Fluid dynamic pressure bearing device

一种流体动压轴承、流体动压的技术,应用在滑动接触轴承、轴承、旋转运动的轴承等方向,能够解决油膜破断等问题,达到稳定轴承性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

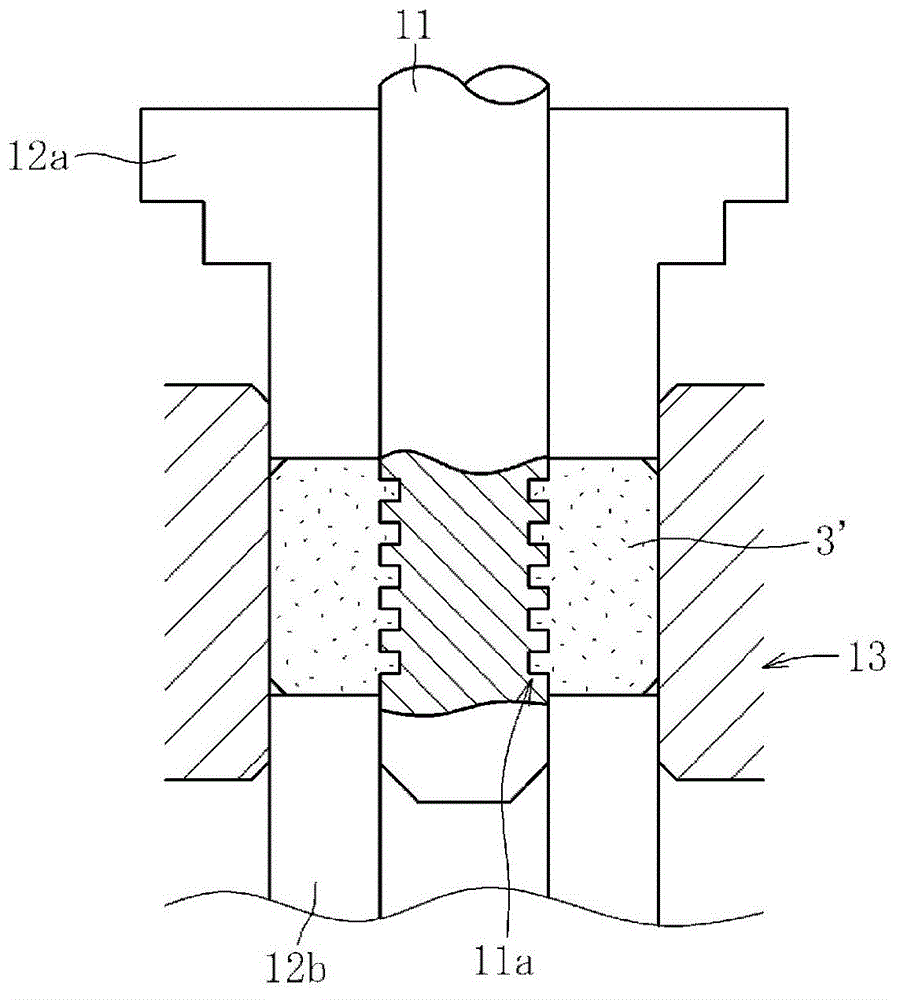

[0028] Hereinafter, embodiments of the present invention will be described based on the drawings. In addition, in the following description, for the convenience of description, the upper side in a drawing and the lower side in a drawing are called an "upper side" and a "lower side", respectively, in order to show directionality.

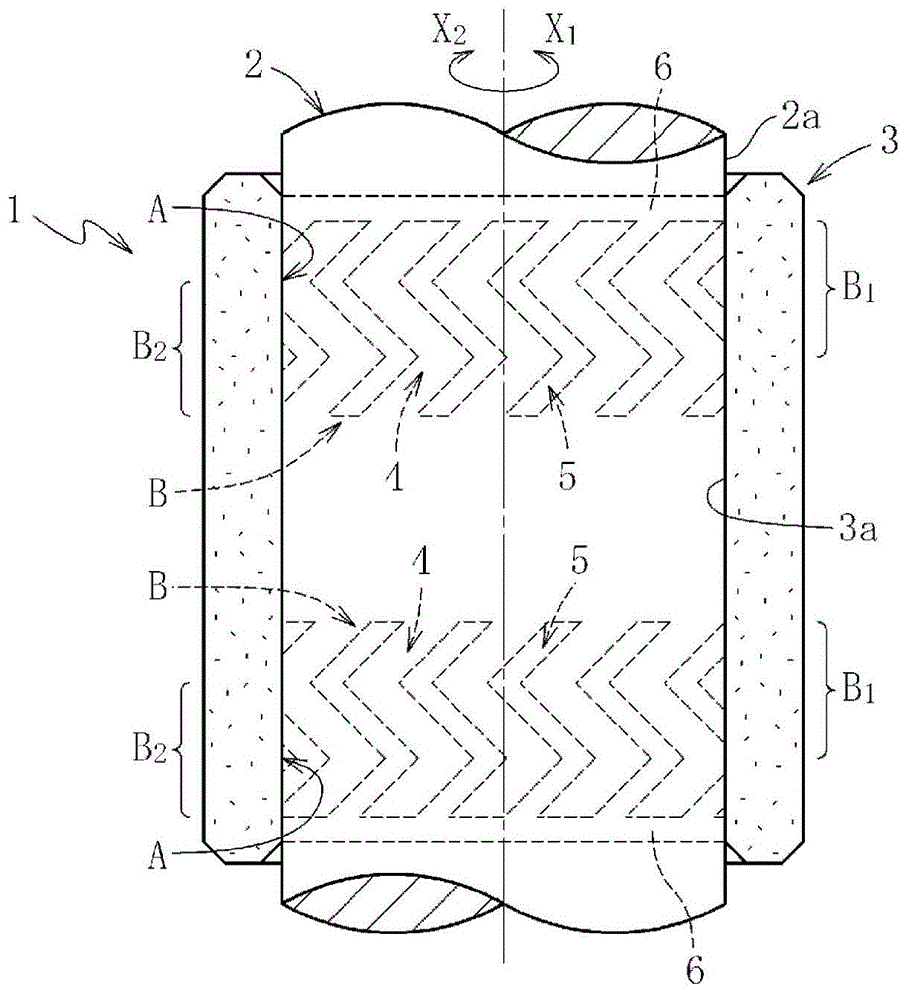

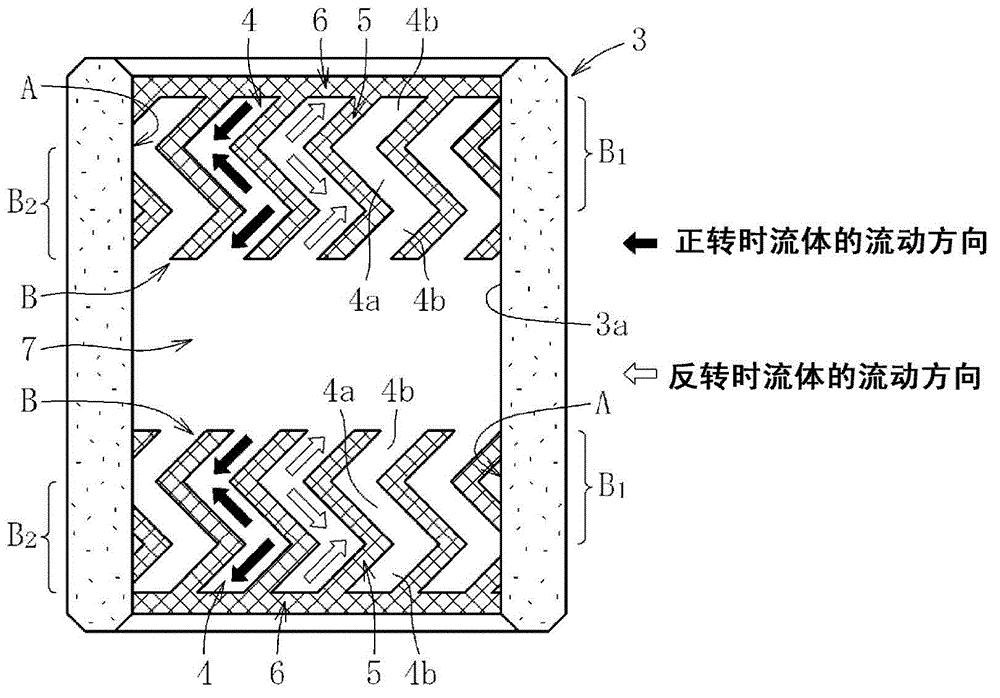

[0029] figure 1 It is a schematic cross-sectional view of a fluid dynamic pressure bearing device 1 according to an embodiment of the present invention. The fluid dynamic pressure bearing device 1 includes a bearing member 3 and an inner periphery inserted into the bearing member 3, and the fluid dynamic pressure bearing device 1 is provided in a forward direction or a reverse direction with respect to the bearing member 3 . Relatively rotating shaft member 2. The shaft member 2 is formed of a metal material such as stainless steel, and the outer peripheral surface 2 a facing the inner peripheral surface 3 a of the bearing member 3 is formed in a sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com