Production process of ceramic ball bearing ring

A bearing ring and production process technology, applied in the production process field of ceramic ball bearing rings, can solve problems such as grinding difficulties, achieve high grinding efficiency, improve grinding efficiency, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

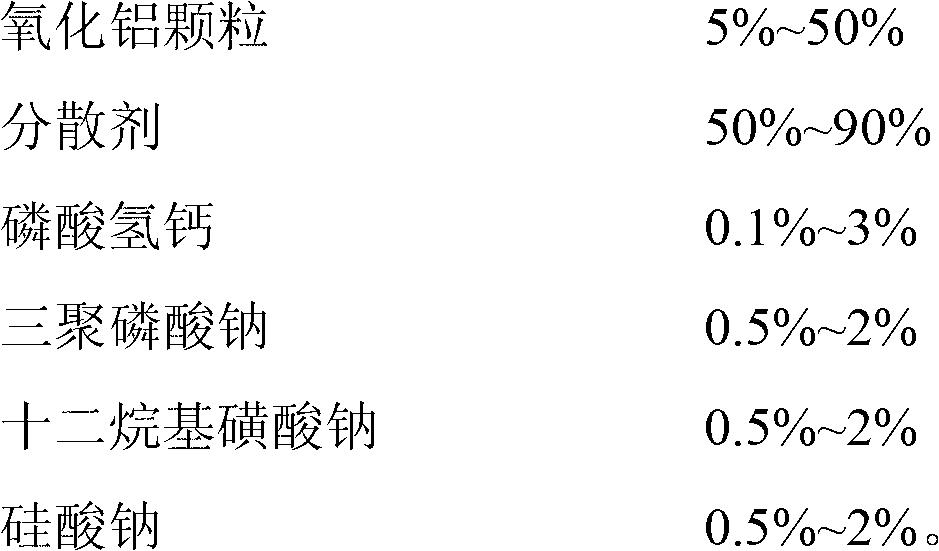

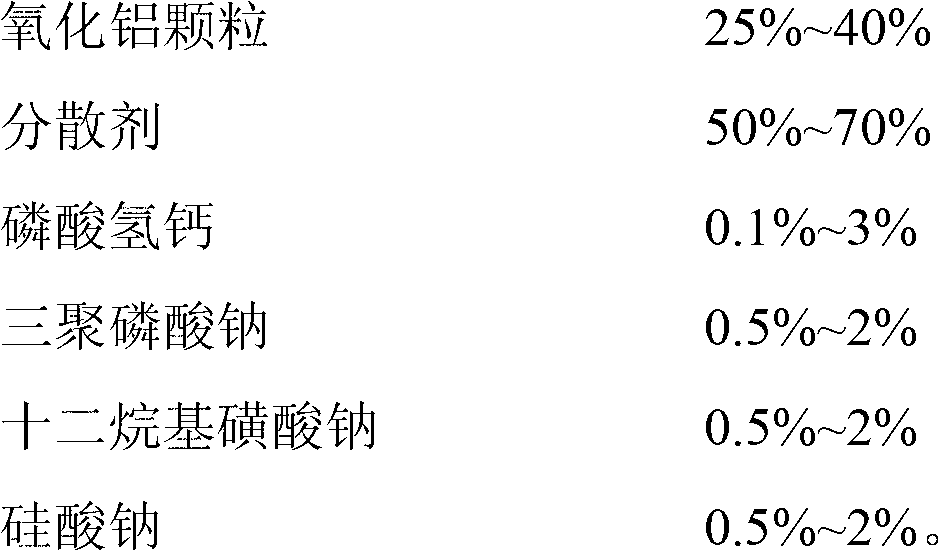

Method used

Image

Examples

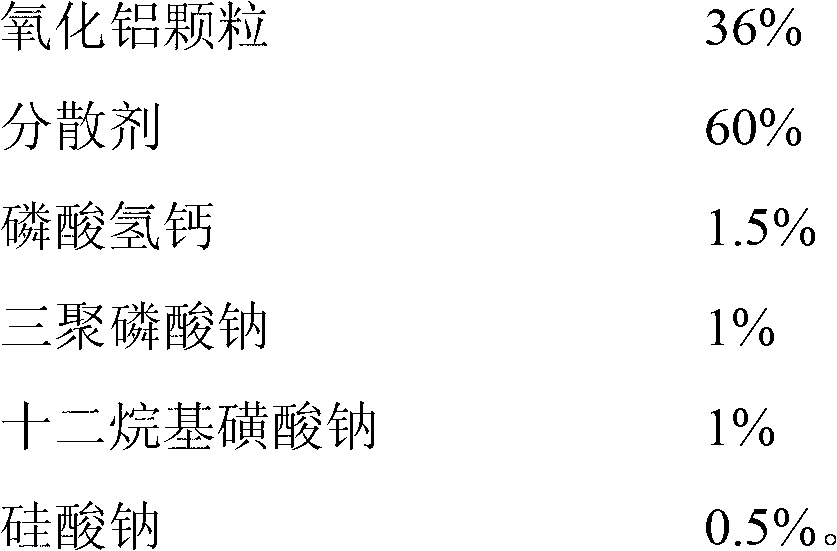

Embodiment 1

[0032] A production process of a ceramic ball bearing ring is carried out according to the following process steps:

[0033] ①Processing and forming: use machine tools to process the billet into a ring and then carry out the cold rolling and expanding process. The cold rolling and expanding process basically processes and shapes the ferrule, and adopts heat treatment and cryogenic treatment: the quenching hardness of heat treatment is HRC62, and the cryogenic temperature is controlled at minus 70 ℃;

[0034] ② Grinding and polishing: The workpiece after the cold rolling and expanding process is subjected to initial grinding and fine grinding process, and the plane, outer diameter, inner hole, and groove of the ferrule are ground to achieve the dimensional accuracy of the part; finally, the ultra-fine grinding process is carried out. Carry out ultra-fine grinding to the groove of bearing ring, reduce the roughness of groove and improve the roundness of groove, and its roughness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com