Automatic tapping control system of inverted pouring station

A control system and the technology of the can dumping station, which is applied in the field of automatic tapping control system of the can dumping station, can solve the problems of reducing tapping efficiency, increasing labor intensity of workers, and lack of interlock protection, so as to increase safety and improve tapping Efficiency, the effect of solving the labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical solutions and advantages of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

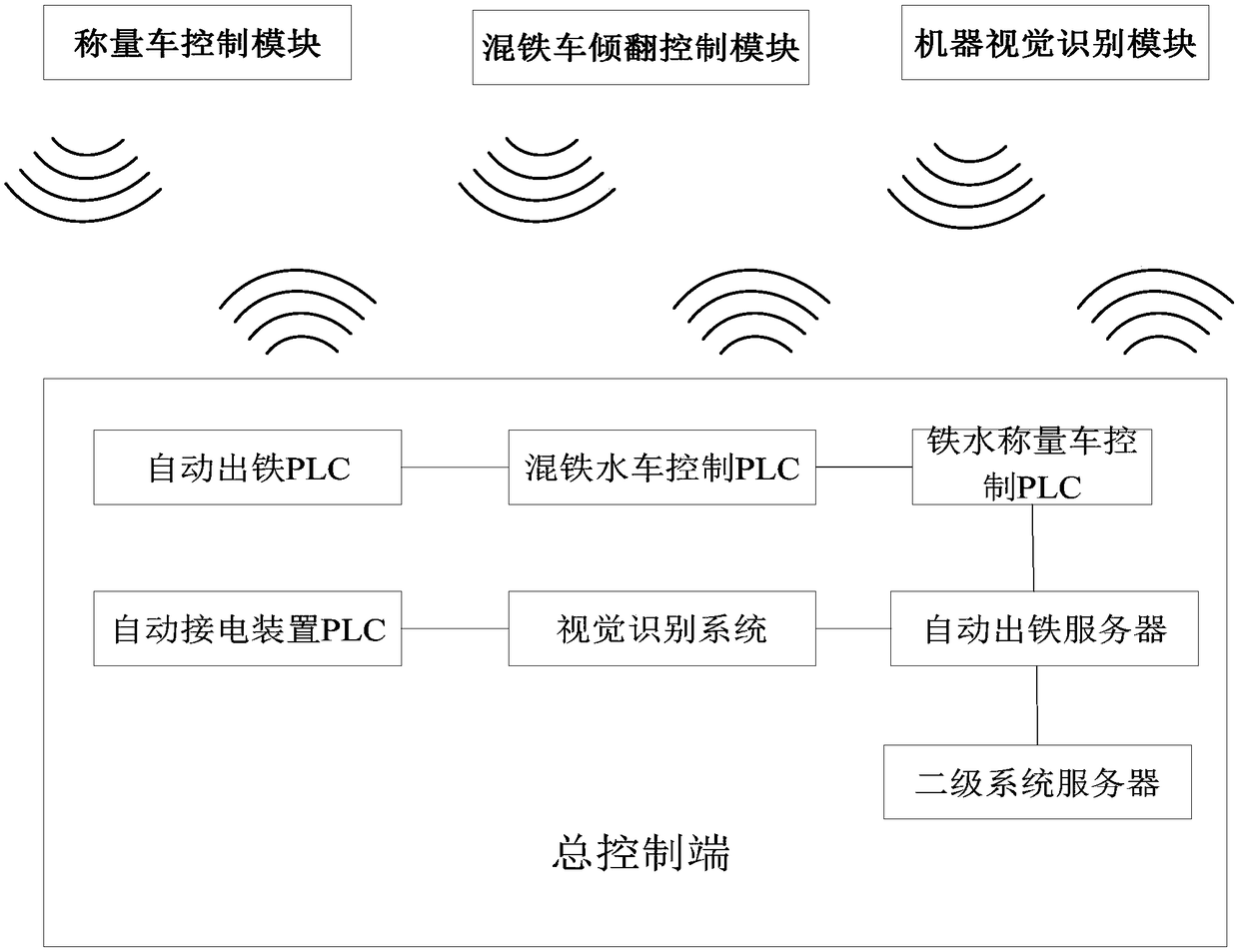

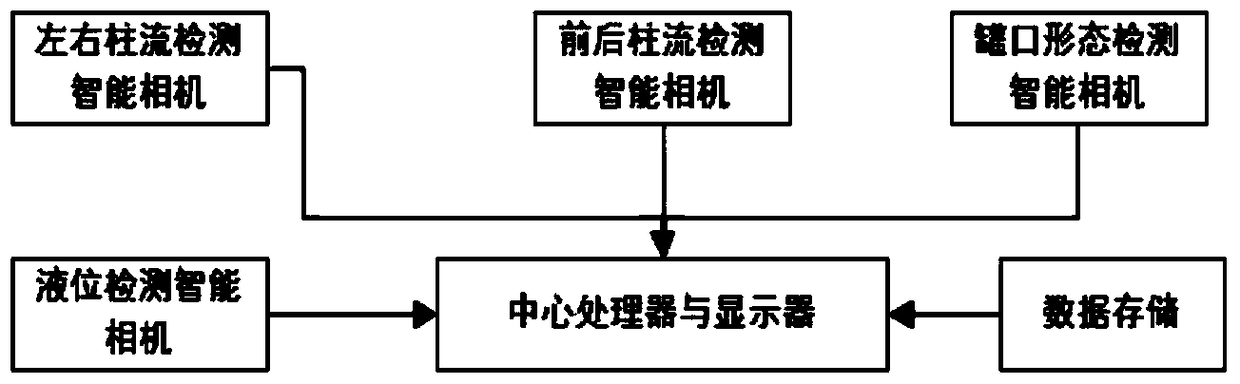

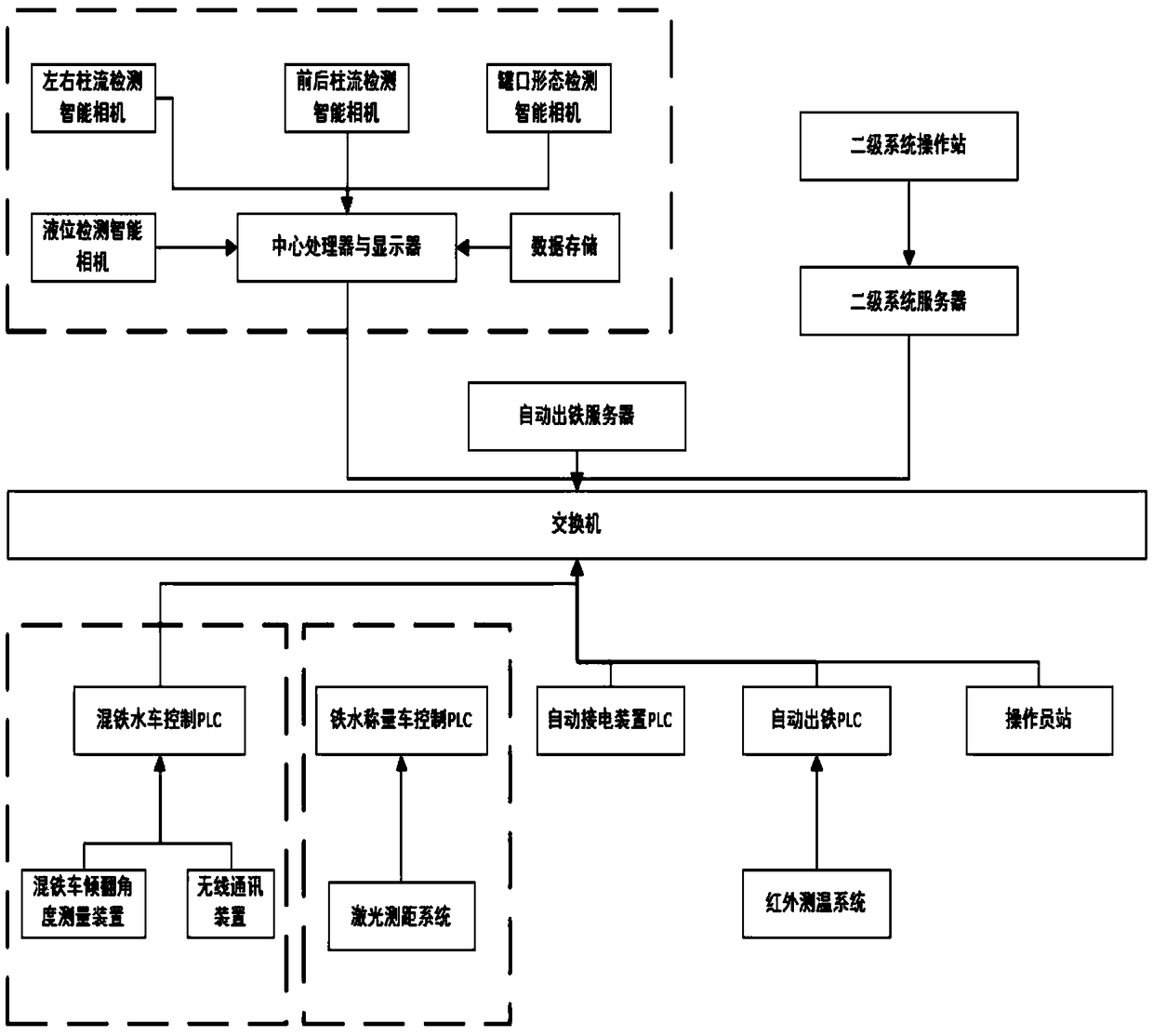

[0022] Such as Figure 1-Figure 3 The automatic tapping control system of the can dumping station is shown. This system automatically analyzes the shape of the tank mouth, automatically detects and analyzes the molten iron column flow, and automatically measures the liquid level and temperature of the molten iron through visual recognition technology, so as to complete the automatic tipping of the mixed iron water truck. and the automatic weighing of the molten iron weighing vehicle; the real-time detection of the position of the molten iron weighing vehicle through laser positioning technology, so that the automatic operation of the complete weighing molten iron weighing vehicle; the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com