Method and device for collection of natural rubber latex

A technology of natural rubber latex and collecting device, applied in forestry, application, agriculture, etc., can solve the problems of polluted latex, sundries falling into plastic bowl, increase of non-rubber component content, etc., so as to improve work efficiency and reduce labor consumption. , the effect of increasing labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

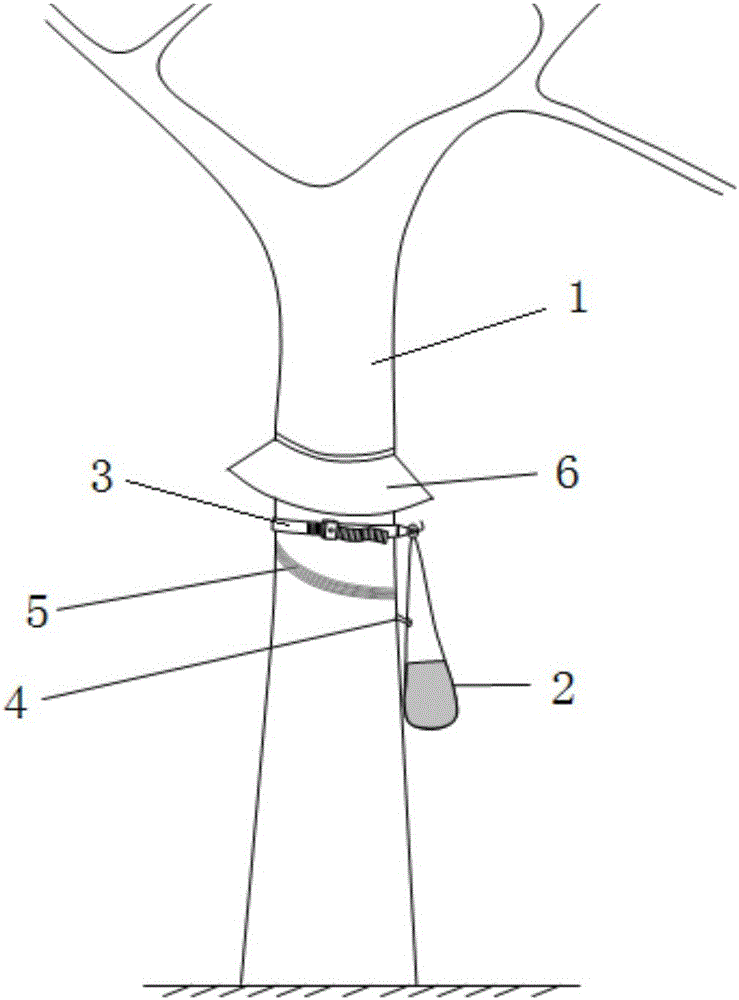

[0031] On the basis of above-mentioned research, the embodiment of the present invention provides a kind of collection method of natural rubber latex, by the latex collection method provided by the present invention, can make the collected latex coagulate under natural condition, need not add ammoniacal liquor and acetic acid, improve the quality of the latex.

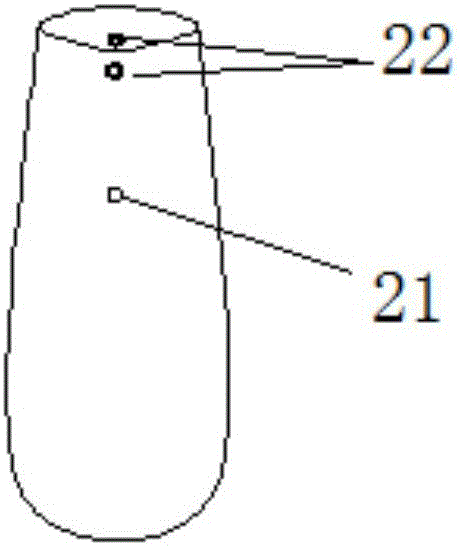

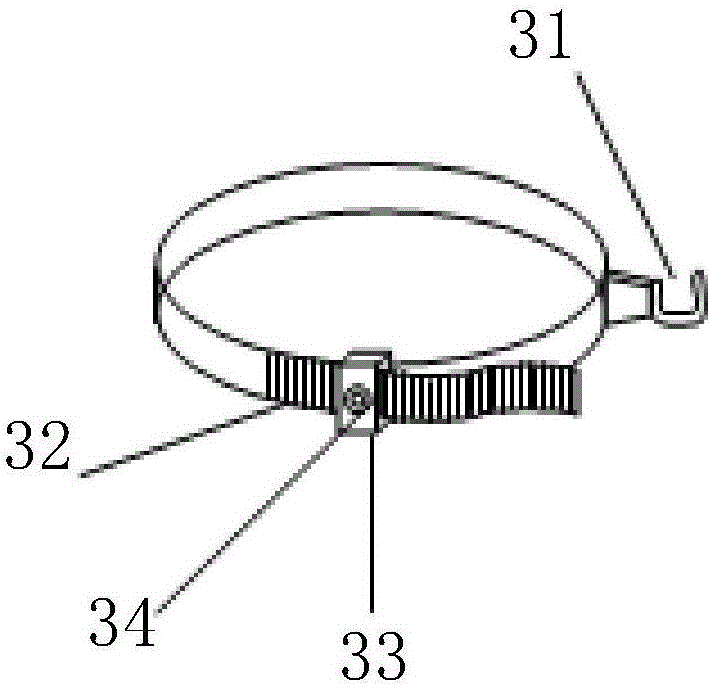

[0032] The present invention also provides a collection device for realizing the collection method of natural rubber latex. The latex collection device provided by the present invention prevents debris from falling into the container from the top of the container, thereby damaging the quality of the latex in the container. Moreover, it avoids the tedious work of placing the rubber bowl before and after tapping, pouring the latex in the rubber bowl into the rubber bucket, and cleaning the rubber bowl to prepare for the next collection of latex. This series of tedious tasks improves work efficiency.

[0033] In order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com