Shaft member for fluid bearing device, manufacturing method therefor, and fluid bearing device

A technology of fluid bearings and manufacturing methods, which is applied in the direction of bearing components, bearings, manufacturing tools, etc., which can solve the problems of reduced grinding accuracy, inconsistent sliding shoe support positions, and reduced bearing performance, and achieve axial width stability and shortened grinding Time, the effect of improving bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Embodiments of the present invention will be described below based on the drawings.

[0055] As an example of a fluid bearing device, the figure 1 A hydrodynamic bearing arrangement for a general-purpose HDD is shown in .

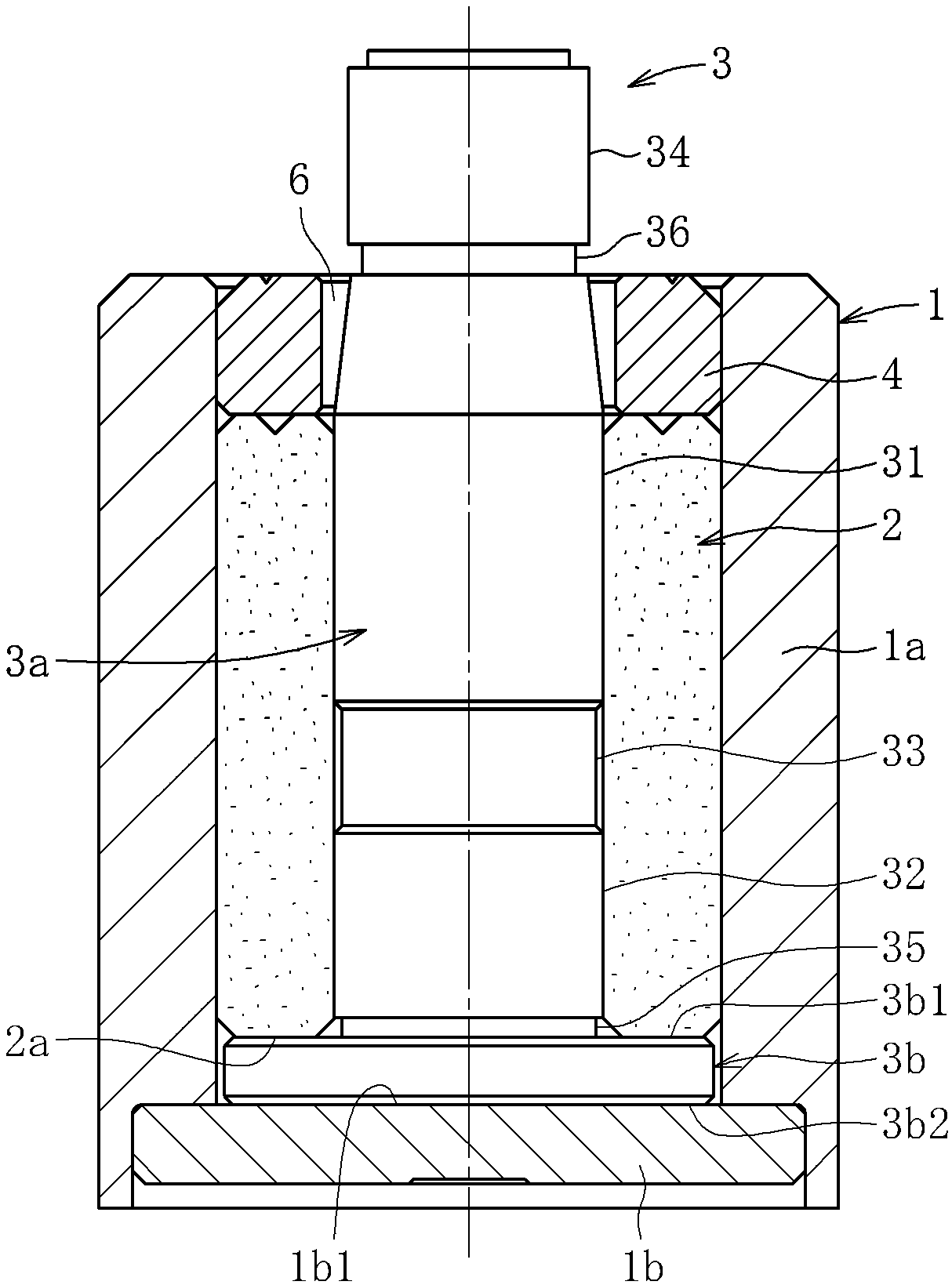

[0056] This fluid dynamic pressure bearing device has a bottomed cylindrical housing 1, a cylindrical bearing member 2 fixed to the inner periphery of the housing 1, a shaft member 3 inserted into the inner periphery of the bearing member, and The sealing member 4 configured in the opening.

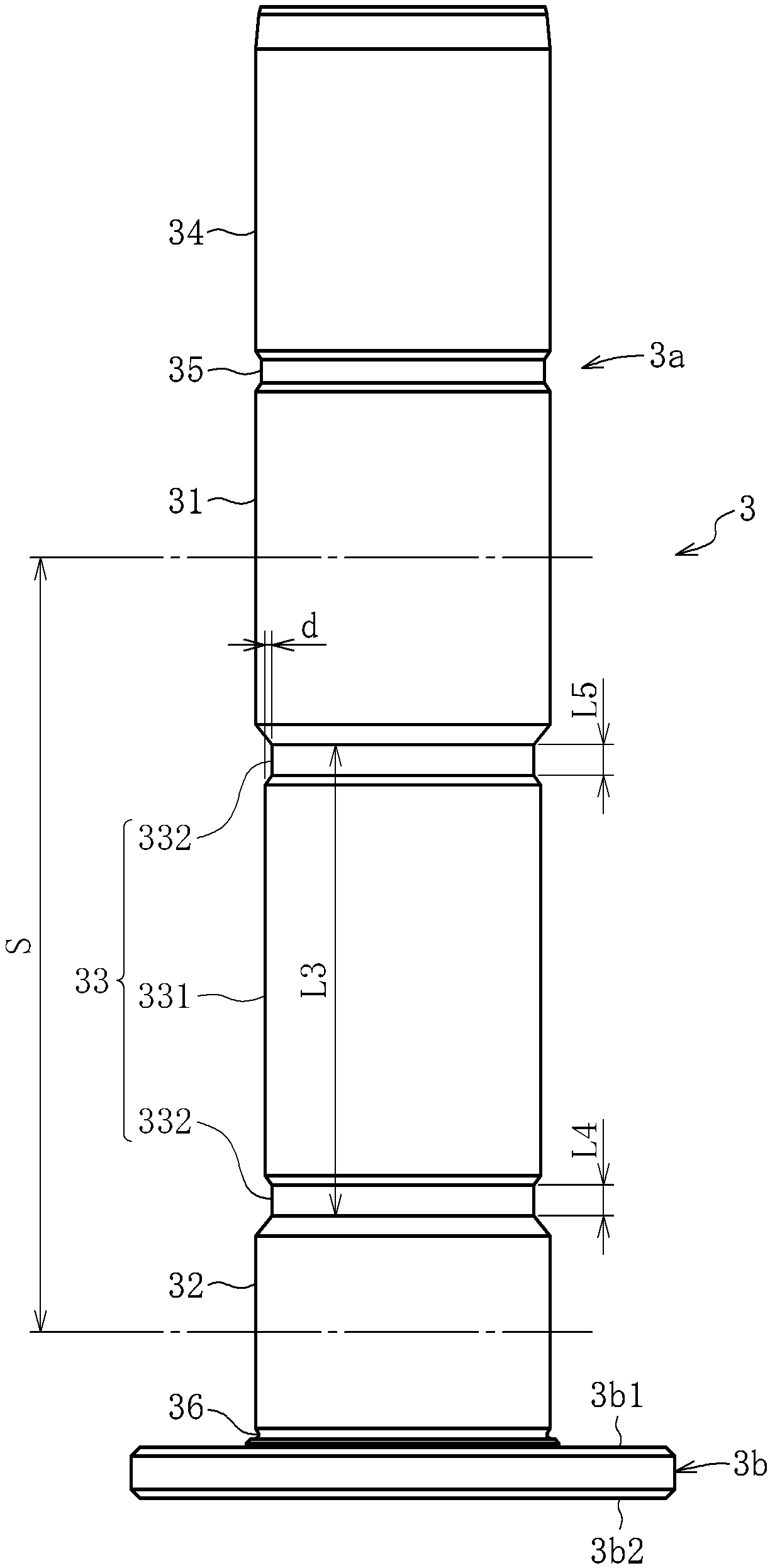

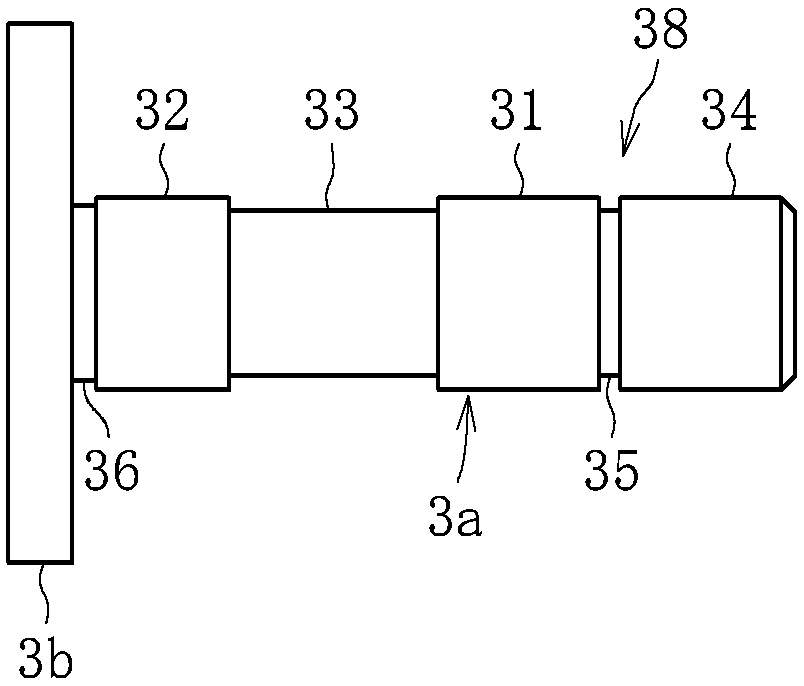

[0057] The housing 1 has a cylindrical side portion 1a and a bottom portion 1b that closes an opening at one axial end of the side portion 1a. The bottom portion 1b of the housing 1 may be formed integrally with the side portion 1a instead of being formed separately from the side portion 1a. The shaft member 3 is formed of stainless steel or the like, and has a shaft portion 3a and a flange portion 3b provided at one axial end of the shaft portion 3a. The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com