Electric power steering device

A technology of electric power steering and steering nut, which is applied in the direction of electric steering mechanism, power steering mechanism, steering mechanism, etc., which can solve the problems of difficult overall design, high integration, and large output torque of steering device, and achieve compact structure, The effect of reducing the installation area and avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

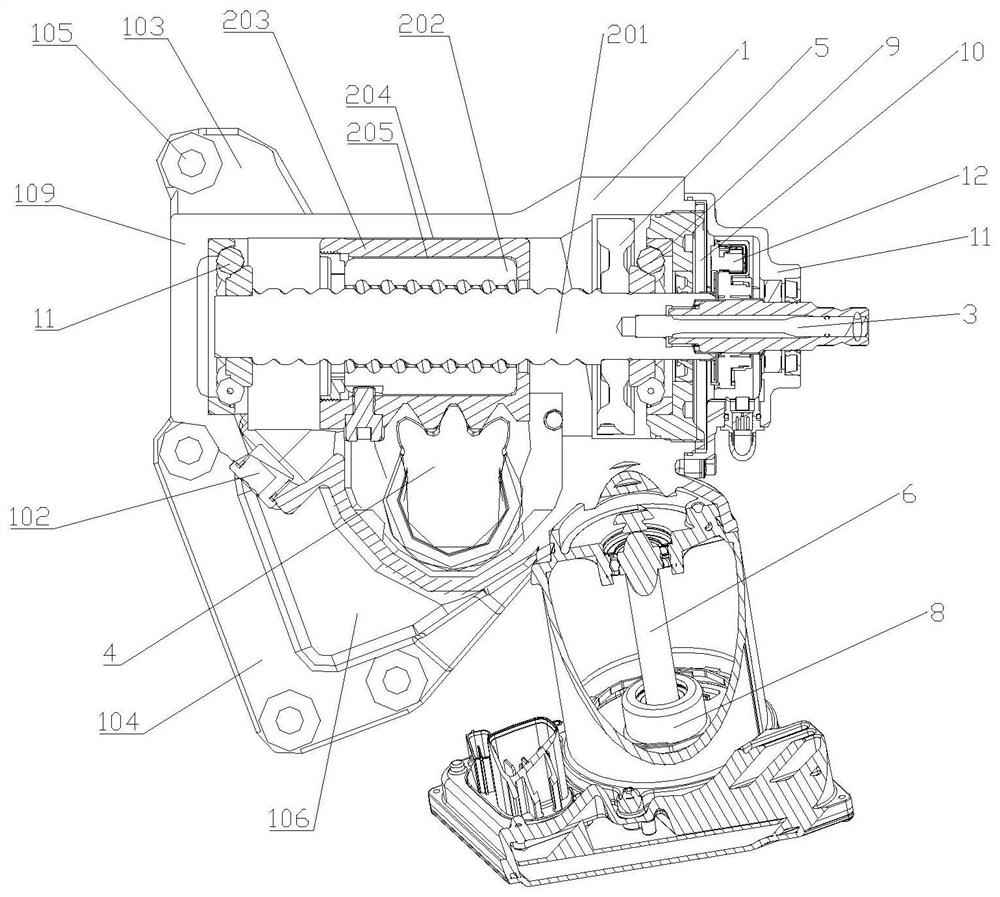

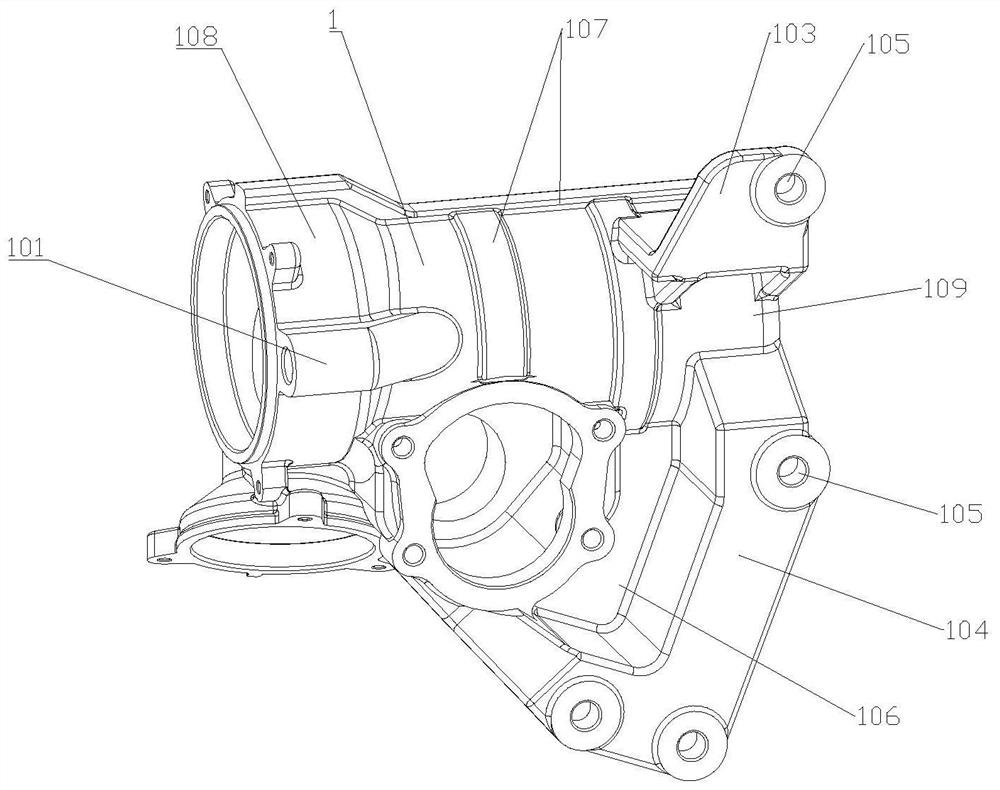

[0030] combined with Figure 1-5, the electric power steering device of this embodiment includes a housing 1, a nut and screw assembly 2, an input shaft 3, an output shaft 4, a worm wheel 5, a worm 6, a torque sensor 12 and a motor 8, wherein: the housing 1 is installed with a nut and screw assembly 2, one end of the nut and screw assembly 2 is installed inside the housing, and the other end of the nut and screw assembly 2 protrudes to the outside of the housing and is connected to the input shaft 3; the input shaft 3 is used to connect the steering wheel; the output shaft 4 is installed in the housing 1 along the direction perpendicular to the nut and screw assembly 2; the worm wheel 5 is sleeved on the nut and screw assembly 2 One end connected to the input shaft 3, and the worm gear 5 is located in the housing; the worm 6 is installed obliquely inside the housing 1, one end of the worm 6 meshes with the worm gear 5, and the other end is connected with the motor 8; the torqu...

Embodiment 2

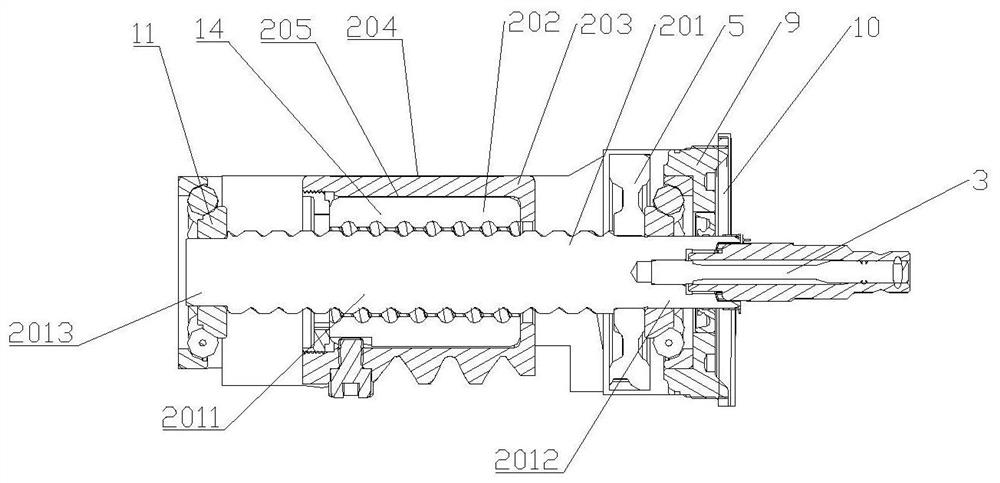

[0032] combined with Figure 1-5 , the electric power steering device of this embodiment, compared with the technical solution of Embodiment 1, can be improved as follows: the nut and screw assembly 2 includes a screw 201, a steering nut 203 and a screw nut 202, the screw The rod nut 202 is looped on the screw rod 201, the steering nut 203 is sleeved on the outer periphery of the screw nut 202, the steering nut 203 is engaged with the output shaft 4, and there is a first shaft between the housing 1 and the steering nut 203 A gap 204, there is a second gap 205 between the steering nut 203 and the screw nut 202, the width of the first gap 204 and the width of the second gap 205 are perpendicular to the axial direction of the steering nut 203, the The width of the first slit 204 is smaller than the width of the second slit 205 . The output shaft 4 exerts a reverse radial force on the steering nut 203, and the radial force pushes the steering nut 203 to move in the radial directi...

Embodiment 3

[0034] combined with Figure 1-5 , the electric power steering device of this embodiment, compared with the technical solution of Embodiment 1 or 2, can be improved as follows: the screw rod 201 includes a screw segment 2011 and a first smooth segment 2012 arranged at one end of the screw segment 2011, so The first smooth section 2012 is sleeved with a first bearing 9 and a worm wheel 5, one end of the worm wheel 5 cooperates with the first bearing 9, and the other end of the worm wheel 5 abuts against the screw section 2011 and the first smooth section 2012 at the connected shoulders. One end of the worm gear 5 cooperates with the first bearing 9, and the other end abuts against the shaft shoulder connected between the screw segment 2011 and the first smooth segment 2012, so that the worm gear 5 is fixed between the first bearing 9 and the screw segment 2011, when When the worm gear 5 meshes with the worm screw 6, the worm gear 5 is not easy to slip and has greater transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com