Grease compostion for automobile electrical equipment auxiliary device and prelubricated rolling using the grease composition

a technology of automobile electrical equipment and grease composition, which is applied in the direction of lubricant composition, thickeners, mechanical equipment, etc., can solve the problems of insufficient supply of greases which can fully meet the diverse requirements of above-enumerated greases, and the lowering of the output due to miniaturization is inevitable, so as to improve the seizure performance of bearings and excellent lubricating performan

Inactive Publication Date: 2006-04-06

NSK LTD

View PDF5 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

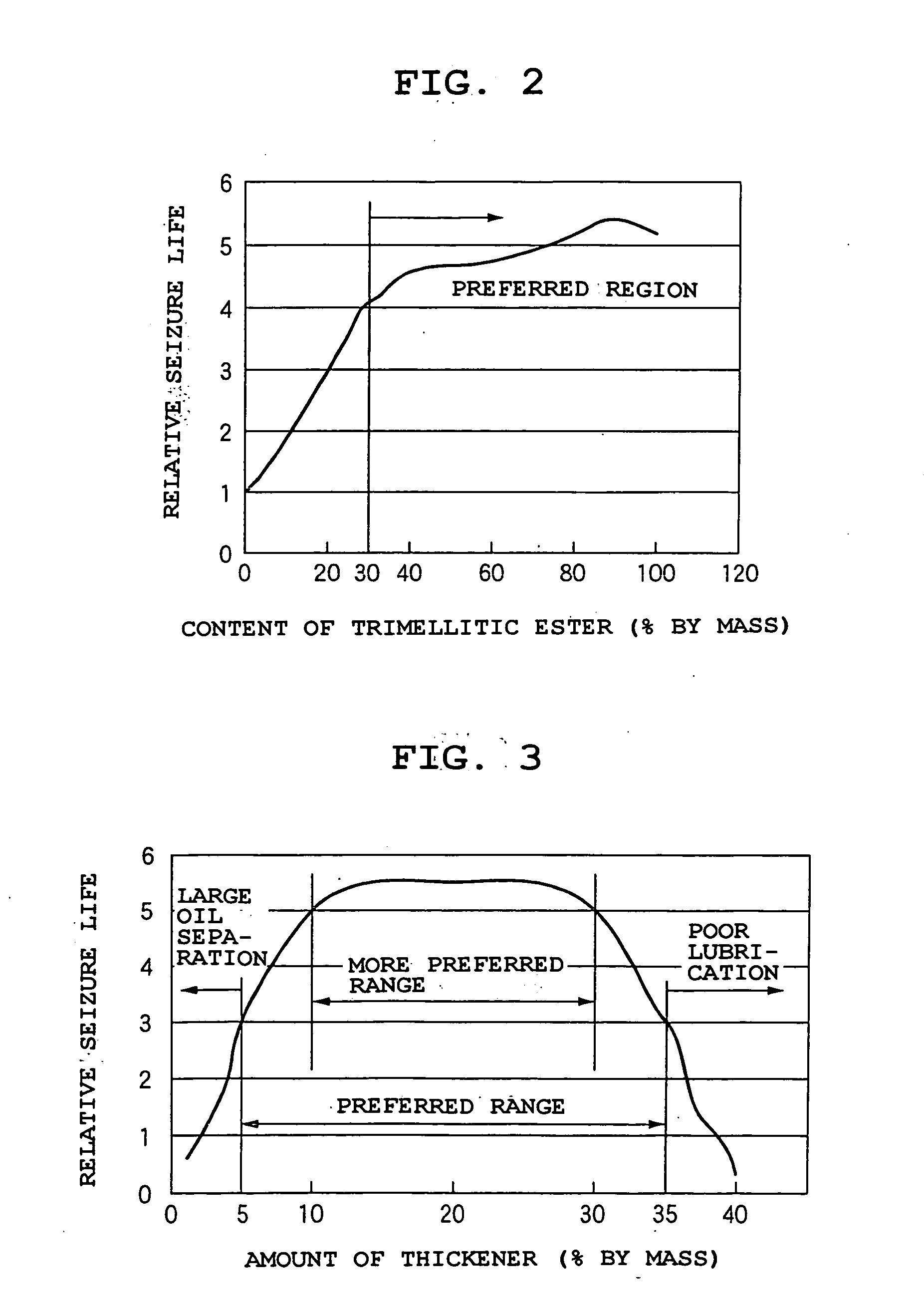

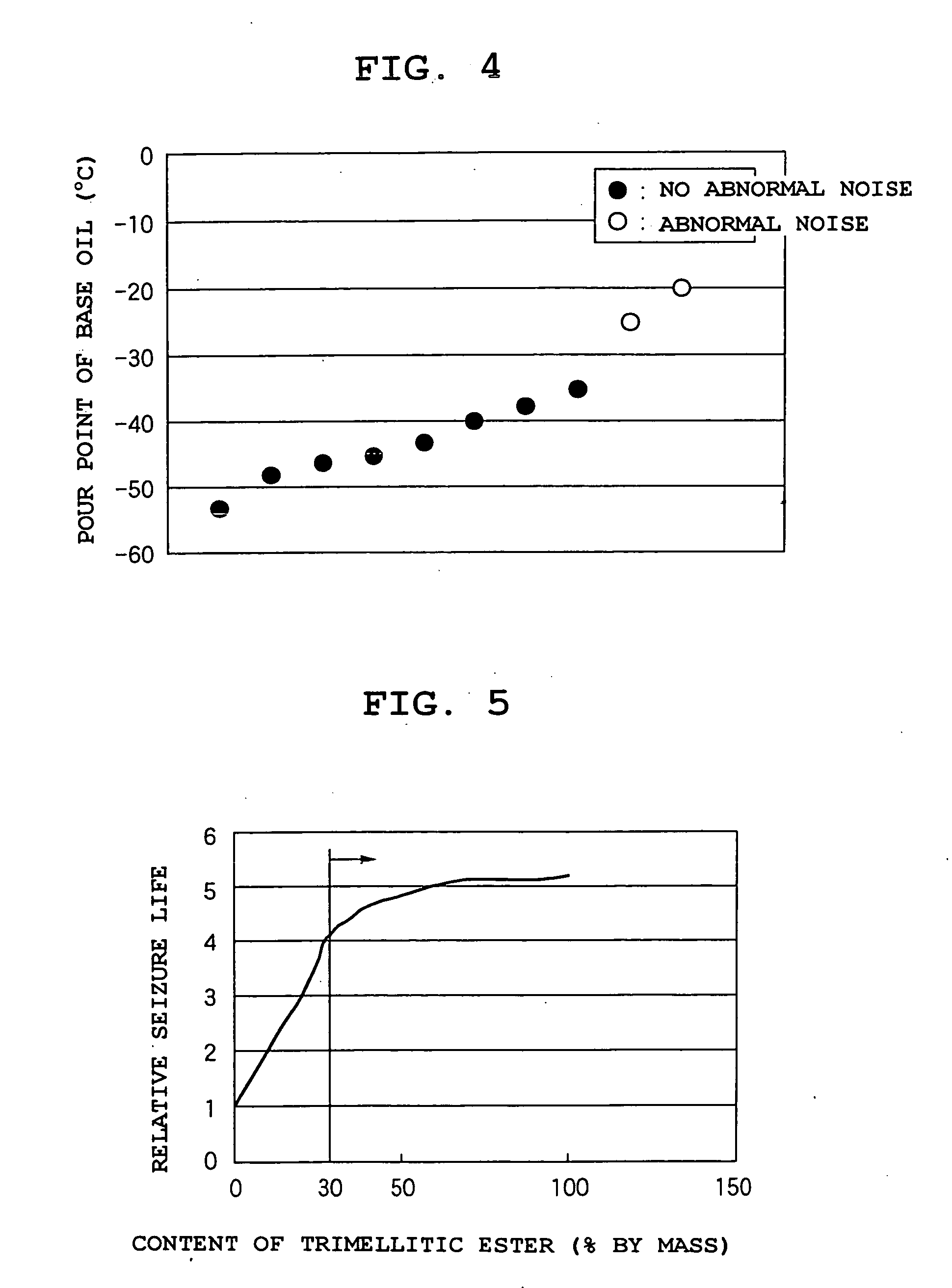

[0006] In order to solve the foregoing problems, the present inventors made extensive and intensive investigations. As a result, it has been found that among diurea compounds, those having an alicyclic hydrocarbon group, when combined with a base oil containing an aromatic ester oil, exhibit an excellent lubricating performance over a wide temperature range of from an extremely low temperature to a high temperature, do not generate abnormal noises at a low temperature, and can improve greatly a seizure performance of a bearing, leading to accomplishment of the invention.

[0008] Also, the invention provides the foregoing grease composition for auxiliary machinery of automobile electrical component, which is characterized by containing at least one member of carbon black and carbon nano tube as a conductive powder for the purpose of imparting conductivity. Further, it is preferable that two or more members selected from rust preventives made of a carboxylic acid or a carboxylate, ester based rust preventives, and amine based rust preventives are contained as a rust preventive in an amount of from 0.2 to 10% by mass in total and from 0.1 to 9.9% by mass singly based on the whole amount of the grease composition, whereby sufficient rust preventing properties are imparted. Also, such rust preventives are free from adverse influences against the environment.

Problems solved by technology

However, a lowering of the output due to the miniaturization is inevitable.

However, greases which can fully meet these diverse requirements inclusive of the above-enumerated greases have not been obtained yet.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

examples

[0045] The invention will be further described below with reference to the following Examples and Comparative Examples, but it should be construed that the invention is not limited thereto in any way.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Login to View More

Abstract

To provide a grease composition for auxiliary machinery of automobile electrical component containing an aromatic ester oil-containing base oil having a specific diurea compound as a thickener blended therewith and a rolling bearing having the foregoing grease composition packed therein. The foregoing grease composition and rolling bearing do not generate abnormal noises even at an extremely low temperature of −40° C., have excellent seizure resistance even under a high temperature closed to 180° C., have excellent rust preventing performance, and are suitable especially for electrical parts and auxiliary machineries of engines, etc.

Description

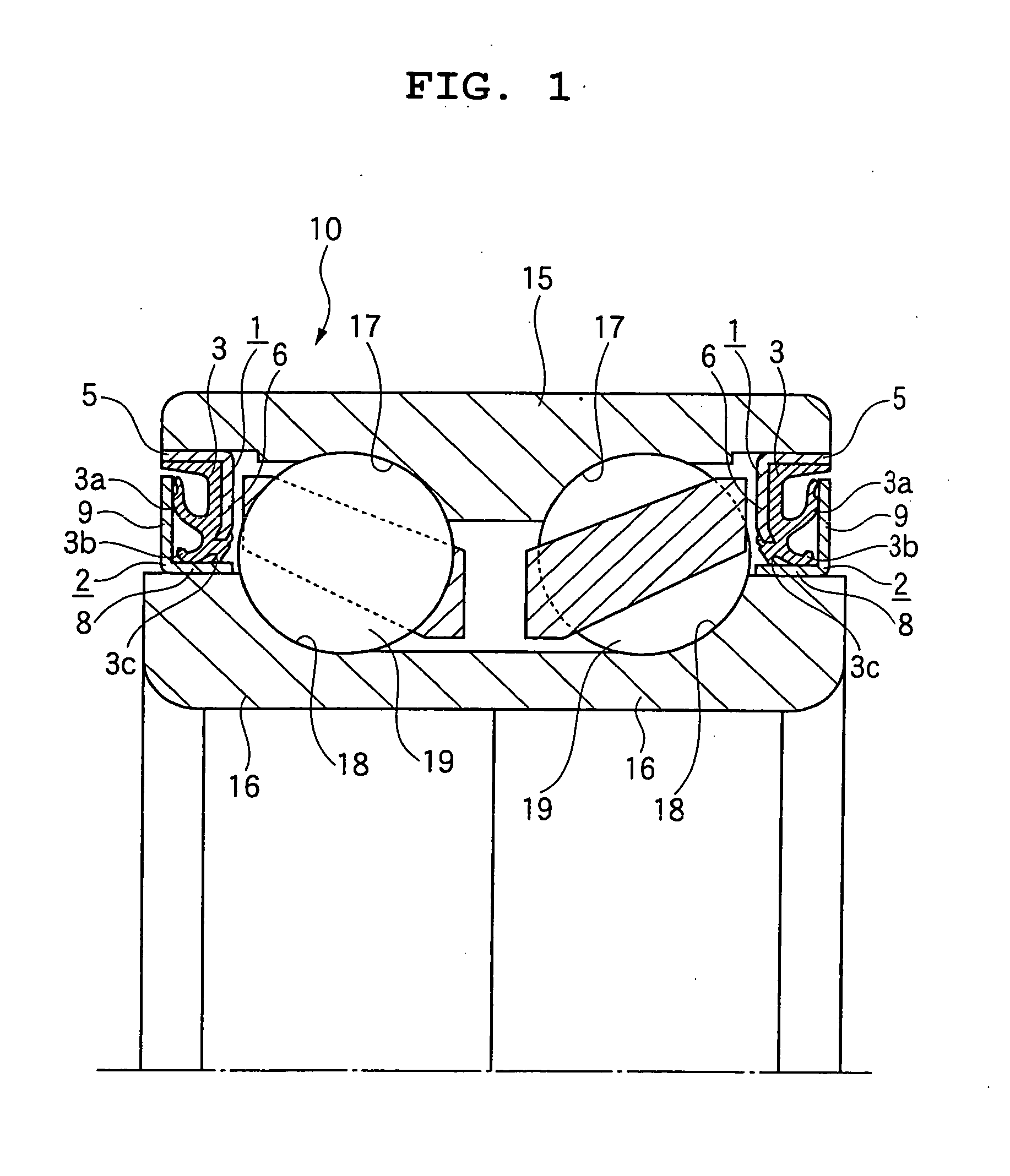

TECHNICAL FIELD [0001] The present invention relates to a grease composition which is used especially under severe conditions of high temperature, high speed, high load and vibration in automobile electrical parts or auxiliary machineries of engines such as alternators, intermediate pulleys, and electromagnetic clutches for car air conditioners and further which is used for parts required to have fluidity at an extremely low temperature of −40° C., and to a rolling bearing having the foregoing grease composition packed therein. BACKGROUND ART [0002] In automobiles, by the spread of FF (front engine front drive) vehicles aiming at miniaturization and lightening and the demands of enlargement of an accommodation space, a reduction of the engine room space is unavoidable, miniaturization and lightening of the above-enumerated electrical parts and auxiliary machineries of engines are further being advanced, and respective parts to be integrated thereinto are required to have high perfor...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(United States)

IPC IPC(8): C10M115/08C10M105/36F16C33/78C10M125/02C10M129/26C10M129/28C10M129/76C10M133/06C10M169/02C10N10/02C10N10/04C10N10/06C10N20/06C10N30/00C10N30/06C10N30/08C10N30/12C10N40/02C10N50/10F16C33/66

CPCB82Y30/00C10M169/02C10M2207/2855C10M2215/1026C10N2230/08C10N2230/12C10N2240/02C10N2240/20C10N2250/10F16C33/7879F16C19/184C10N2030/08C10N2030/12C10N2040/02C10N2040/14C10N2050/10

Inventor FUJITA, YASUNOBUNAKATANI, SHINYADENPOU, KATSUAKISUMIYA, HISAO

Owner NSK LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com