Automatic rubber tapping machine for rubber trees

A rubber tree, automatic technology, applied in forestry, application, agriculture, etc., can solve the problems of low efficiency, high labor intensity and long time for rubber tapping workers, and achieve the effect of convenient operation, complete functions and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

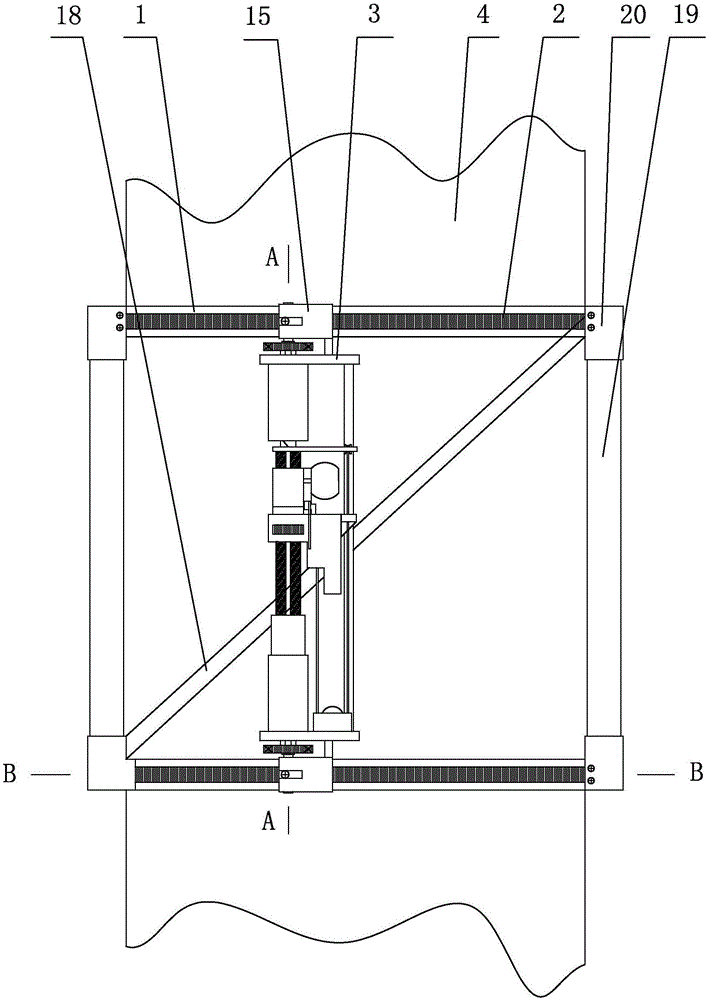

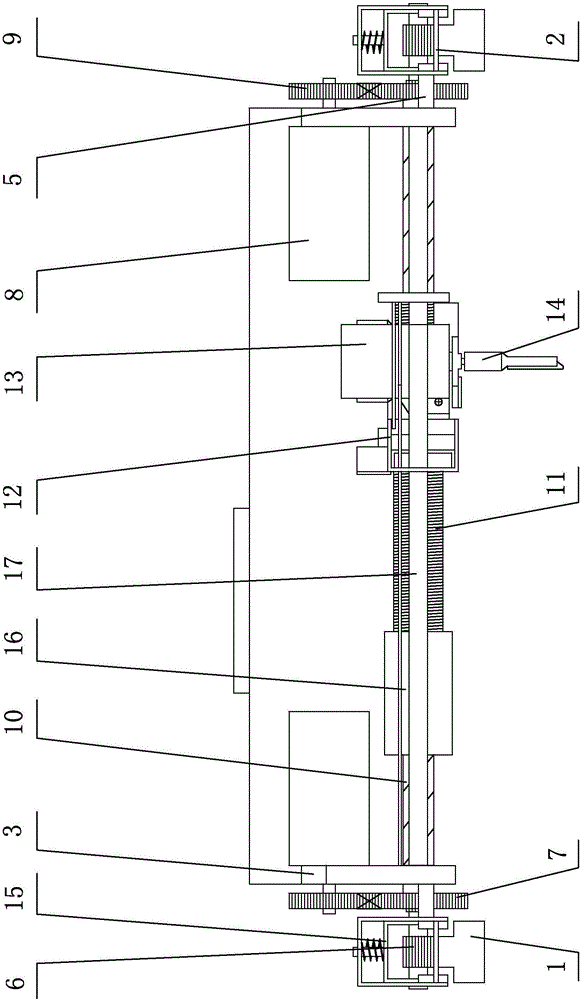

[0018] The rubber tree automatic rubber tapping machine of the present invention, its mechanical structure part comprises guide rail device, walking device and cutting device.

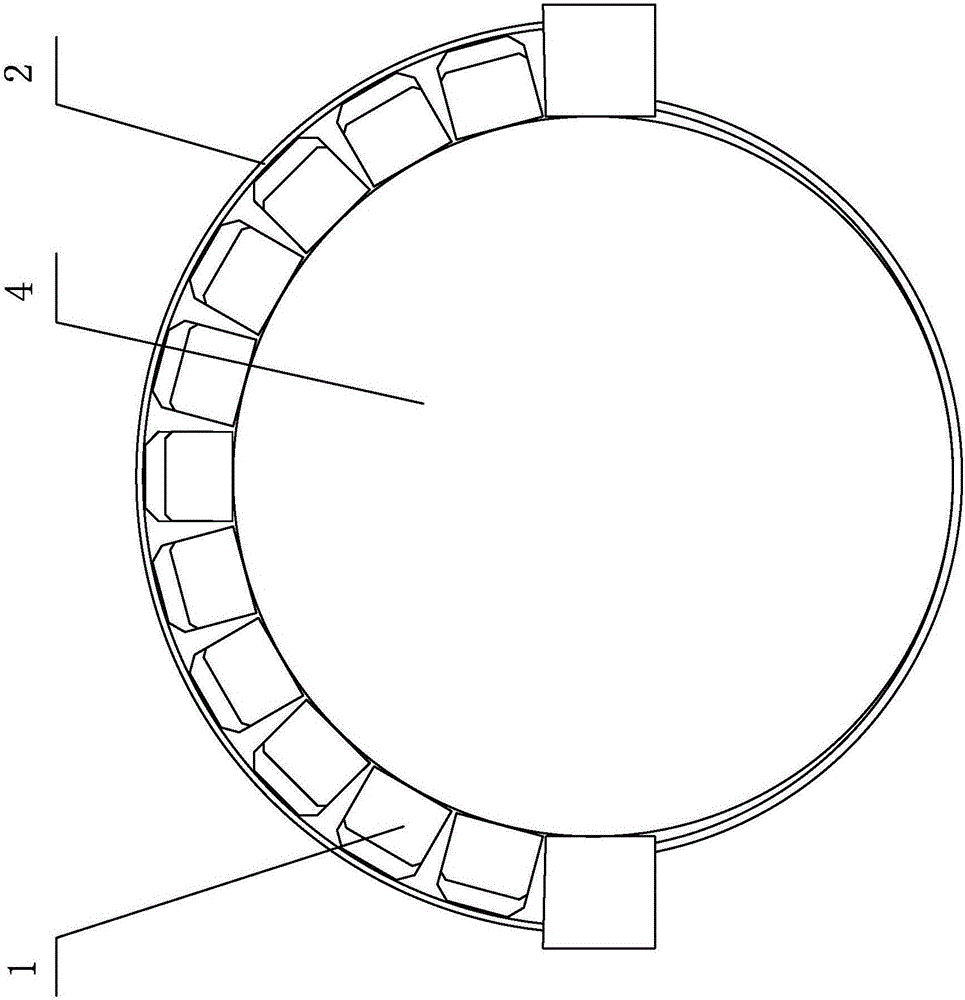

[0019] Described rail device comprises upper and lower two arc track bodies 1, the left and right ends of upper and lower arc track bodies 1 are connected with the upper and lower ends of left and right vertical rod bodies 19 through joints 20, Two curved racks 2 (thin steel racks) are pasted on the upper and lower arc track body 1 respectively, and the left and right ends of each arc rack 2 are respectively installed on the corresponding joints. 20; the top of the arc-shaped track body 1 (made of rubber and plastic material) is spaced inwardly with saw cuts, so that the arc-shaped track body 1 and the arc-shaped rack 2 can be bent and deforme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com