Dynamic pressure bearing device

A technology of dynamic pressure bearings and thrust bearings, which is applied in the direction of sliding contact bearings, bearings, rotating bearings, etc., can solve the problems of high cost, achieve low cost, high bearing performance, and maintain the effect of bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

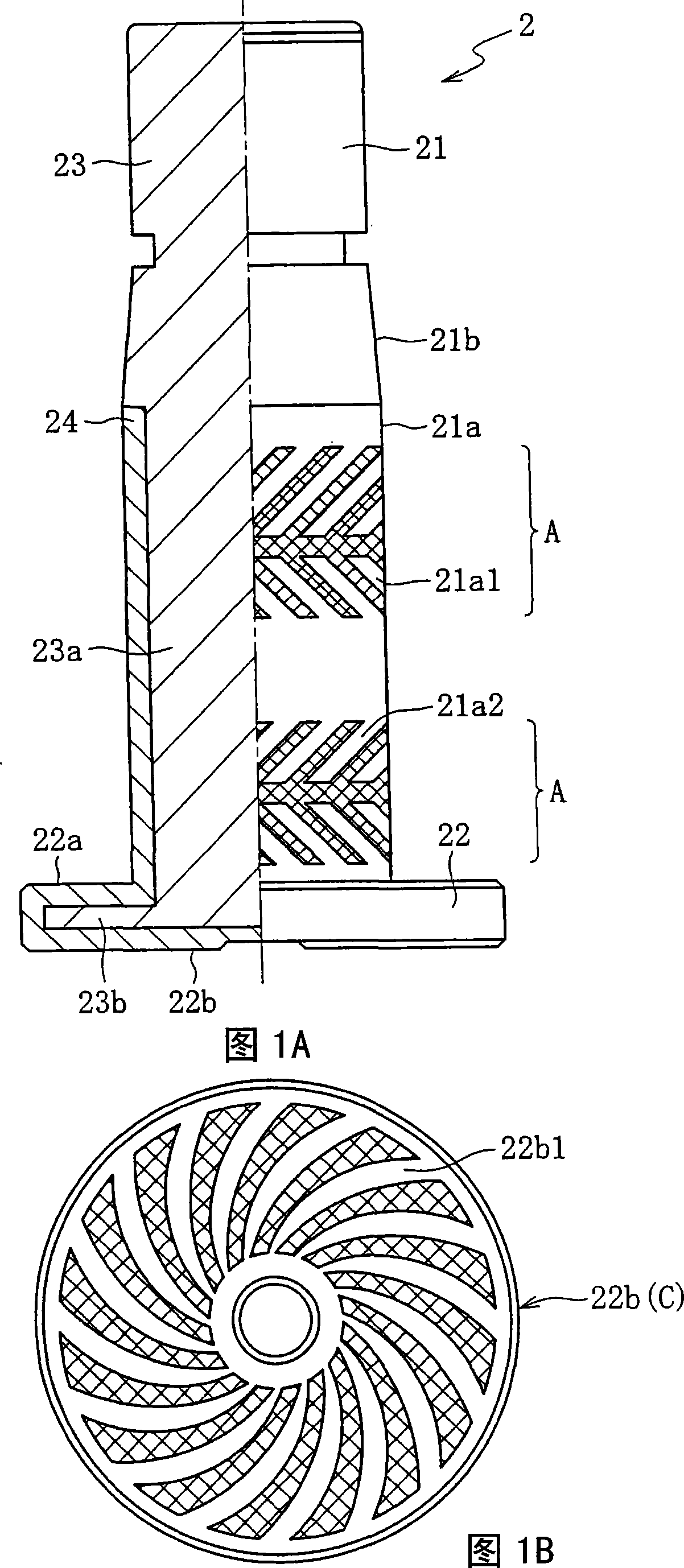

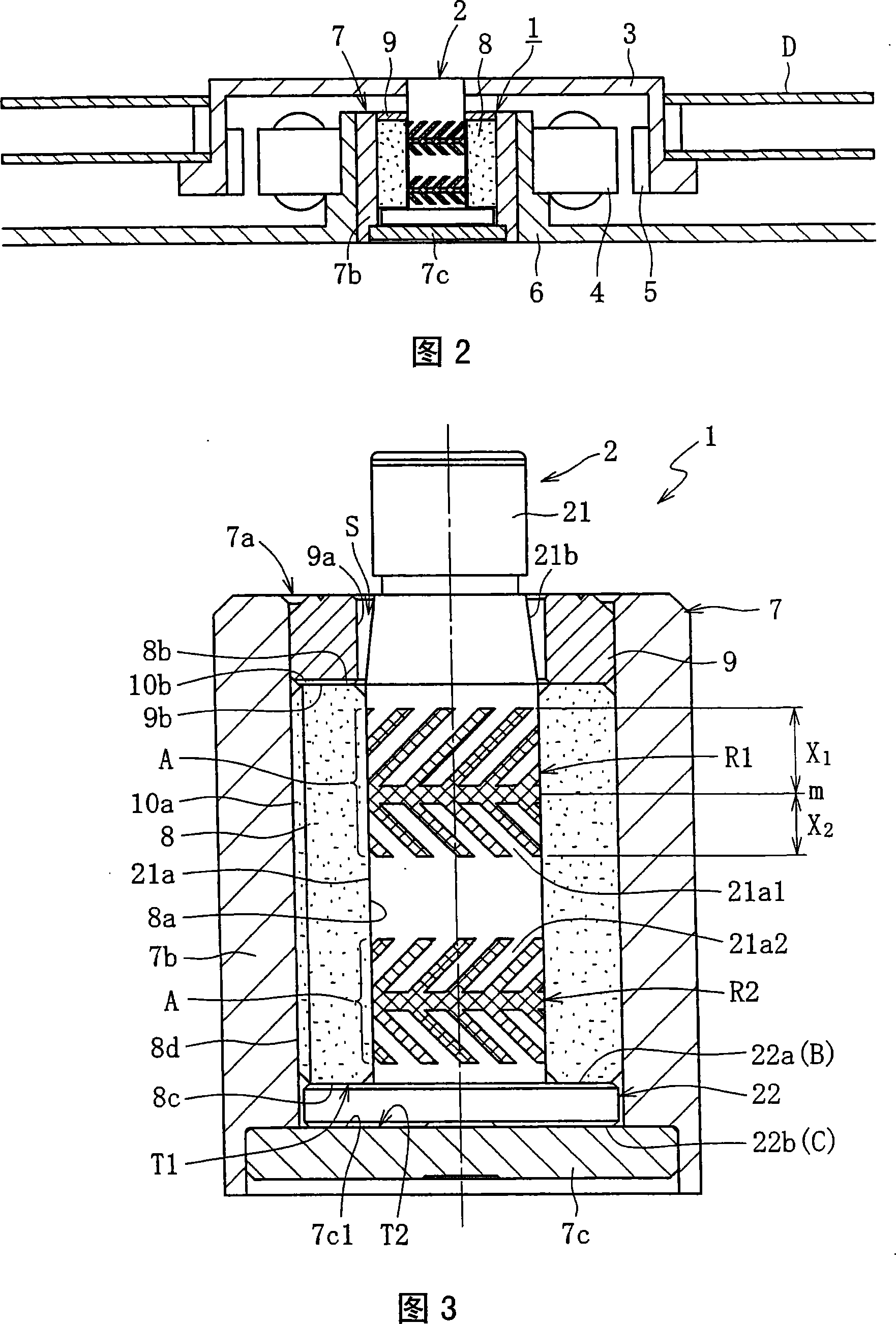

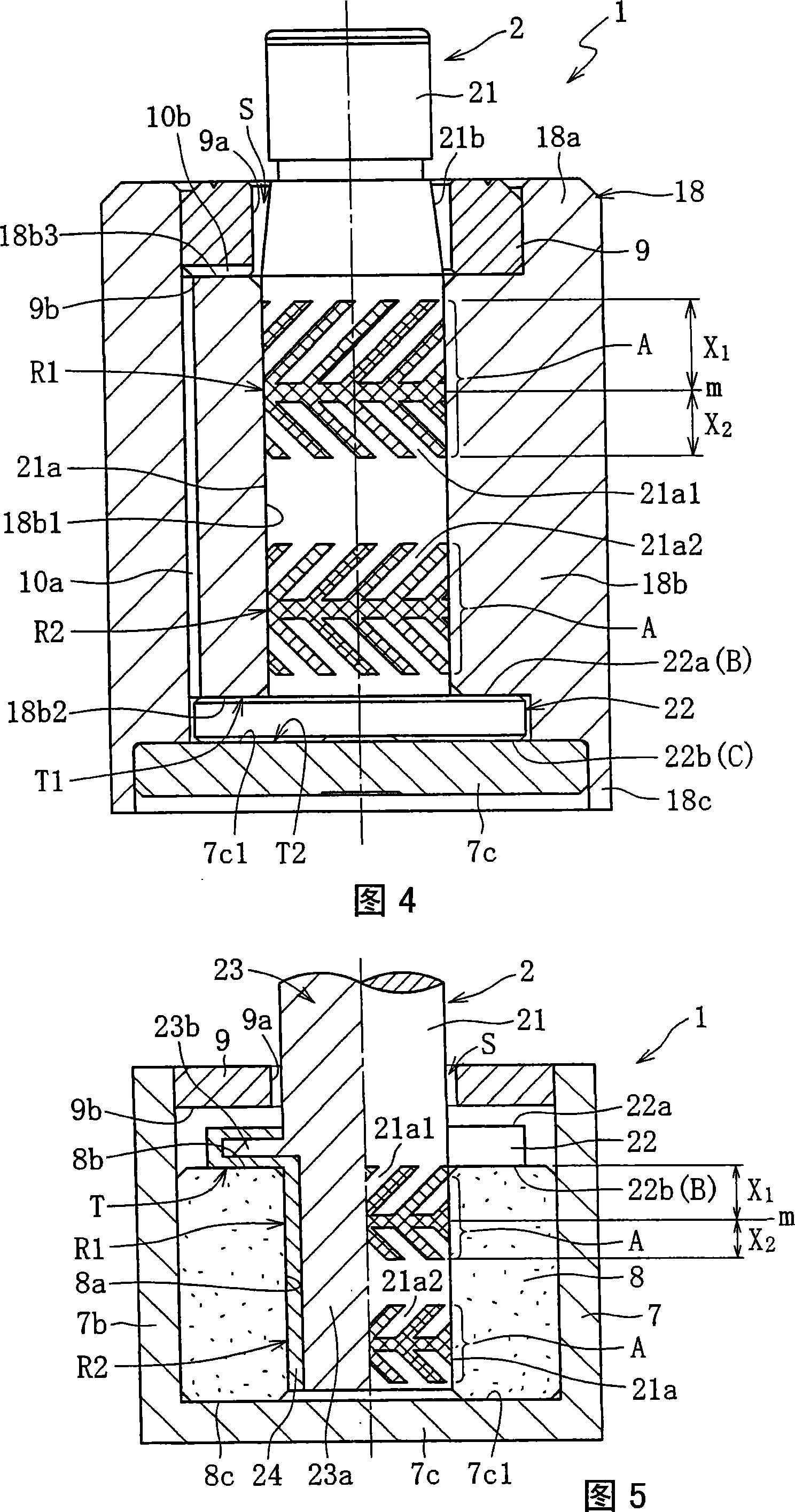

[0030] In the following, embodiments of the present invention will be described with reference to the drawings.

[0031] FIG. 2 shows an example of the structure of a spindle motor for an information device, in which a fluid dynamic pressure bearing device 1 according to the present invention is incorporated. This spindle motor is used in a disk drive device such as an HDD, and the spindle motor is equipped with: a fluid dynamic pressure bearing device 1, a disk hub 3 mounted on a shaft member 2 of the fluid dynamic pressure bearing device 1, a The stator coil 4 and the rotor magnet 5, and the bracket 6 are opposed to each other through the medium of the gap. The stator coil 4 is mounted on the outer periphery of the bracket 6 , and the rotor magnet 5 is mounted on the inner periphery of the hub 3 . The hub 3 holds one or more disks D such as magnetic disks in its outer periphery. Furthermore, the housing 7 of the fluid dynamic bearing device 1 is mounted on the inner periph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com