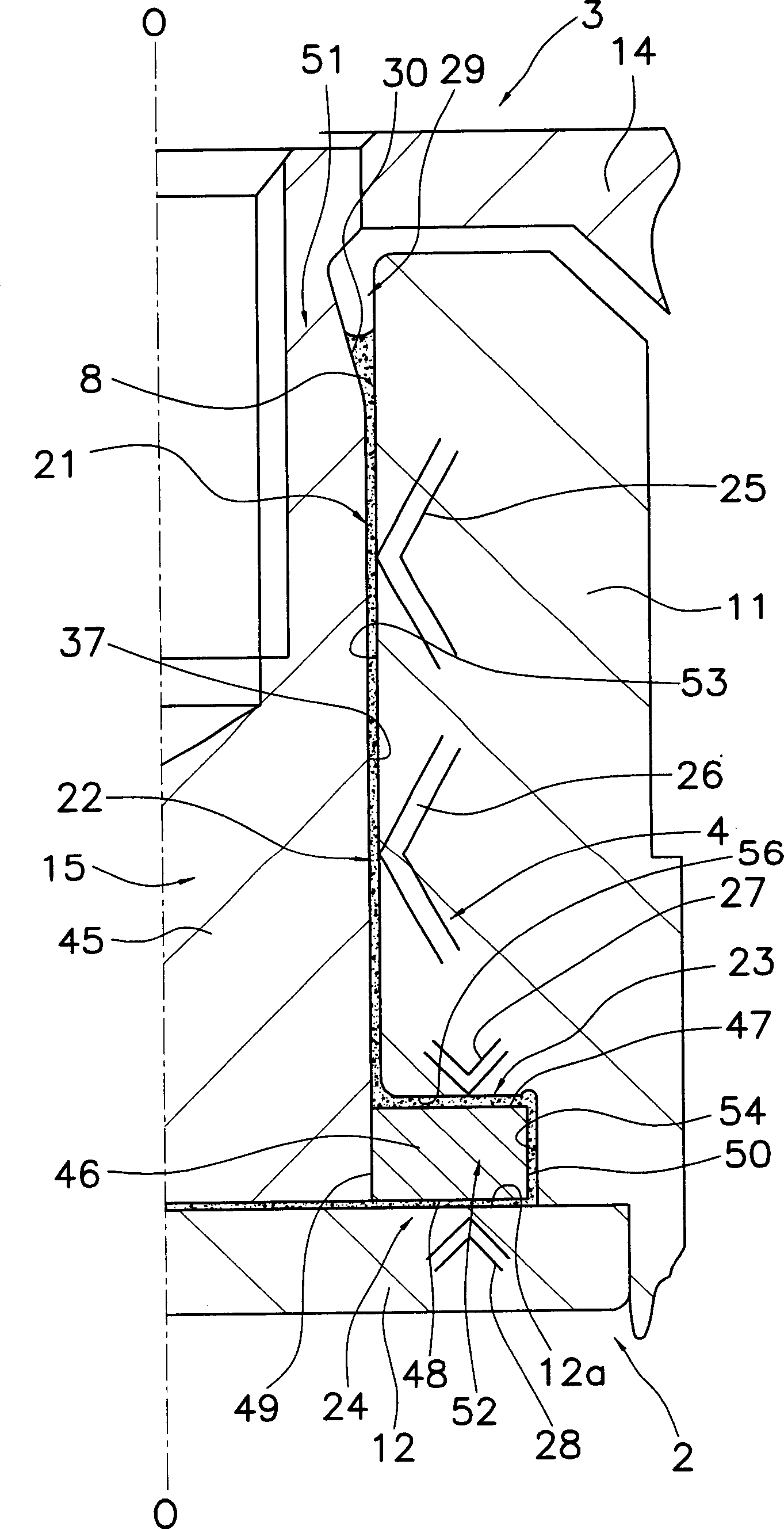

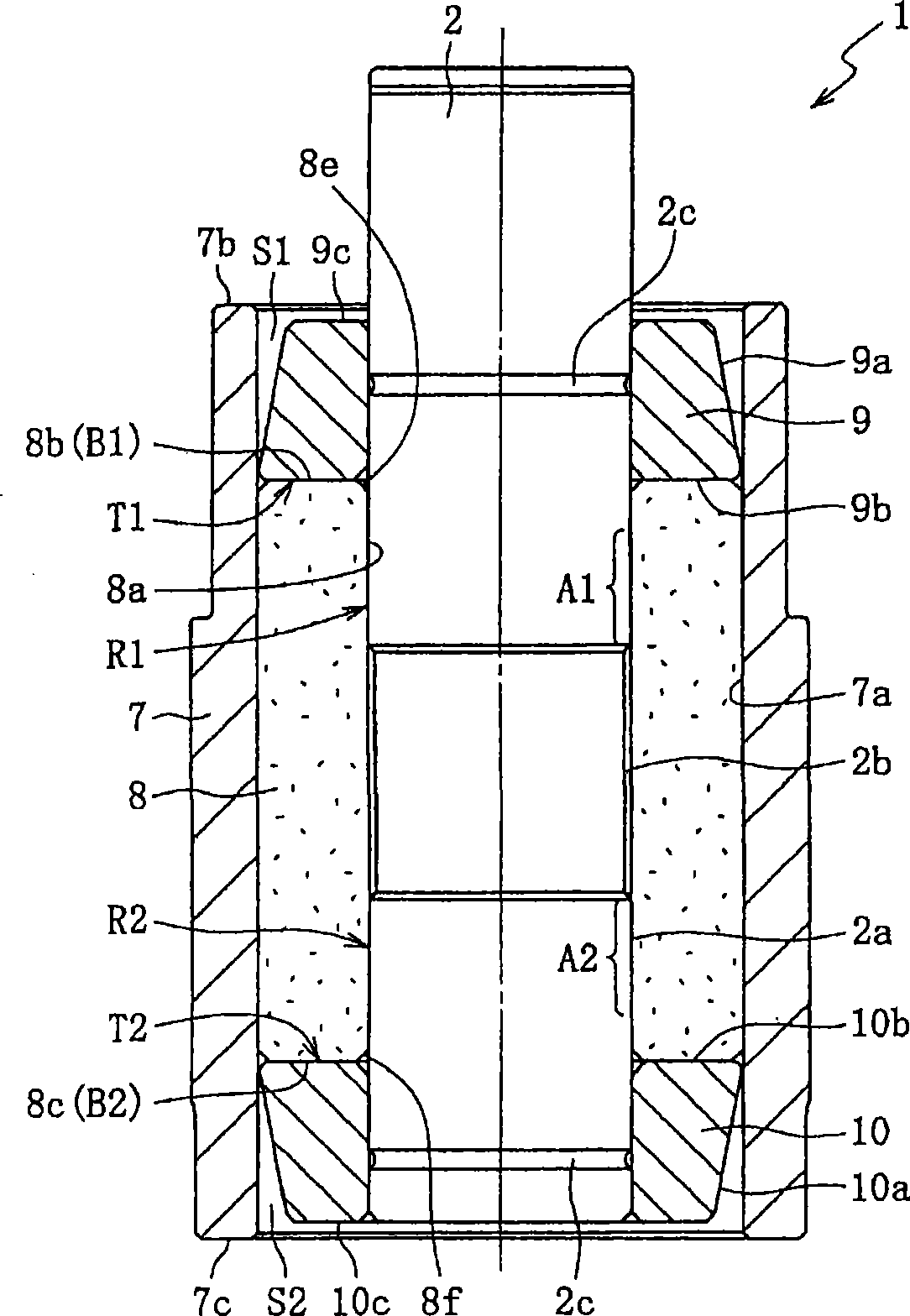

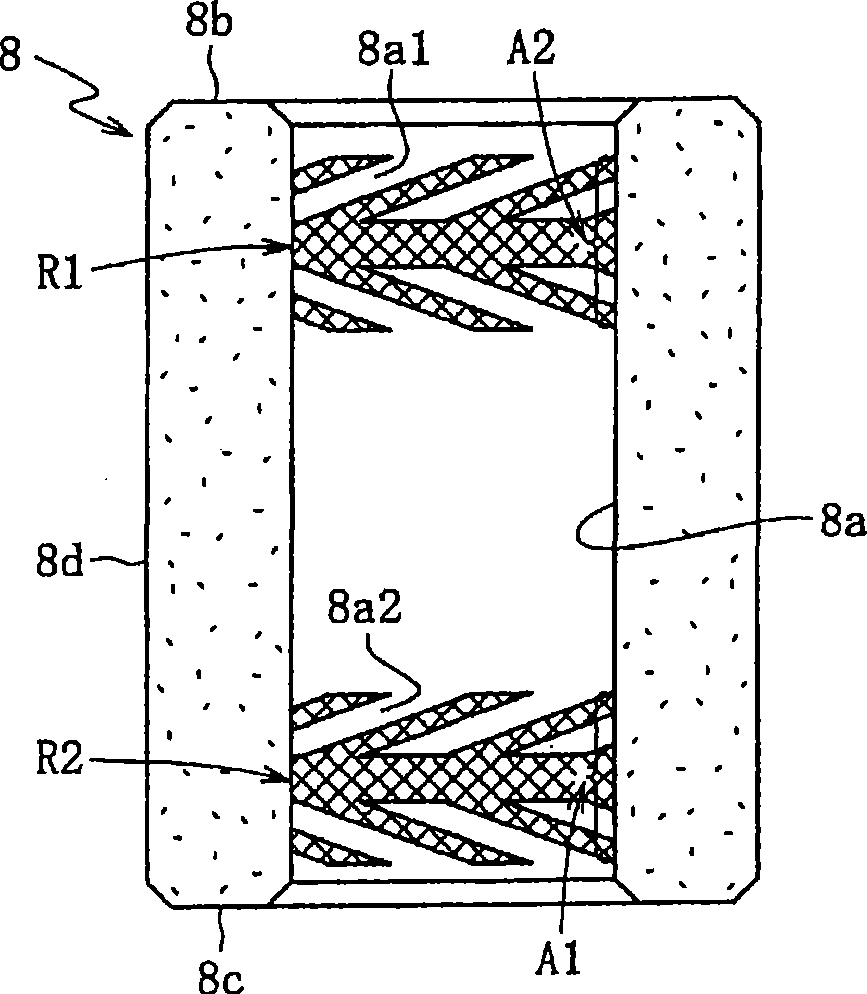

Fluid dynamic bearing apparatus

InactiveCN101203685AImprove bearing performanceLow costBearing componentsSliding contact bearingsPressure generationEngineering

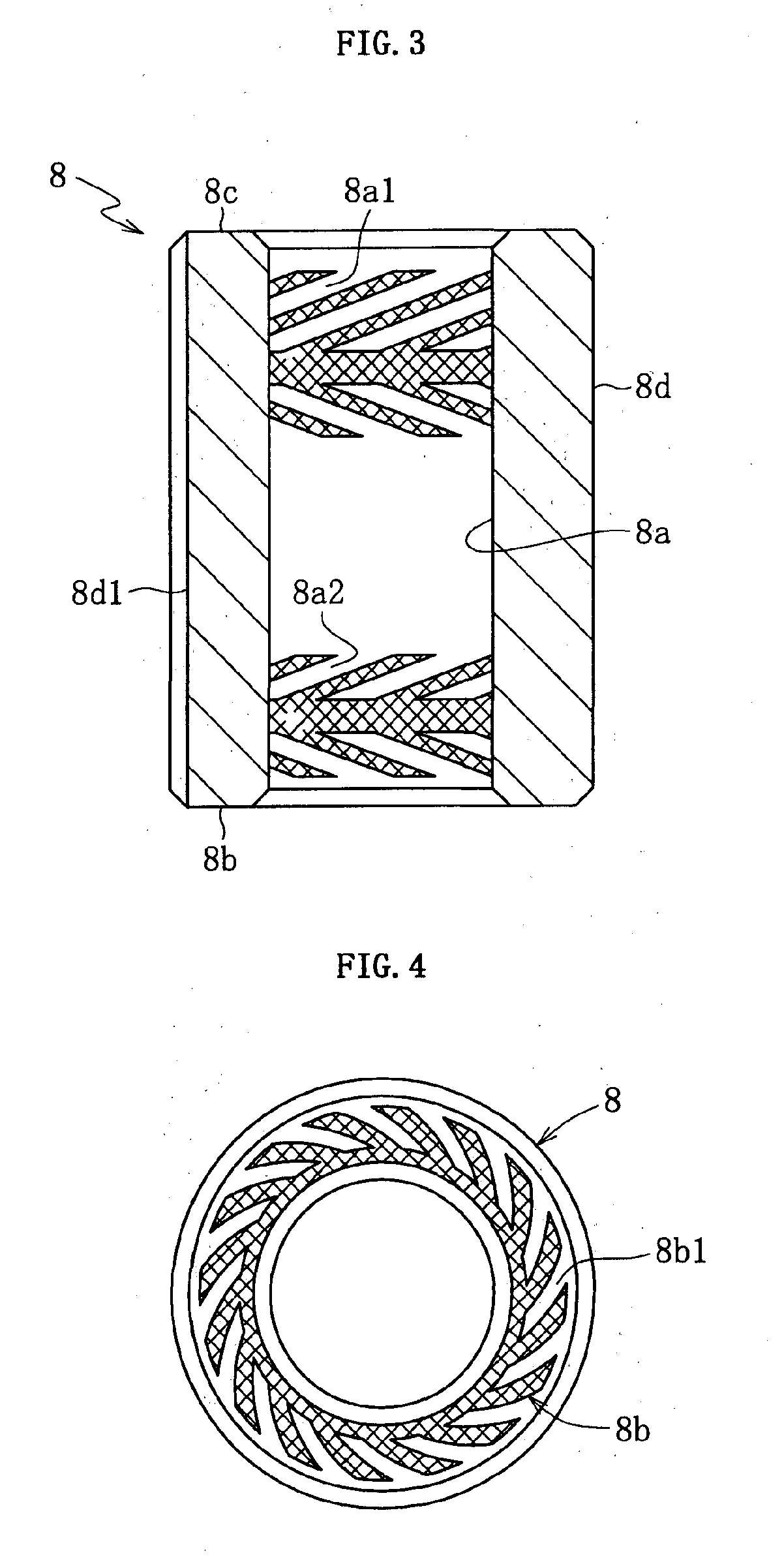

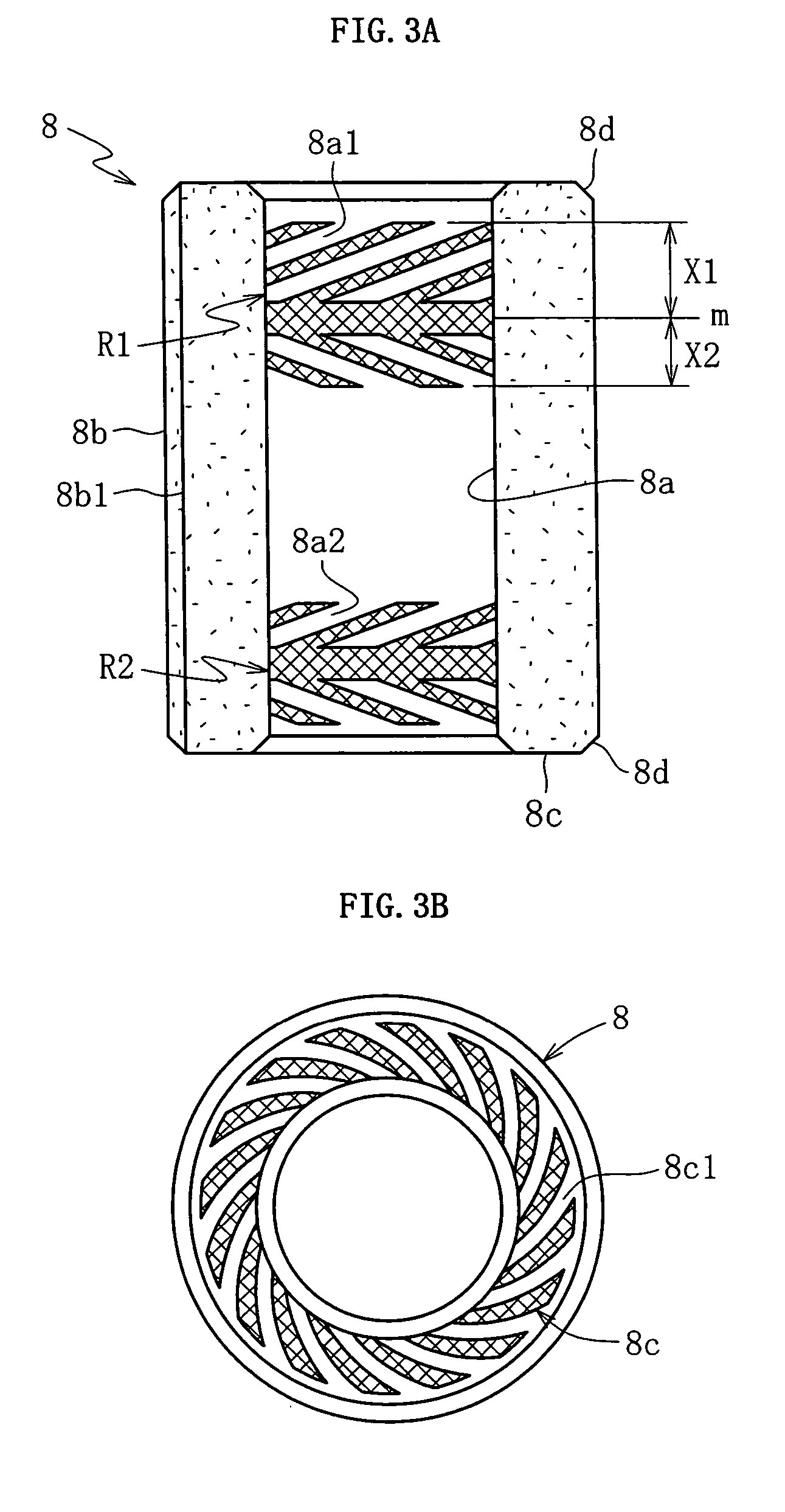

The purpose of the invention is a bearing member comprising highly accurate dynamic pressure generating portions and stably manufacturable at low cost. Dynamic pressure grooves (8a1) and (8a2) as the dynamic pressure generating portions are formed in the inner peripheral surface of an electroformed part (10) by electroforming, and the electroformed part (10) is inserted and the bearing member (8) is injection-molded with a resin. A shaft member (2) is inserted to the inner periphery of the bearing member.

Owner:NTN CORP

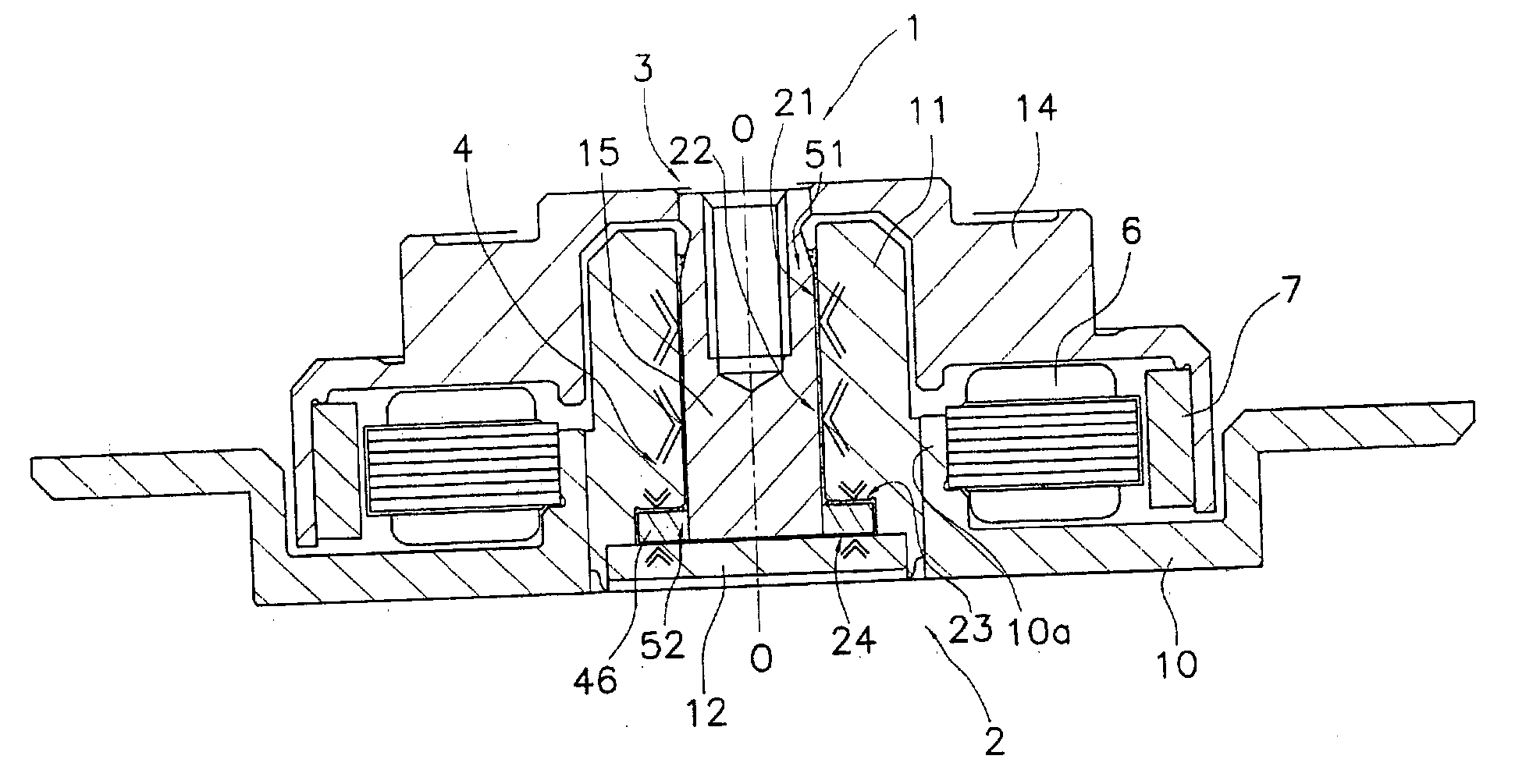

Dynamic pressure bearing device

InactiveCN101006280AHigh strengthLow costShaftsRecord information storageThrust bearingHigh intensity

A dynamic pressure bearing device having a shaft member with high strength and capable of maintaining high bearing performance is provided at low cost. A shaft blank (23) integrally has a shaft section (23a) formed of a material having higher strength than resin and a projection section (23b) projecting toward the outer diameter side of the shaft section (23a). A shaft member (2) has the shaft blank (23) and a resin section (24) that covers at least one end surface of the projection section (23b) of the shaft blank (23) and faces a thrust bearing clearance.

Owner:NTN CORP

Mfg. method of thrust plate and mfg. method of shaft for fluid power bearing

InactiveCN1447035AImprove bearing performanceImprove runout accuracyShaftsMetal-working apparatusPunchingThrust bearing

A method of manufacturing a thrust plate for a dynamic pressure bearing, the upper and lower end surfaces of the thrust plate have a high-precision vertical angle with respect to its center hole. The thrust plate is circular, and a central hole for the shaft assembly is formed therein. Thrust surfaces constituting a part of the thrust bearing are formed on both end surfaces of the thrust plate. The manufacturing method of the thrust plate comprises the steps of: a blanking step of press-cutting a disc-shaped workpiece to obtain a circular blank semi-finished product, an end face polishing step of polishing both end faces of said blank semi-finished product, and simultaneously press-cutting the inner hole of the polished blank semi-finished product and the outer circumference in order to scrape off its surface scraping step.

Owner:株式会社长野早出 +1

Aluminum bearing-alloy

InactiveUS6875290B2Excellent in wear and fatigue resistance propertyImprove bearing performanceShaftsBearing componentsAluminium alloyCrystallite

An aluminum bearing-alloy containing 1.5 to 8 mass % of Si is provided, in which there can be observed Si grains on the sliding surface of the aluminum bearing-alloy. A fractional area of the observed Si grains having a grain size of less than 4 μm is 20 to 60% of a total area of all the observed Si grains. Another fractional area of the observed Si grains having a grain size of from 4 to 20 μm is not less than 40% of the total area of all the observed Si grains.

Owner:DAIDO METAL CO LTD

Turbocharger

ActiveUS9790950B2Reduce harmImprove the lubrication effectEngine manufacturePump componentsTurbochargerEngineering

A turbocharger includes: a bearing provided in a turbocharger body, and configured to rotatably support a turbine shaft in an insertion hole formed in the bearing; and an opposing portion which faces an end surface of the bearing in an axial direction of the turbine shaft. An end-surface guide portion is provided to any one of an opposing surface of the bearing which faces the opposing portion, and an opposing surface of the opposing portion which faces the bearing. The end-surface guide portion configured to make the insertion hole and an outer peripheral edge of the end surface of the bearing in radial directions of the turbine shaft communicate with each other extends forward in a rotational direction of the turbine shaft from a part of the end surface of the bearing which communicates with the insertion hole.

Owner:IHI CORP

Fluid dynamic bearing motor

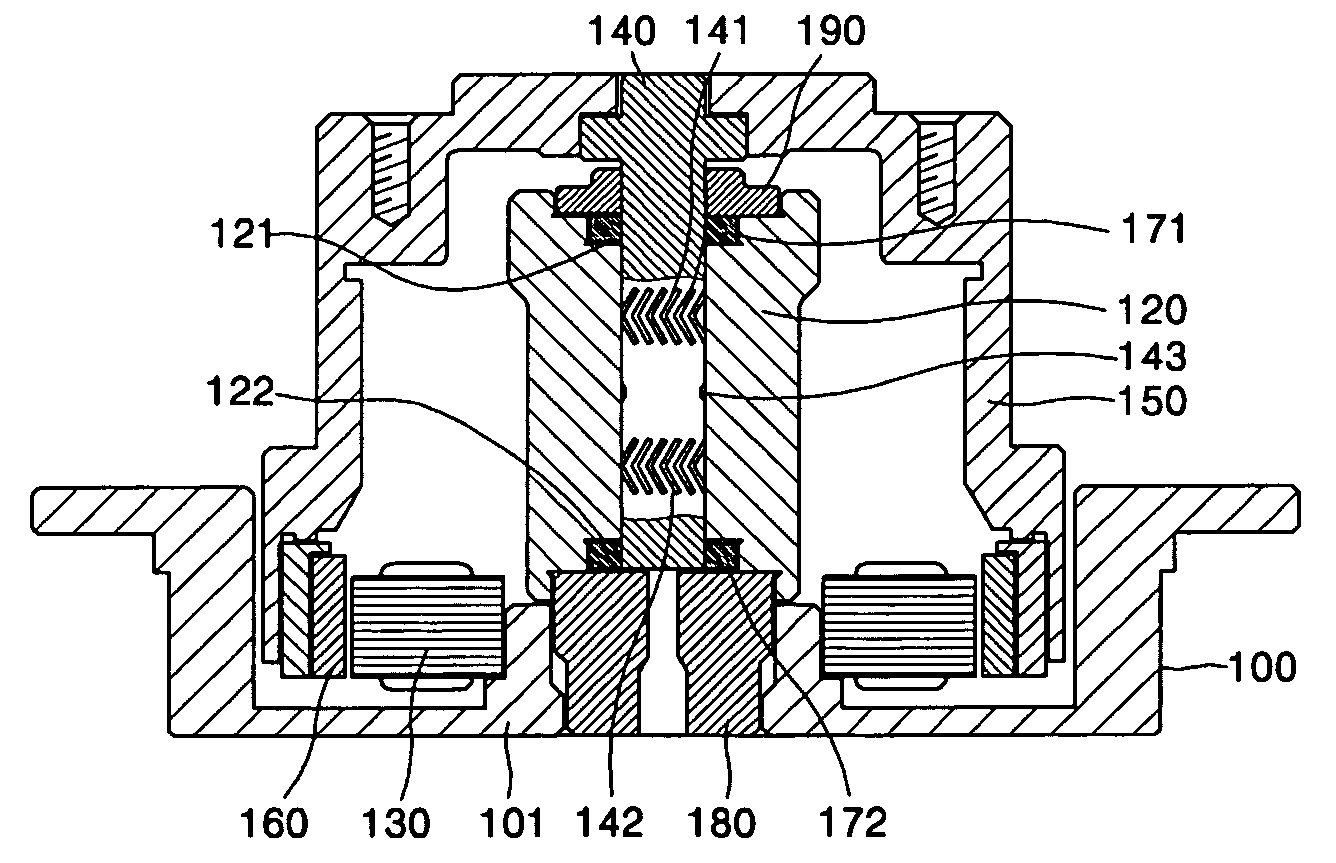

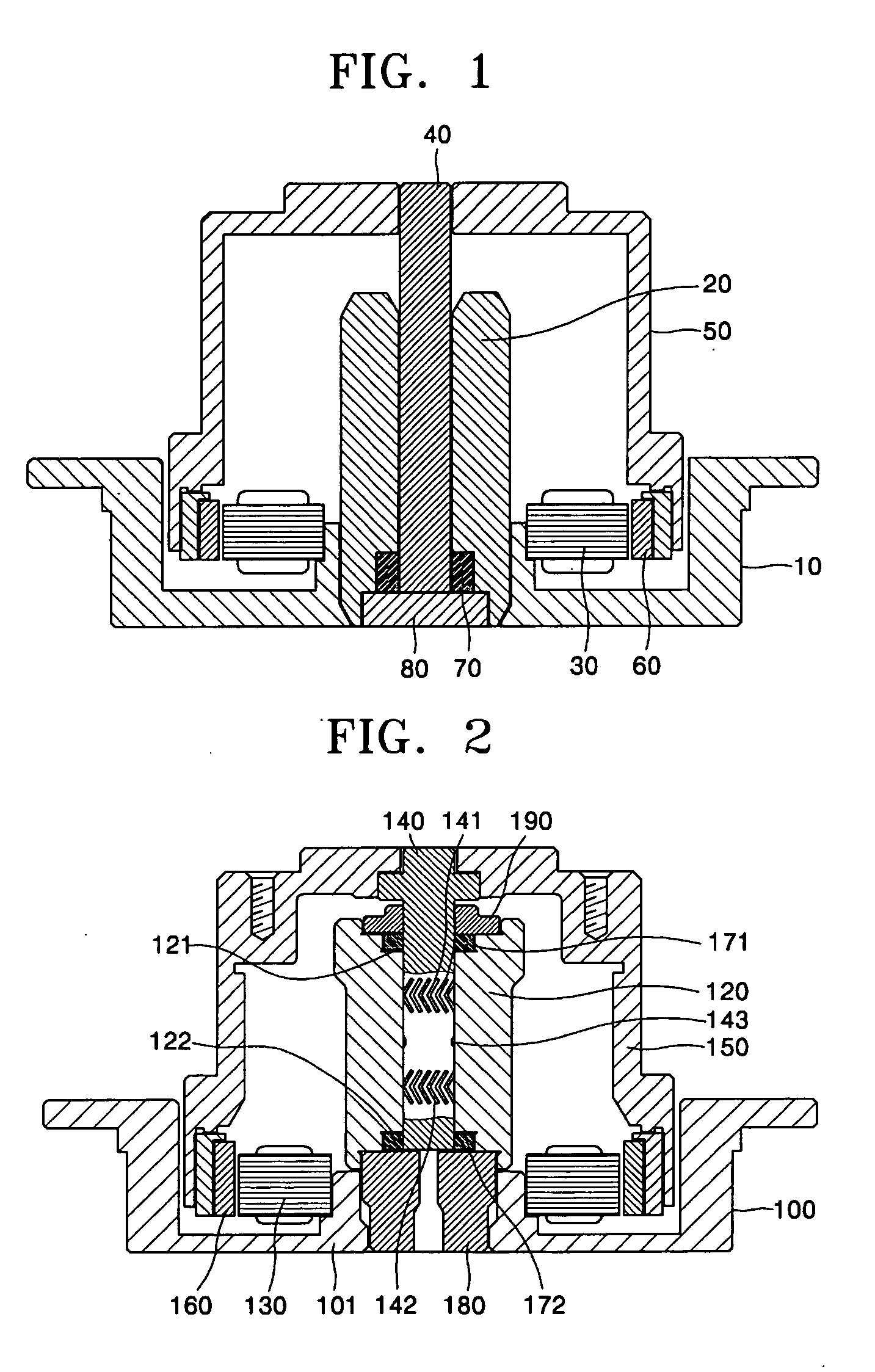

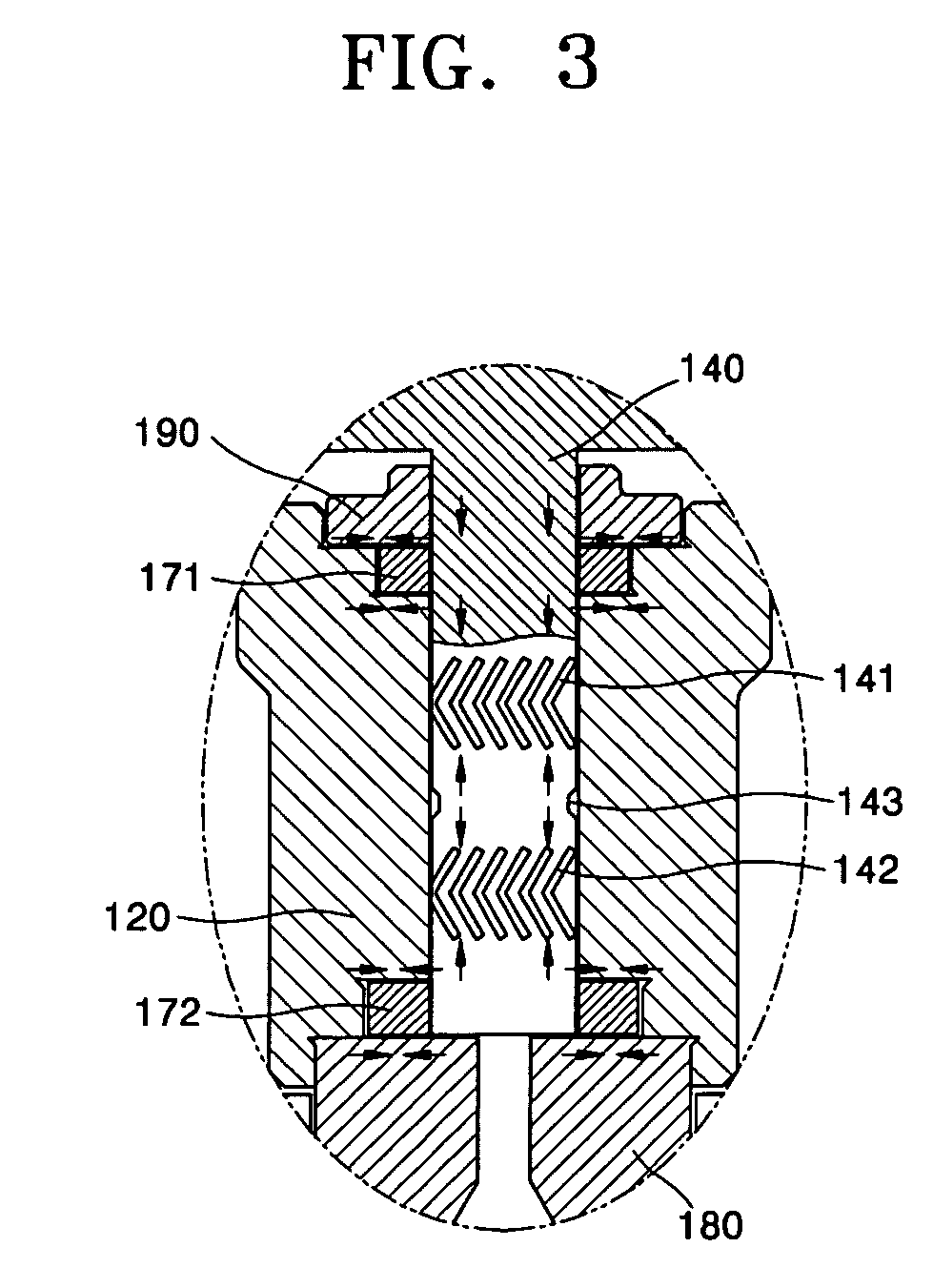

InactiveUS20050094908A1Vibration of shaft is preventedLow heat generationShaftsRecord information storageInternal pressureThrust bearing

Provided is a fluid dynamic bearing motor that can reduce vibration, oil deterioration, and power consumption by employing at least one pair of thrust bearings on upper and lower portions of a shaft. The fluid dynamic bearing motor includes: a housing to which a core with a coil wound around it, a sleeve having an axial hole at a central portion thereof, and a cover block supporting the sleeve are fixed; a shaft rotatably inserted into the axial hole to form an oil gap with the hole; a hub fixed to an upper end portion of the shaft and having a downwardly extending portion to an inner surface of which a magnet generating an electromagnetic force through an interaction with the core is attached; and circular thrust plates respectively fixed to upper and lower portions of the shaft, wherein receiving grooves are formed on an inner portion of the sleeve and accommodate the thrust plates to form fluid dynamic bearing surfaces. Since the fluid dynamic bearing motor employs the thrust fluid dynamic bearings on the upper and lower portions of the shaft, conical vibration of the shaft is prevented and heat generation and power consumption are reduced. Furthermore, since the fluid dynamic bearing motor employs the hydrodynamic pressure cover, oil leakage is prevented and an internal pressure of the fluid dynamic bearing is enhanced.

Owner:G&W TECH

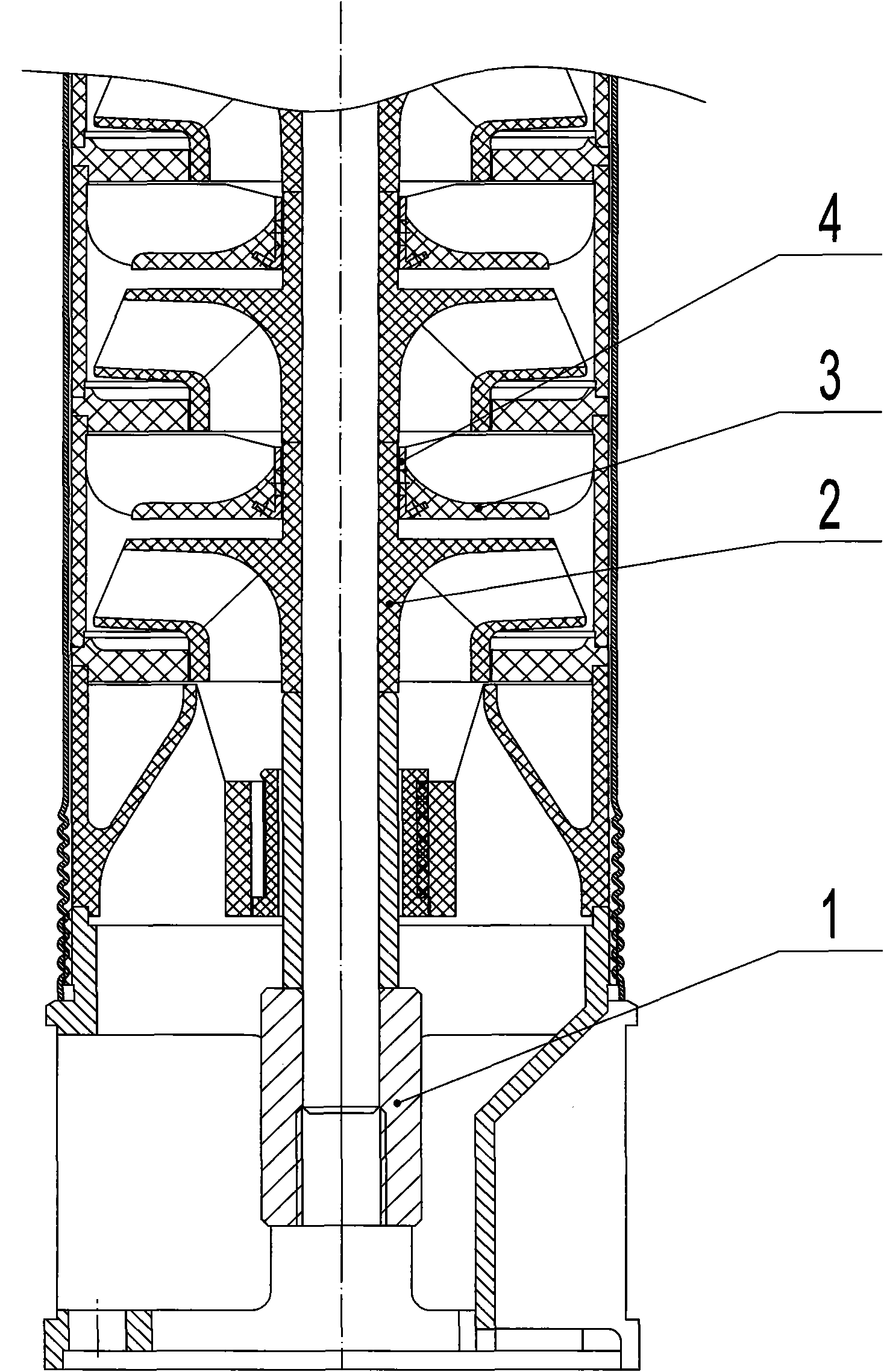

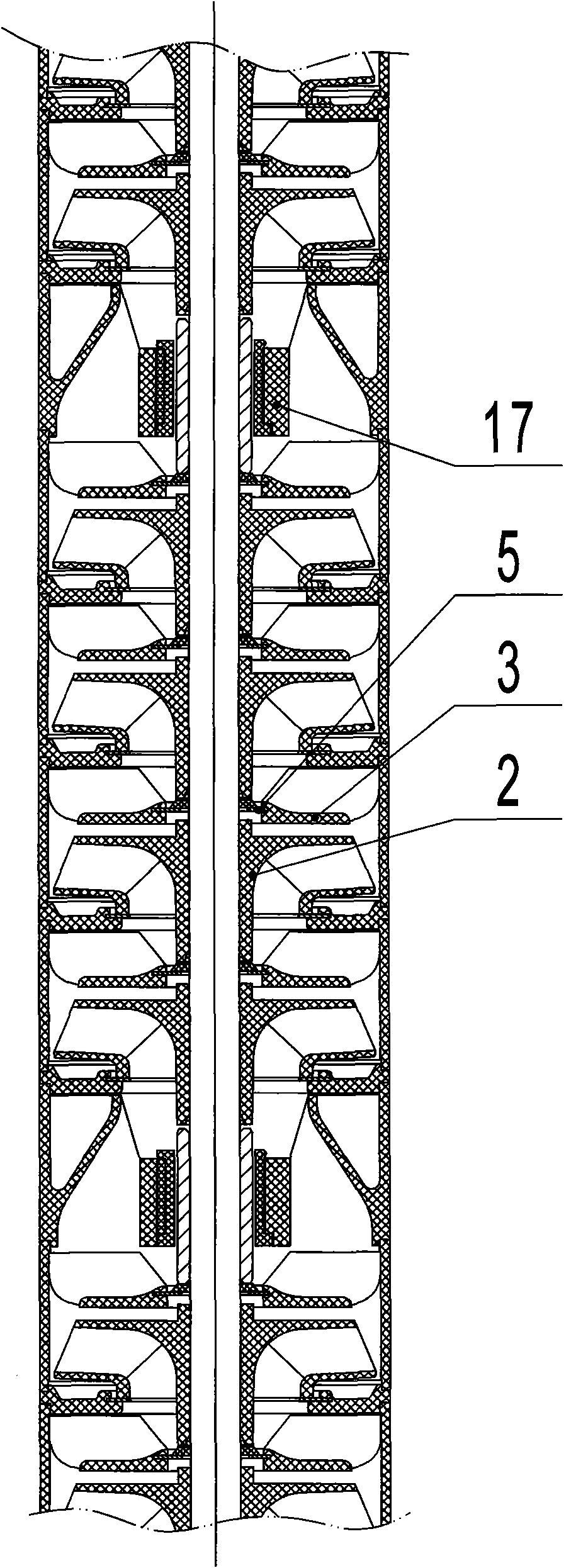

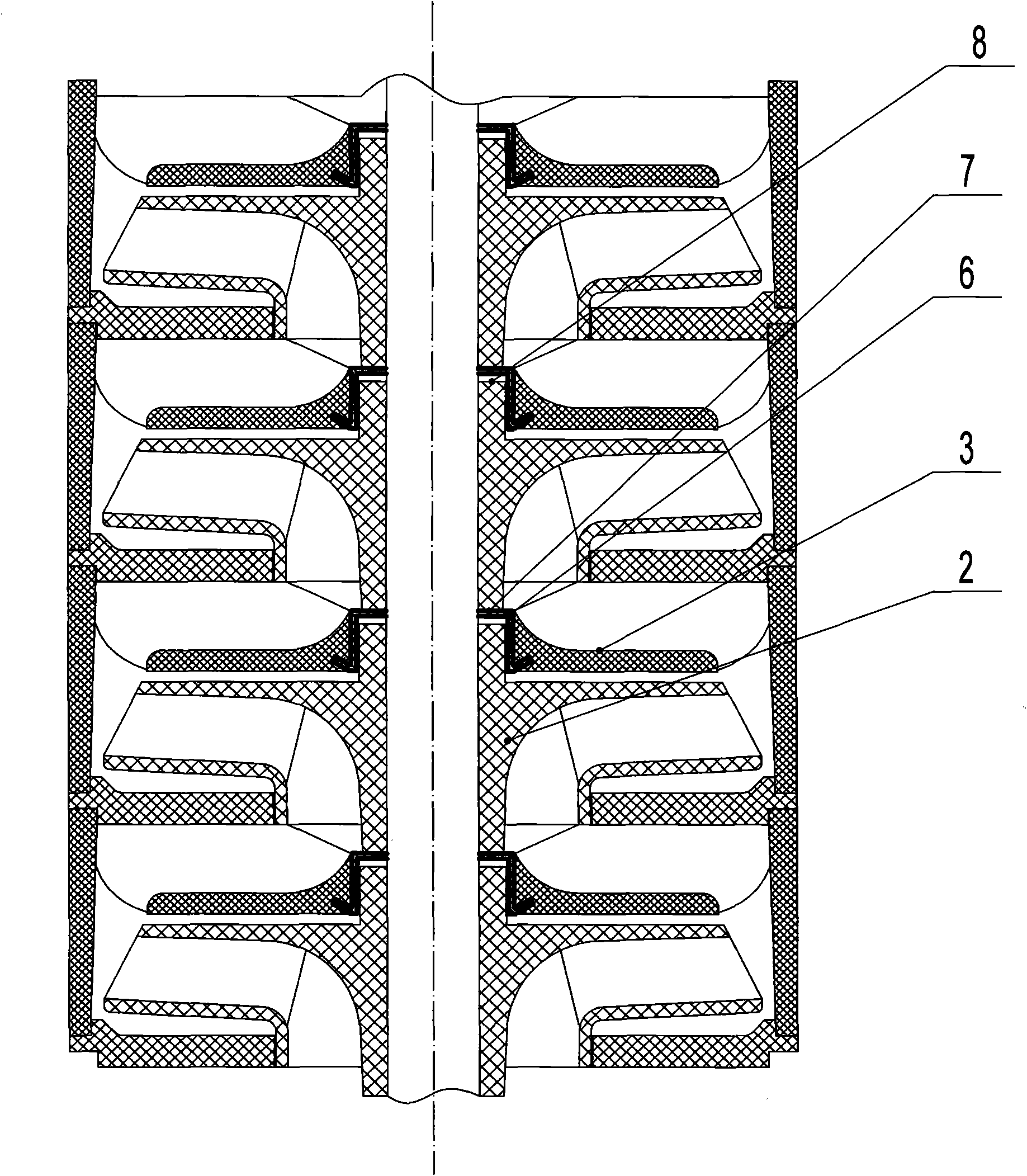

Bearing insert to be inserted in inner hole part of plastic flow deflector shell of engineering plastic well pump

InactiveCN101936304AAvoid radial forceOvercome the downward axial forcePump componentsPumpsImpellerPunching

The invention discloses a bearing insert to be inserted in the inner hole part of the plastic flow deflector shell of an engineering plastic well pump, which is formed by punching a stainless steel plate and is matched with an engineering plastic impeller hub to form a sliding radial bearing and a sliding thrust bearing for bearing the radial force and axial force of the impeller. The upper side of the top part of the insert and the lower end of the impeller hub on the upper side form a lower plain thrust bearing for bearing the downward axial force of the impeller; the downside of the top part of the insert and the upper end of the impeller hub on the down side form an upper plain thrust bearing for bearing the upward axial force applied when the well pump starts; and the inner wall of the cylinder of the insert and the external circle of the impeller hub form a radial sliding bearing for bearing the radial force of the impeller. As a bearing pair with high performance is made of stainless steel and the engineering plastic, the reliability of the engineering plastic multi-stage well pump is improved greatly. The shape of the bearing insert is very suitable to be formed by punching and is also very suitable to be connected with the plastic flow deflector shell into a whole firmly, so material and labor can both be saved.

Owner:JIANGSU UNIV

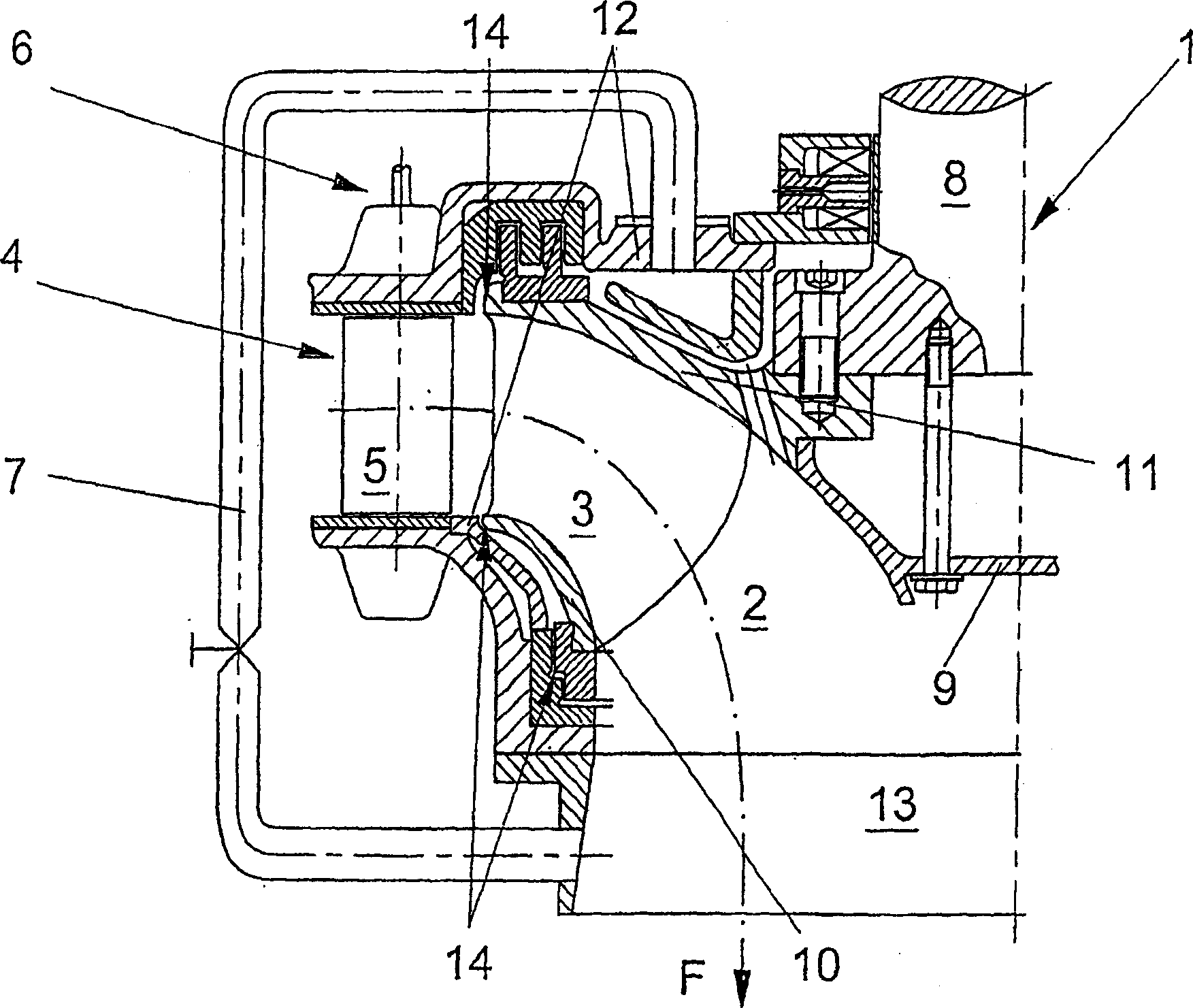

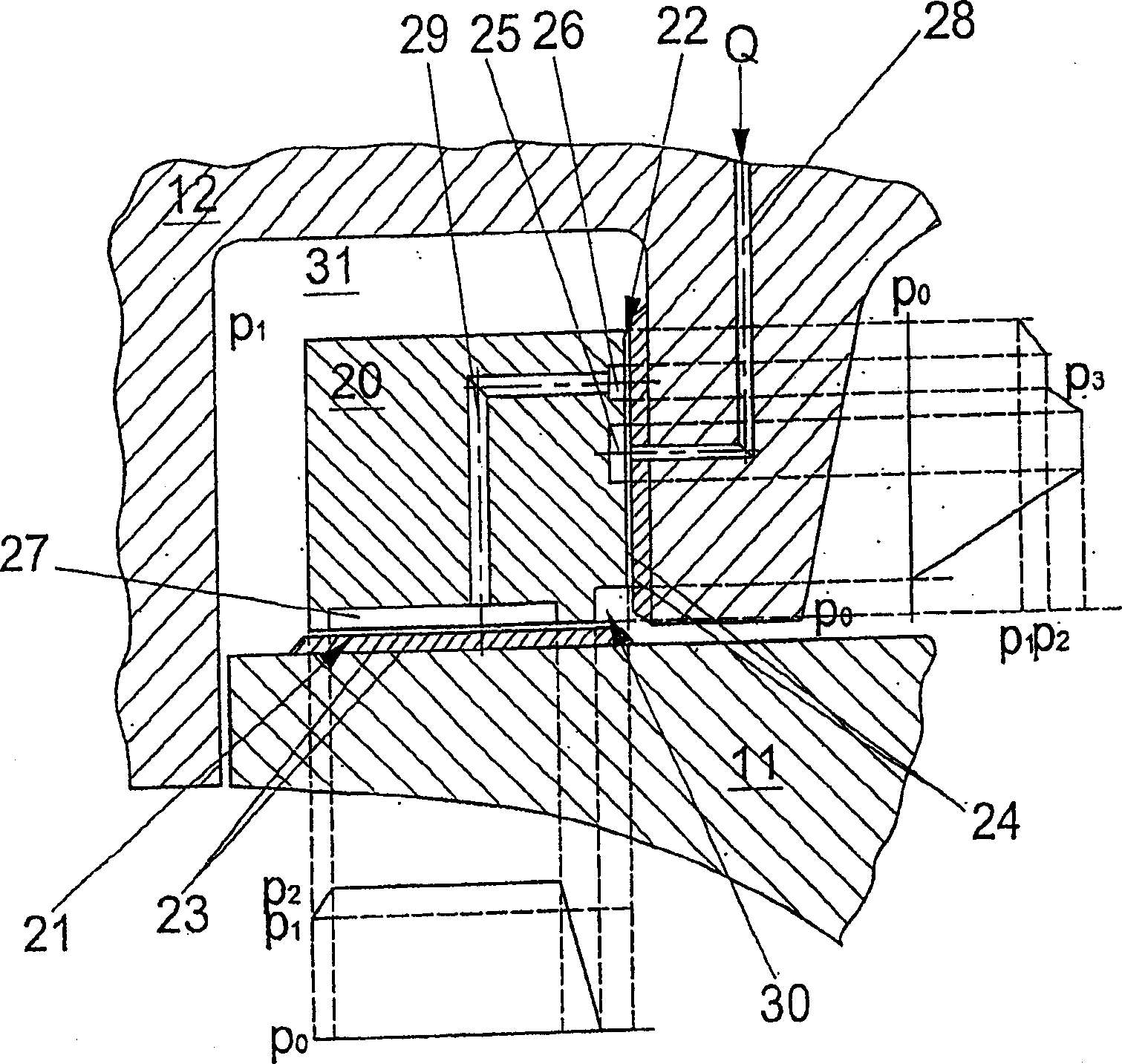

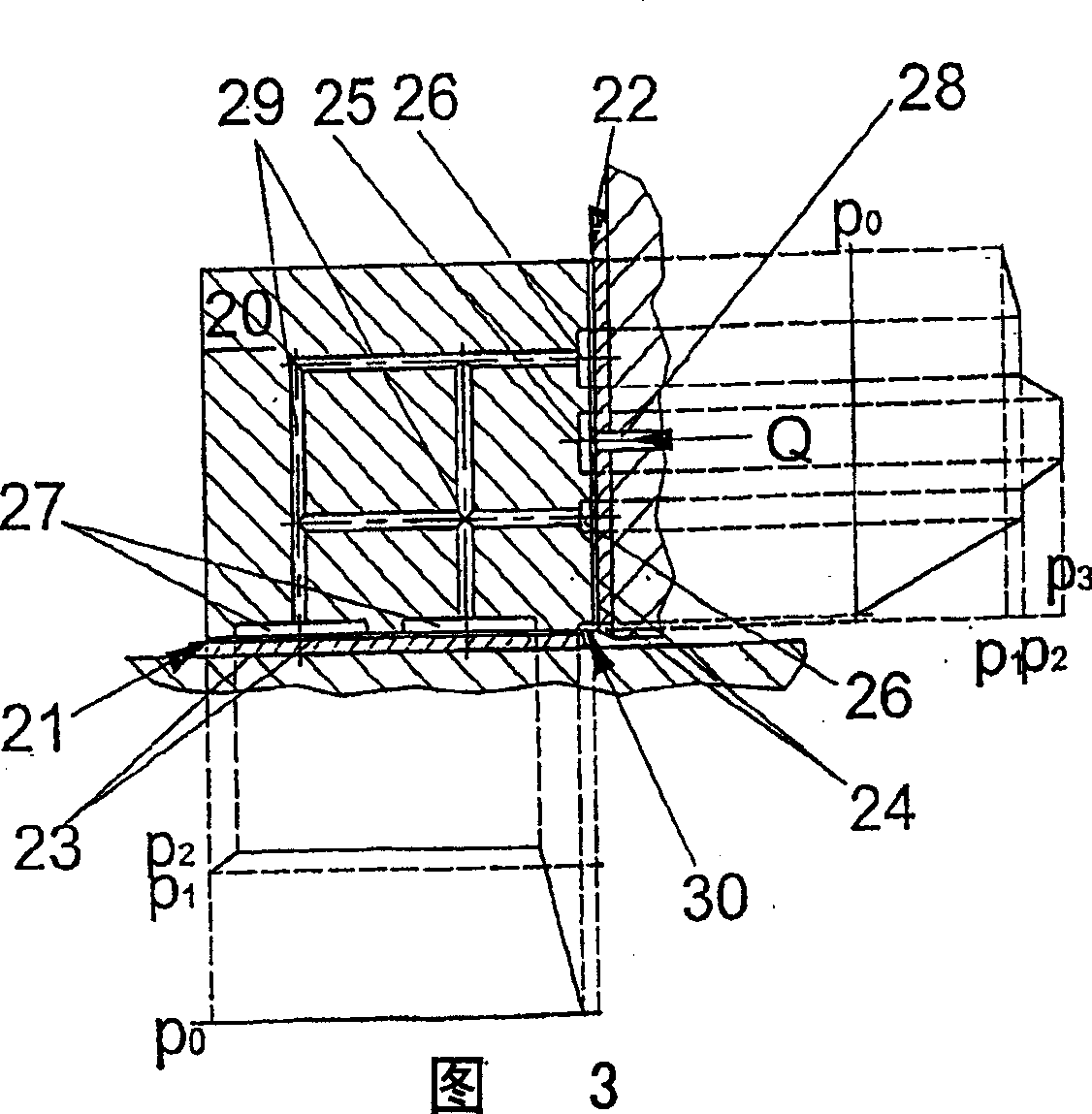

Seal for use between two mobile parts of a hydraulic machine

InactiveCN1625651AStable operating positionImprove operational reliabilityEngine sealsPump componentsImpellerEngineering

The invention relates to a seal arranged between relatively moving parts of a hydraulic machine, such as an impeller, and a housing, said parts being almost hermetic, but still simple in construction, characterized in that a seal is supported on two hydrostatic bearings superior.

Owner:DIPL ING DR TECHN GITTLER PHILIPP

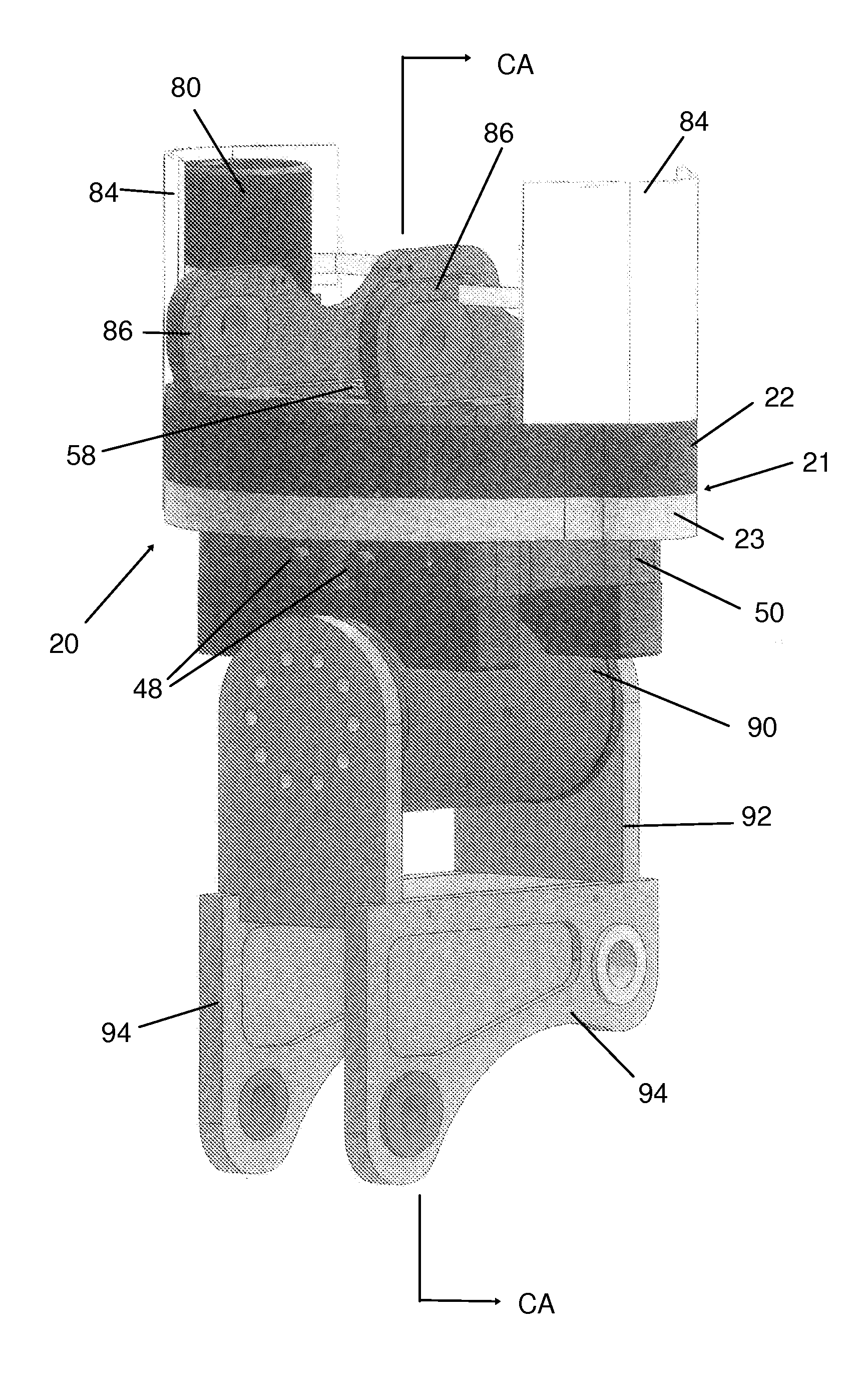

Excavating apparatus employing swivel adapter with gear bearings having gears with divergent thickness

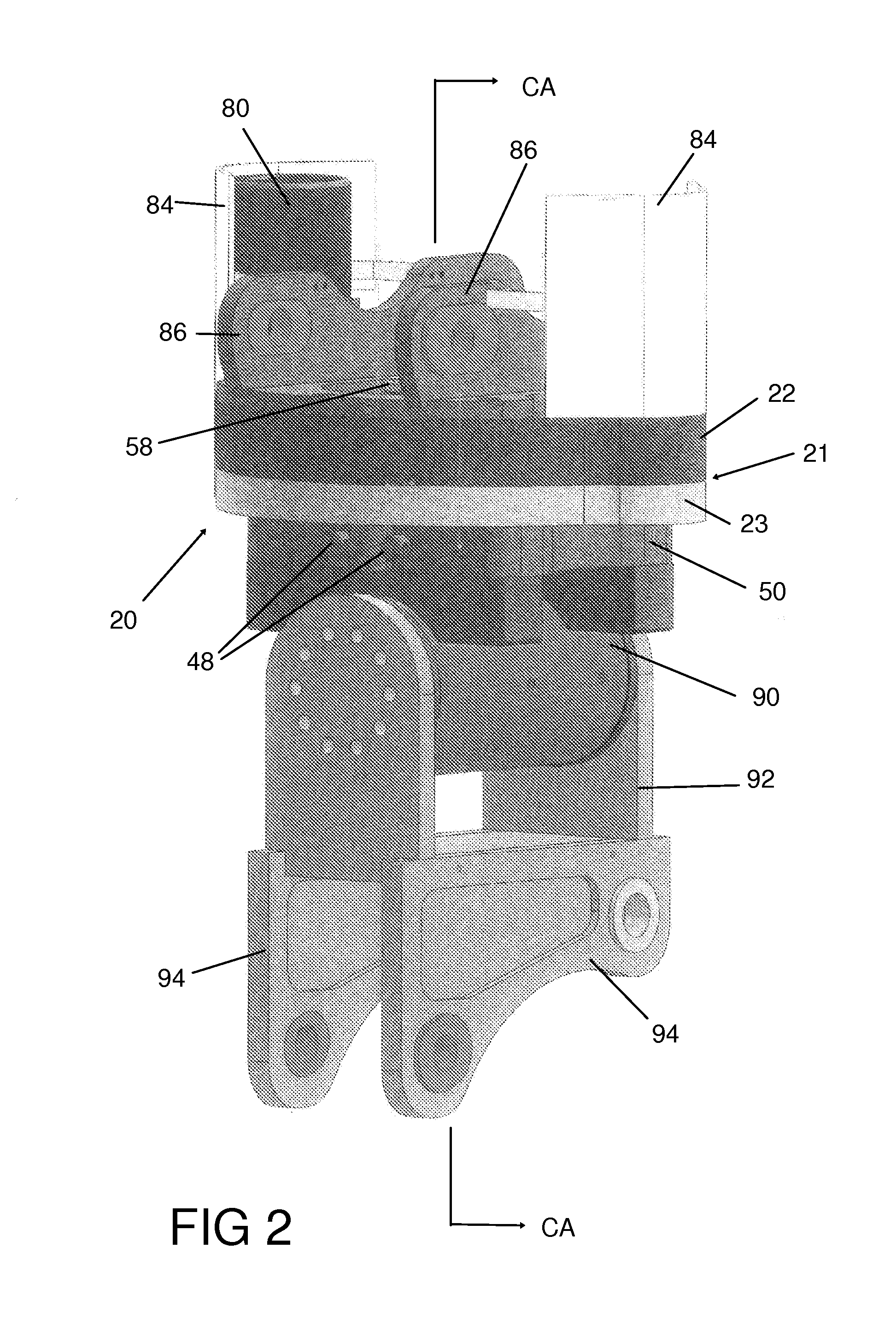

InactiveUS20130343807A1Easy to useImprove securityYielding couplingMechanical machines/dredgersGear wheelEngineering

An apparatus for swiveling an implement, such as a bucket, relative to a device, such as an excavator boom, includes a rotary union and a bearing disc mounted in a housing. The bearing disc rotates relative to the housing so that the implement can be rotated relative to the device. A gear or geared bearing assembly is located between the bearing disc and top and bottom housing portions for bearing loads transverse to the axis about which the implement is rotated relative to the device. The rotary union has fluid passages extending from the top to the bottom of a central shaft, which is affixed to the bearing disc, and the shaft and disc can comprise a one piece combination rotary union and bearing disc.

Owner:MDC INNOVATIONS LLC

Bearing structure and turbocharger

ActiveUS20170044933A1Improve bearing performanceReduce vibrationPump componentsBlade accessoriesEngineeringMechanical engineering

A bearing structure includes a through-hole penetrating through in the axial direction of shaft, a bearing holder accommodated in the through-hole, a semi-floating metal bearing accommodated in the bearing holder and supporting the shaft inserted into the inside, and a positioning member being inserted into a radial direction of the shaft for both the bearing holder and the semi-floating metal bearing and regulating movement of the semi-floating metal bearing in the axial direction and in a rotating direction of the shaft relative to the bearing holder. For the bearing holder, a press-fit portion to be press-fitted into the through-hole is formed. A gap is formed between at least one of outer circumferential surfaces of both end parts of the bearing holder in the axial direction and the inner circumferential surface of the through-hole.

Owner:IHI CORP

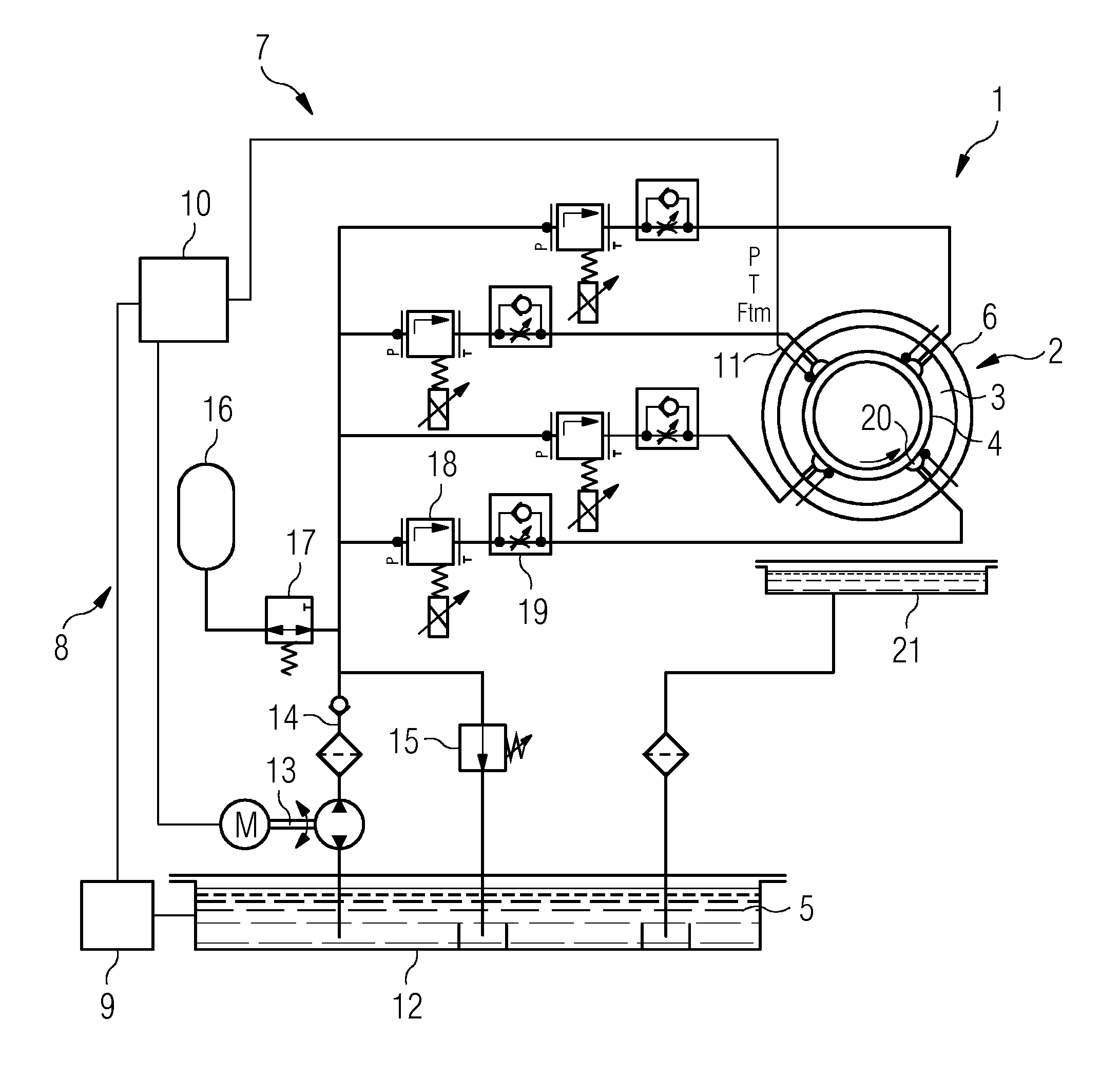

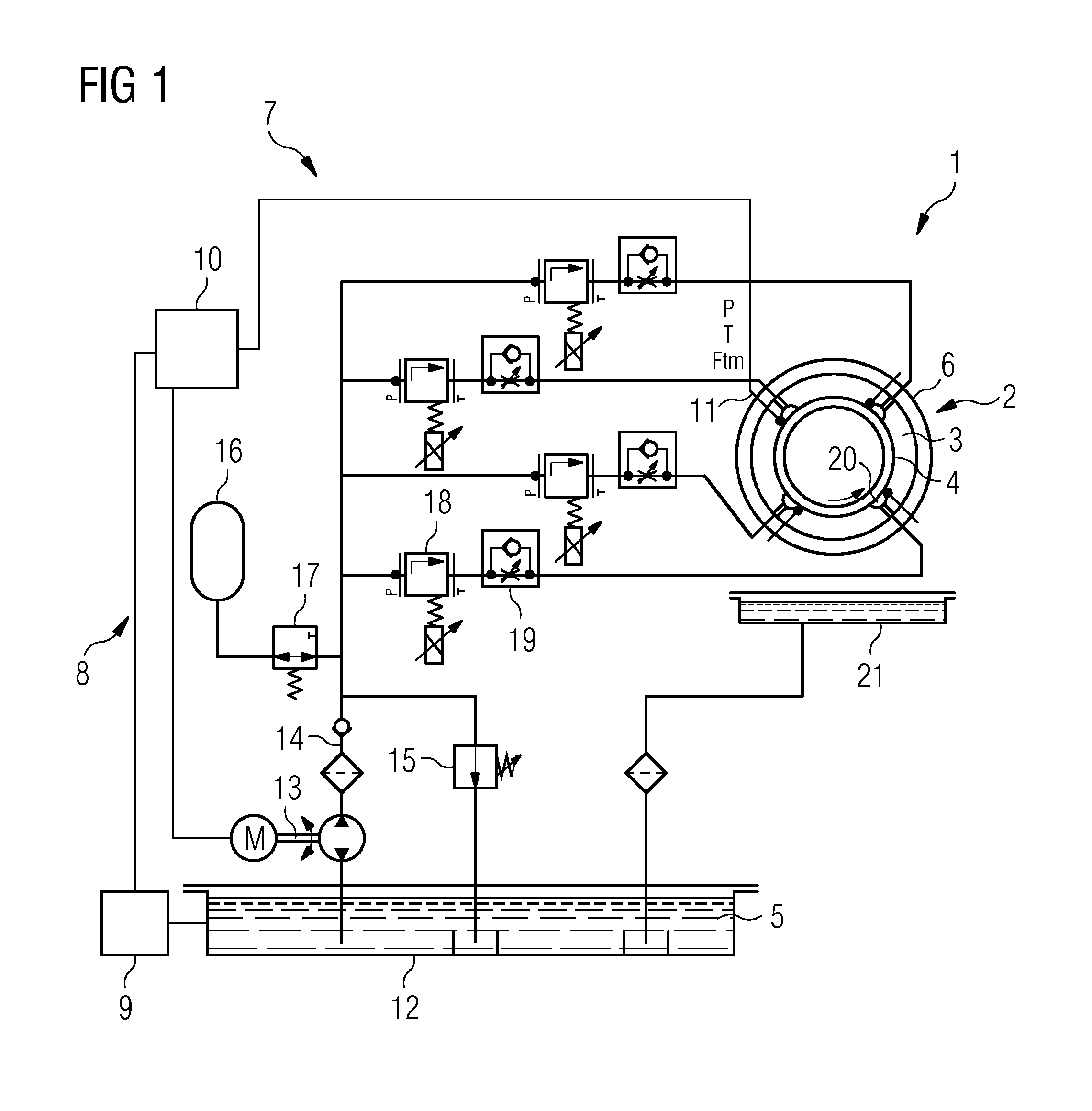

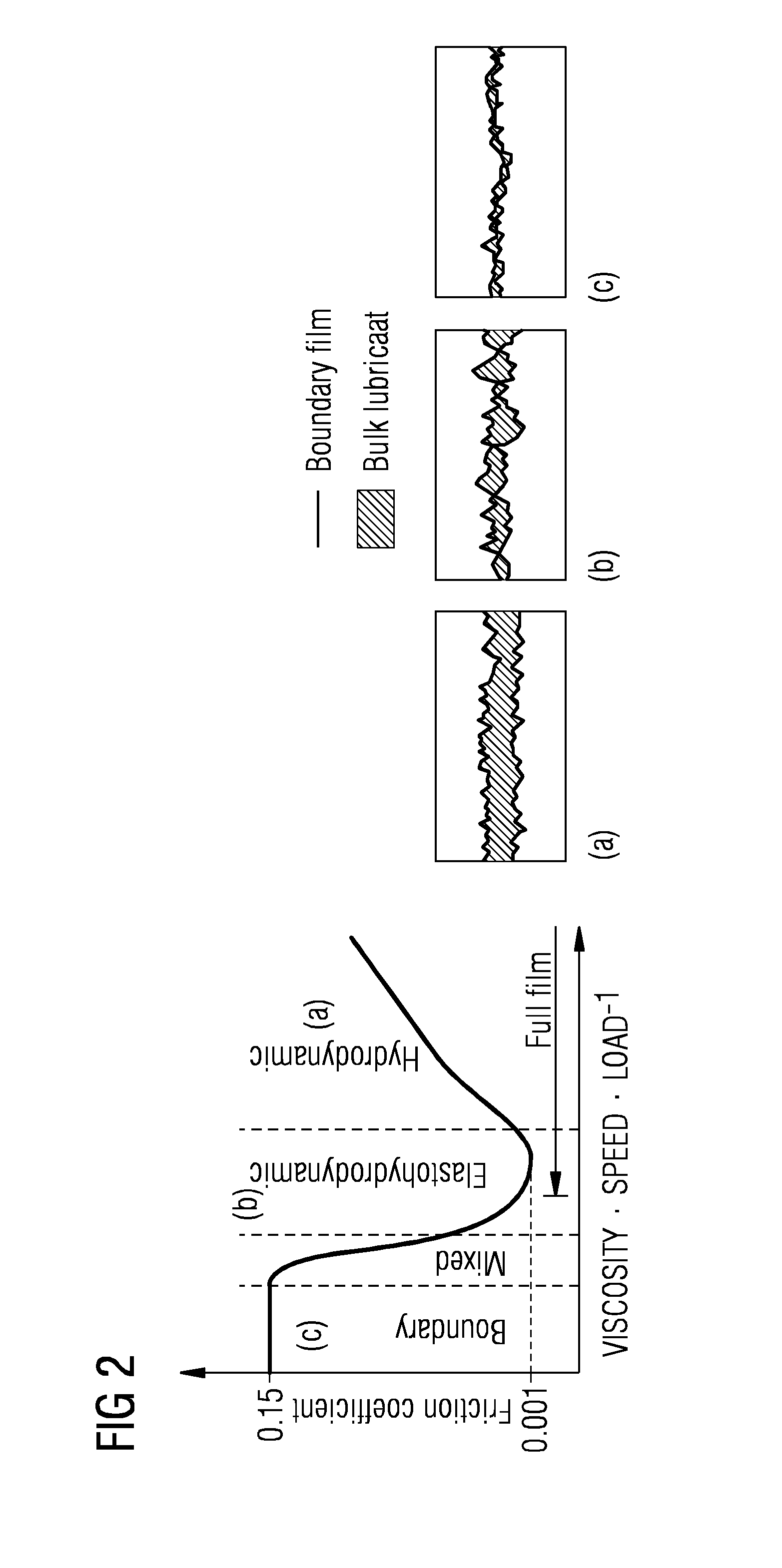

Method for controlling a wind turbine and wind turbine

InactiveUS20140355913A1Easy to operateImprove bearing performanceShaftsBearing componentsTurbineLubrication

A wind turbine and method for controlling a wind turbine with a plain / sliding bearing and bearing lubrication means is disclosed. The method comprising the steps ofOperating the bearing as a hydrodynamic bearing in normal operation; andOperating the bearing as a hydrostatic bearing when the friction of the bearing reaches a threshold.

Owner:SIEMENS AG

Rolling bearing device for supporting pinion shaft

InactiveUS7811000B2Reducing a torque lossImprove bearing performanceGearboxesShaftsBall bearingGear wheel

In a bearing device, a double row rolling bearing for supporting a pinion gear-side portion of a pinion shaft on a case (annular wall) is formed by a tandem-type double row angular contact ball bearing. A first row of balls having a larger pitch circle diameter are disposed between inner and outer rings of the double row angular contact ball bearing at a region near to the pinion gear, and a second row of balls having a smaller pitch circle diameter are disposed between the inner and outer rings at a region remote from the pinion gear. A bearing internal space is divided into a first bearing internal space containing the first ball row and open toward the pinion gear and a second bearing internal space containing the second ball row and sealed by partition walls formed respectively by bearing seals, lubricating grease being sealed in the second bearing internal space.

Owner:JTEKT CORP

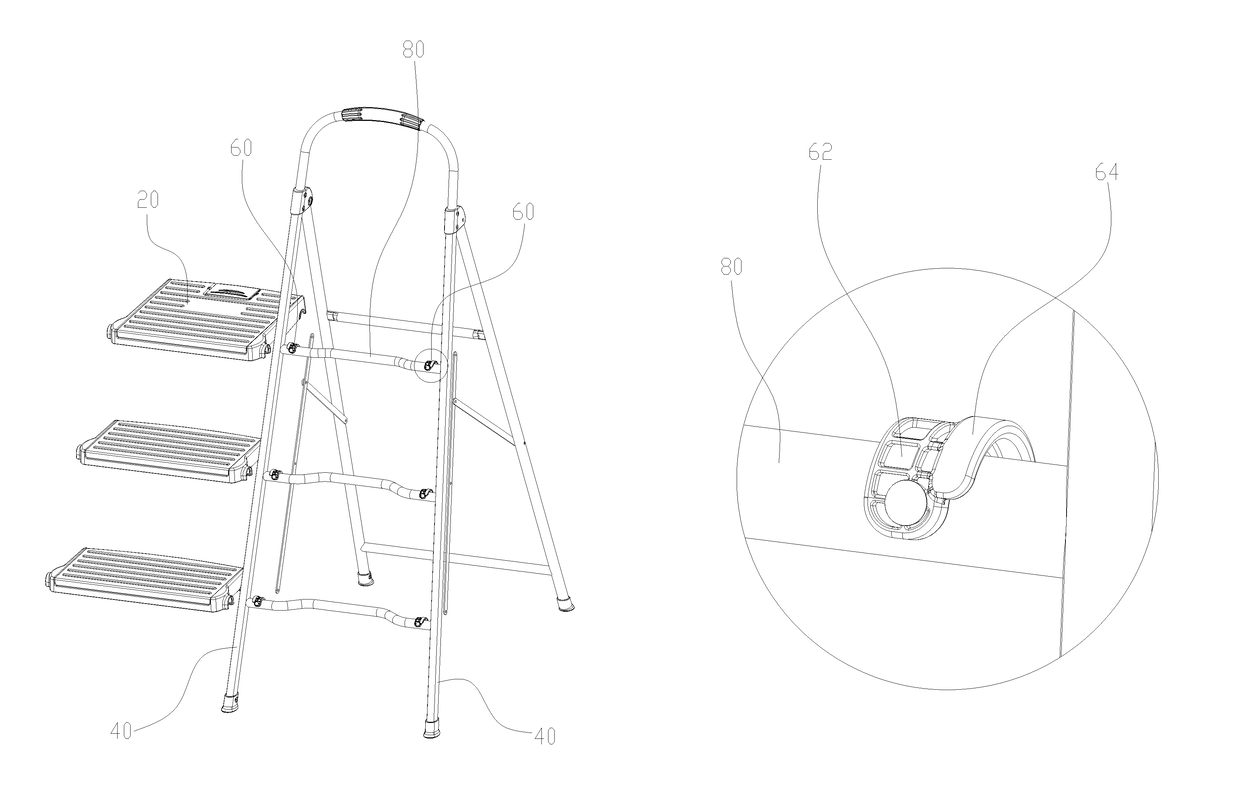

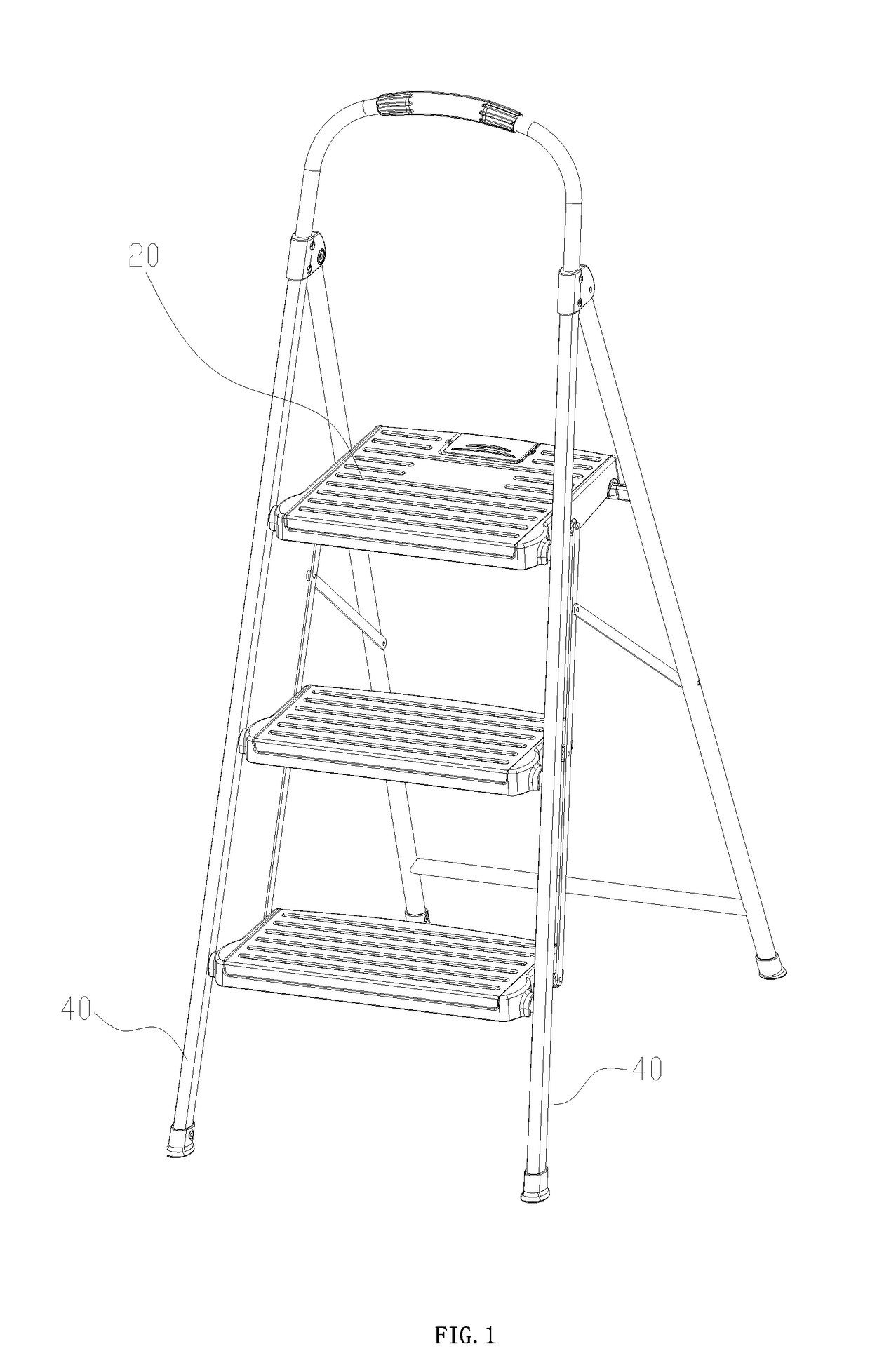

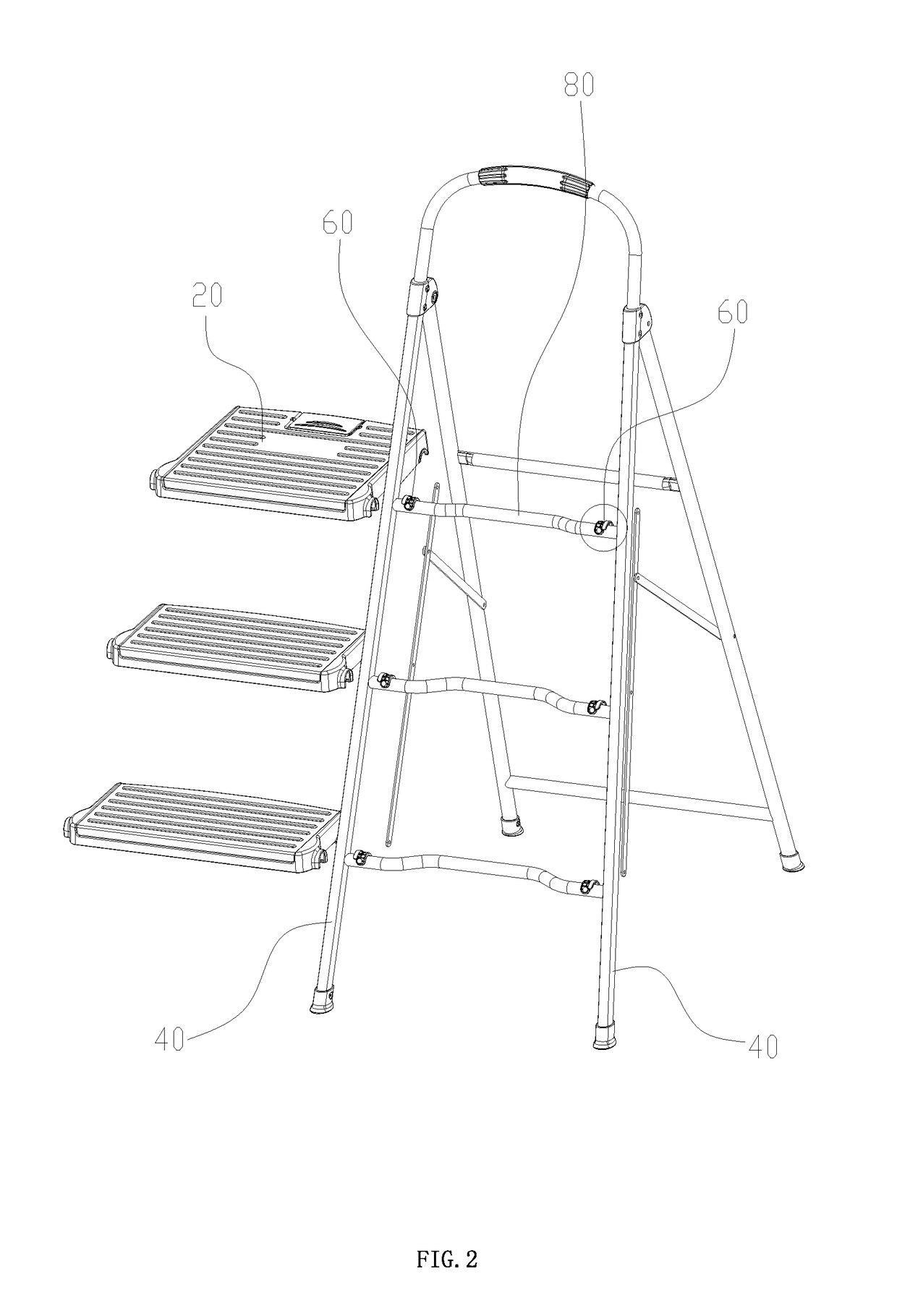

Overturn structure of a footstep of a folding ladder

Owner:NEW TEC INTEGRATION (XIAMEN) CO LTD

Bearing structure

InactiveUS20090208156A1Improve bearing performanceImprove performanceCrankshaftsRotary bearingsRotational axisEngineering

A bearing structure includes a housing having a bore that penetrates the housing, a rotation shaft inserted into the bore, an annular first metal bearing and an annular second metal bearing, which are provided apart from each other in an axial direction in the bore and rotatably support the rotation shaft, and a ventilation passage provided in the housing. The ventilation passage is formed on the housing-side contact surfaces which are formed on an inner surface of the housing, and bypasses at least one of the first metal bearing and the second metal bearing. Through ventilation passage, a closed area sandwiched between the both first metal bearing and second metal bearing inside the bore communicates with an outside area.

Owner:CALSONIC KANSEI CORP

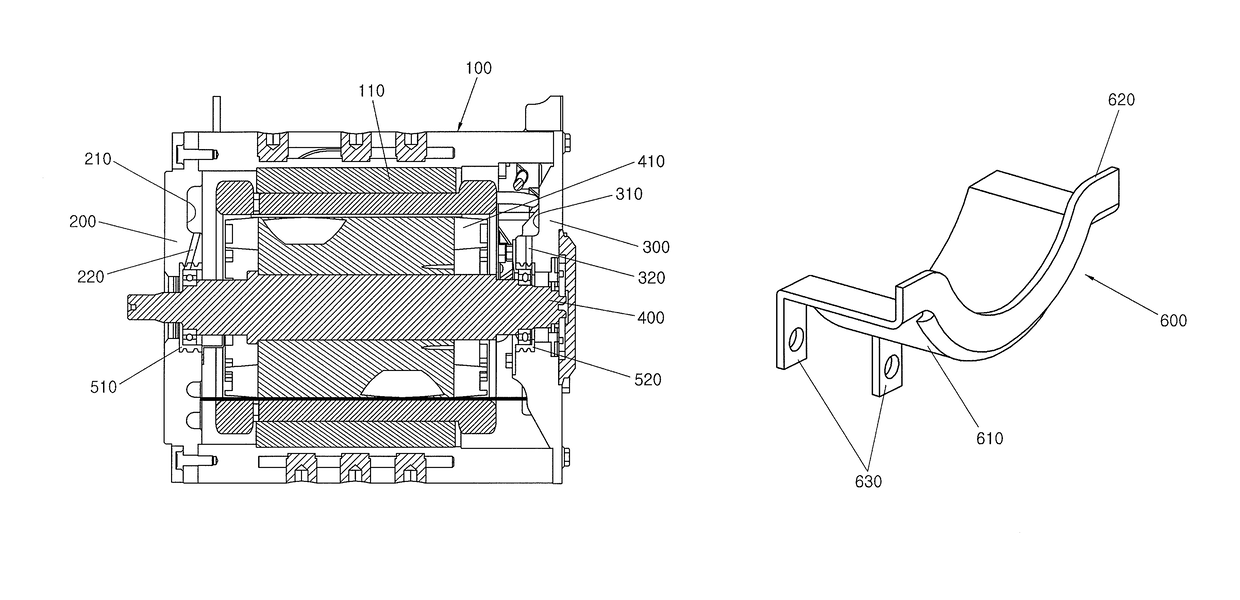

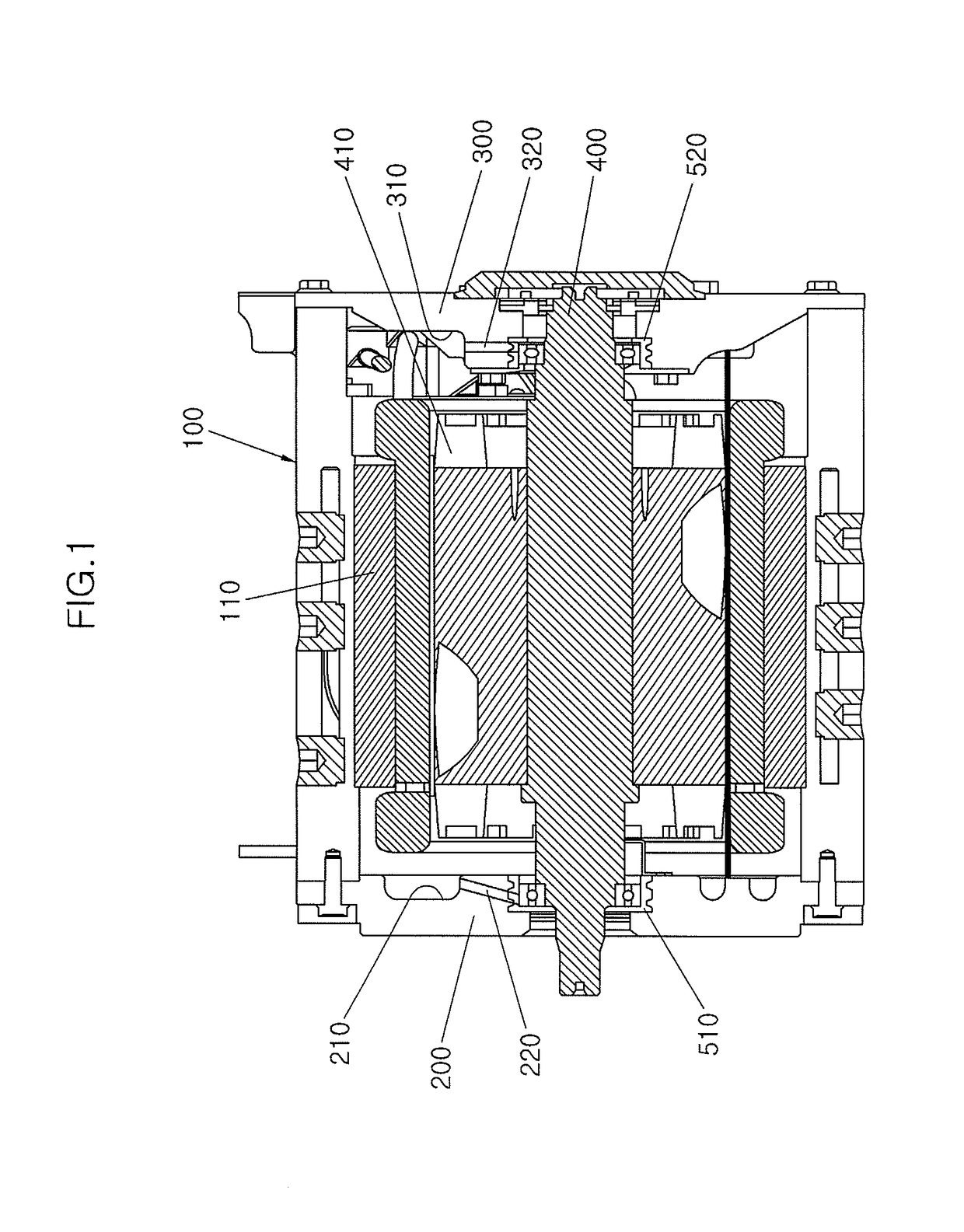

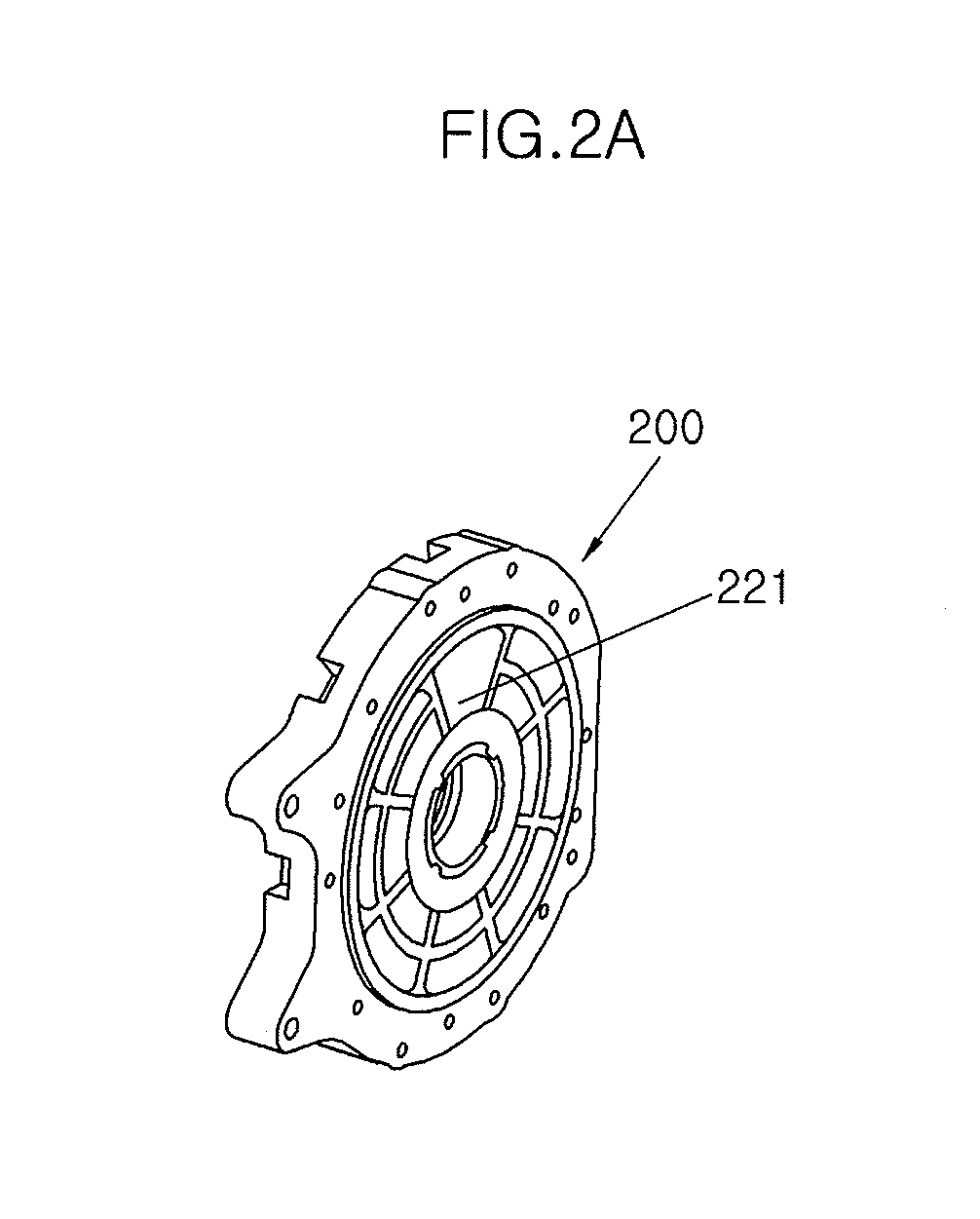

Cooling structure of oil cooling motor

ActiveUS9991764B2Increased durabilityImprove bearing performanceHybrid vehiclesElectric propulsion mountingOil coolingFront cover

A cooling structure of an oil cooling motor may include a housing, a front cover and a rear cover each mounted at both sides of a housing along a length direction of the housing, a rotor shaft extending through the housing and have both ends rotatably supported by bearings of the front cover and the rear cover, a rotor disposed in the housing and rotatably supported by the rotor shaft, a front oil supply groove and a rear oil supply groove formed on opposing inner sides of the front cover and the rear cover and configured to temporarily store oil stored in a bottom of the housing and scattered by churning of the rotor, and a front cover passage and a rear cover passage configured to communicate with the front oil supply groove and the rear oil supply groove, respectively.

Owner:HYUNDAI MOBIS CO LTD

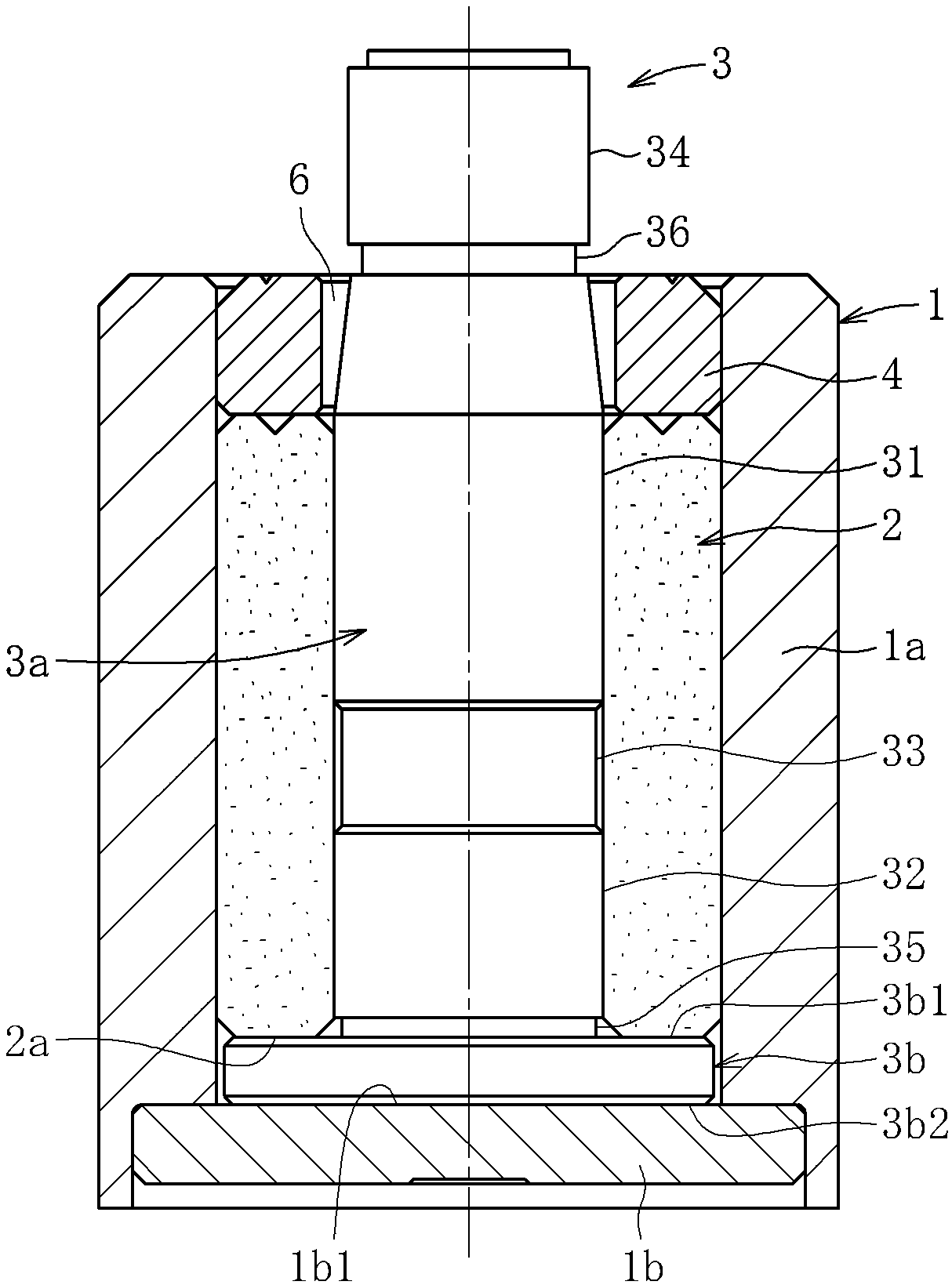

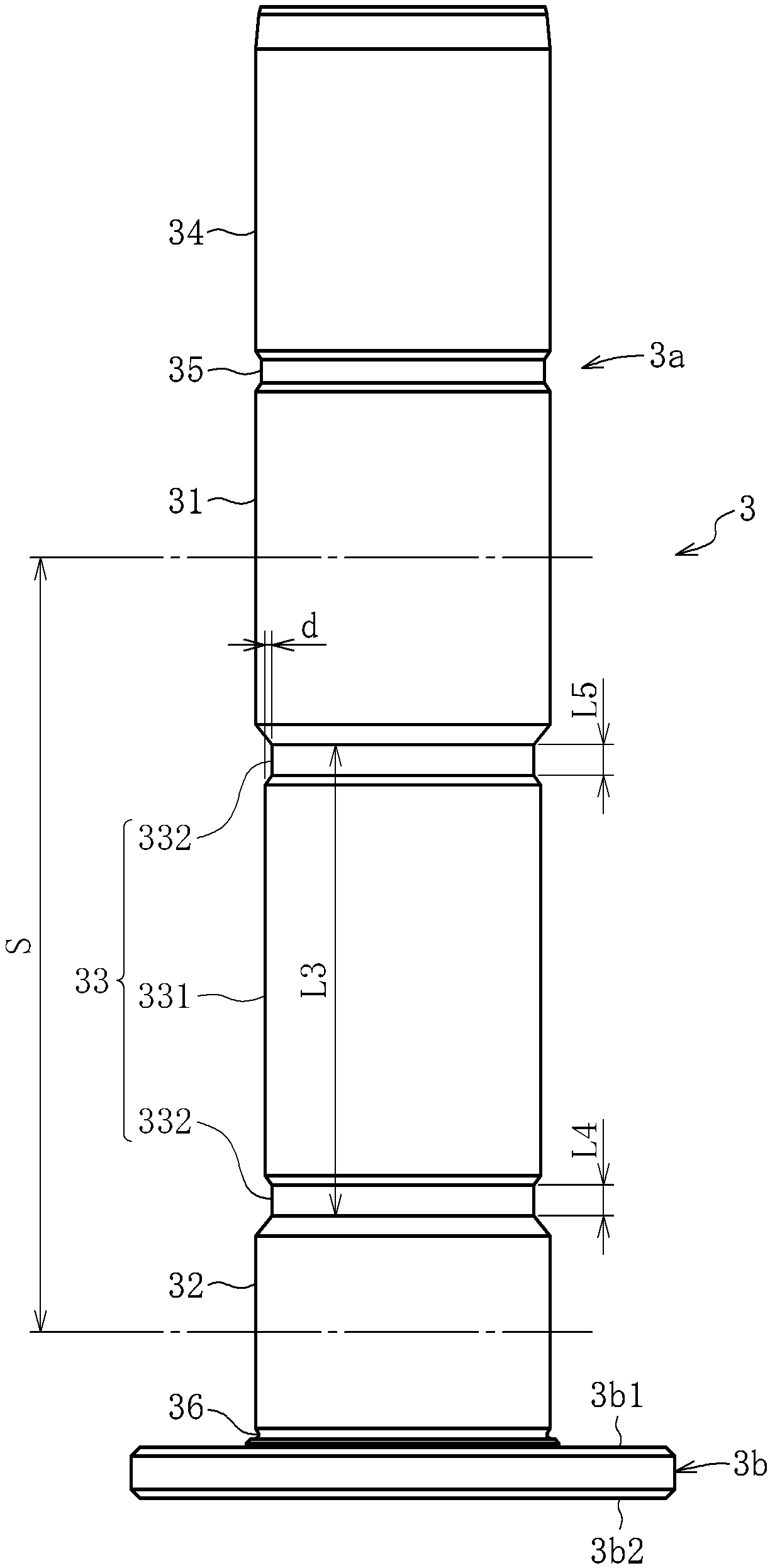

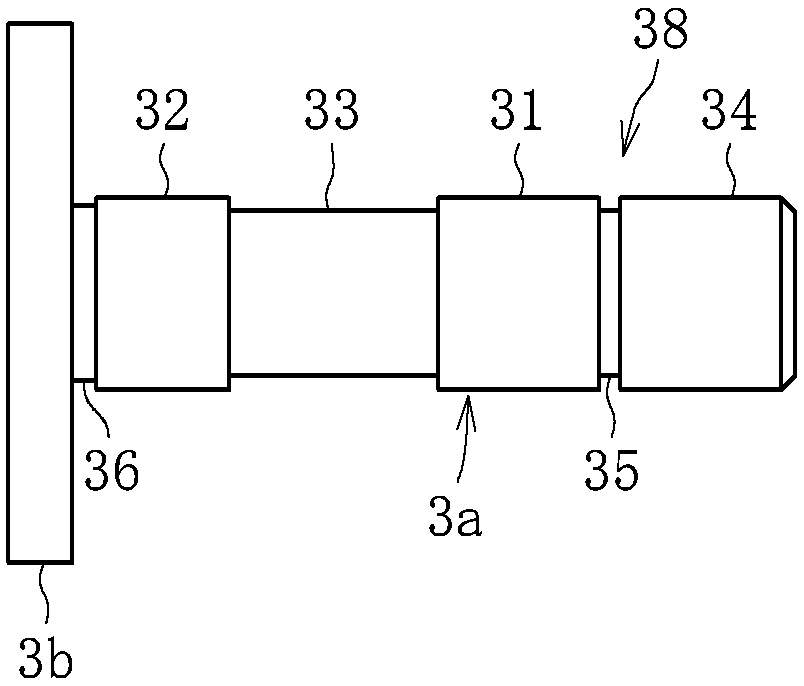

Shaft member for fluid bearing device, manufacturing method therefor, and fluid bearing device

ActiveCN107869512AAxial Width StabilityShorten grinding timeRevolution surface grinding machinesShaftsEngineeringFluid bearing

The present invention provides a shaft member for fluid bearing device, a manufacturing method therefor, and a fluid bearing device. The shaft member comprises two bearing surfaces (31,32) separated from each other at the outer circumference in the axial direction, and a central recessed section (33) formed between the bearing surfaces (31,32) and having a smaller diameter than the bearing surfaces. The central recessed section (33) is provided with a cylindrical surface section (331) comprising a grinding surface, and a step sections (332) arranged on both sides of the cylindrical surface section in the axial direction and having a different diameter than the cylindrical surface section.

Owner:NTN CORP

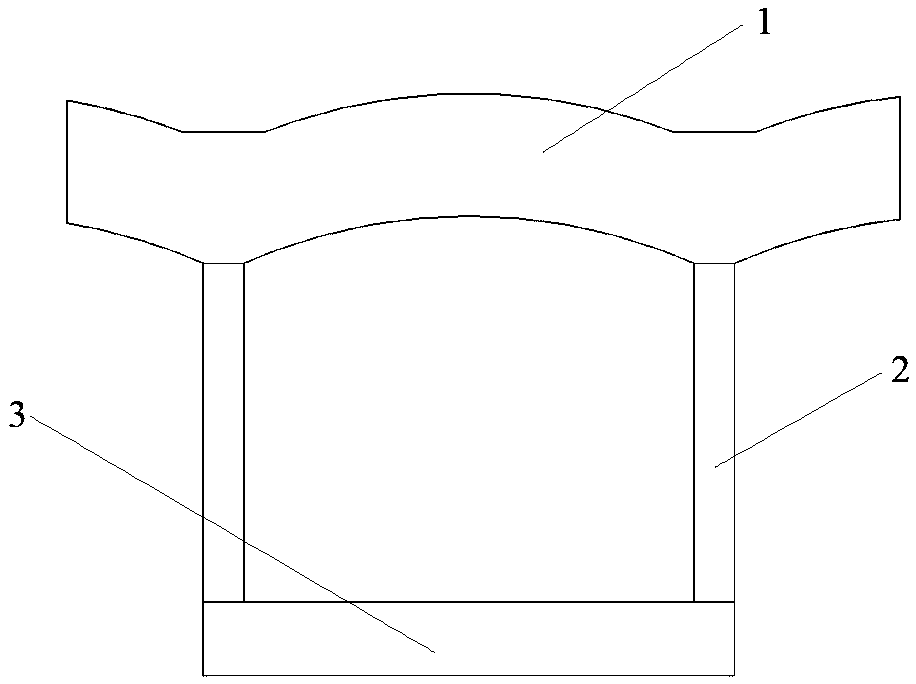

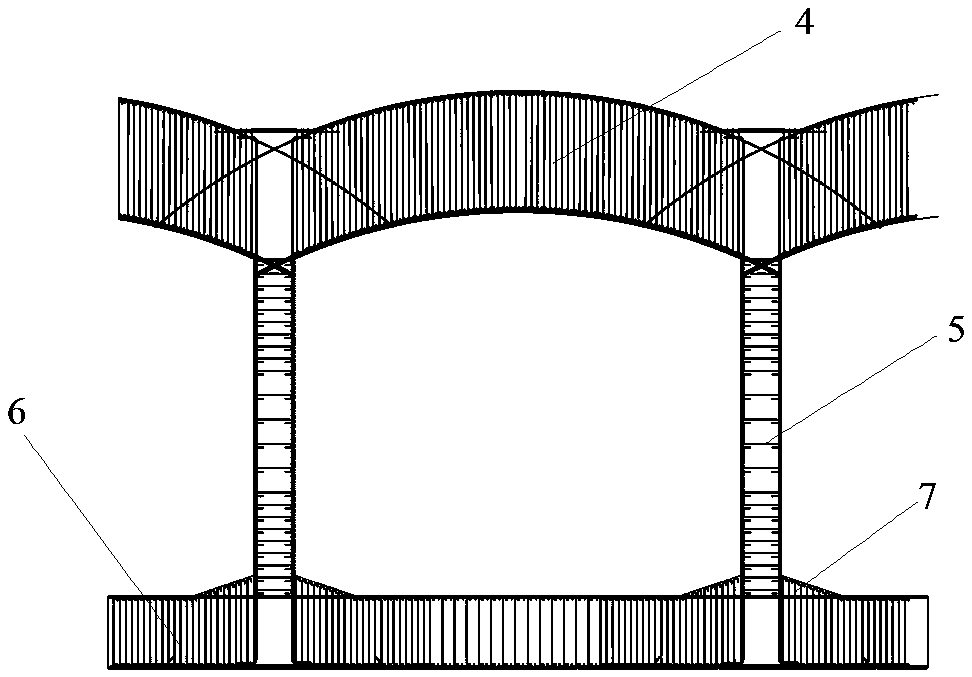

Closed steel bar framework of thick-roof arch structure and optimization method

ActiveCN110318783AImprove bearing performanceReduction in total reinforcement usageUnderground chambersTunnel liningRebarArchitectural engineering

The invention discloses a closed steel bar framework of a thick-roof arch structure and an optimization method. The closed steel bar framework comprises a roof steel bar framework positioned on a roofof the arch structure, partition steel bar frameworks connected to two end parts of the roof steel bar framework, and bottom plate steel bar frameworks connected to the bottoms of the two partition steel bar frameworks, wherein the top plate steel bar frames are arranged in a layered mode, and the interlayer steel bar meshes are connected through top plate single-limb stirrups and are connected to a group of steel bar supports. The method mainly adopts the methods of upright post bearing, single-limb stirrup replacement and the like during the steel bar optimization. According to the closed steel bar framework of the thick-roof arch structure and the optimization method, the roof steel bar frameworks are arranged in the layered mode, so that the layered pouring, vibrating and stress of the roof are conveniently carried out; vertical steel bar frameworks and cross beams among the steel bar frameworks are arranged, so that the force bearing performance of roof structure after pouring isimproved; according to the equal strength method and the equal area method, closed stirrups are replaced by the single-limb stirrups, so that the stress of the top plate structure is ensured, the steel bar using amount of the whole arch-shaped structure closed steel bar framework is further optimized, and the construction is convenient, and the working efficiency is improved.

Owner:BEIJING URBAN CONSTR GROUP

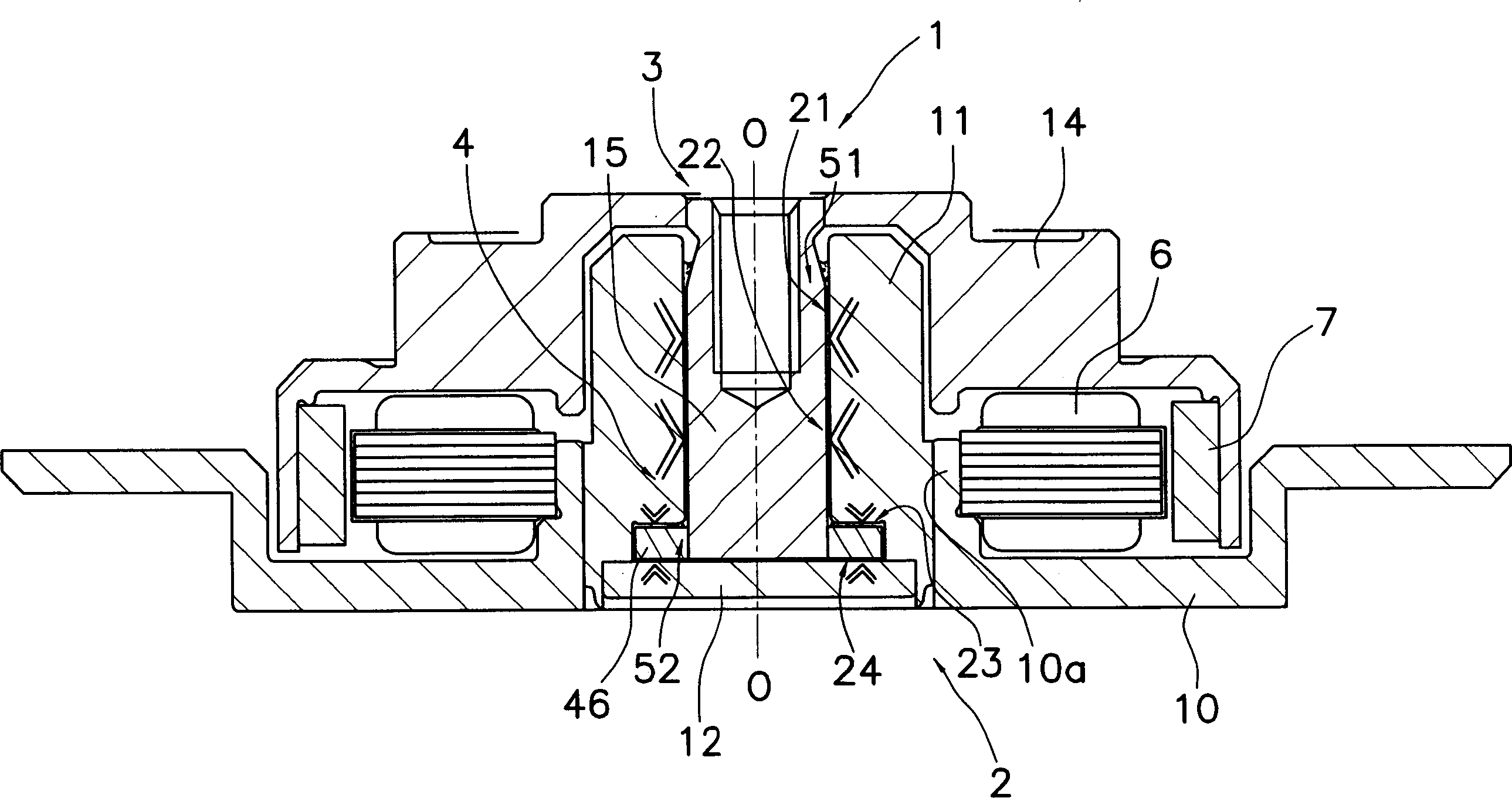

Fluid bearing device

InactiveCN101400912AImprove assembly accuracyImprove bearing performanceSliding contact bearingsBearing unit rigid supportEngineeringFluid bearing

A fluid dynamic bearing device capable of exercising high bearing performance is provided at low cost. A housing 7 is injection molded with a bearing sleeve 8 as an insert. Accordingly, the molding of the housing 7 and the assembly of the housing 7 and the bearing sleeve 8 can be performed in a single step. In addition to this, by simply increasing the die precisions the housing 7 and the bearing sleeve 8 can be fixed easily with high precision. Since the housing 7 is opened at both ends, it is possible to sandwich the bearing sleeve 8, and accordingly, the bearing sleeve 8 can be accurately positioned inside the dies with reliability.

Owner:NTN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com