Automatic rubber tapping machine

A glue machine, automatic technology, applied in forestry, application, agriculture, etc., can solve the problems of increased work intensity, poor rubber tapping path accuracy, and large subjective influence of manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The core of the present invention is to provide an automatic rubber tapping machine, which is easy to operate, accurate and efficient, can effectively reduce the labor intensity of workers, and improve the precision and efficiency of tapping operations.

[0023] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

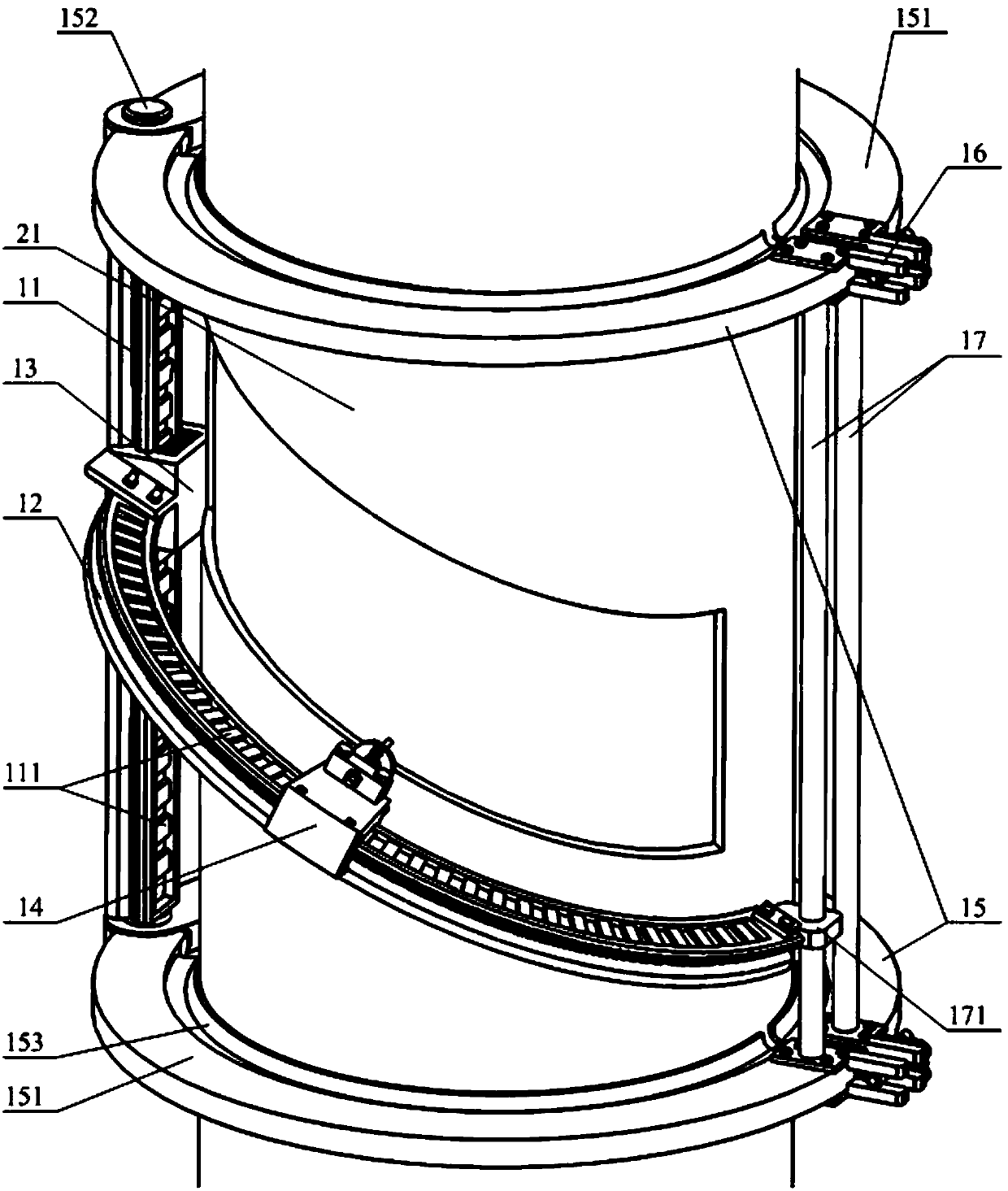

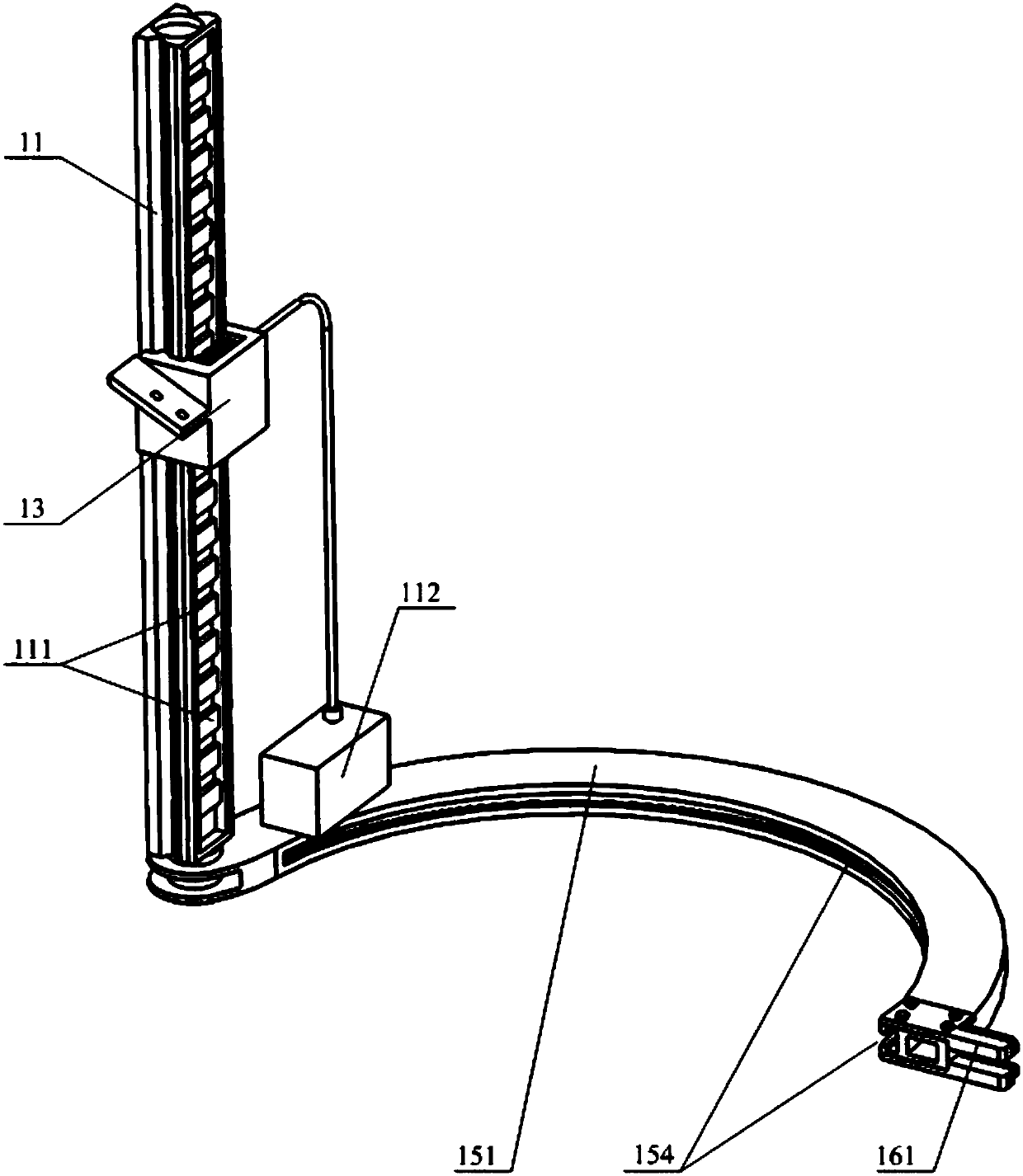

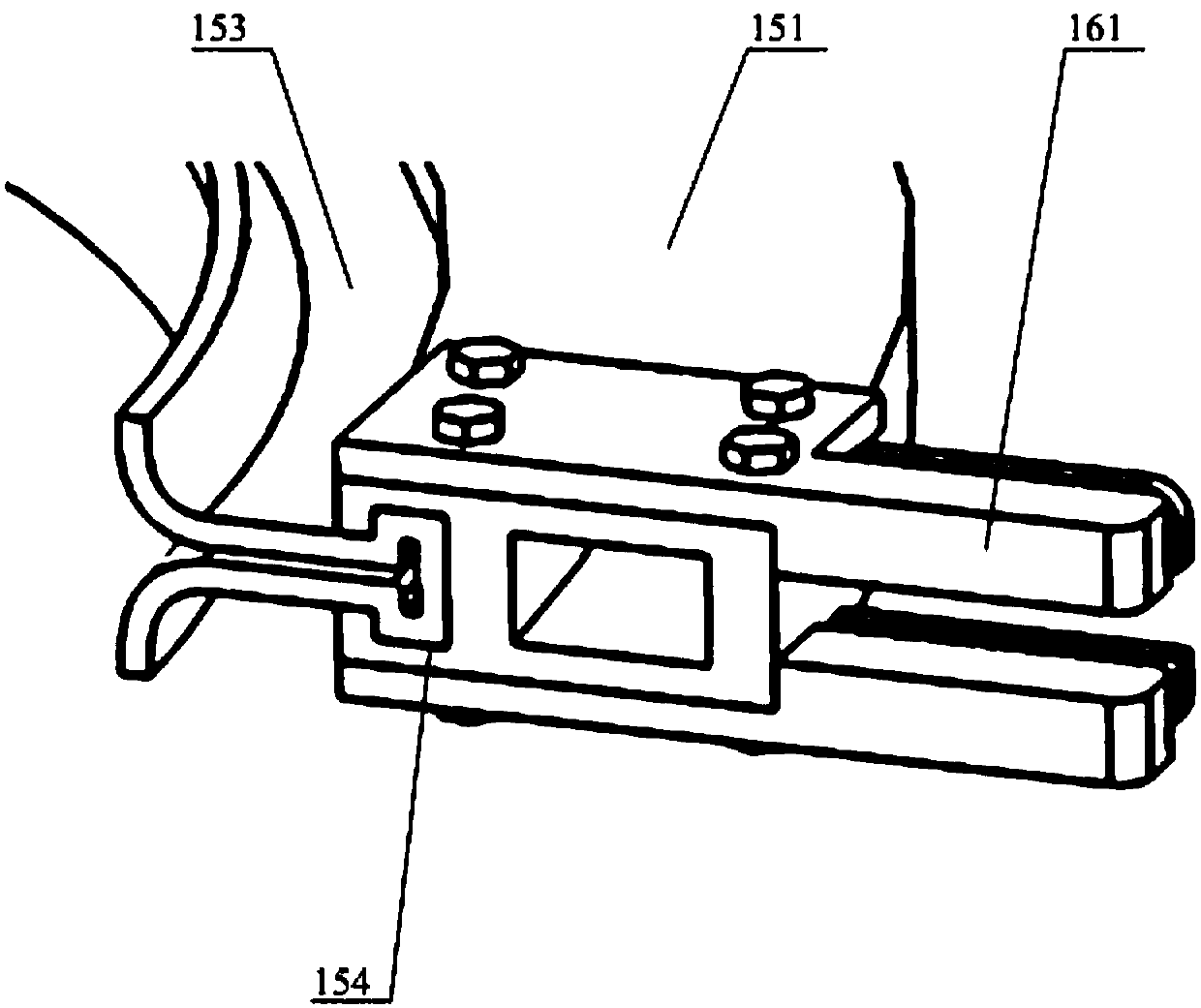

[0024] Please refer to figure 1 and figure 2 , figure 1 The structural front view of the automatic rubber tapping machine provided for a specific embodiment of the present invention; figure 2 for figure 1 top view.

[0025] In a specific embodiment, the automatic rubber tapping machine provided by the present invention includes a detachable support adapted to the trunk 21, and the support is provided with a longitudinal track 11 extending in the vertical direction and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com