Ramming material for blast-furnace tapping channel and preparation method thereof

A blast furnace tapping and ramming material technology, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of shortened service life of tapping channel materials, difficulty in re-dissolving adhering slag, repeated trench repairs, etc. Achieving high tapping efficiency, improving corrosion resistance, and solving the problem of sticky slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

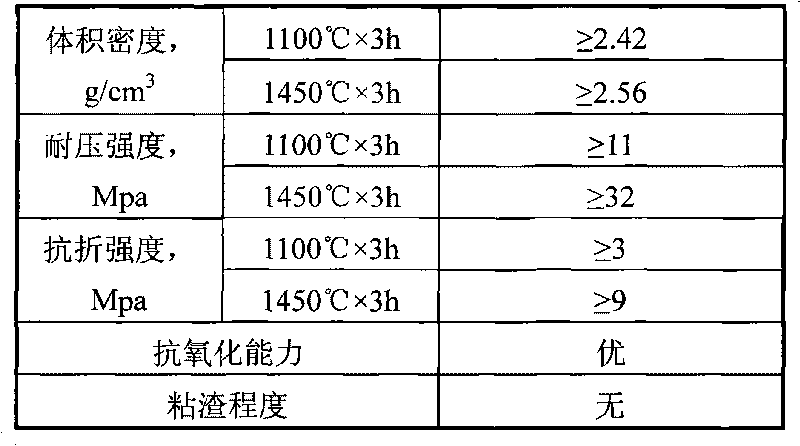

Examples

Embodiment 1

[0016] A ramming material for a blast furnace tapping trough and a preparation method thereof. First, 15-25wt% brown corundum, 40-60wt% super alumina, 5-6wt% soft clay, 10-15wt% silicon carbide, 3-5wt% high-temperature pitch, 3-5wt% Si Powder, 2-3wt% of alumina micropowder and 1-5wt% of titanium-containing blast furnace slag are mixed, plus 4-7wt% of the above-mentioned mixture of thermosetting phenolic resin, mixed and milled for 5-10 minutes, stirred evenly, and packaged for use.

Embodiment 2

[0018] A ramming material for a blast furnace tapping trough and a preparation method thereof. First, 1-15wt% brown corundum, 55-65wt% super alumina, 4-5wt% soft clay, 5-10wt% silicon carbide, 4-5wt% high-temperature pitch, 5-6wt% Si Powder, 3-4wt% alumina micropowder and 5-10wt% titanium-containing blast furnace slag are mixed, plus 4-7wt% thermosetting phenolic resin of the above-mentioned mixture, mixed and milled for 5-10 minutes, stirred evenly, and packaged for use.

Embodiment 3

[0020] A ramming material for a blast furnace tapping trough and a preparation method thereof. First, 31-32wt% super-grade bauxite, 32-33wt% first-grade bauxite, 4-5wt% soft clay, 10-15wt% silicon carbide, 4-5wt% high-temperature asphalt, 4-6wt% Si powder, 2-4wt% alumina micropowder and 1-5wt% titanium-containing blast furnace slag are mixed, plus 4-7wt% thermosetting phenolic resin of the above-mentioned mixture, mixed and milled for 5-10 minutes, stirred evenly, and packaged for use .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com