Slay direct connection type pneumatic trimming device

A direct connection and sley technology, applied in the direction of textile, textile, papermaking, loom, etc., can solve the problems of inaccurate control, increased weaving cost, low efficiency, etc., to avoid radial force, prolong service life, The effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

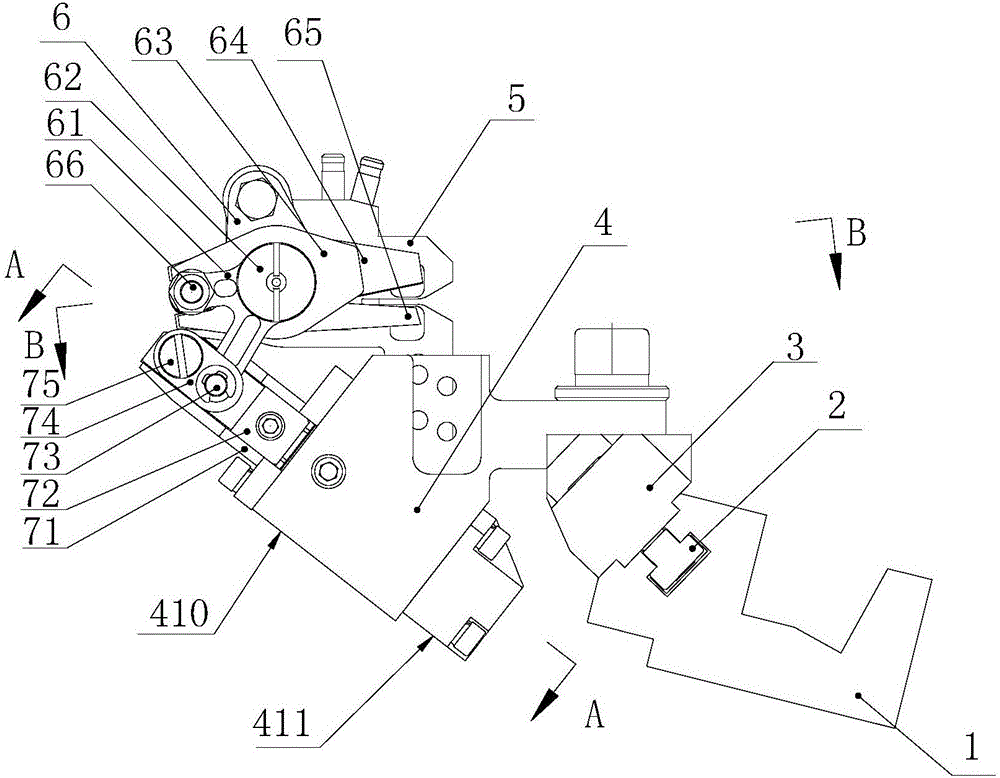

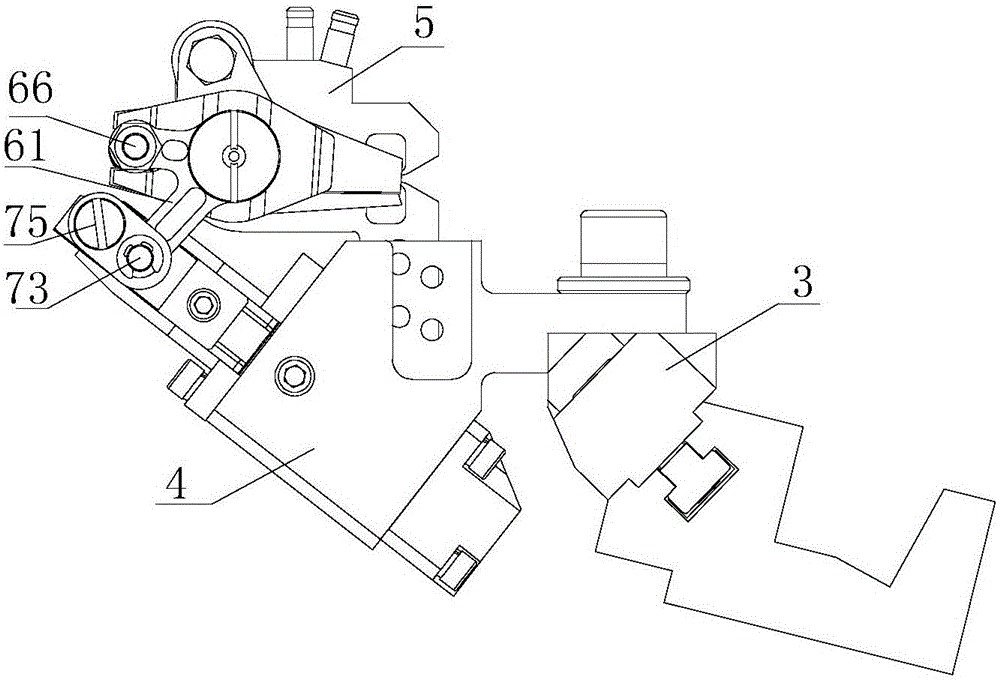

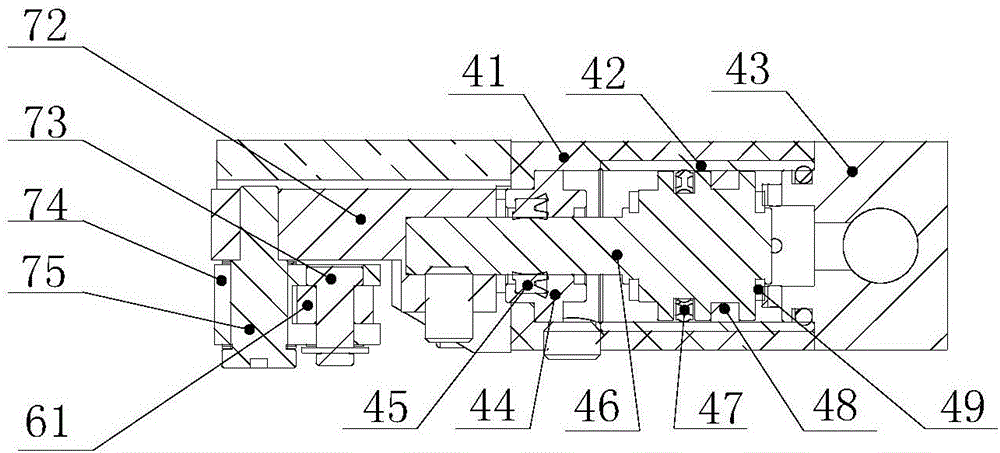

[0030] Such as Figure 1 to Figure 4 As shown, a sley direct-connected pneumatic smoothing device includes a beating sley 1, a cylinder 4, a pneumatic hemming device 5, and a weft scissors mechanism 6. The cylinder 4 is connected to the beating sley 1, and the pneumatic folding Side device 5 is installed on the cylinder 4, and weft yarn scissors mechanism 6 is arranged on the pneumatic hemming device 5, and described cylinder 4, pneumatic hemming device 5 and weft yarn scissors mechanism 6 swing together with beat-up sley 1.

[0031] The sley direct connection type pneumatic smoothing device also includes a cylinder positioning seat 3, the cylinder 4 is installed on the cylinder positioning seat 3, the cylinder positioning seat 3 is installed on the beating sley 1, and the cylinder 4 is mounted on the cylinder positioning seat 3. The installation position on the cylinder is adjustable, and the cylinder positioning seat 3 is provided with a long hole 9 for installing the cylind...

Embodiment 2

[0040] Such as Figure 5 As shown, the structure and principle of this embodiment and Embodiment 1 are basically the same, the only difference lies in the structural composition of the scissors driving mechanism, the scissors driving mechanism in this embodiment includes a second guide seat 81, a second driving slider 82 and the third pin shaft 83, the second guide seat 81 is connected with the cylinder 4, the second drive slider 82 is connected with the piston rod 46 of the cylinder 4, and the second guide seat 81 is provided with a Adapted second guide groove, the second drive slider 82 is driven by the piston rod 46 to do linear reciprocating motion along the second guide groove; the scissors driving mechanism also includes a roller 84, and the second drive slider 82 is provided with The third guide groove that is compatible with the roller 84, the roller 84 is hinged with the scissors rocker arm 61 through the third pin shaft 83, when the second drive slider 82 does recipr...

Embodiment 3

[0042] The structure and principle of this embodiment and the second embodiment are basically the same, the only difference is: the roller 84 is replaced by the third driving slider, at this time, the third guide groove is matched with the third driving slider, and the third driving slider The three driving sliders are hinged with the scissors rocker arm 61 through the third pin shaft 83. When the second driving slider 82 is doing reciprocating linear motion, when the side wall of the third guide groove touches the third driving slider, it will drive the third driving slider. The three drive sliders slide, thereby driving the rocker arm 61 of the scissors to swing, and driving the moving piece of the scissors 64 to rotate around the eccentric pin shaft 66, so as to realize the opening and closing of the moving and static pieces of the scissors.

[0043] The working principles of the second embodiment and the third embodiment are roughly: when the beating sley 1 of the loom swin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com