Fixing device used for machining long-cylinder thin-walled parts

A technology for fixing devices and thin-walled parts, used in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problem that the accuracy of the outer circle and inner hole at both ends of the part cannot be guaranteed, increase the processing cost of the part, and the radial deformation of the part. It can reduce the deformation of parts, save manufacturing costs, and improve the qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

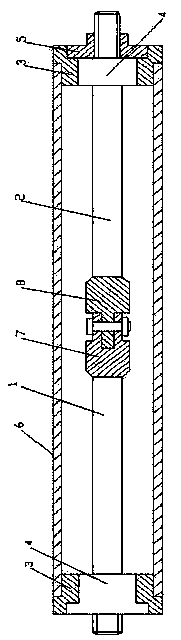

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] refer to figure 1 , is a fixing device for the processing of long-tube thin-walled parts, including a tie rod I1, a tie rod II2 and a positioning block 3. Both ends of the tie rod I1 and the tie rod II2 are provided with threads, and the threaded ends of the tie rod I1 and the tie rod II2 are Both are equipped with connectors 4, the connectors 4 are threadedly connected to the pull rod I1 and the pull rod II2, the positioning blocks 3 are respectively arranged on the connectors 4 of the pull rod I1 and the pull rod II2, and the connectors of the pull rod II2 4 The right end is provided with a fixed screw sleeve 5, and the said pull rod I1 and the pull rod II2 are fixedly connected.

[0012] One end of the pull rod I1 is provided with a fork joint 7, and one end of the pull rod II2 is provided with a flat joint 8, and the fork joint 7 and the flat joint 8 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com