Metal injection molding product and manufacturing method thereof

A manufacturing method and technology of molded products, which are applied in the directions of threaded fasteners, connecting members, nuts, etc., can solve the problems of difficult metal injection molding, cost increase, positioning, etc., so as to reduce the cost of tapping, avoid tapping breakage, The effect of improving tapping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

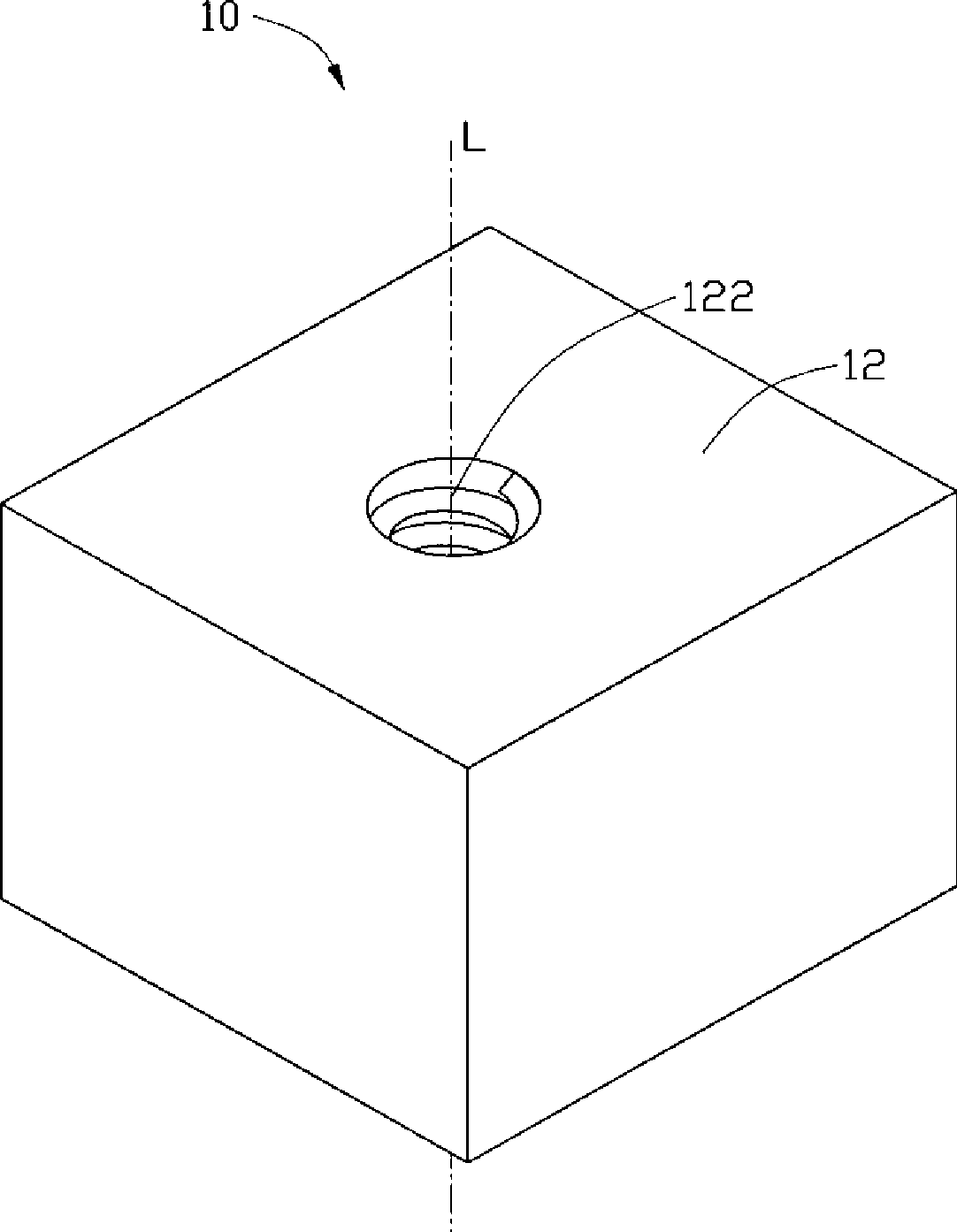

[0020] The tapping method of the metal injection molded product in the preferred embodiment of the present invention is described by taking the tapping of the metal injection molded product 10 as an example. see figure 1 , the metal injection molded product 10 includes a base body 12, the base body 12 along figure 1 The L line needs to tap a first threaded hole 122. The base 12 is made of metal material, such as stainless steel SUS17-4H.

[0021] The manufacturing method of the metal injection molded product 10 mainly includes the following steps:

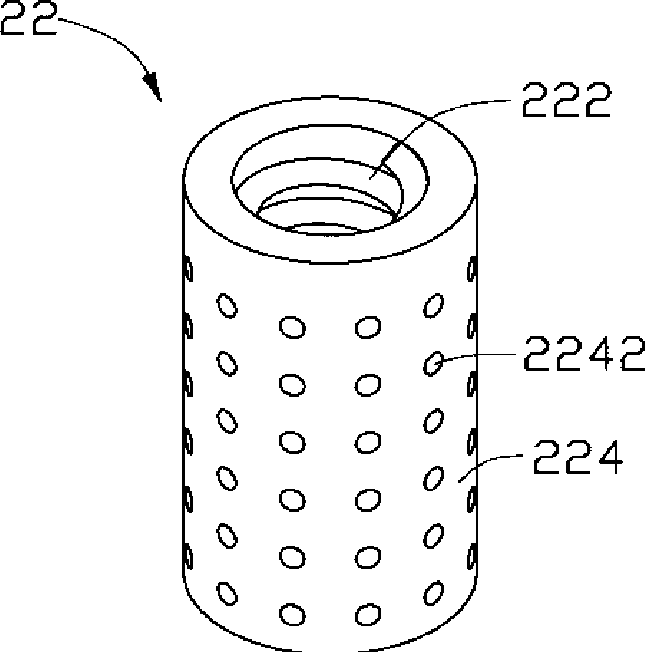

[0022] see figure 2 , provide a stud 22, the stud is a hollow cylinder, its specific shape can be different according to actual needs, such as square cylinder, circular cylinder or rhombus cylinder, the present embodiment is a cylinder, the screw A second threaded hole 222 is provided in the column 22, the shape and size of the second threaded hole 222 are equivalent to the shape and size of the first threaded hole 12 to be ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com