Converter tapping hole sliding gate slag-stopping process

A sliding nozzle technology for slag blocking and tapping, which is used in the improvement of process efficiency, manufacturing converters, etc., can solve the problems of uncontrollable, low automation, low success rate of slag blocking, etc. Reduce processing cost, good slag blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

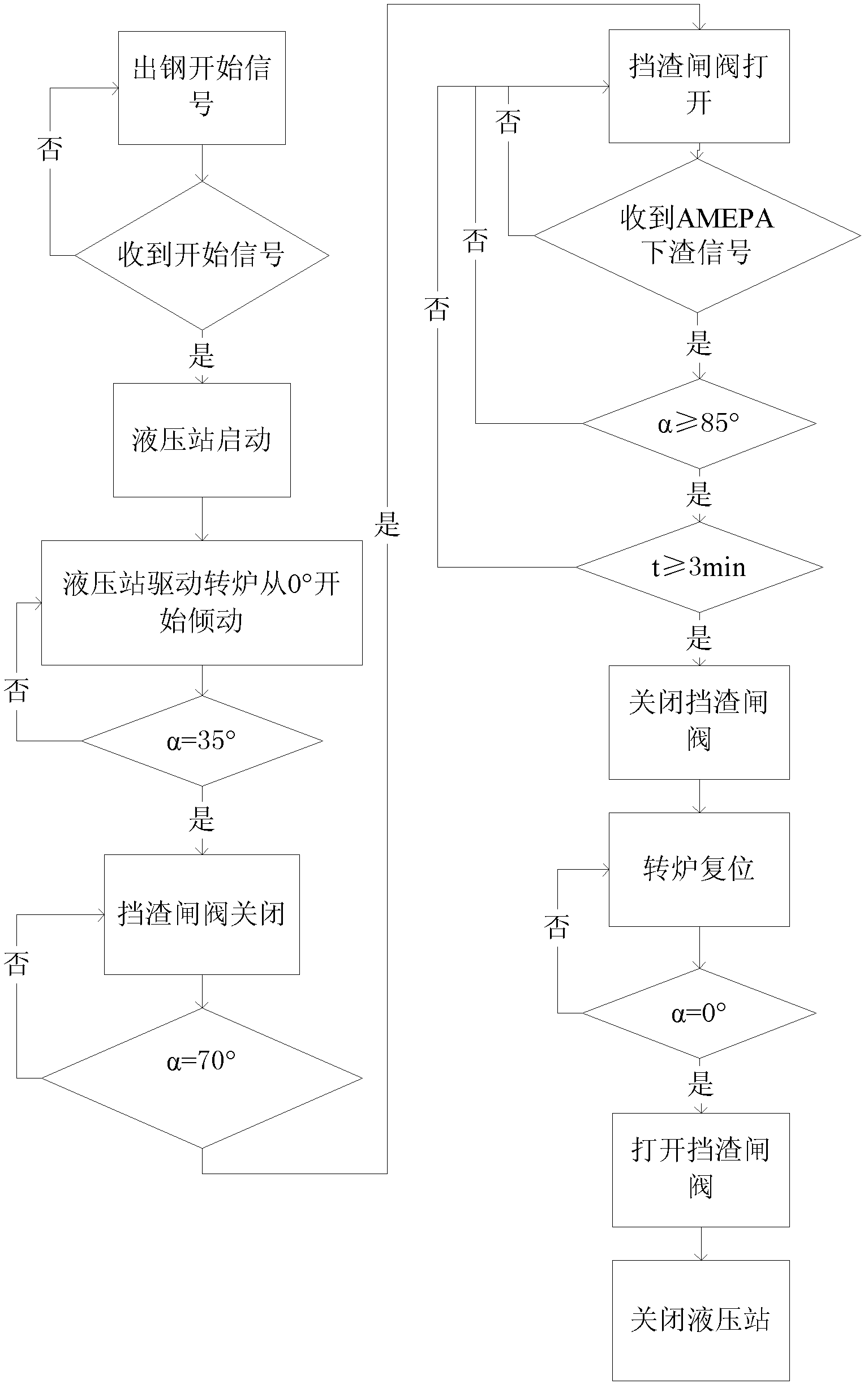

[0036] The slag retaining process of the present invention will be further described in detail below in conjunction with the drawings and specific embodiments of the specification.

[0037] figure 1 The step flow of the slag blocking process of the present invention in this embodiment is shown. Such as figure 1 As shown, the slag blocking process steps of the present invention are as follows ( figure 1 Among them, α is the tilting angle of the converter, t is the tapping time, and AMEPA is the infrared slag detection system. ):

[0038] (1) After the PLC receives the converter tapping start signal, it sends the hydraulic station start instruction to the hydraulic station;

[0039] (2) The converter starts to tilt from the starting position where the converter tilt angle is 0 degrees to tap steel into the ladle, and the tilt angle signal is sent to the PLC in real time. When the converter tilt angle reaches 35 degrees (the preset first critical value) ), PLC controls the hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com