Automatic rubber cutting robot

An automatic cutting and robotic technology, applied in forestry, application, agriculture, etc., can solve problems such as difficulty in ensuring consistent cutting depth, complicated structure of the line feeder, unstable power supply of solar panels, etc., and achieve the effect of good promotion and use value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] combine figure 1 -7 The present invention is further described in detail.

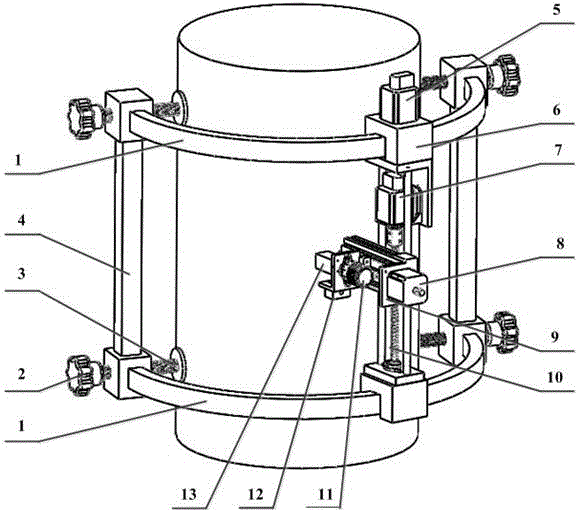

[0021] figure 1 It is the overall structure diagram of an automatic rubber cutting robot. The automatic rubber tapping robot consists of a clamping mechanism composed of a rotating block and a support rod, a depth adjustment mechanism composed of a graduated rotating disk and a movable positioning wheel, and a stepping motor. The power device is composed of the upper and lower circular tracks, the trolley drive mechanism and the cutting trajectory control mechanism composed of the screw nut mechanism.

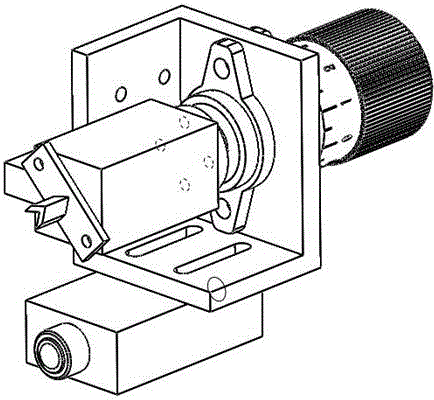

[0022] figure 2 It is a schematic diagram of the cutting depth adjustment mechanism, which is controlled by a stepping motor to realize the feeding and retracting actions. The rotating disk with scale is mainly used to manually control the cutting depth, and the positioning wheel is moved to adjust the cutting depth.

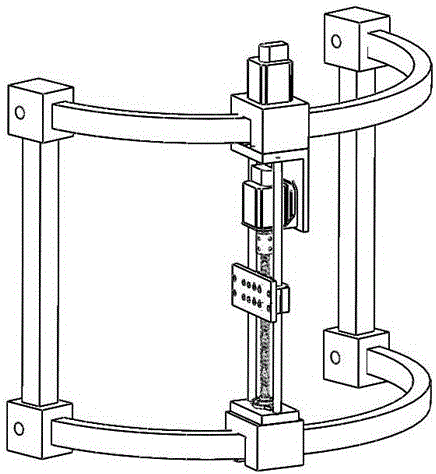

[0023] image 3 It is a schematic diagram of the cutting track control me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com