Rubber tapping machine

A technology of tapping machine and tapping rubber, applied in forestry, application, agriculture, etc., can solve the problems of low labor efficiency, high labor intensity, simple labor tools, etc., and achieve the effect of solving high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

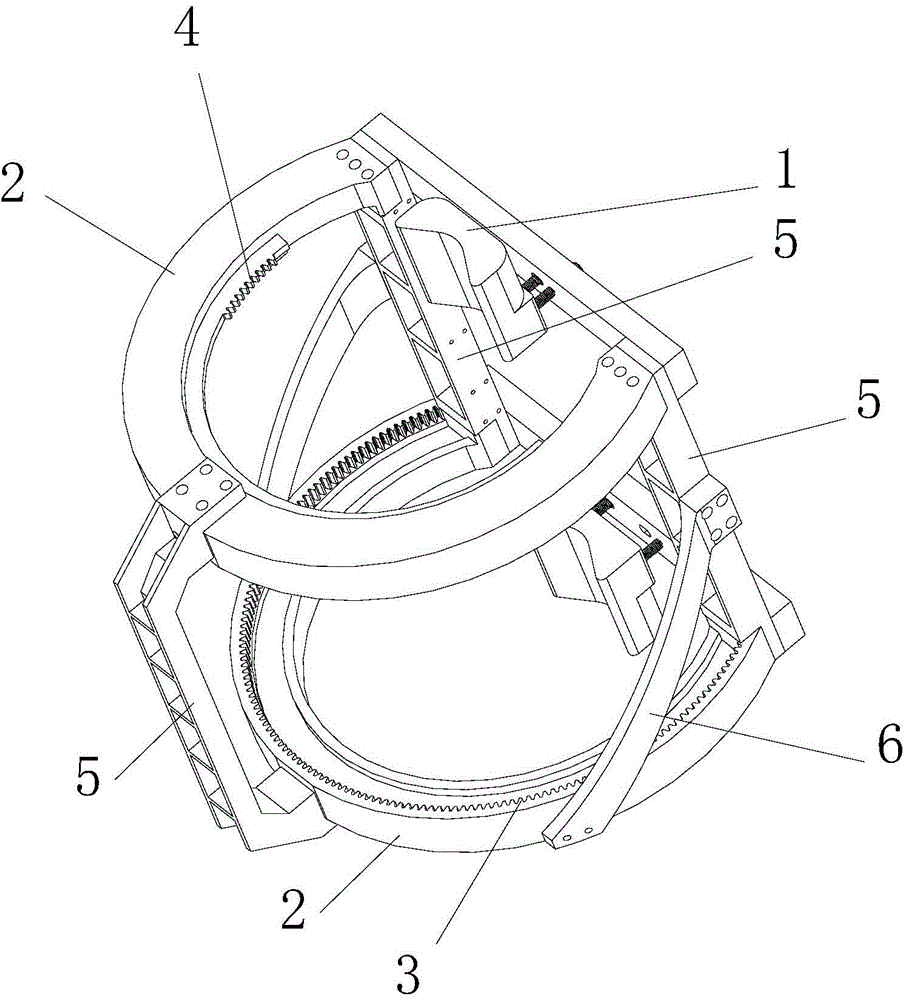

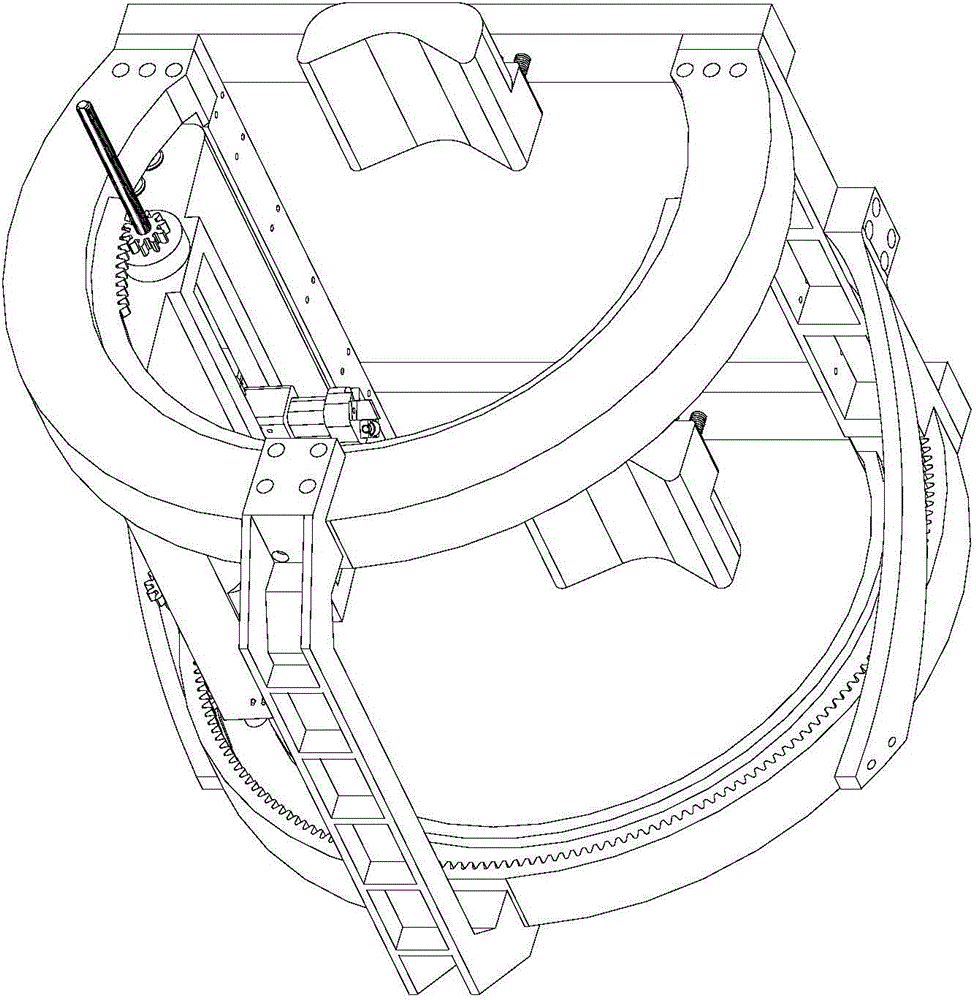

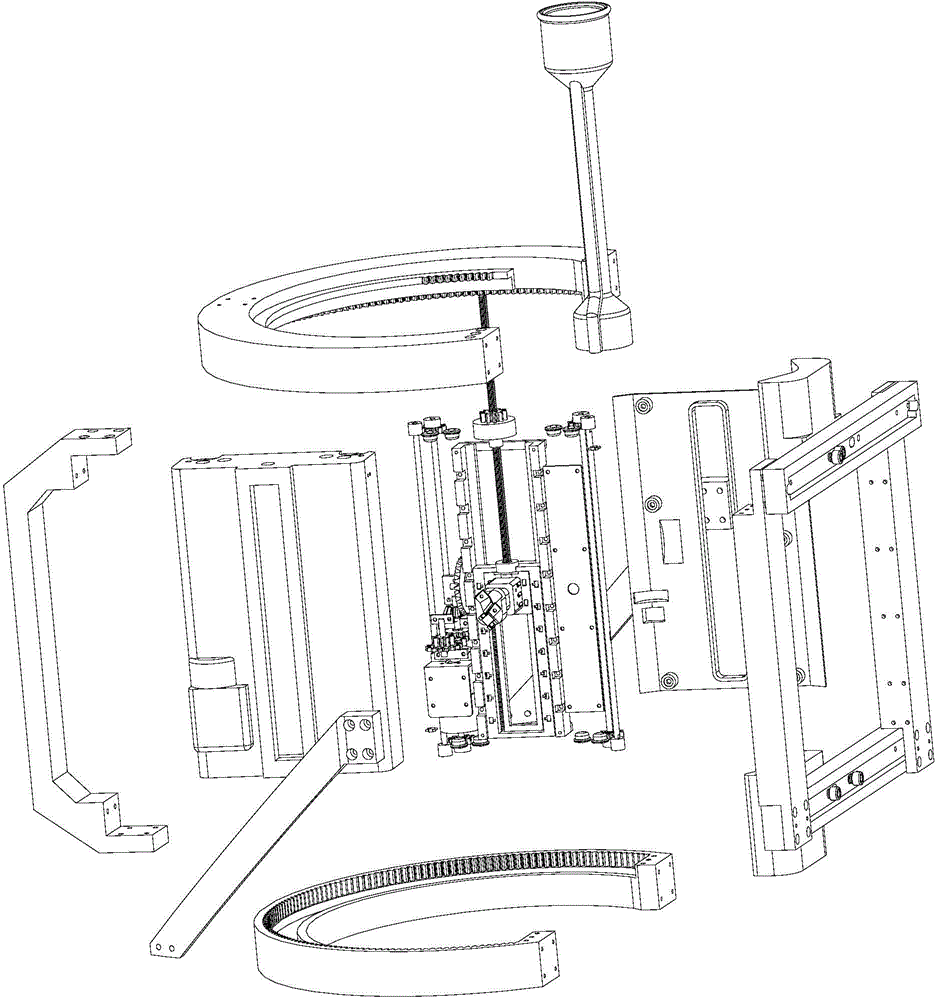

[0024] Example 1, such as figure 1 As shown, the rubber tapping machine disclosed in this embodiment includes a tree-tying fixed frame and two annular planetary gear casings 2 respectively installed on the upper and lower ends of the tree-binding fixed frame 1, and the inner walls of the two planetary gear casings 2 are provided with The annular planetary gear 3, in addition, on the inner side wall of the planetary gear housing 2 at the upper end, there is also a rubber tapping knife step to carry out the star gear 4 separately. Between the two planetary gear housings 2, three fixed mounts 5 are vertically arranged, one of which is arranged at the center of the ring, and the other two fixed mounts are respectively arranged at the two ends of the ring and are connected with the tree-tying fixed mounts. Connected, the fixed mounts at both ends of the ring are connected to the planetary gear housing at the lower end through an obliquely arranged fastening bracket 6 .

[0025] l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com