Automatic rubber tapping machine for rubber tree rubber picking

A rubber tree, automatic technology, applied in the field of automatic rubber tapping machines, can solve the problems of high labor intensity, low production efficiency and long time of rubber tapping workers, and achieve the effects of low cost, pollution prevention and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

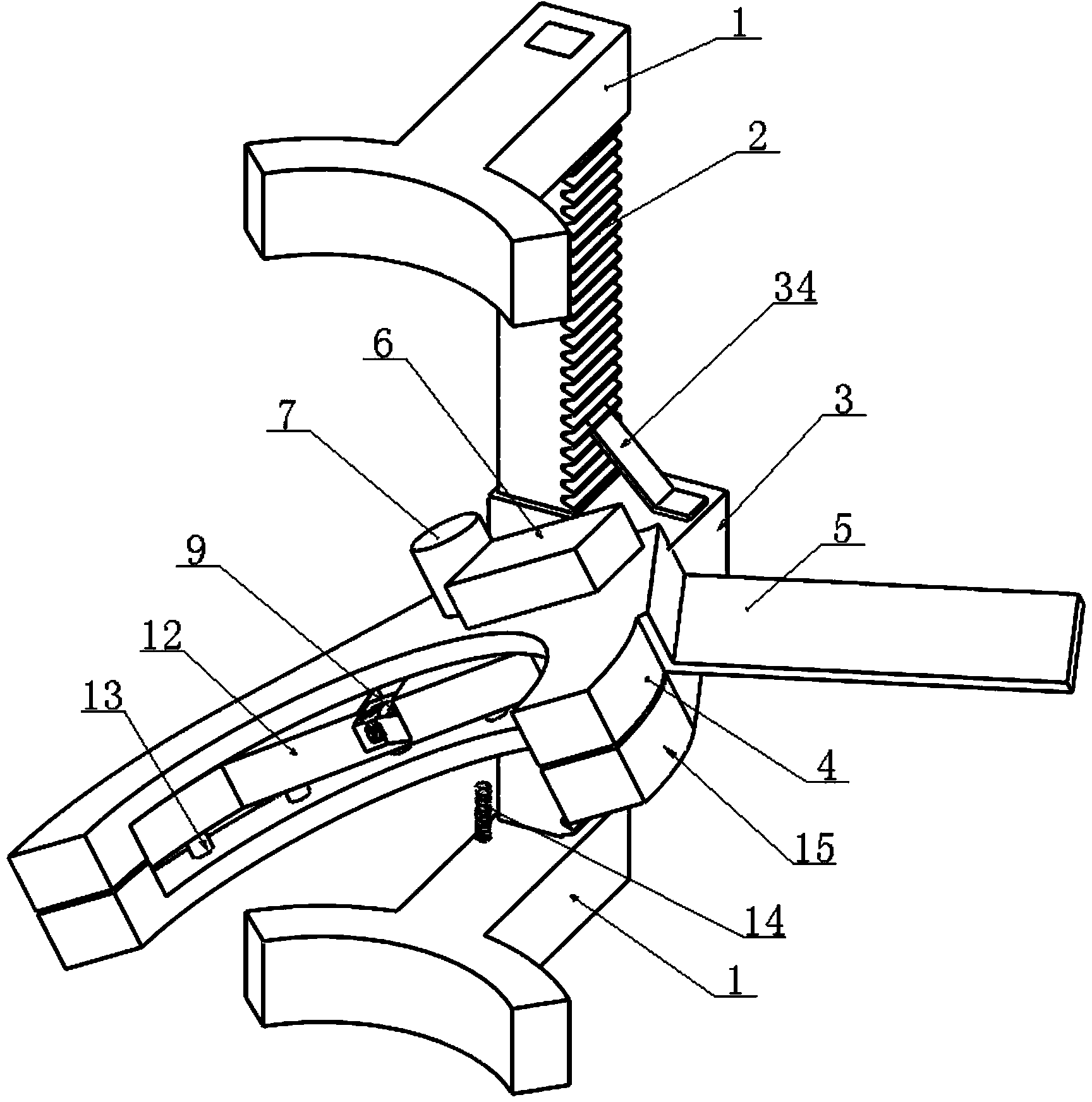

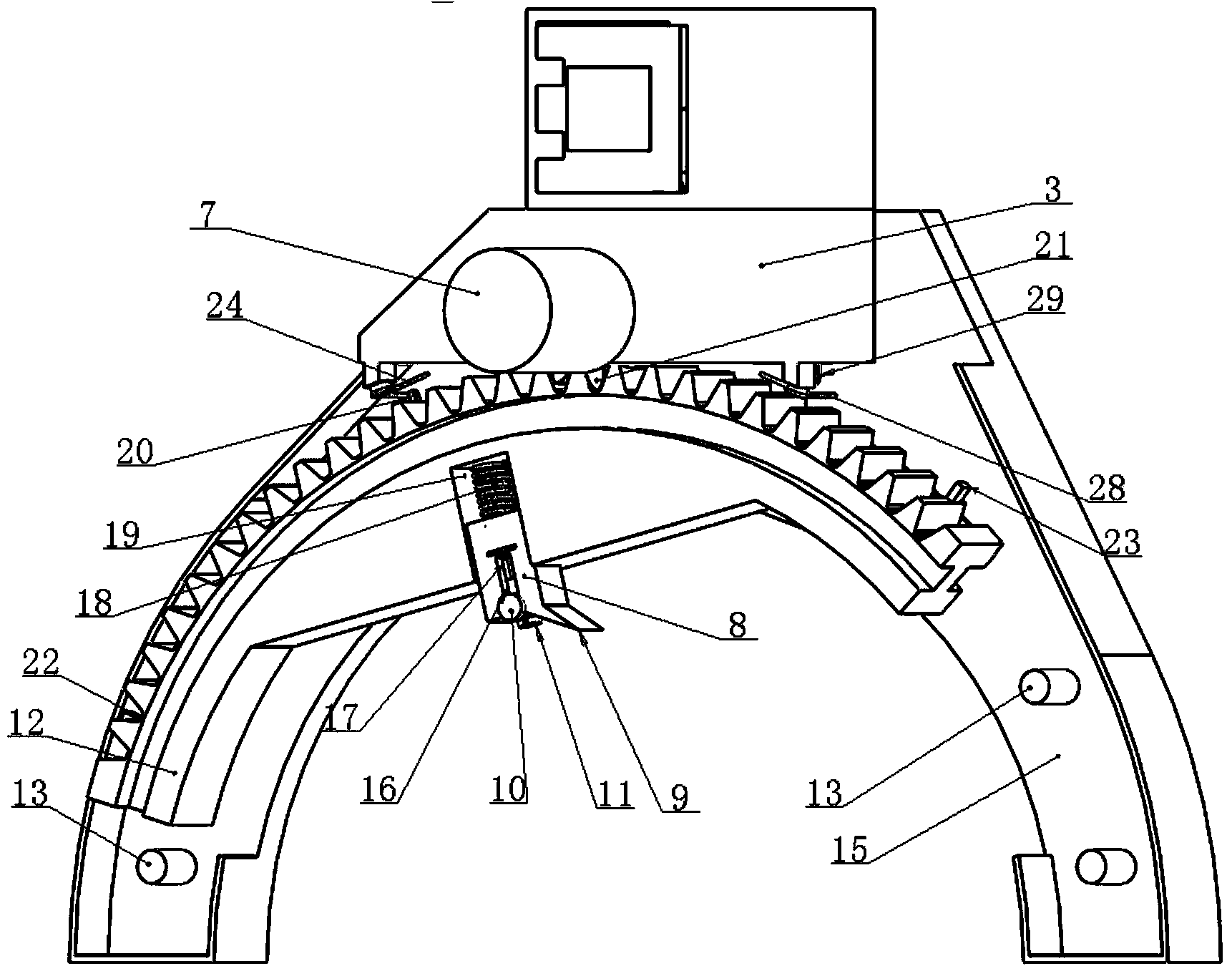

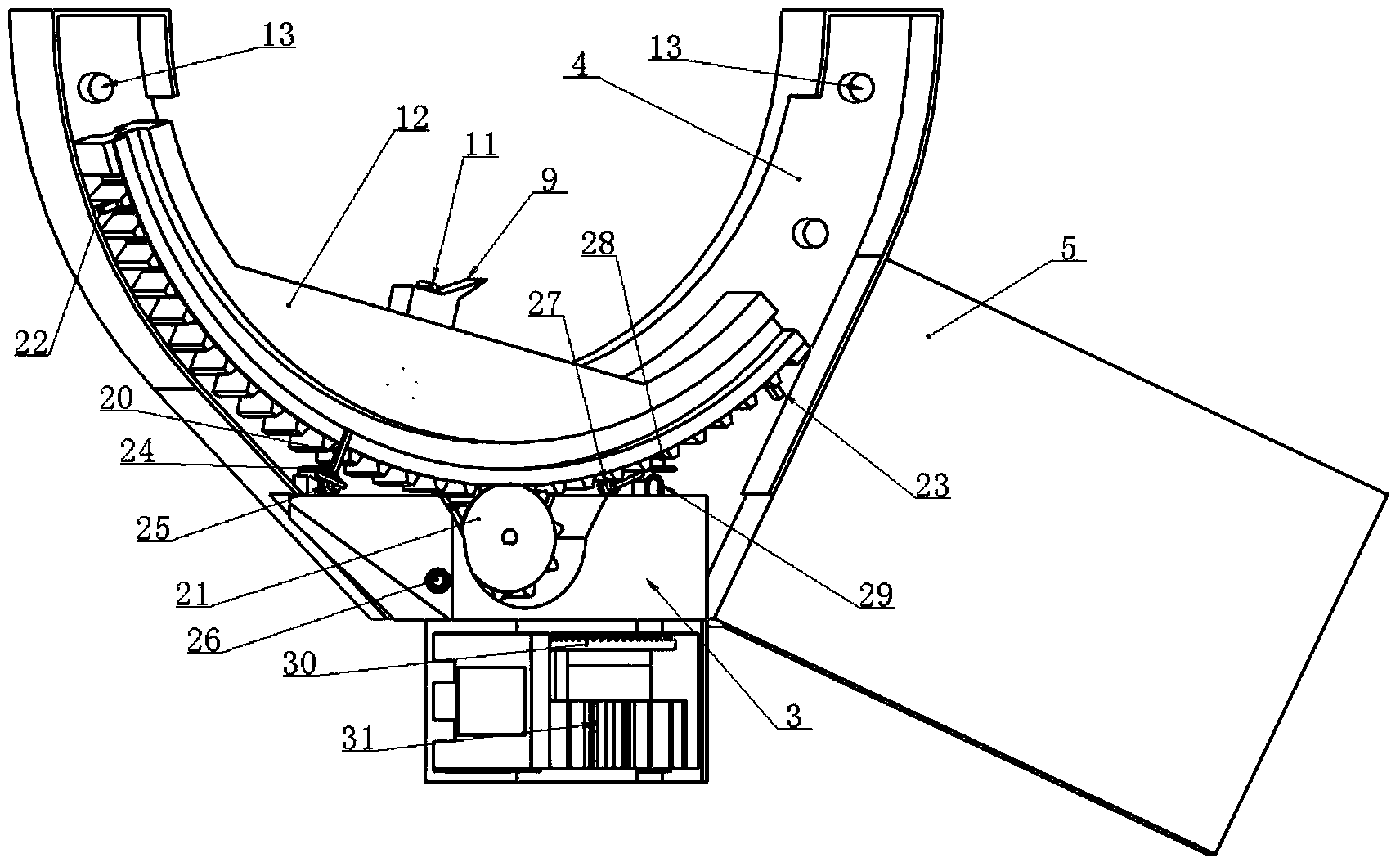

[0029] refer to Figure 1-Figure 5 , the present embodiment includes a cutting frame, the cutting frame is composed of a support rod 2 and a support arm 1 arranged at both ends of the support rod; Solar power supply structure and control structure; the end point detection structure detects the motion trajectory of the tool in the curved knife structure to limit the range of motion of the tool, and the signal output end of the end point detection structure is connected to the signal input end of the control structure; the control output of the control structure The end is connected to the control input end of the knife-edge depth positioning structure, curved line knife structure and automatic line-wrapping positioning structure through a driving mechanism; the knife-edge depth positioning structure has a mechanism for adjusting and positioning the cutting depth of the knife, and the curved line knife structure has the functions of simultaneously realizing arc movement, The mecha...

specific Embodiment 2

[0046] The feature of Embodiment 2 is: the locator 10 is made of bearings, and the tool track locator 13 is made of bearings. All the other are identical with embodiment 1.

[0047] In this implementation, bearings are used to form the locator 10 and the knife track locator 13, which can reduce the friction force during the knife movement and further improve the performance of the machine.

specific Embodiment 3

[0048] The feature of the third embodiment is that the left end point sensor 27 and the right end point sensor 25 are made of magnetic induction sensors. All the other are with specific embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com