Cutting mechanism and method for collecting natural rubber at high position

A cutting mechanism and technology of natural rubber, applied in application, forestry, agriculture, etc., can solve the problems of not being able to collect rubber, and achieve the effects of ensuring a healthy state, improving rubber production efficiency, and increasing growth efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

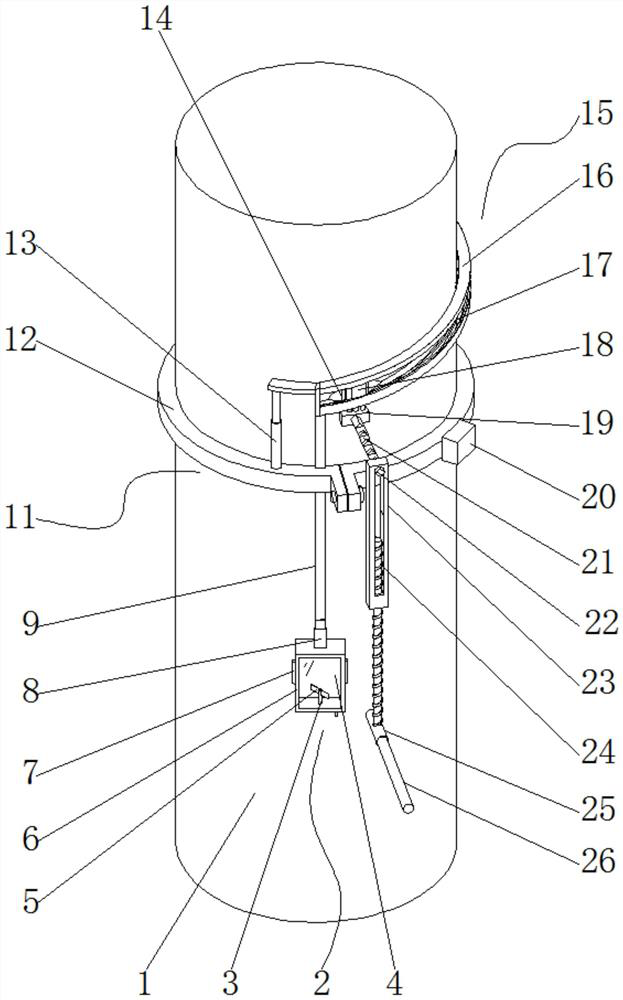

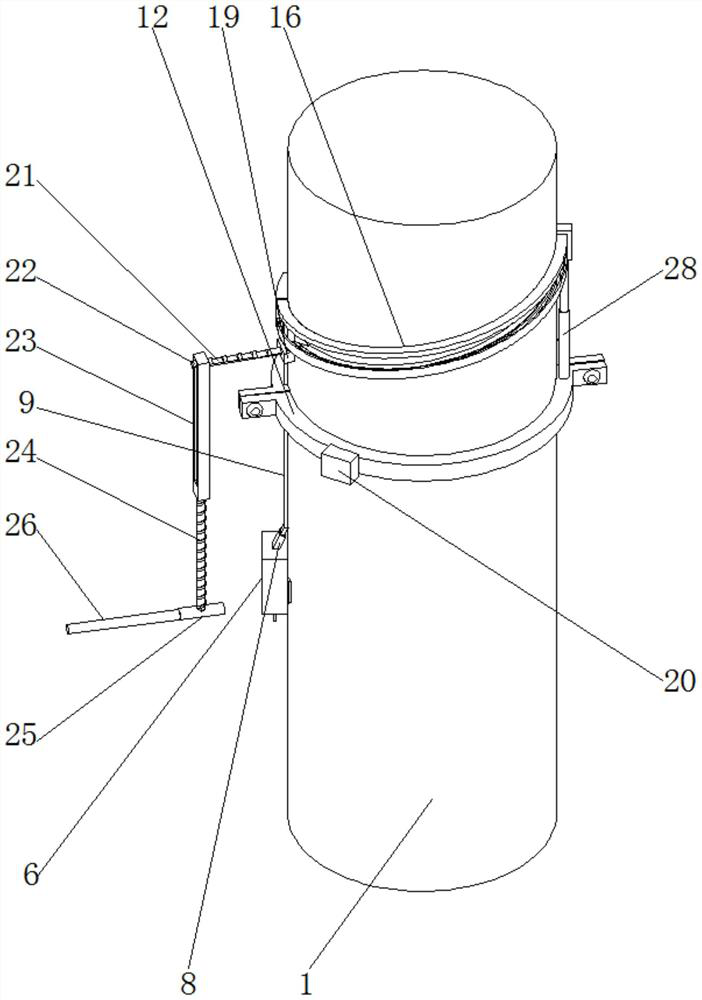

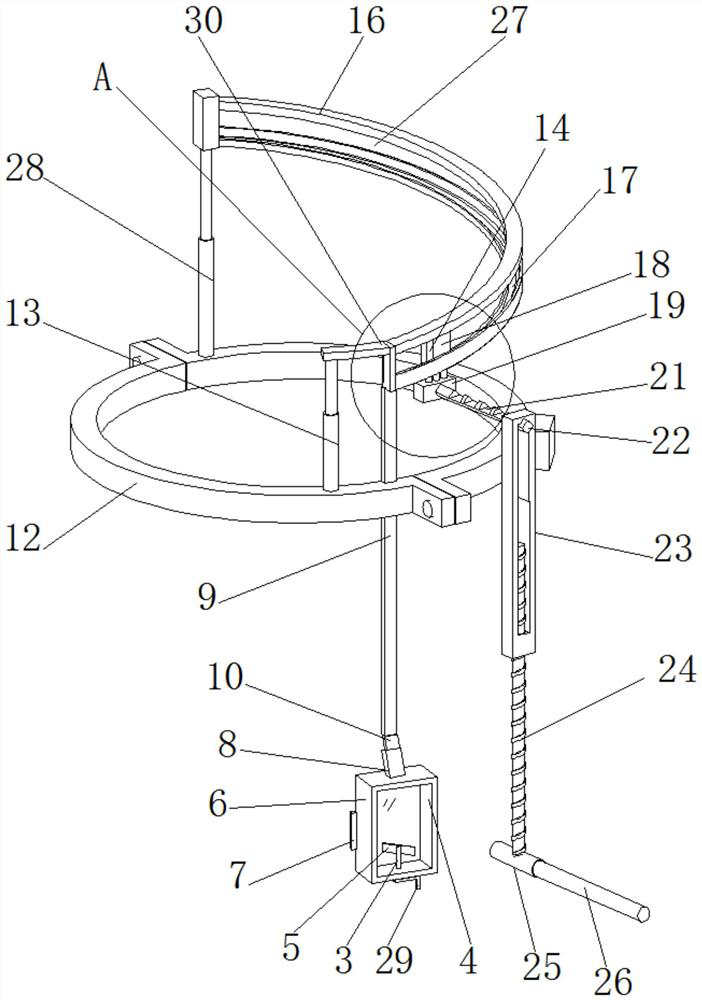

[0033] Embodiments of the present invention provide a cutting mechanism and cutting method that can collect natural rubber at high places, such as Figure 1-6 As shown, it is arranged on the trunk part of the rubber tree 1 higher than the height of a normal person. It includes a cutting mechanism 15 and a fixing assembly 11 . The fixing assembly 11 is sleeved on the rubber tree 1 , and the cutting mechanism 15 is arranged on the fixing assembly 11 . The cutting mechanism 15 includes a spiral slide 16 , a scraper 14 , a slide block 18 , a connecting rod 22 , a threaded rod 24 , a fixed sleeve 25 , a handle 26 and a connecting block 19 . The spiral slideway 16 is arranged on the semicircular clamp 12 , and the section of the spiral slideway 16 is concave and fits on the surface of the rubber tree 1 . The bottom of the spiral slideway 16 is provided with a slot one 17, and the side of the spiral slideway 16 close to the rubber tree 1 is provided with a slot two 27. The slide b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com