Mfg. method of thrust plate and mfg. method of shaft for fluid power bearing

A manufacturing method and thrust plate technology, which are applied in the directions of shafts and bearings, sliding contact bearings, manufacturing of motor generators, etc., can solve the problems of product height variation and insufficient elimination, and achieve the effect of improving bearing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0040] a. The overall structure of the spindle motor

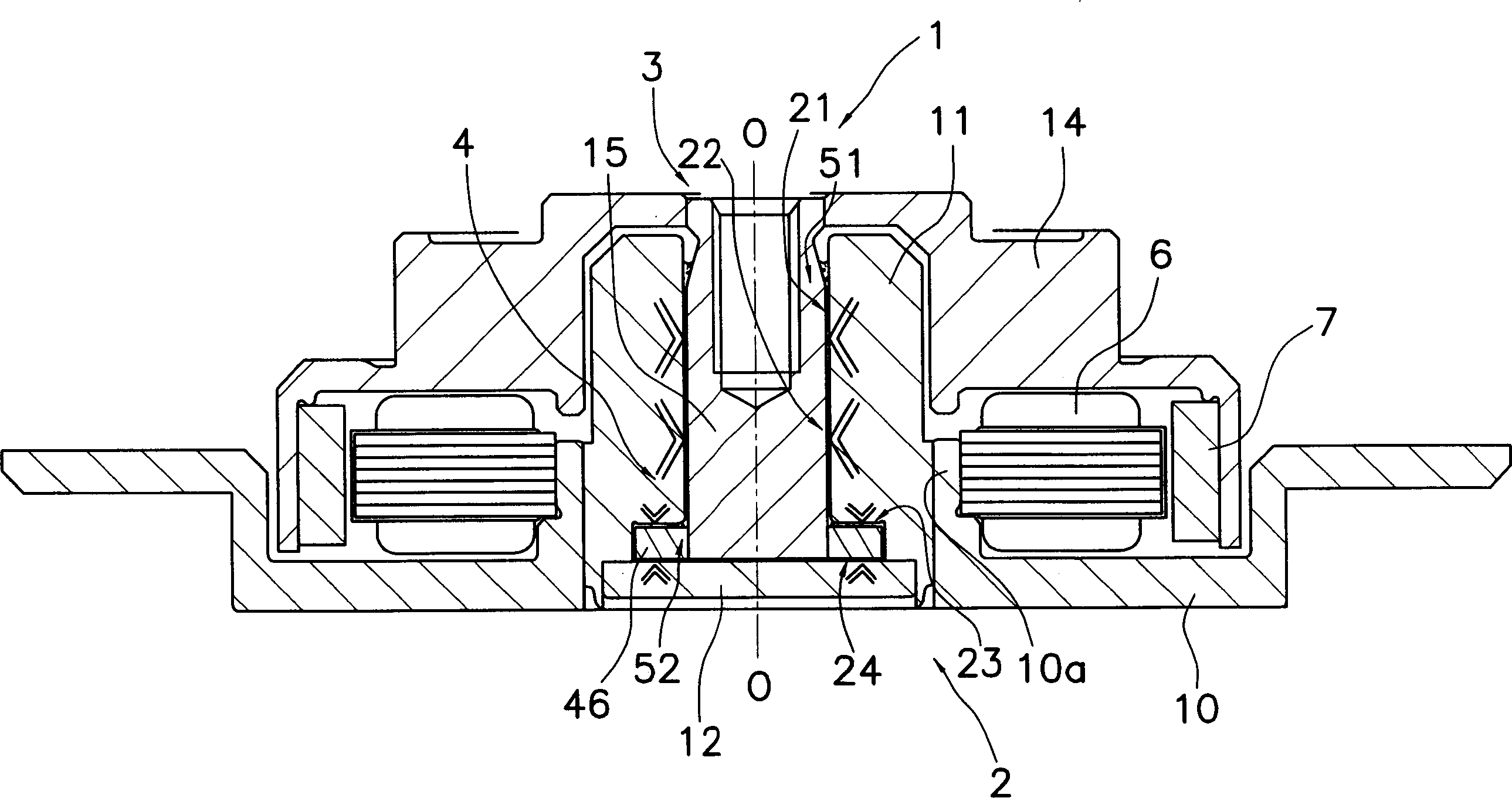

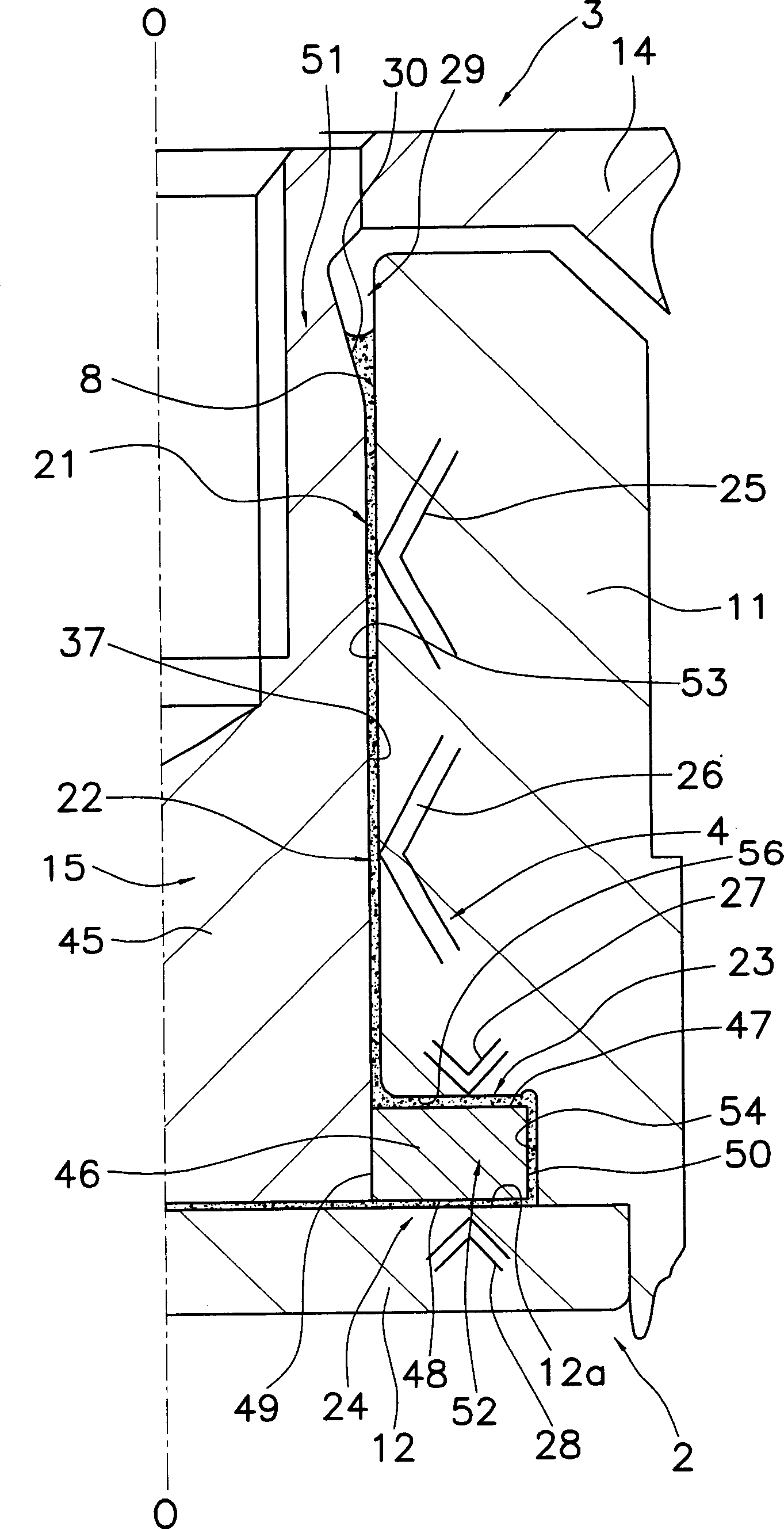

[0041] figure 1 is a longitudinal sectional view showing a simplified structure of a spindle motor according to an embodiment of the present invention. The spindle motor 1 is a spindle motor for recording disk drive, and constitutes an integral part of a recording disk drive device such as a hard disk or the like.

[0042] It should be pointed out that figure 1 The middle O-O line is the axis of rotation of the spindle 1. In addition, although in this embodiment for the sake of brevity the figure 1 The vertical direction in is described as the axis vertical direction, but the actual position where the spindle motor 1 is installed is not limited thereto.

[0043] exist figure 1 Among them, the main shaft 1 mainly includes a stationary part 2, a rotating part 3 and a bearing mechanism 4, and the bearing mechanism 4 is used to support the rotating part 3 on the stationary part 2, so that the rotating part 3 can freely ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com