Rubber tapping machine and rubber tapping method

A rubber tapping machine and rubber tapping technology, applied in forestry, application, agriculture, etc., can solve the problems of thickness adjustment, laborious tapping, poor effect, etc., to achieve uniform cutting depth, improve practicability, and improve stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

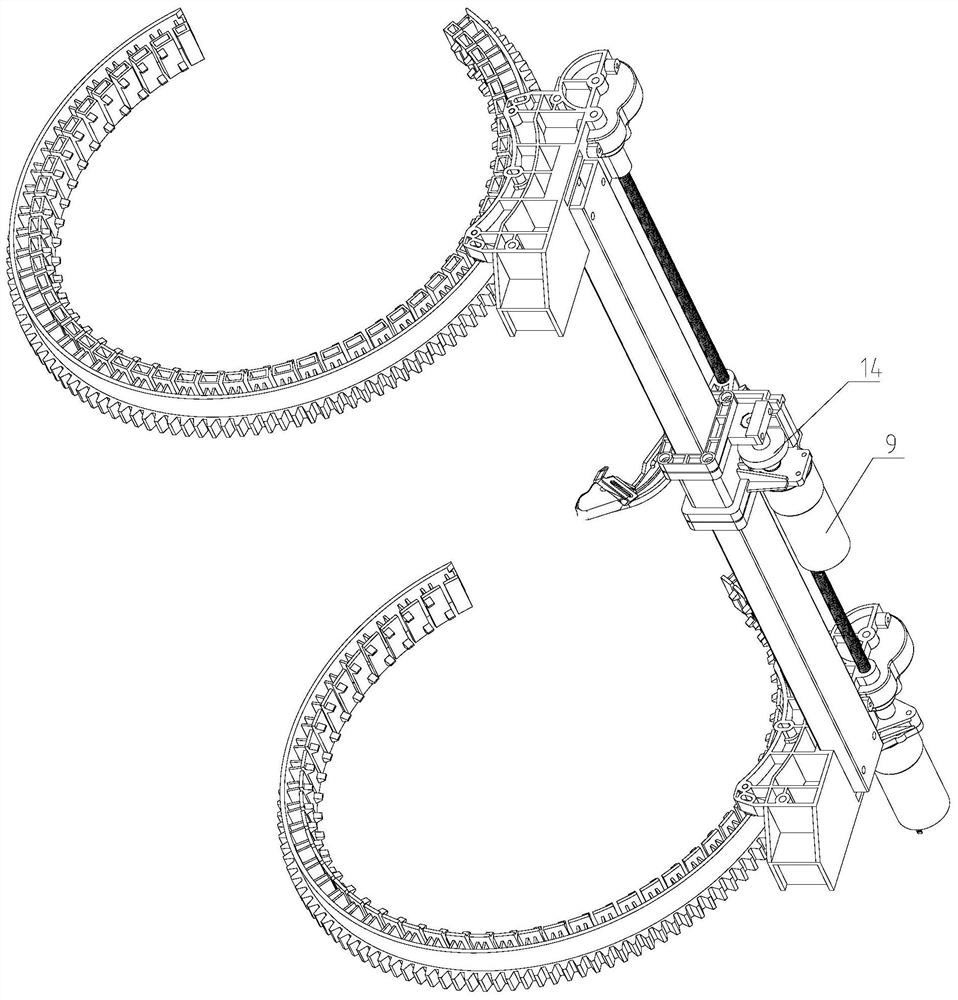

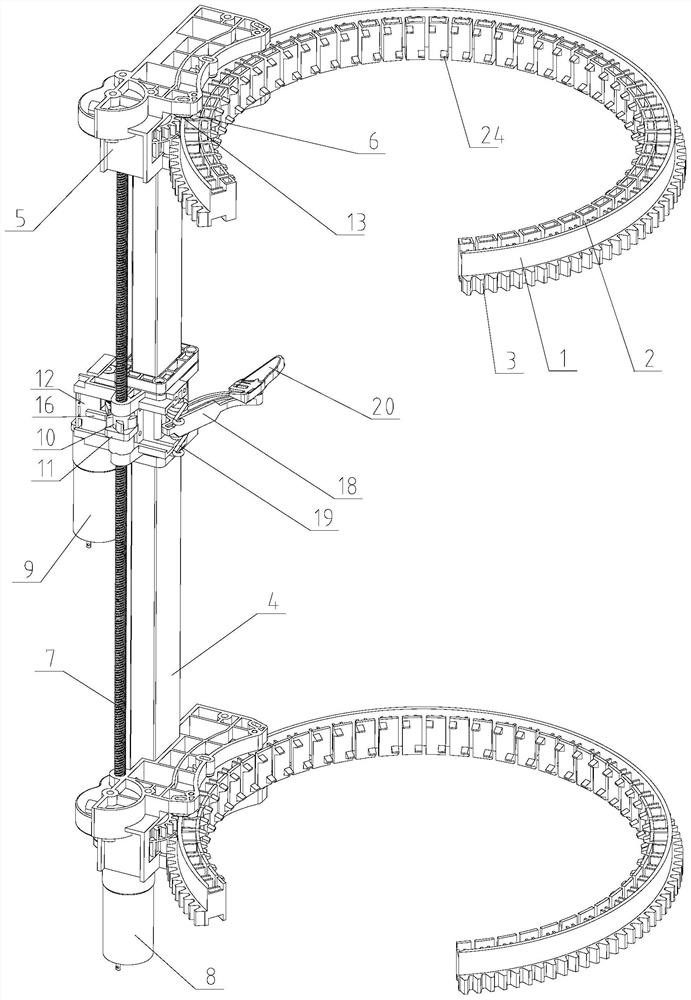

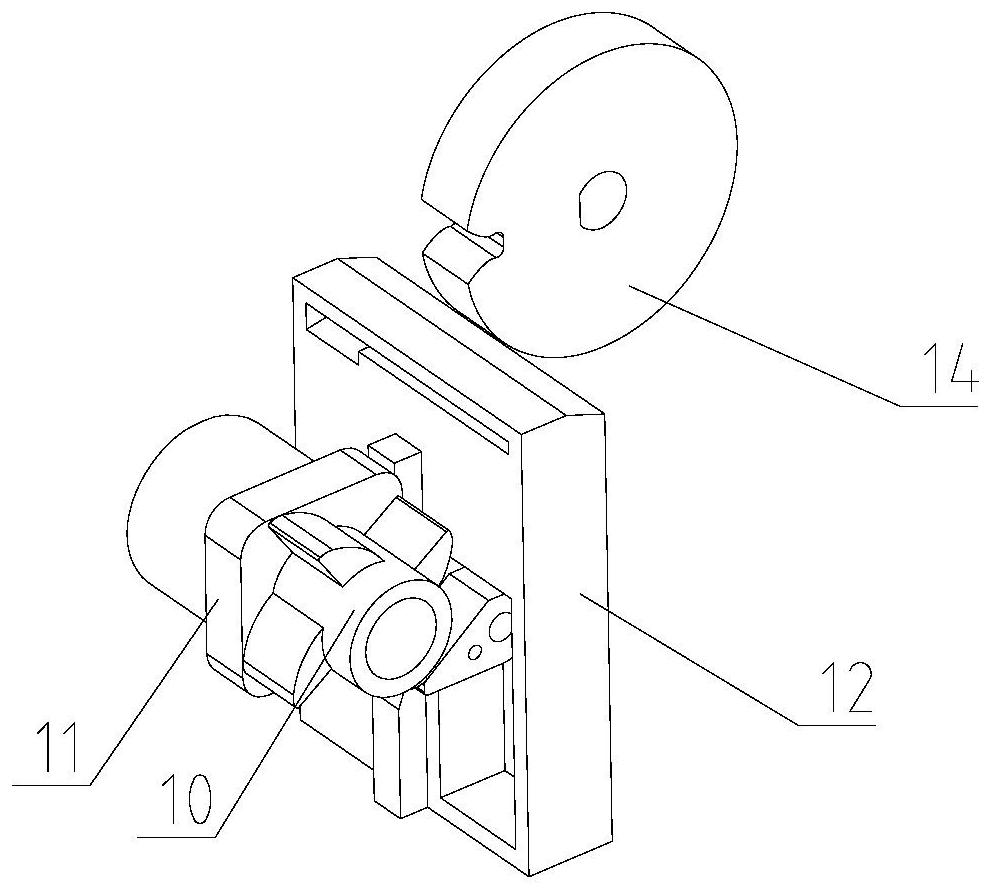

[0040] Example 1, such as figure 1, as shown in 2, this embodiment discloses a rubber tapping machine, the rubber tapping machine includes two deformable guide rails 1 up and down, a chute 2 is formed between the inner and outer walls of the deformable guide rails, and the outer wall of the deformable guide rail 1 is arranged outside Teeth 3; the rubber tapping machine also includes a longitudinal guide rail 4, the upper and lower guide rail frames 5 are respectively installed at the two ends of the longitudinal guide rail 4, inner grooves are arranged on the rail frame 5, and the upper and lower two deformable guide rails 1 are inserted into the upper and lower guide rails respectively In the inner groove of the frame 5, the gears in the guide rail frame 5 are meshed with the teeth 3 on the outer wall of the deformable guide rail, and the horizontal limit wheel 6 and the longitudinal limit slider 13 are respectively arranged on the upper and lower guide rail frames. The posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com