Automatic rubber tapping machine profiling and cutting mechanism for rubber trees

A technology of cutting mechanism and profiling mechanism, which is applied in agriculture, forestry, application, etc., can solve problems such as failure to meet production requirements, failure to meet output requirements, shallow tapping depth, etc., to avoid damage to the trunk mechanism and improve work efficiency. Efficiency, the effect of meeting market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific structure and working process of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

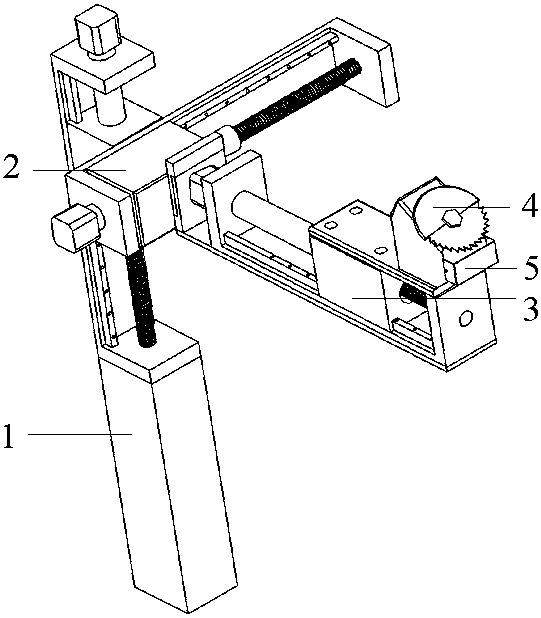

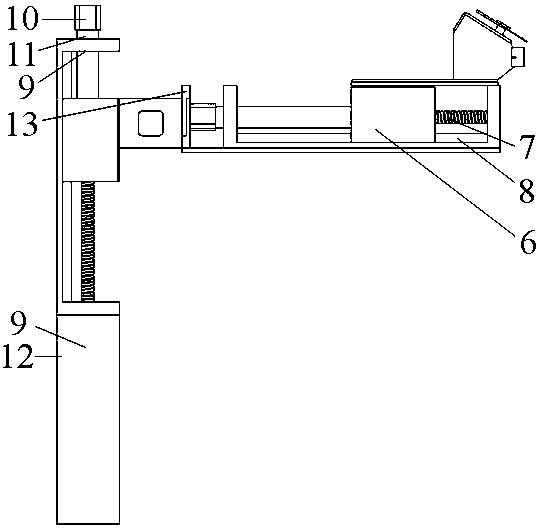

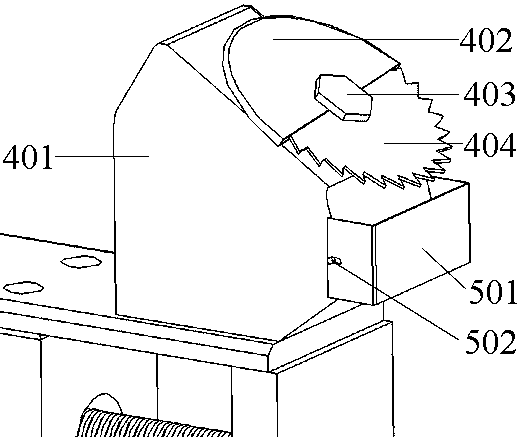

[0017] Such as figure 1 A schematic diagram of the three-dimensional structure of the profiling and cutting mechanism of an automatic rubber tapping machine for rubber trees, which is mainly composed of a profiling mechanism and a cutting mechanism. The profiling mechanism is composed of CNC three-axis slide table, that is, CNC slide table I1, CNC slide table II2, and CNC slide table III3. CNC sliding table I1 can control the movement in the up and down direction, CNC sliding table II2 can control the movement in the left and right direction, and CNC sliding table III3 can control the movement in the front and rear direction. CNC sliding table Ⅰ1 and CNC sliding table Ⅱ2 form a cross structure perpendicular to each other to realize the plane copying function; The three-axis slide table realizes the function of thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com