Clamping mechanism for double end threading machine

A technology of clamping mechanism and tapping machine, which is applied in the direction of clamping, thread cutting machine, metal processing machinery parts, etc., can solve the problems of difficult to achieve machining accuracy, poor safety, easy deviation, etc., and achieve quality and consistency assurance , Stable and safe work, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

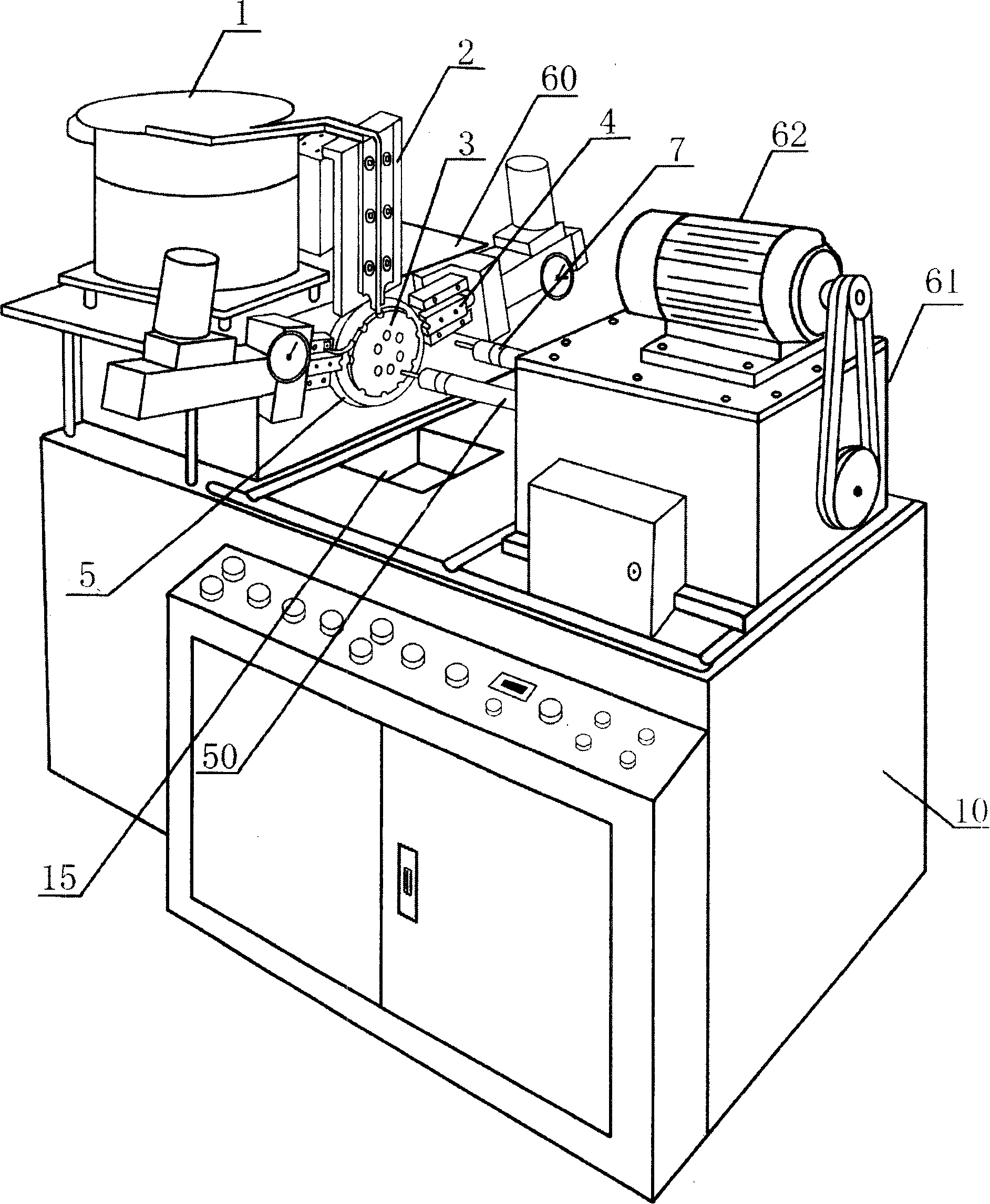

[0026] Embodiment 1: refer to attached figure 1 , the double-head tapping machine includes a fuselage (10), a vibrating feeding device (1) equipped with a workpiece (52) to be processed, a linear chute (2) for guiding materials, and is installed on a workbench (60). The workpiece clamping mechanism and the feed box (61) that control two tapping main shafts (50) horizontally feed, and the front end of the tapping main shaft (50) is provided with a tapping device (7). The clamping mechanism is installed on one side of the workbench (60), opposite to the feed box (61) and the motor (62) thereon, and the tapping on the tapping spindle (50) in the feed box (61) The device corresponds to the two processing positions on the chuck (3). The positioning mechanism is located at the rear of the chuck (3) and below the workbench (60).

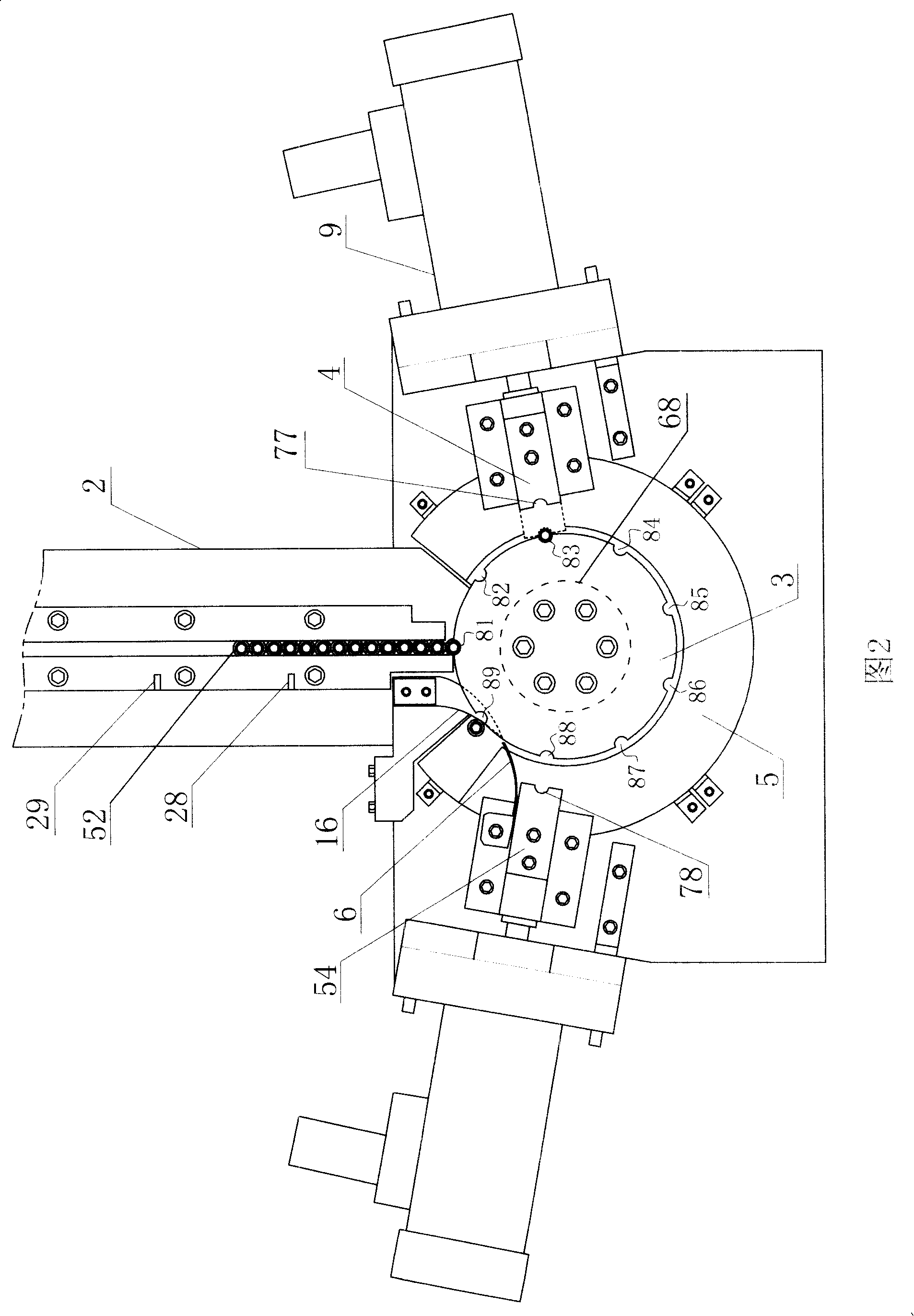

[0027] Refer to accompanying drawing 2, attached image 3 , the rotatable chuck (3) with a semi-circular arc clamping position is connected to the rotat...

Embodiment 2

[0034] Embodiment 2: The clamping positions on the chuck (3) are "V" type, and the number is 11, which are evenly arranged on its outer circumference. The opening grooves on the first clamp (4) and the second clamp (54) ( 77) is also a "V" type, corresponding to the card position. The angle that the chuck (3) rotates each time is 360°÷11×2. The included angles between the first clamp (4) and the second clamp (54) and the horizontal plane are 90°-(360°÷11×2), which are used to control the positioning wheel (11) in the positioning mechanism of the chuck (3) The number of cards on the card is also 11. Others can refer to embodiment 1, which is the same as embodiment 1.

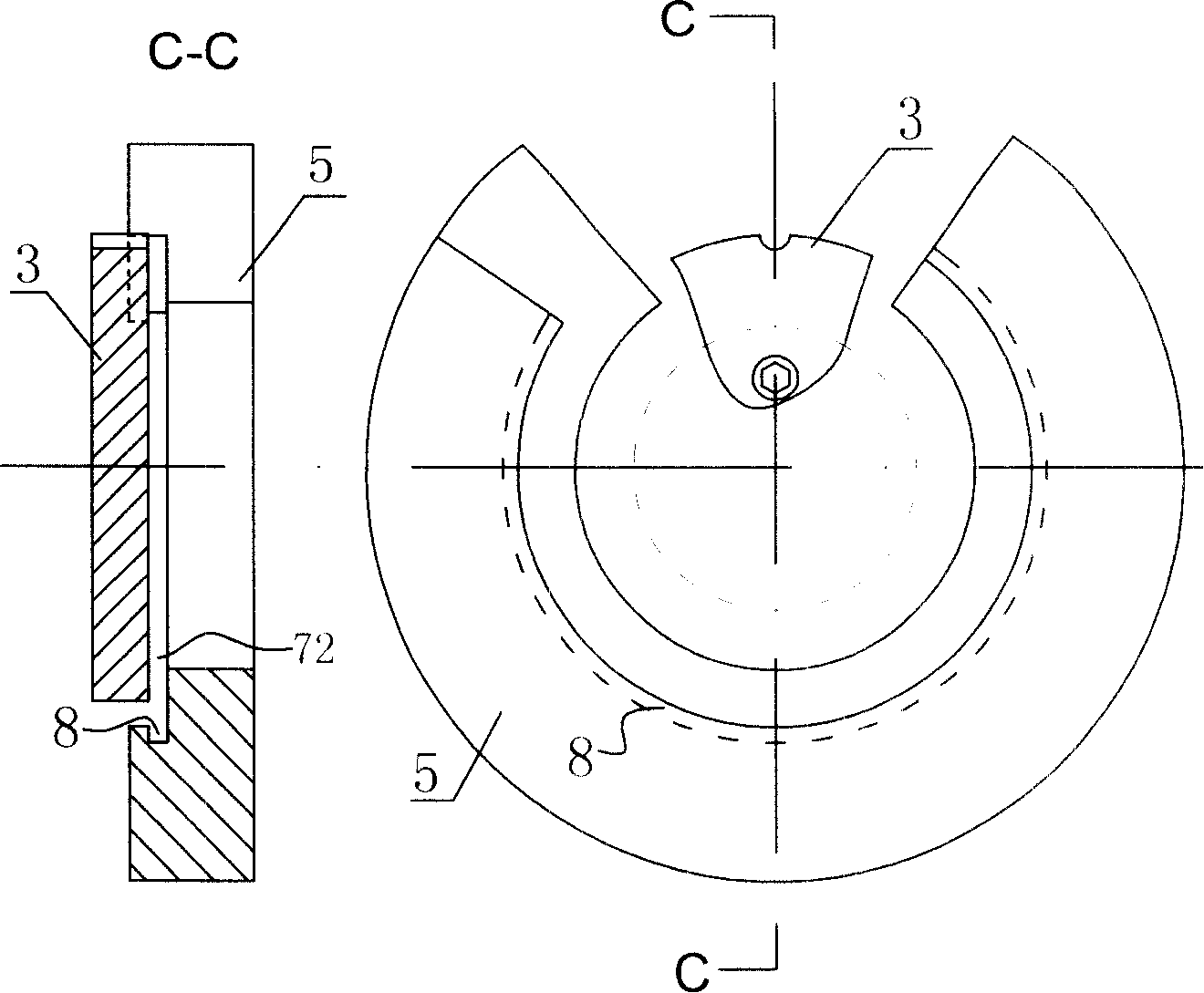

[0035] The open groove (77) on the clamp among the present invention and the clamping position on the chuck (3) can have several different matching modes, as Figure 4 Shown: a, the clamping position on the chuck (3) is a semicircular arc groove, and the opening groove (77) is also a semicircular arc groove; b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com