Electric rubber cutting machine

A technology of electric rubber tapping machine and rubber tapping knife, applied in forestry, application, agriculture, etc., can solve the problems of high technical requirements, high labor intensity and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to preferred embodiments of the present invention.

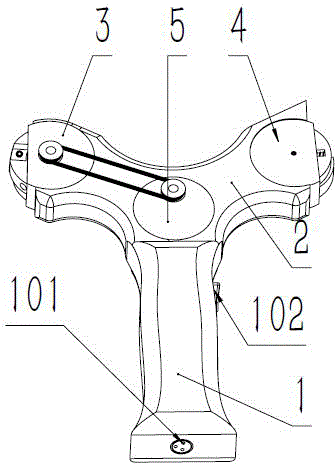

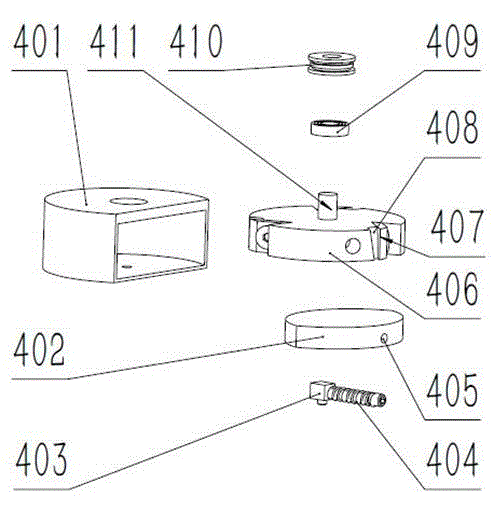

[0016] figure 1 Shown is the preferred embodiment 1. When tapping new rubber trees, use the waterline cutter head (4) of the electric rubber tapping machine to remove the bark layer by layer along the planned assembly line. As the waterline deepens, the profiling block (402) is jointly affected by the compression spring (404) and the pressure of the hand, and controls the waterline blade (407) to reach the required depth along the shape of the bark to complete the waterline.

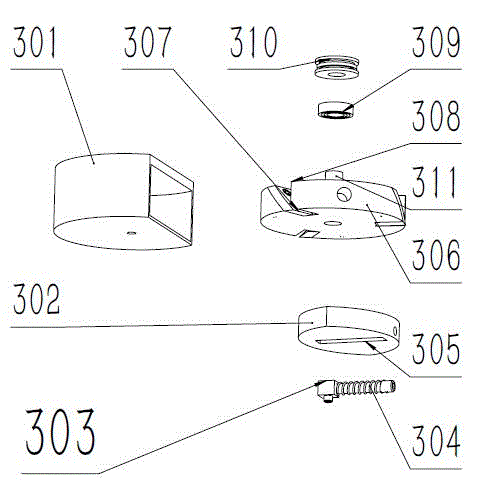

[0017] After the water line is formed or the dry glue at the glue outlet is removed, a thin layer of bark is cut off with the rubber tapping cutter head (3) of the electric rubber tapping machine at the incision, so that the glue can flow out; the depth of the incision is the thickness of the bark cut. The cutting edge of the rubber tapping blade (307) is determined by the distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com