Automatic vertical numerically-controlled wire taping machine

A technology of wrapping machine and wire, applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of cumbersome work, affecting the efficiency of wrapping, wasting manpower, etc., to improve the efficiency of wrapping, reduce labor intensity, Reduce manual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings.

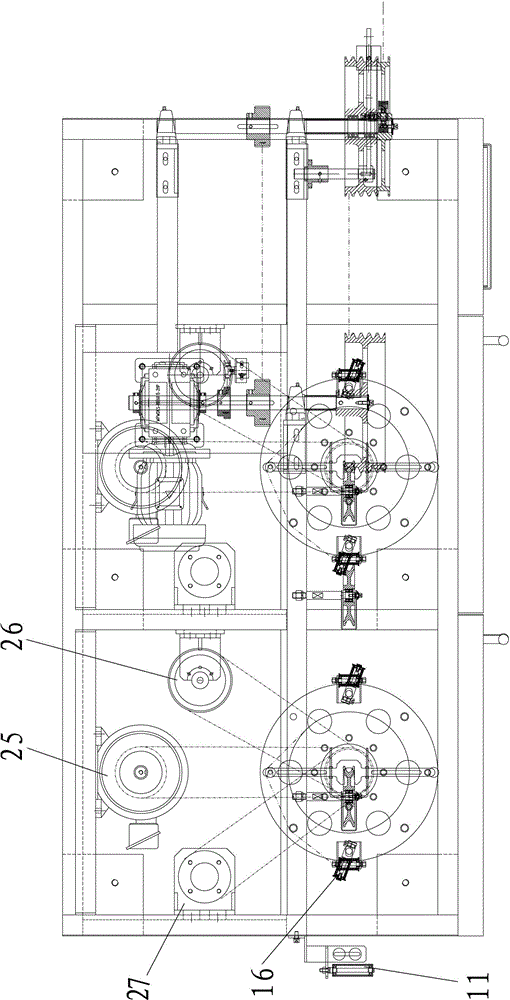

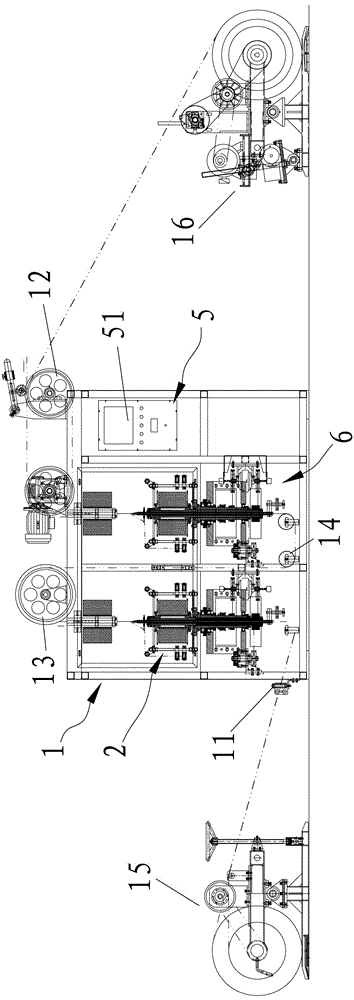

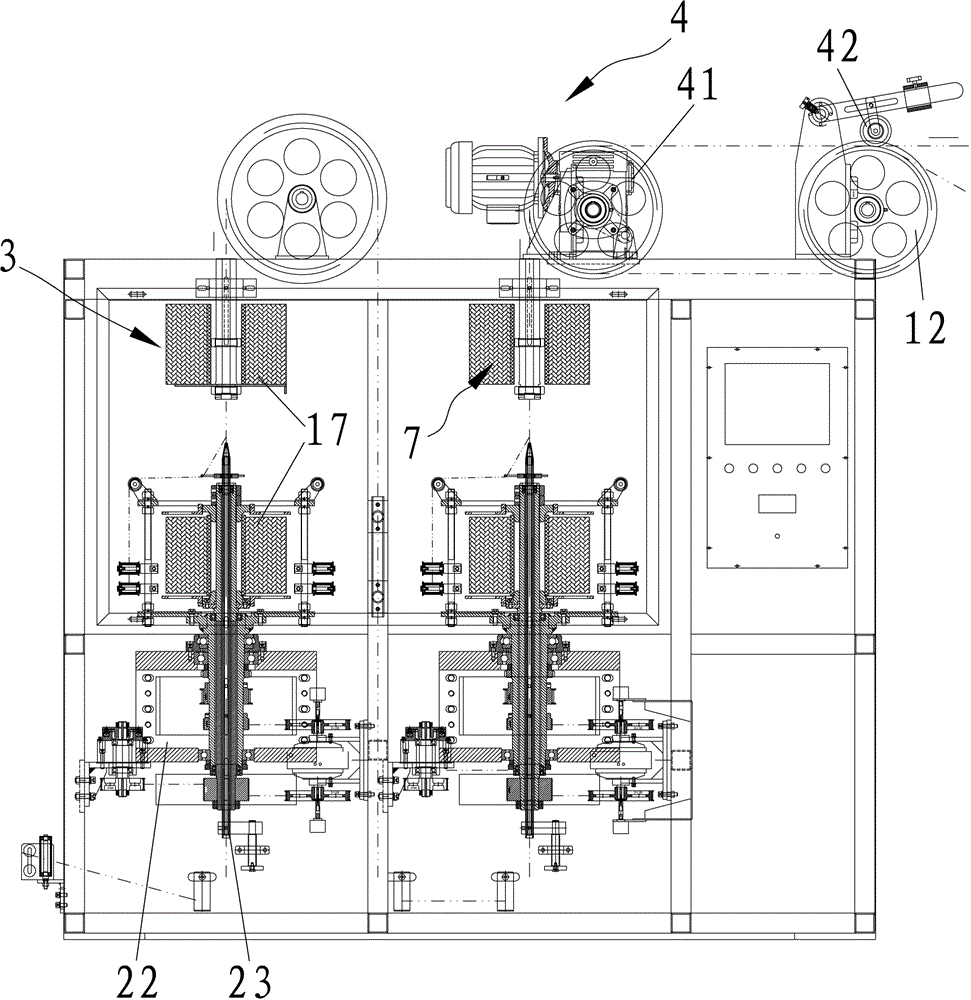

[0037] see Figure 1 to Figure 6 , an automatic vertical numerically controlled wire taping machine, comprising a frame 1, the frame 1 is sequentially provided with a wire feed roller group 11, a first taping rotation device 2, a first tape storage mechanism 3, The wire lead mechanism 4 and the outlet wheel 12, the first wrapping rotating device 2 is provided with an accommodating cavity 211 for accommodating the tape roll 17, and the accommodating cavity 211 is provided with an upper end cover 212 that is detachably connected. A tape storage mechanism 3 is provided with a limiting assembly 32 for limiting the downward movement of the storage tape volume 17; the frame 1 is also provided with a control device 5 for controlling the lead wire mechanism 4 and the first wrapping rotating device 2; this wrapping machine The working principle is: when wrapping the wire for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com