Patents

Literature

31results about How to "Damage quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

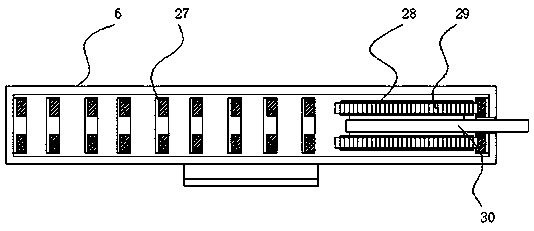

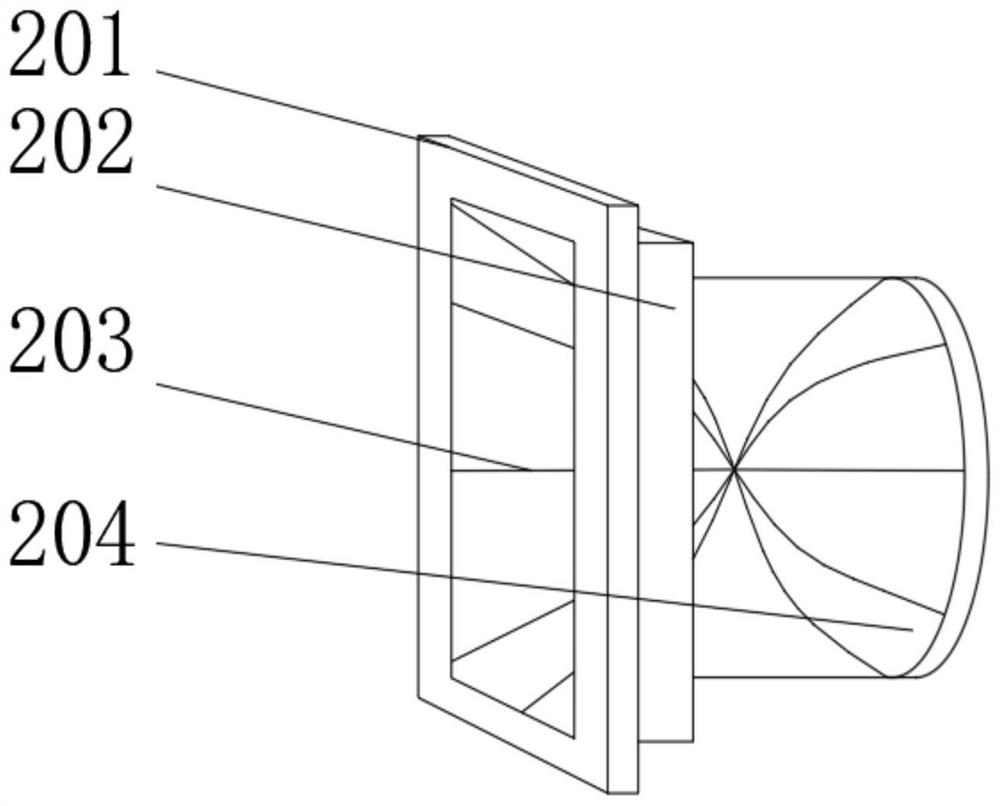

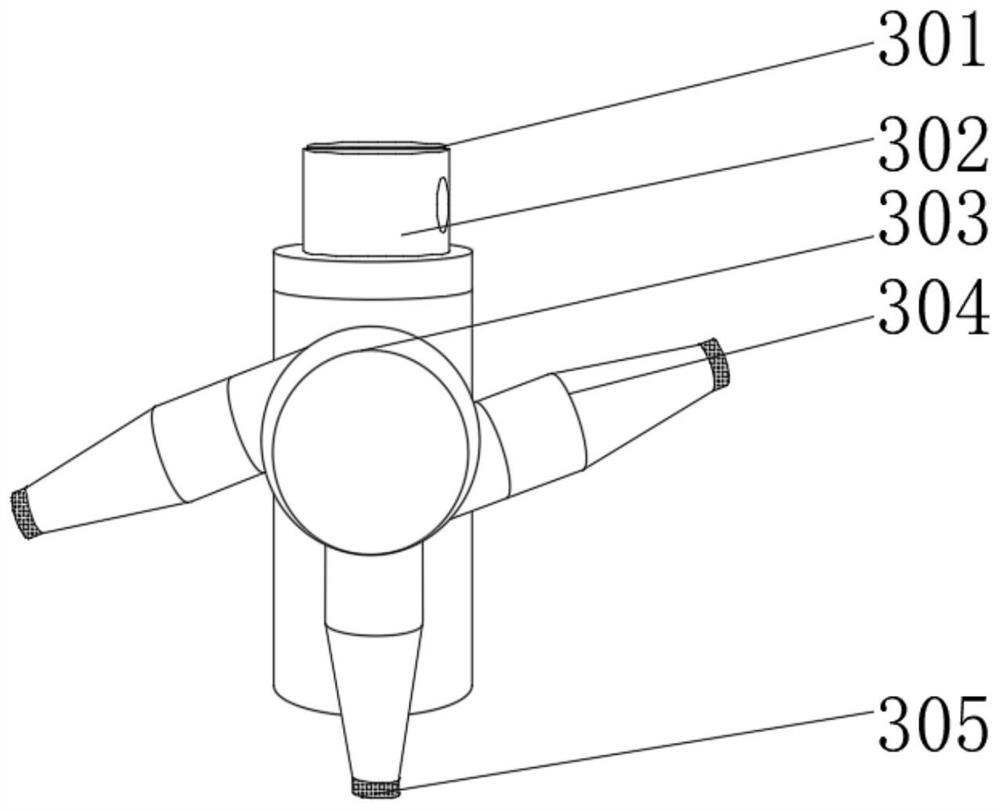

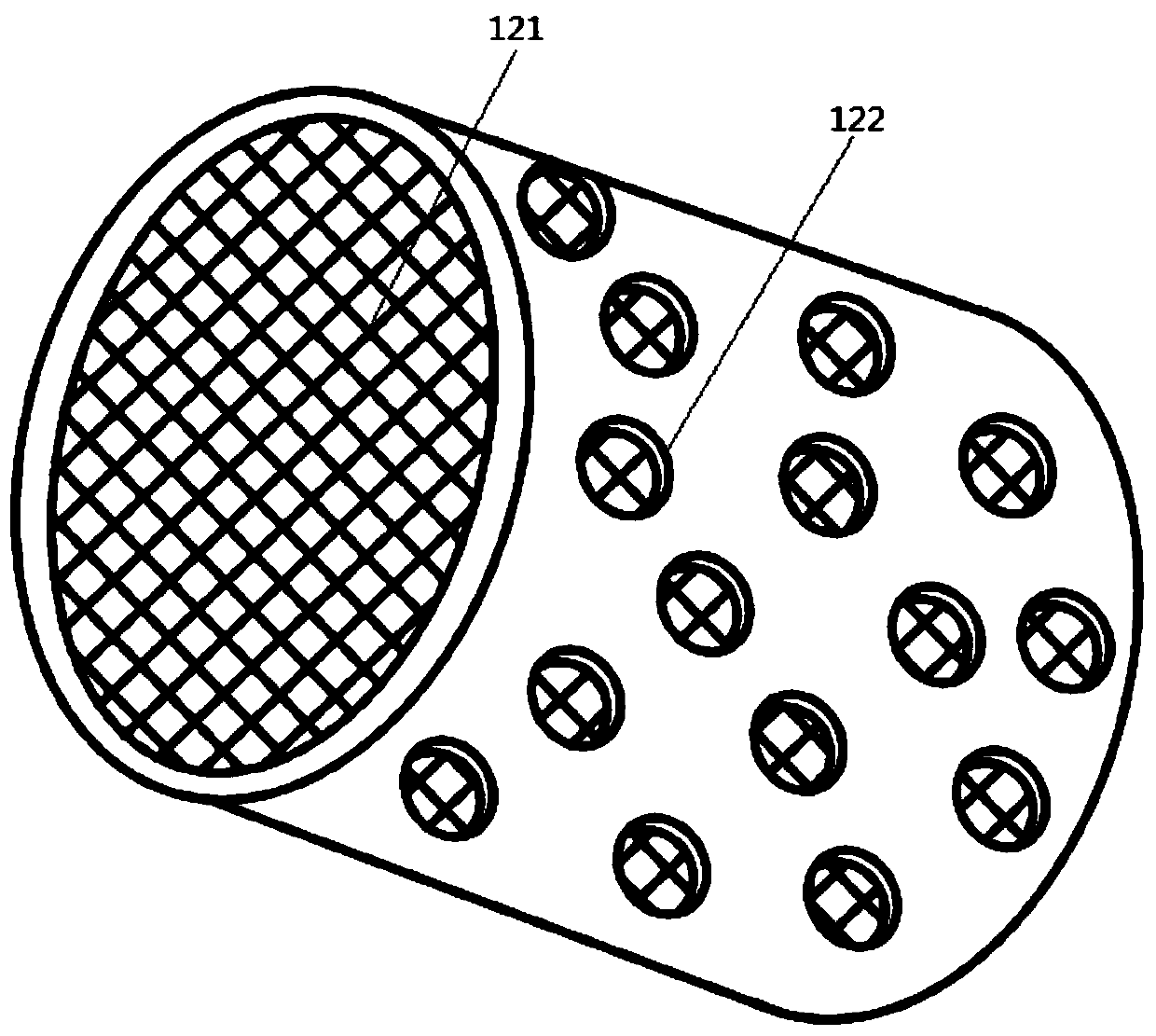

Perforated slat trawl door

InactiveCN101686657AImprove stabilityIncreased angular working rangeFishing netsLeading edgeEngineering

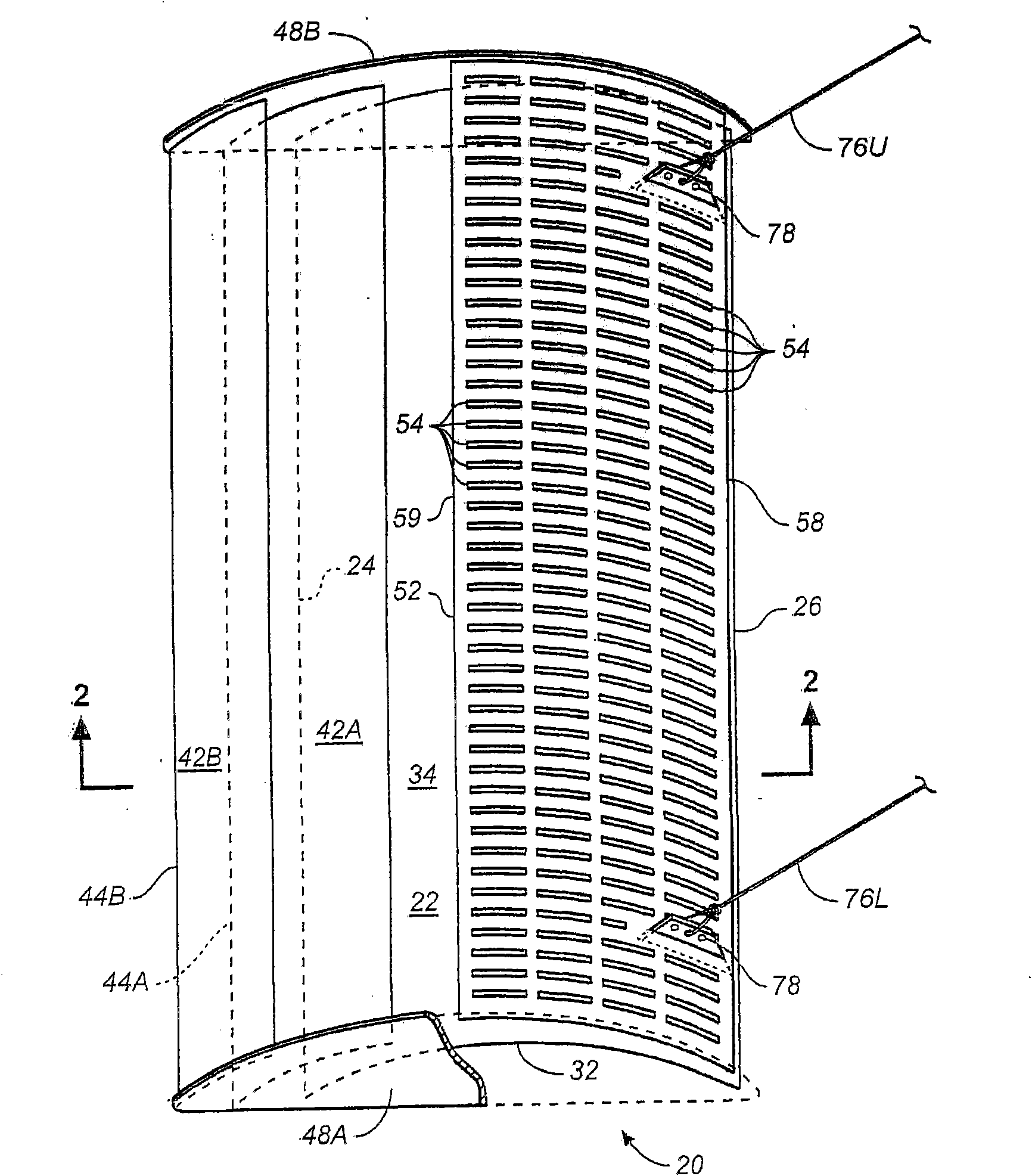

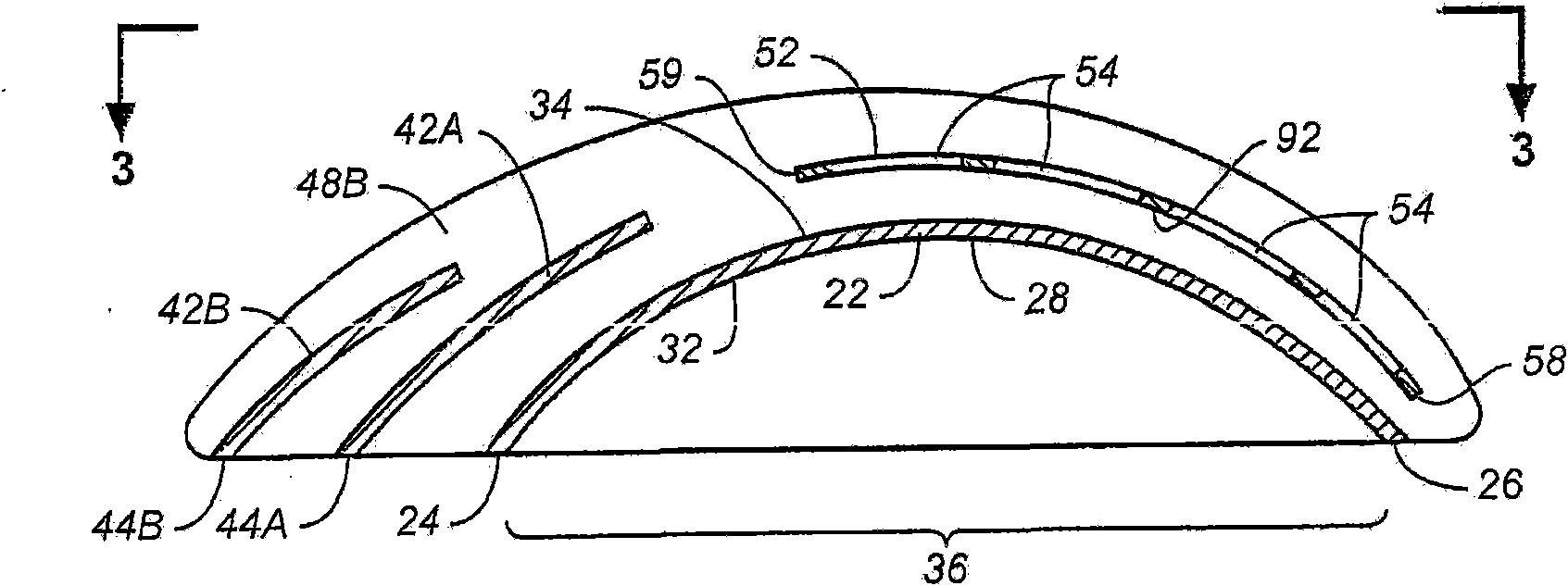

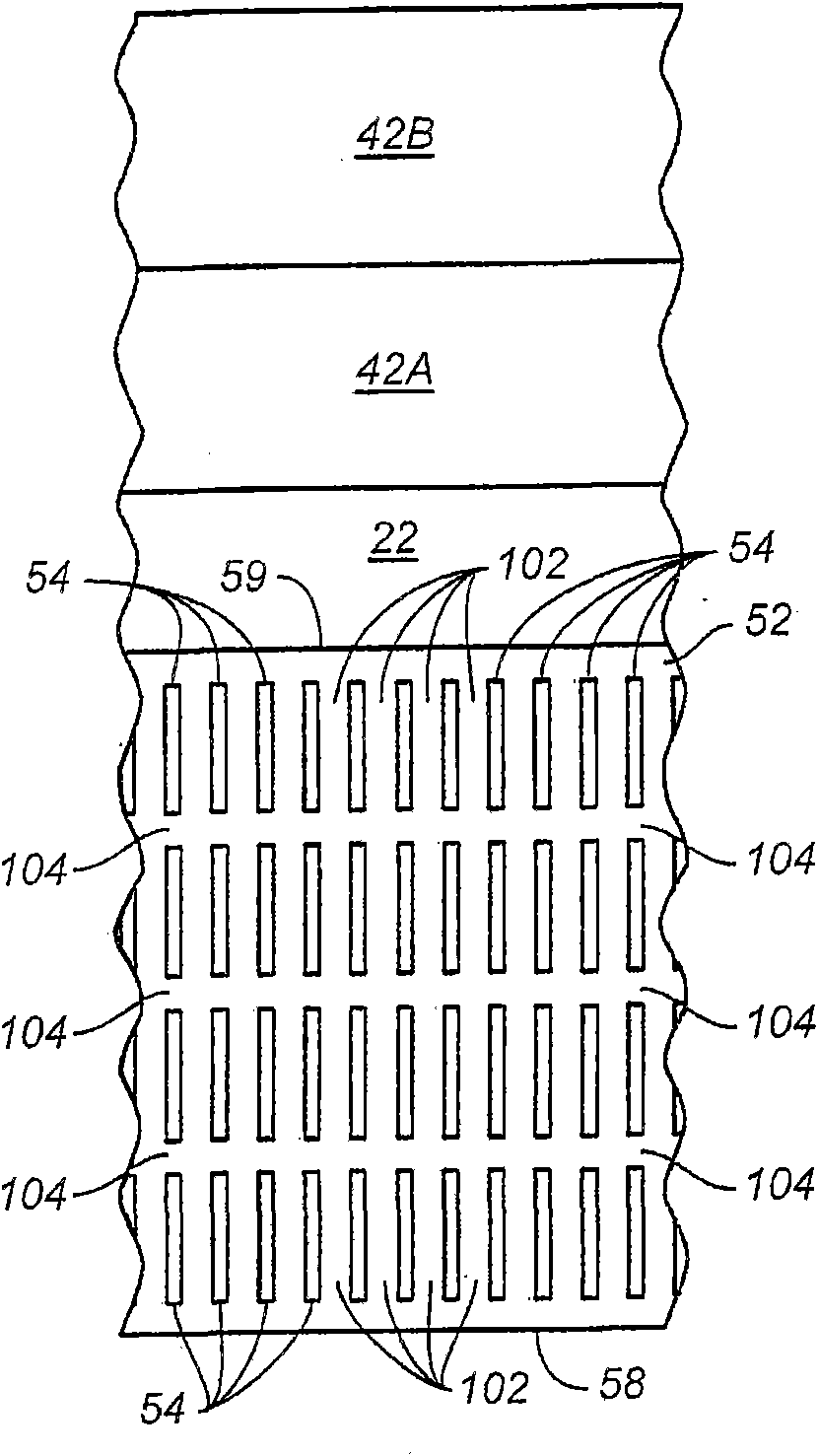

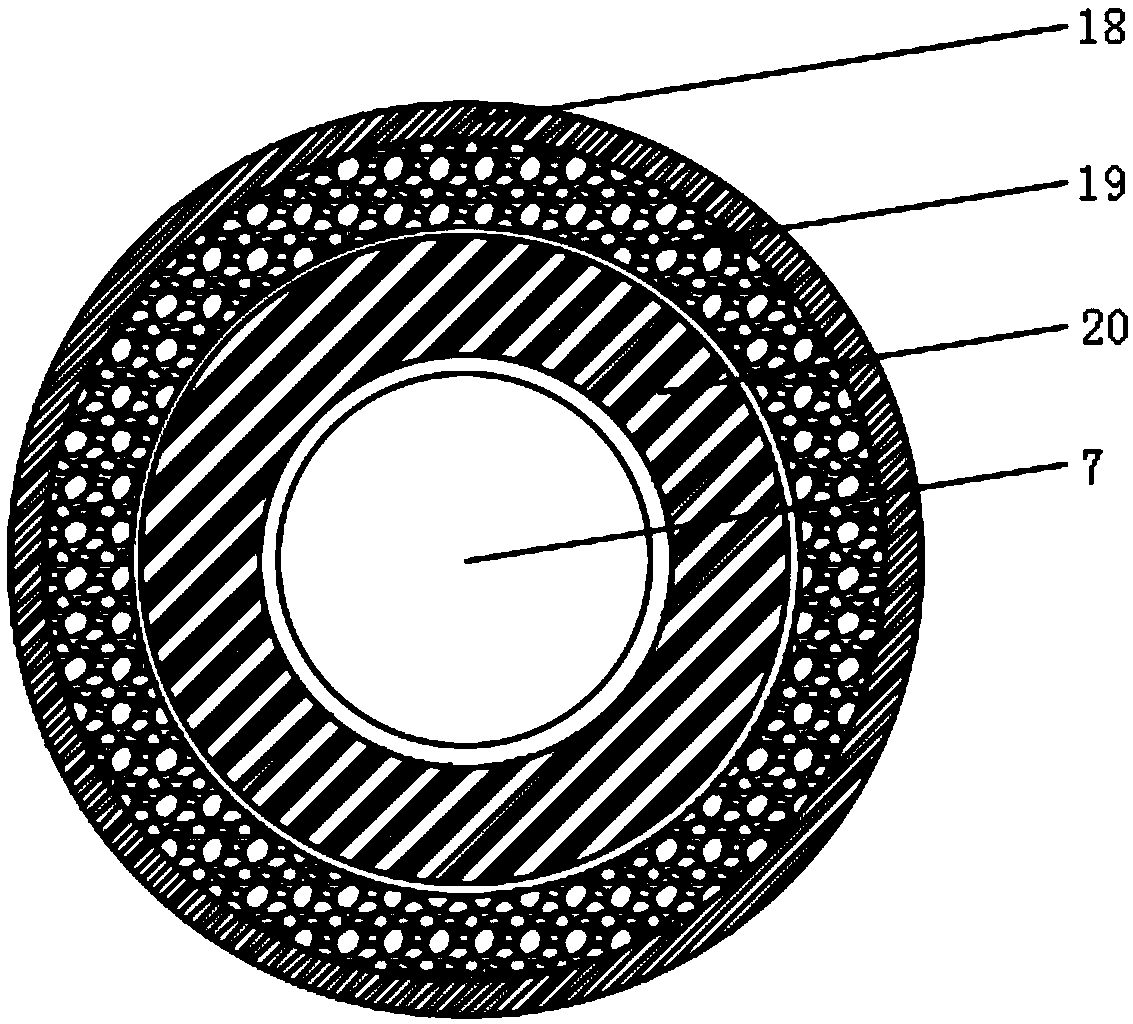

A trawl door (20, 60) or a paravane (120, 140) having at least one main deflector (22, 22U, 22L) includes a permeable structure disposed adjacent to and separated from an outer surface (34) of the main deflector (22, 22U, 22L). The permeable structure extends from near a trailing edge (26, 26U, 26L) of the main deflector (22, 22U, 22L) over and separated from the outer surface (34) toward the maindeflector's leading edge (24, 24U, 24L). In one embodiment of the permeable structure, a plurality of apertures (54, 56) pierce a perforated slat (52, 52U, 52L) thereby establishing a porous surfaceadjacent to the outer surface (34) of the main deflector (22, 22U, 22L). Adding the permeable structure perforated slat (52, 52U, 52L) to a trawl door (20, 60) increases the trawl door's stability when the trawl door is towed through water at a high angle of attack, and also reduces the trawl door's drag when operating at a high angle of attack.

Owner:HAMPIDJAN

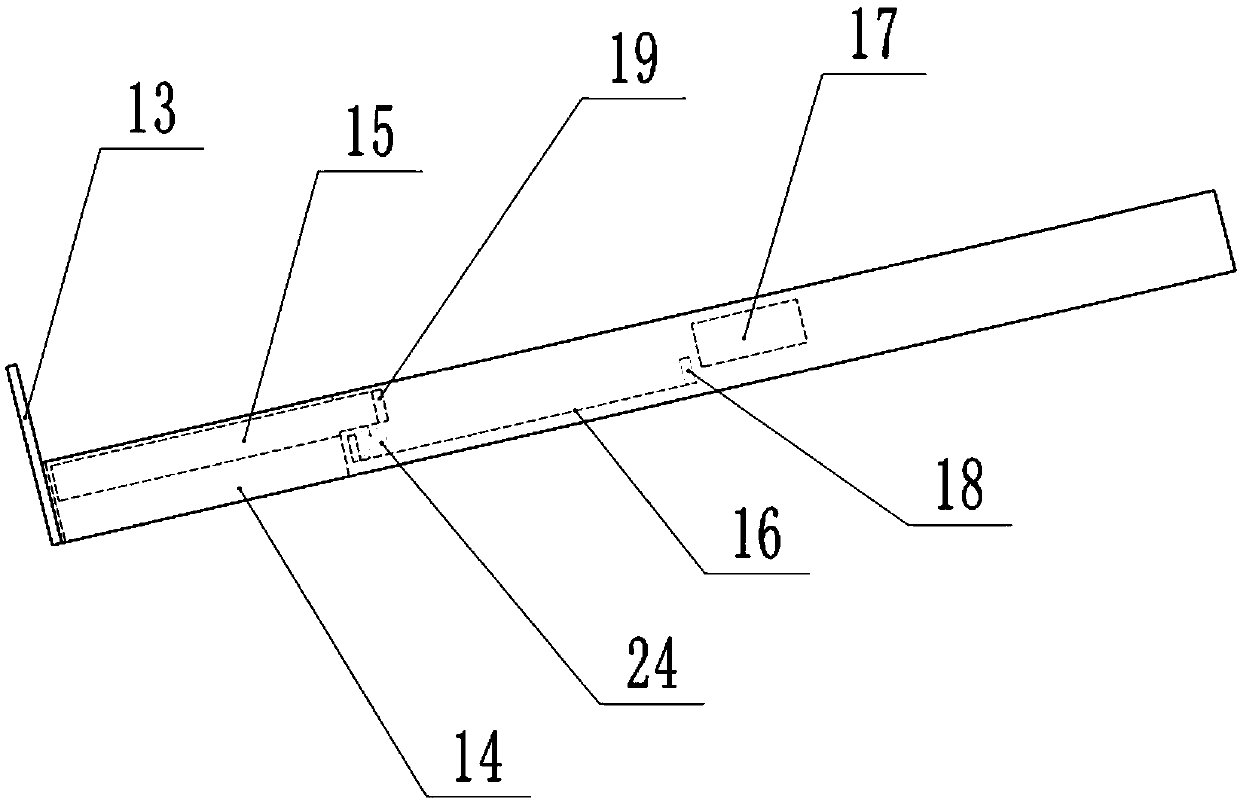

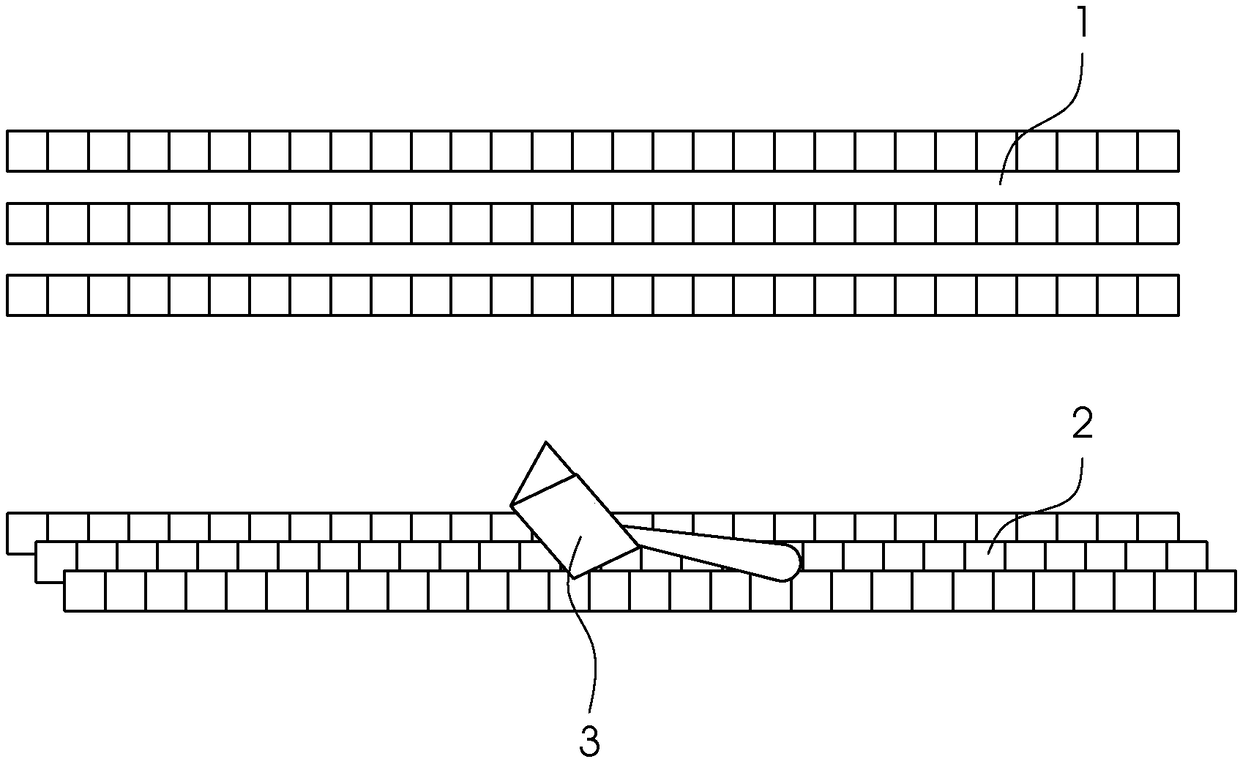

Method and device for collection of natural rubber latex

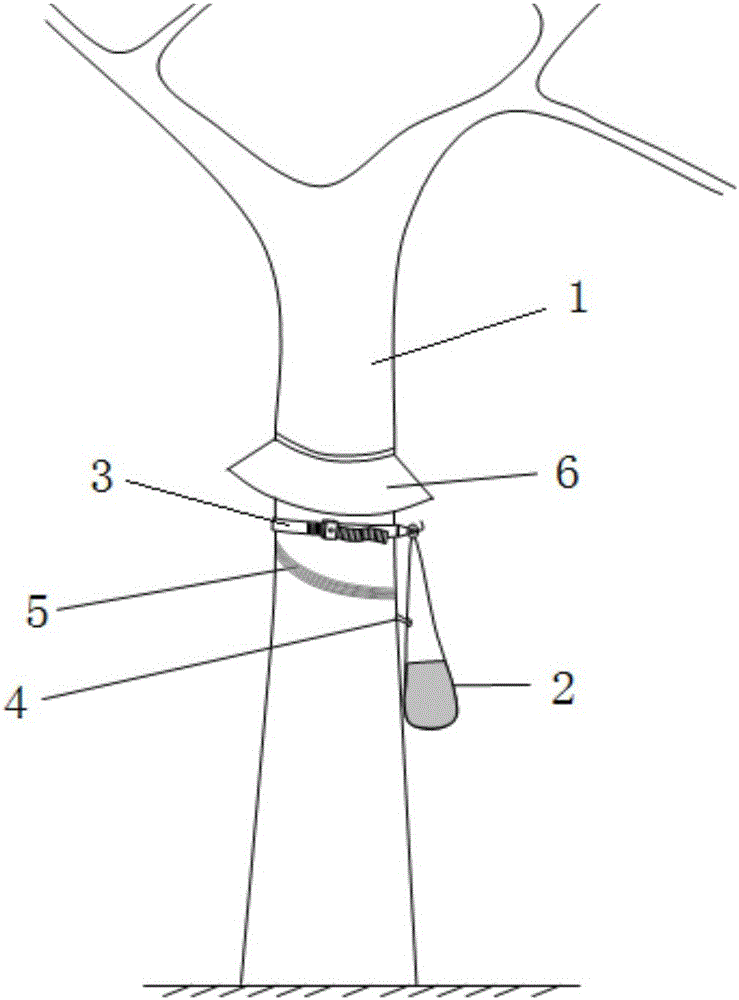

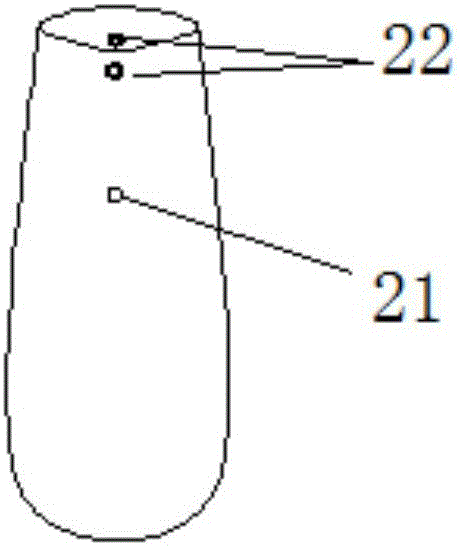

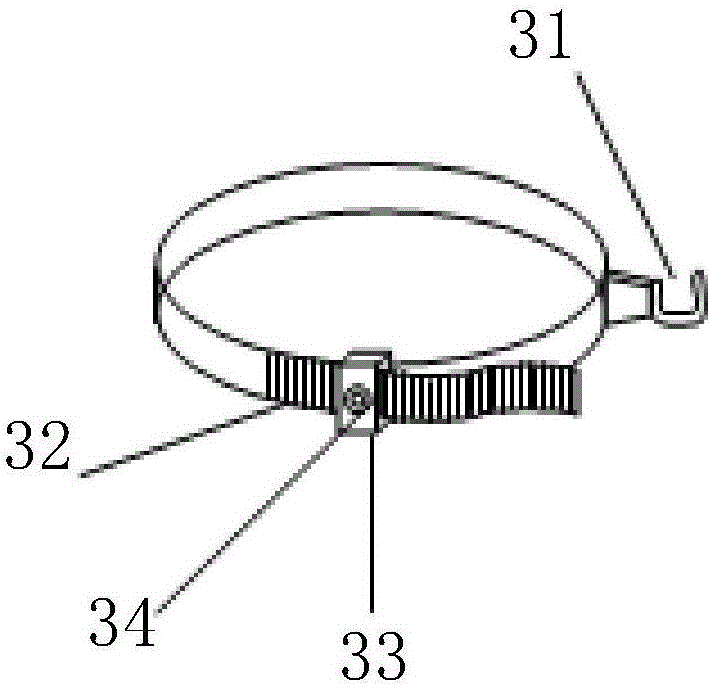

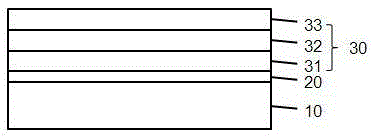

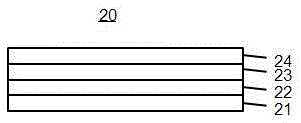

The invention discloses a collection method for a natural rubber latex. The collection method comprises the following steps: collecting the latex flowing along a rubber tapping line after rubber tapping by utilizing a flexible plastic container; and allowing the latex in the flexible plastic container to solidify under natural conditions. Through the collection method for the latex provided by the invention, the collected latex can be solidified under natural conditions, and addition of a chemical substance used for promoting the latex to solidify is not needed, so the purity of the latex is improved. The invention also discloses a collection device used for realizing the above-mentioned collection method for the natural rubber latex. The collection device comprises the flexible plastic container used for collection of the latex, a fixing unit which is used for fixing the flexible plastic container and detachably connected with the flexible plastic container, and a rubber tongue which is used for guiding the latex to enter the flexible plastic container, wherein the side wall of the flexible plastic container is provided with a latex inlet hole; the fixing unit is fixedly arranged on a rubber tree; one end of the rubber tongue is positioned below the bottom part of the rubber tapping line of the rubber tree; and the other end of the rubber tongue is positioned inside the rubber inlet hole.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

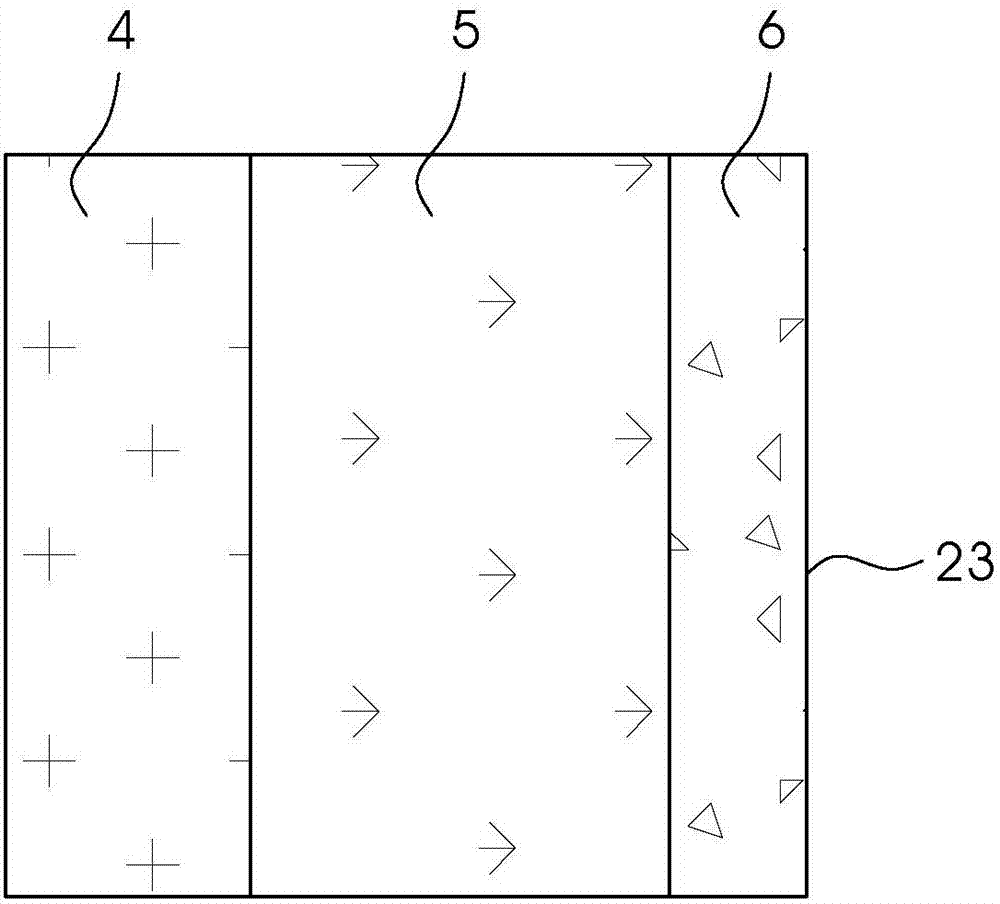

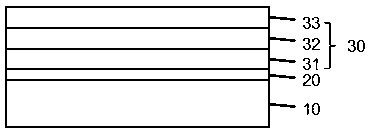

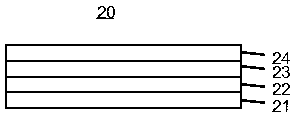

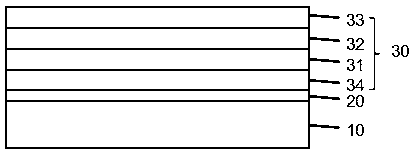

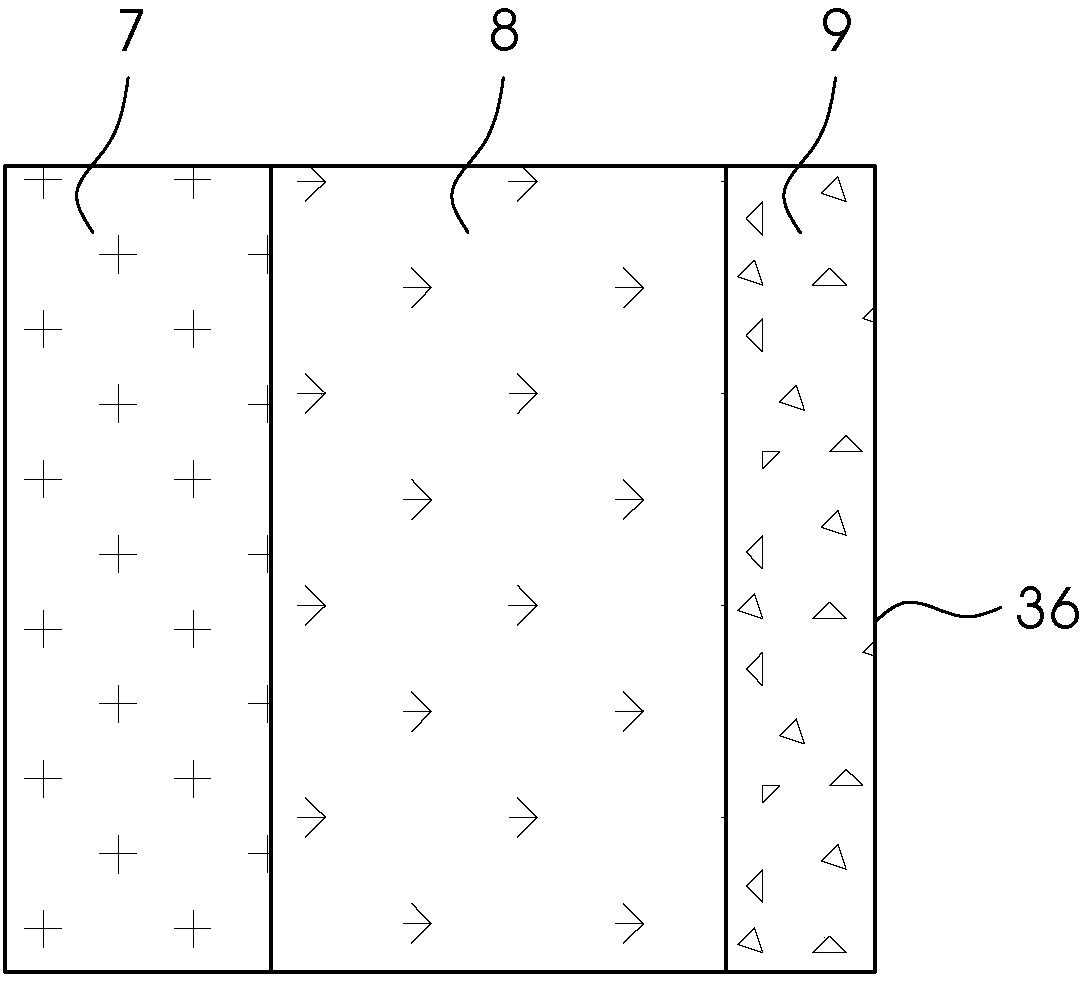

Semiconductor element and preparation method thereof

ActiveCN105336579ADamage qualityReduce lattice differencesSemiconductor/solid-state device manufacturingSemiconductor devicesIndiumPhysical chemistry

The invention provides a semiconductor element. Formation of an amorphous layer on the surface of a silicon substrate can be avoided by growth of a metal protection layer and a metal oxide protection layer on the substrate; and crystal lattice difference of the metal oxide protection layer and a III-IV family buffer layer is reduced by a transition layer so that crystal quality of the III-IV family buffer layer is enhanced. The invention also provides a preparation method. Formation of the amorphous layer near the interface of the silicon substrate can be avoided by the method, and generation of cracks can be avoided. Meanwhile, a high-quality multilayer buffer structure deposited by a PVD method, and a gallium nitride or indium gallium nitrogen or aluminum gallium nitride epitaxial layer grown on the high-quality multilayer buffer structure are fully utilized to manufacture a light-emitting diode element or a transistor element.

Owner:ANHUI SANAN OPTOELECTRONICS CO LTD

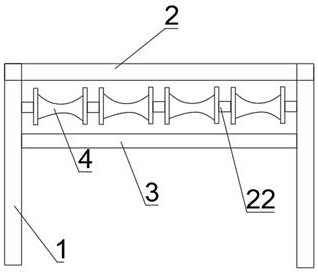

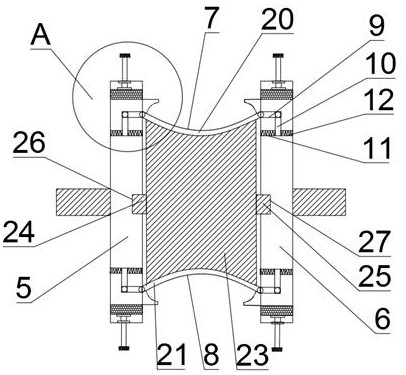

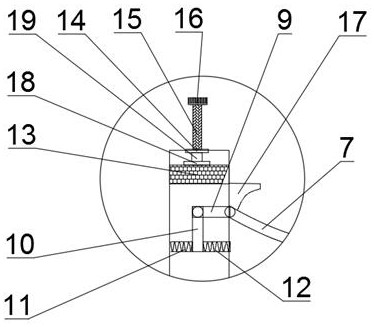

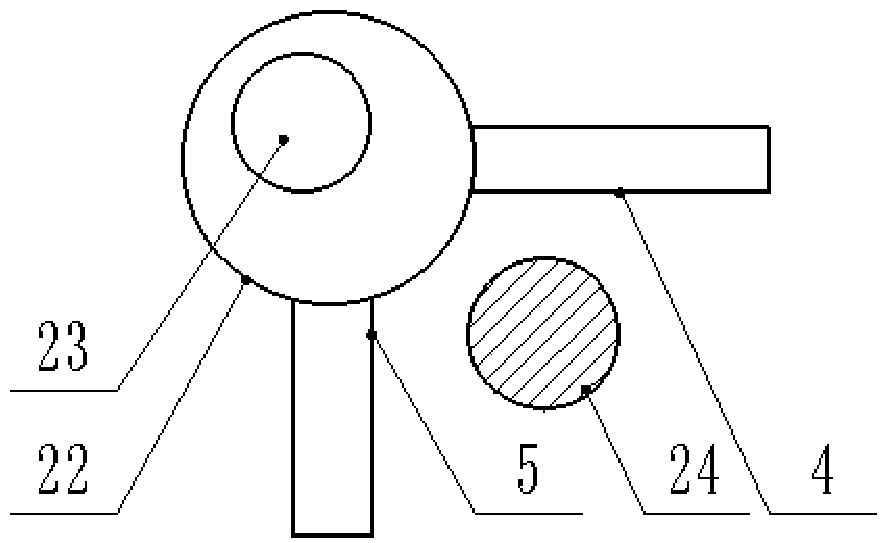

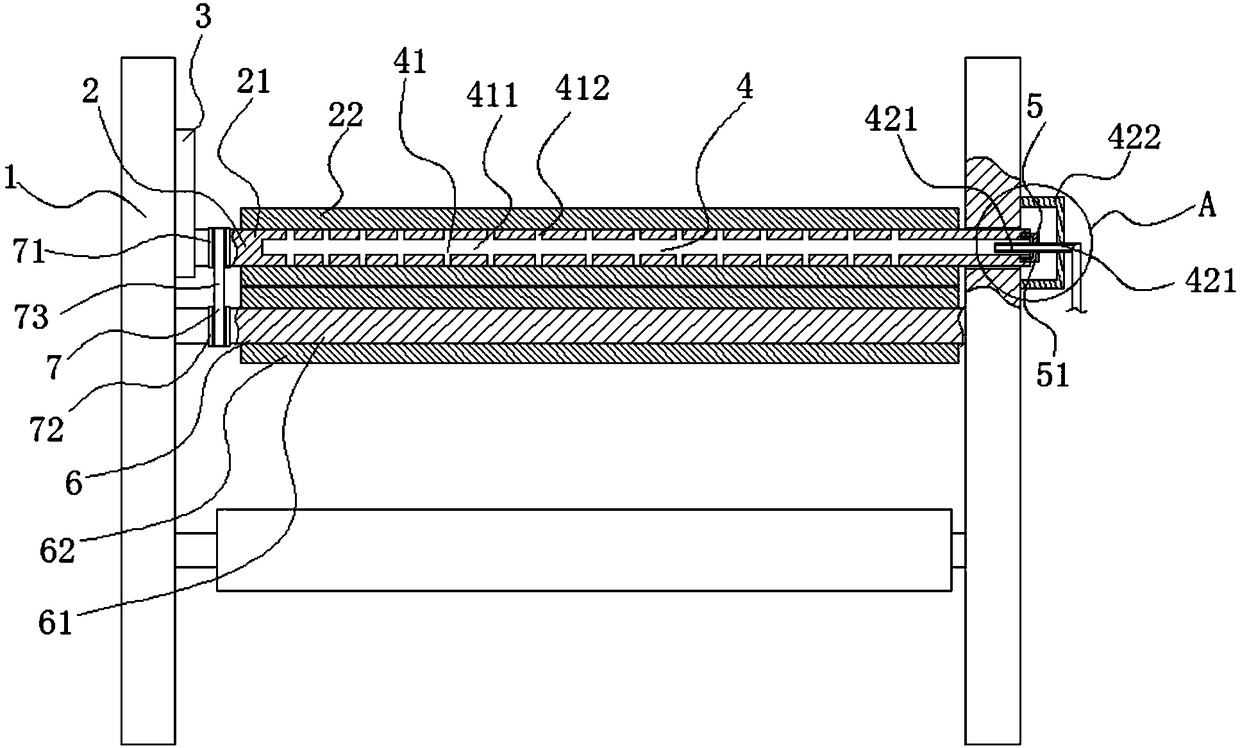

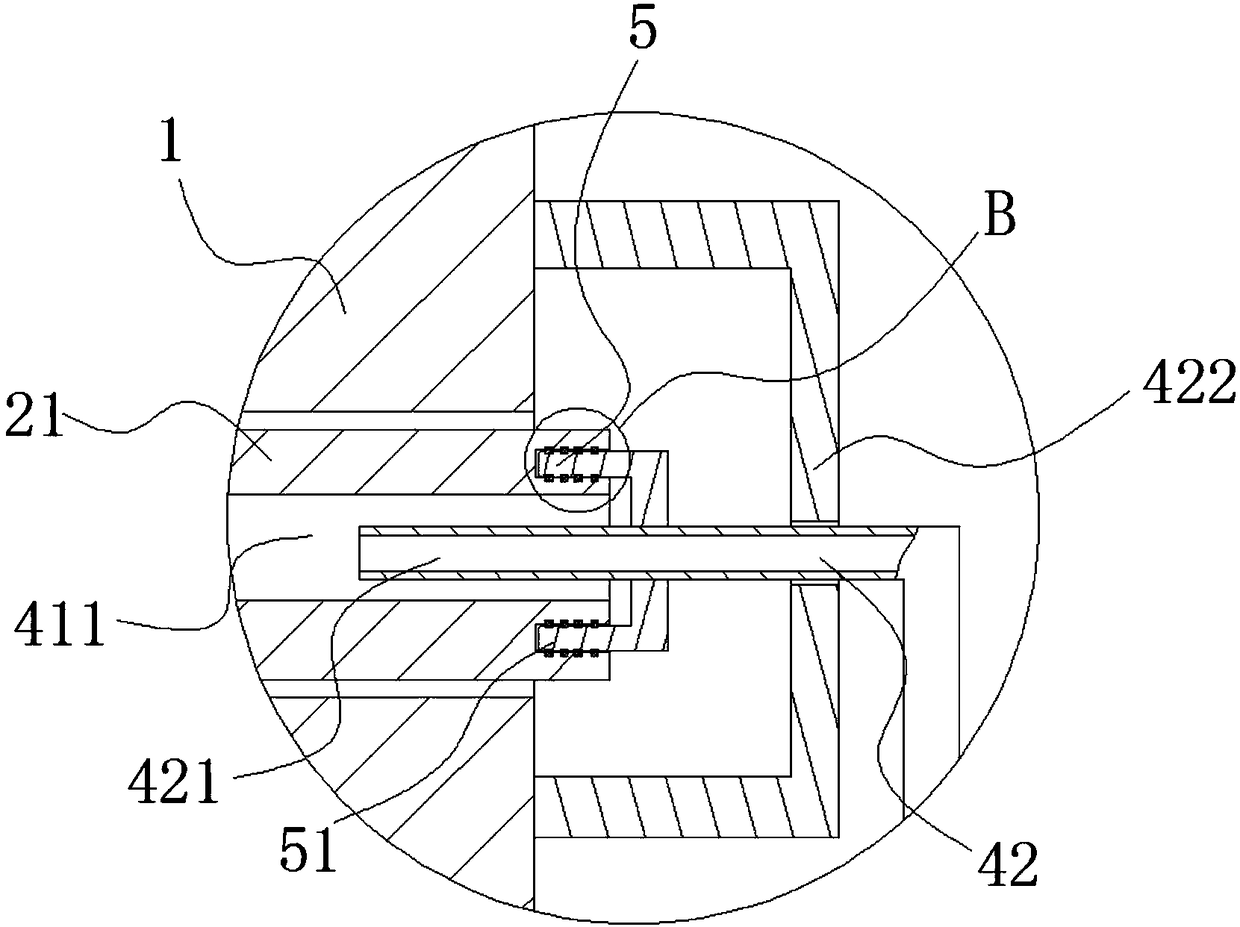

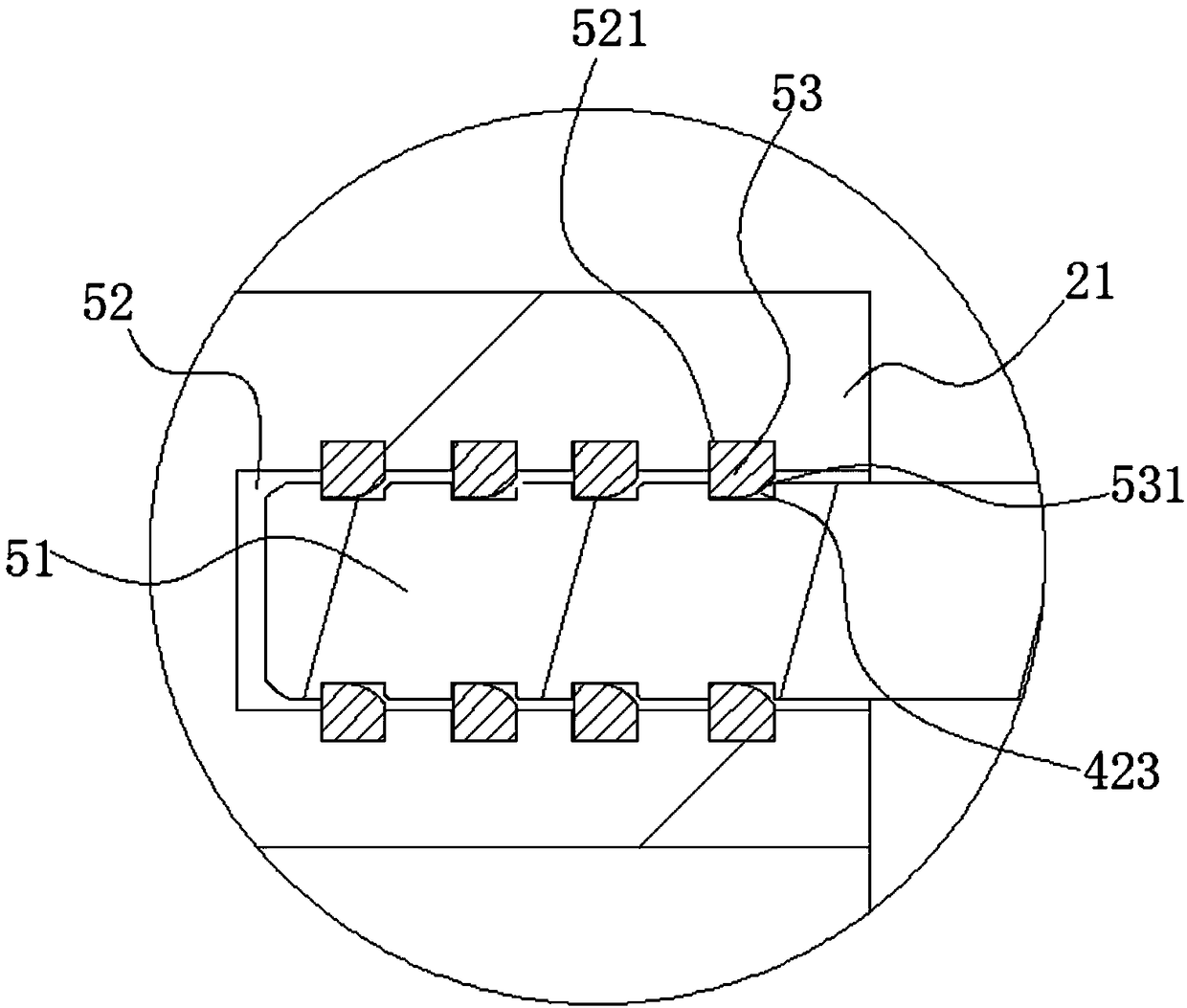

Silk guide mechanism of two-for-one twister for spinning

InactiveCN111893605AIncrease flexibilityImprove practicalityTextiles and paperPolymer scienceEngineering

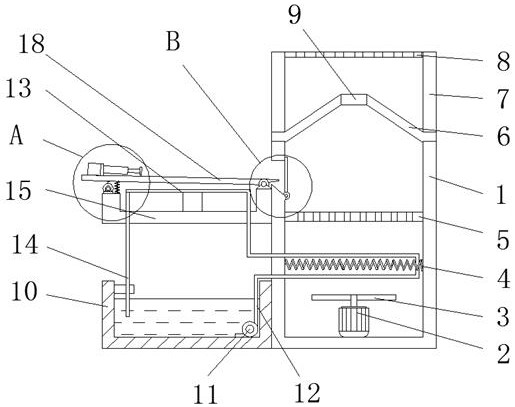

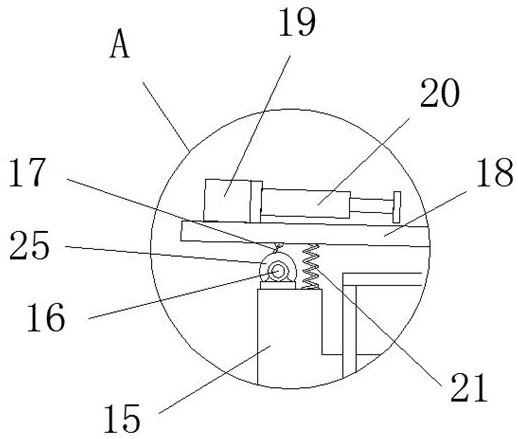

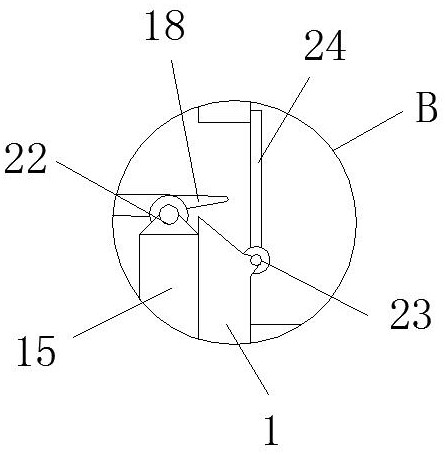

The invention discloses a silk guide mechanism of a two-for-one twister for spinning. The mechanism comprises a bracket, an upper supporting plate, a lower supporting plate and a silk guide wheel, wherein the two ends of the lower supporting plate are fixedly arranged on the bracket respectively, the silk guide wheel is positioned in the middle of the upper supporting plate and the lower supporting plate and fixedly arranged on the bracket, the two ends of the upper supporting plate are fixedly arranged on the bracket respectively, the left side and the right side of the silk guide wheel are provided with a left chuck and a right chuck correspondingly, the silk guide wheel is provided with an upper guide wheel groove and a lower guide wheel groove, the upper side and the lower side of theleft chuck and the right chuck are each provided with a heat conduction mechanism, the upper guide wheel groove is provided with an upper silk guide ceramic sheet, the lower guide wheel groove is provided with a lower silk guide ceramic sheet, the upper silk guide ceramic sheet is rotatably connected with the left chuck and the right chuck, and the lower silk guide ceramic sheet is rotatably connected with the left chuck and the right chuck. The flexibility of the silk guide wheel is improved, and the tension of silk threads is improved.

Owner:湖北中浙梵纺织科技有限公司

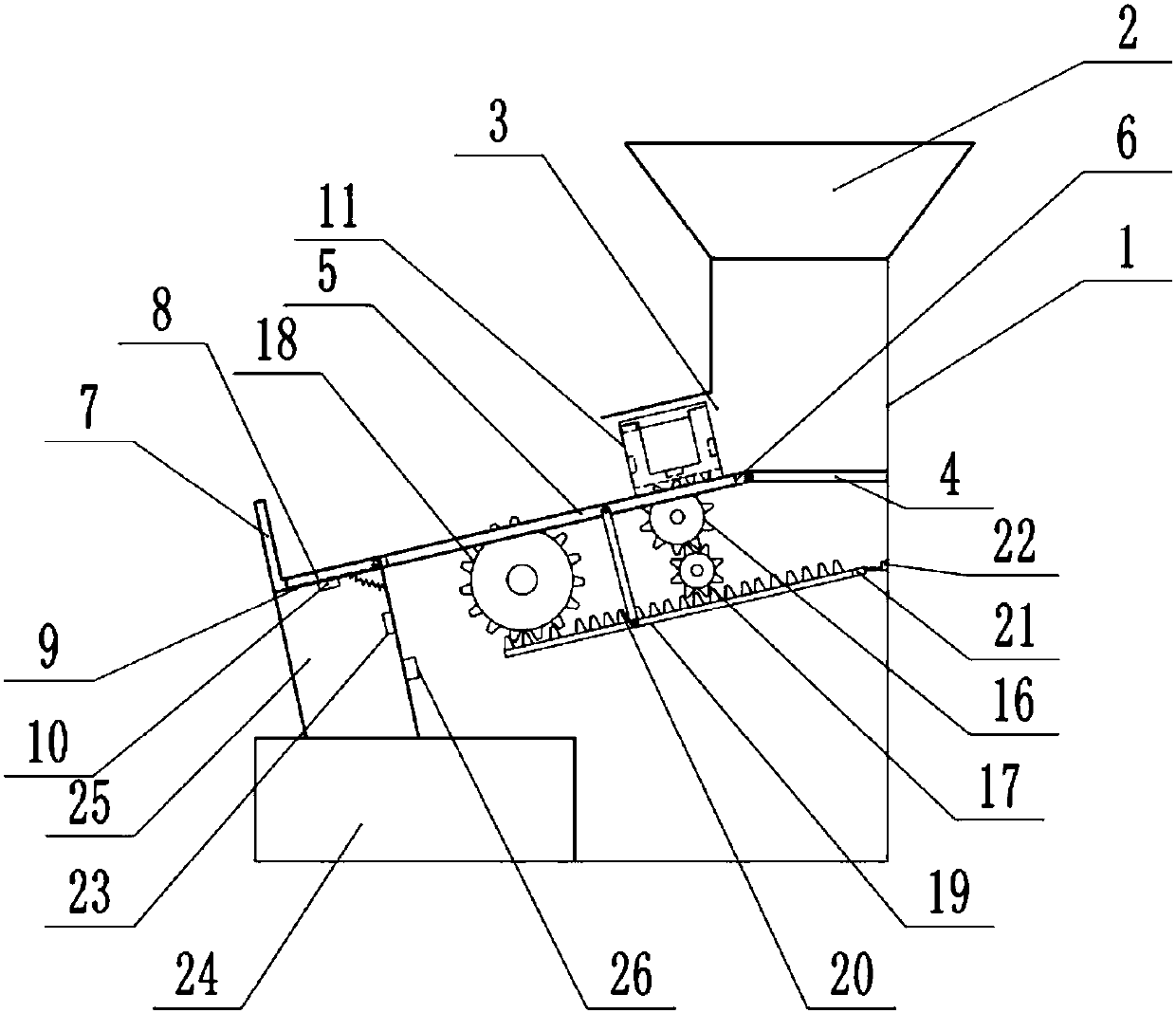

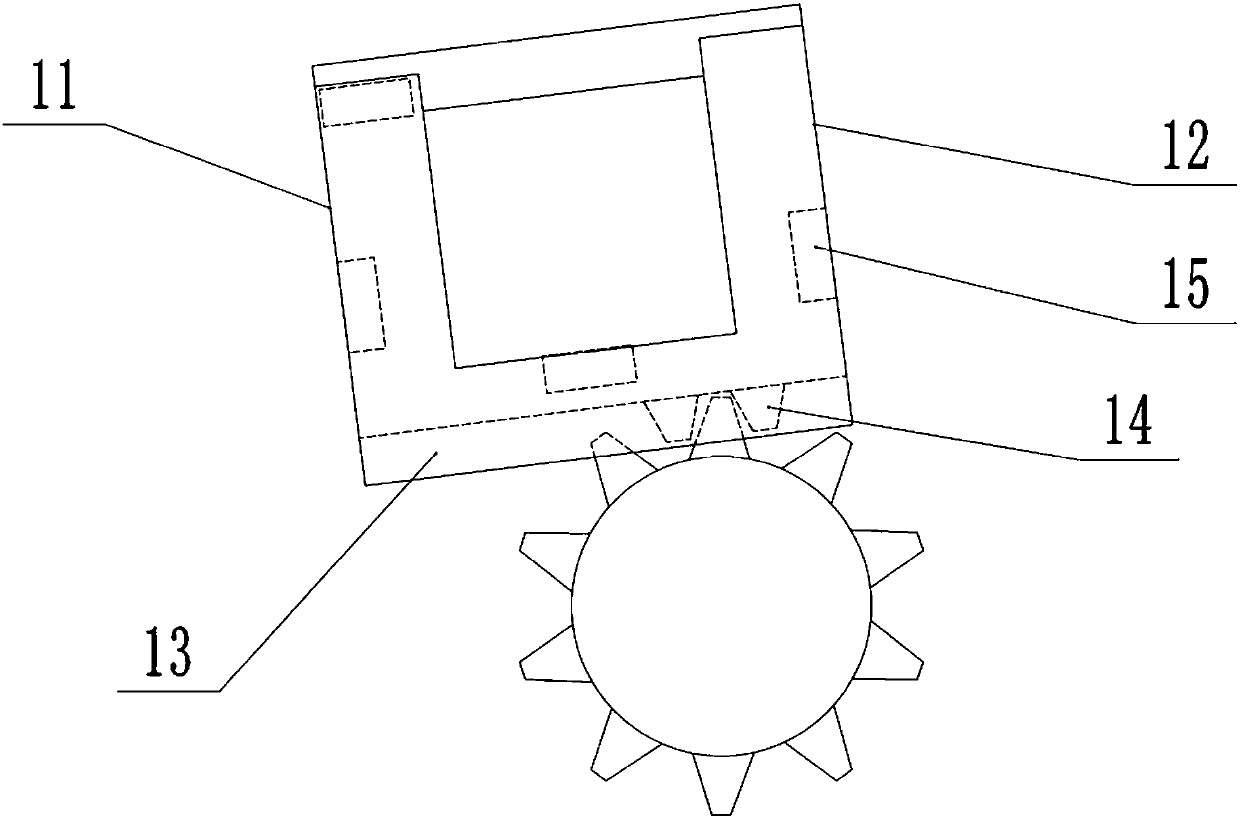

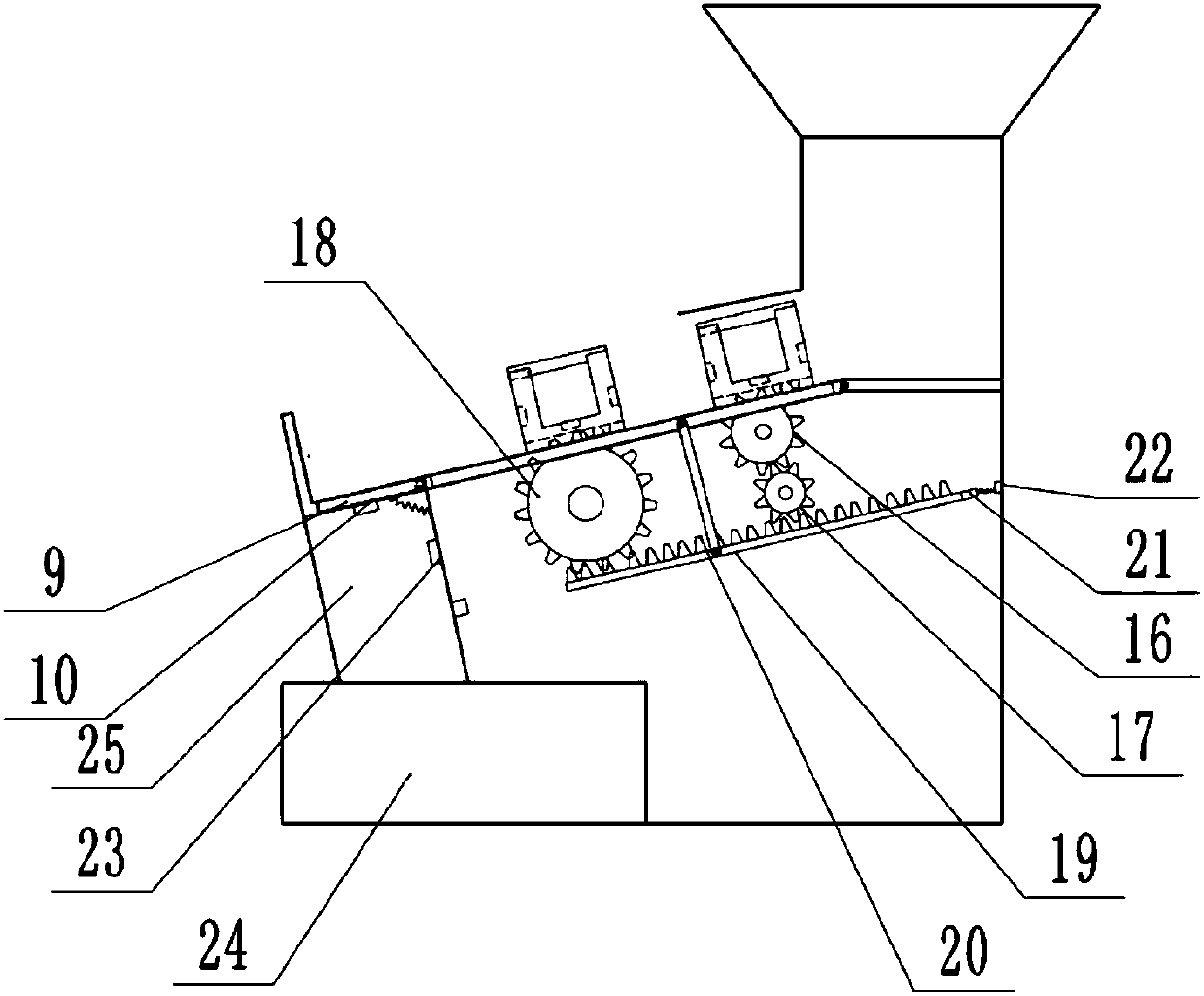

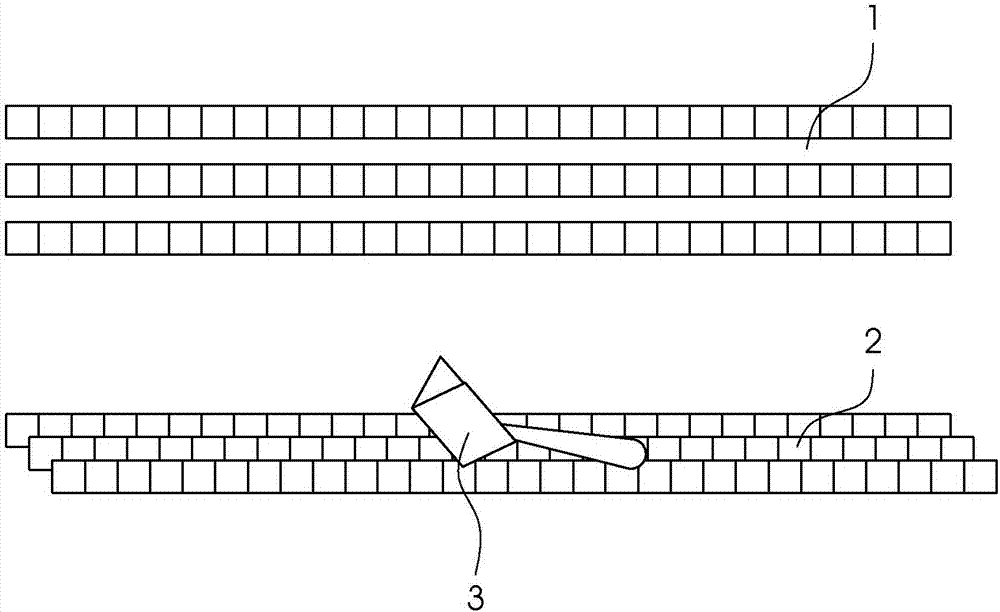

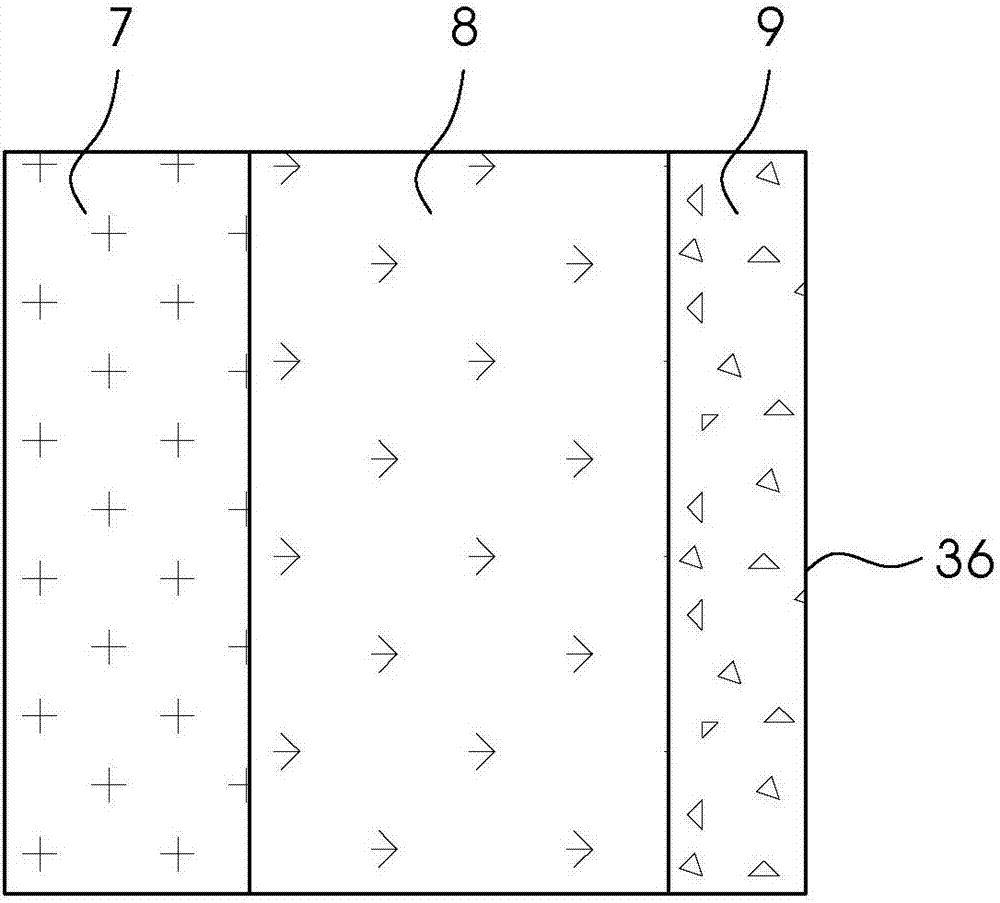

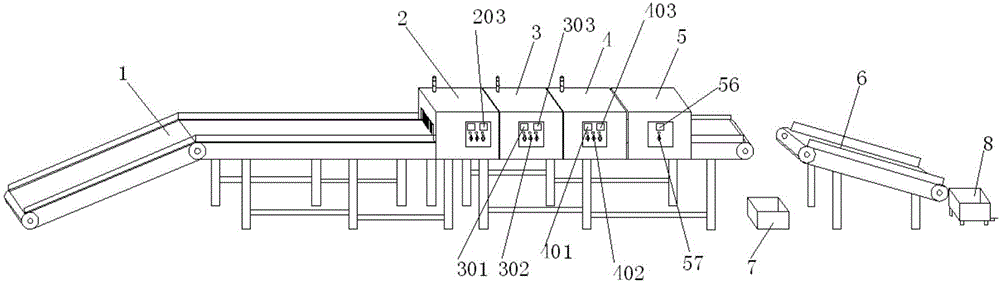

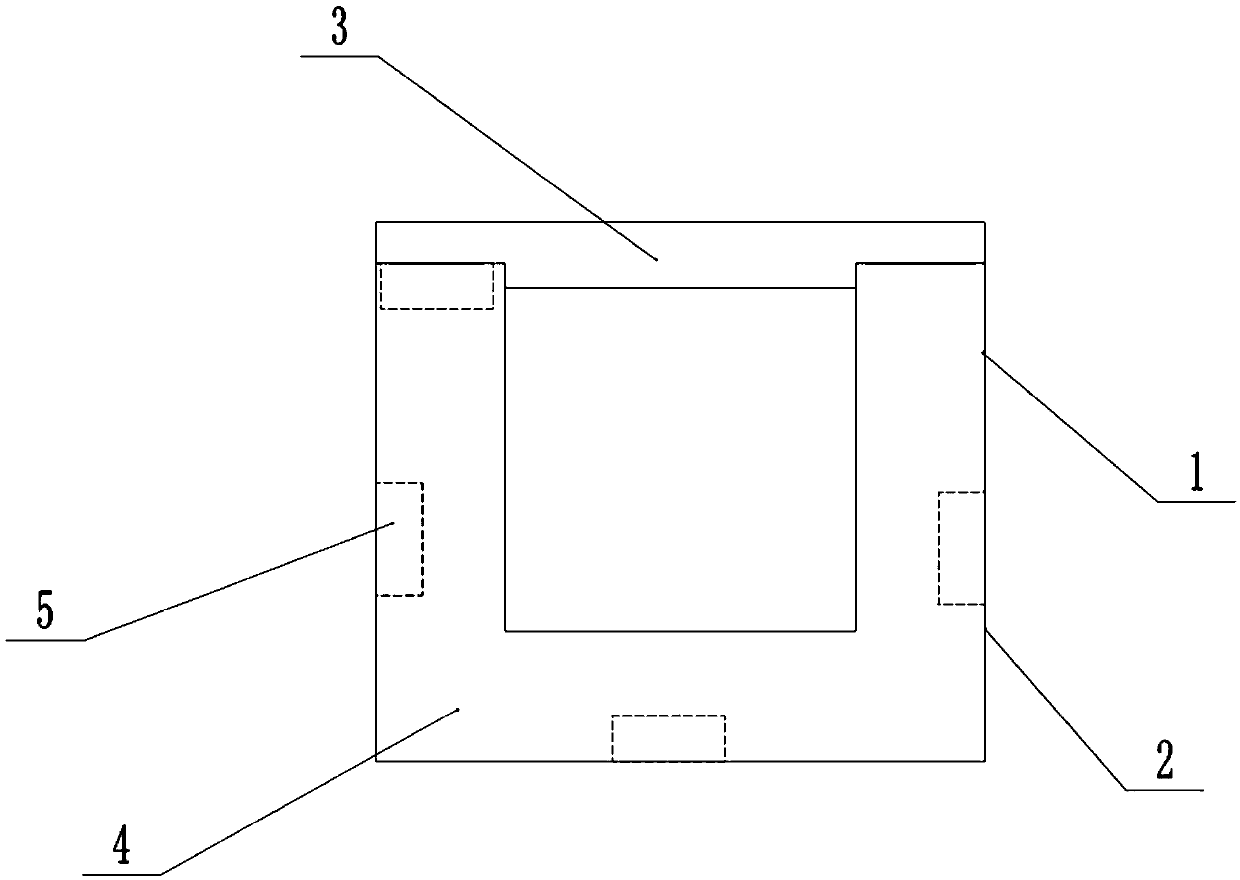

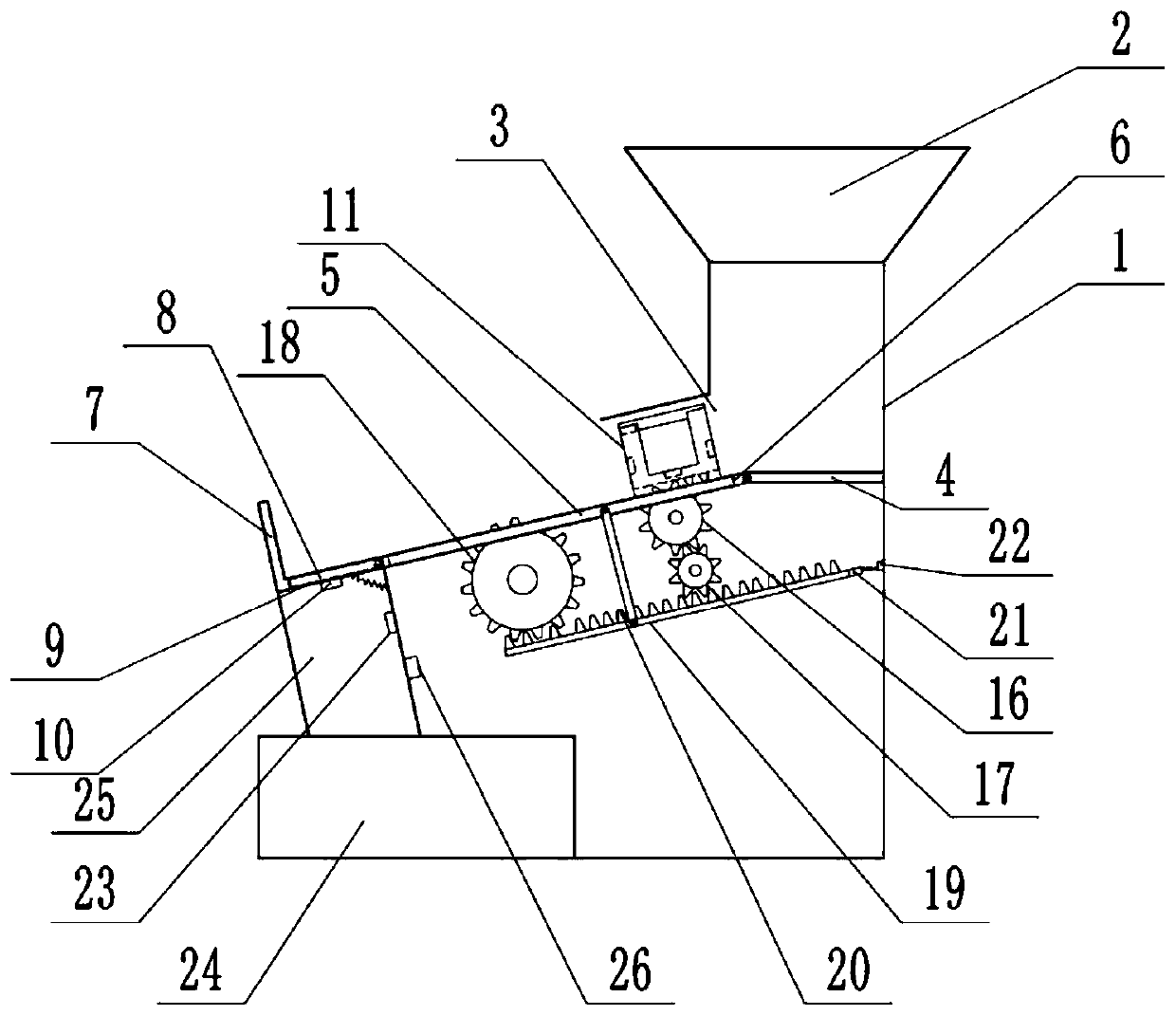

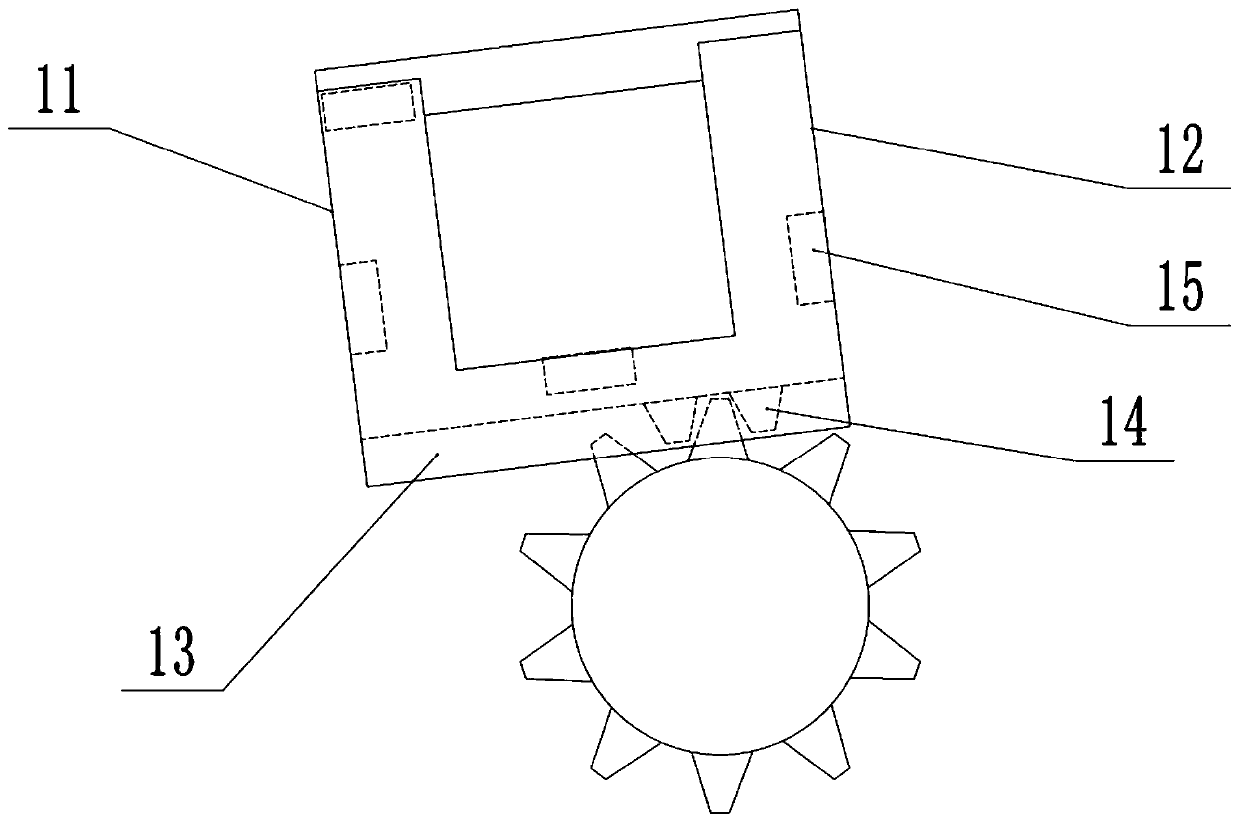

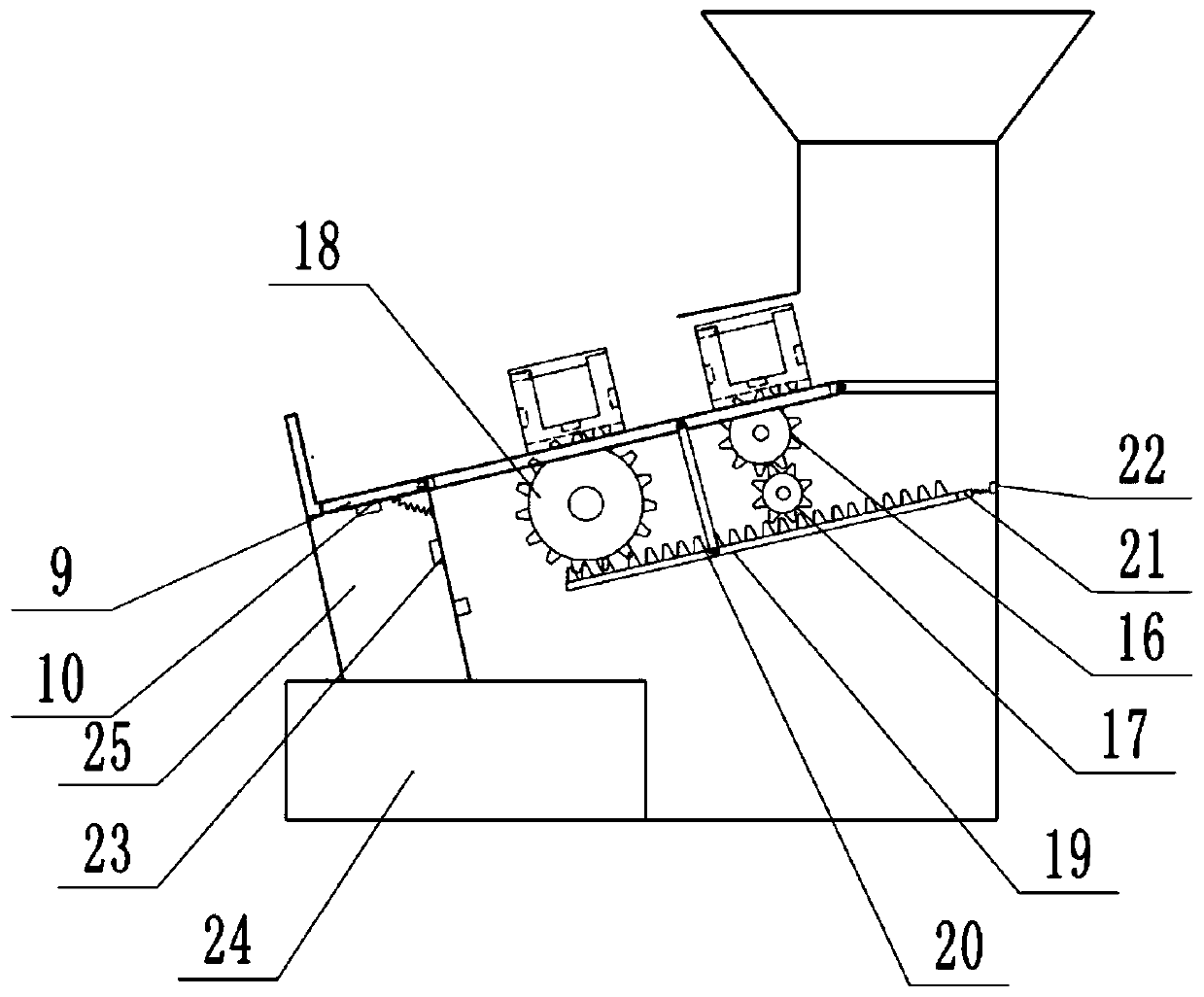

Fruit selling machine realizing split charging and conveying

The invention discloses a fruit selling machine realizing split charging and conveying, relating to the fields of fruit conveying and packing devices. The device comprises a bracket, thermal insulation boxes, a conveying mechanism and a recycling device, wherein a sliding chute is arranged in the bracket, cold sources and magnets are arranged in the thermal insulation boxes, the conveying mechanism comprises a first gear, a second gear and a reversing gear capable of realizing meshing, and the recycling device comprises a recycling box and a recycling channel. With the fruit selling machine realizing split charging and conveying, the problem that during fruit selling on the market, squeezing and damage are easily caused when fruits are stacked together, is solved, and the invention mainlyprovides the fruit selling machine realizing split charging and conveying which can avoid fruit squeezing and can prevent the damage to the quality of the fruits since the fruits are stirred during the process that consumers select the fruits, and also can automatically recycle the fruits with poor appearance and in deterioration.

Owner:徐州宇之阳市场营销策划有限公司

Process for pre-steaming duck blood

PendingCN106616428ADamage qualityAvoid the effects of infringementMeat/fish preservation by heatingChemistry

The invention discloses a process for pre-steaming duck blood. The process comprises the following steps: S1, collecting duck blood; S2, filtering; S3, blending; S4, filling; S5, pre-steaming, namely, putting filled and cured duck blood into a pre-steaming device, and steaming for 40-45 minutes in an environment of 110-130 DEG C; S6, packaging; S7, sterilizing, thereby obtaining the pre-steamed duck blood. By adopting the process disclosed by the invention, the pure duck blood is pre-steamed, so that the situation that harmful substances can be generated and the quality of the duck blood is damaged if the duck blood is heated together with a tray box can be avoided, and the duck blood made by using the process can be taken instantly after a bag is opened, and is tender and tasty and safe to eat.

Owner:河南华英樱桃谷食品有限公司 +1

Image inspection method with a plurality of cameras

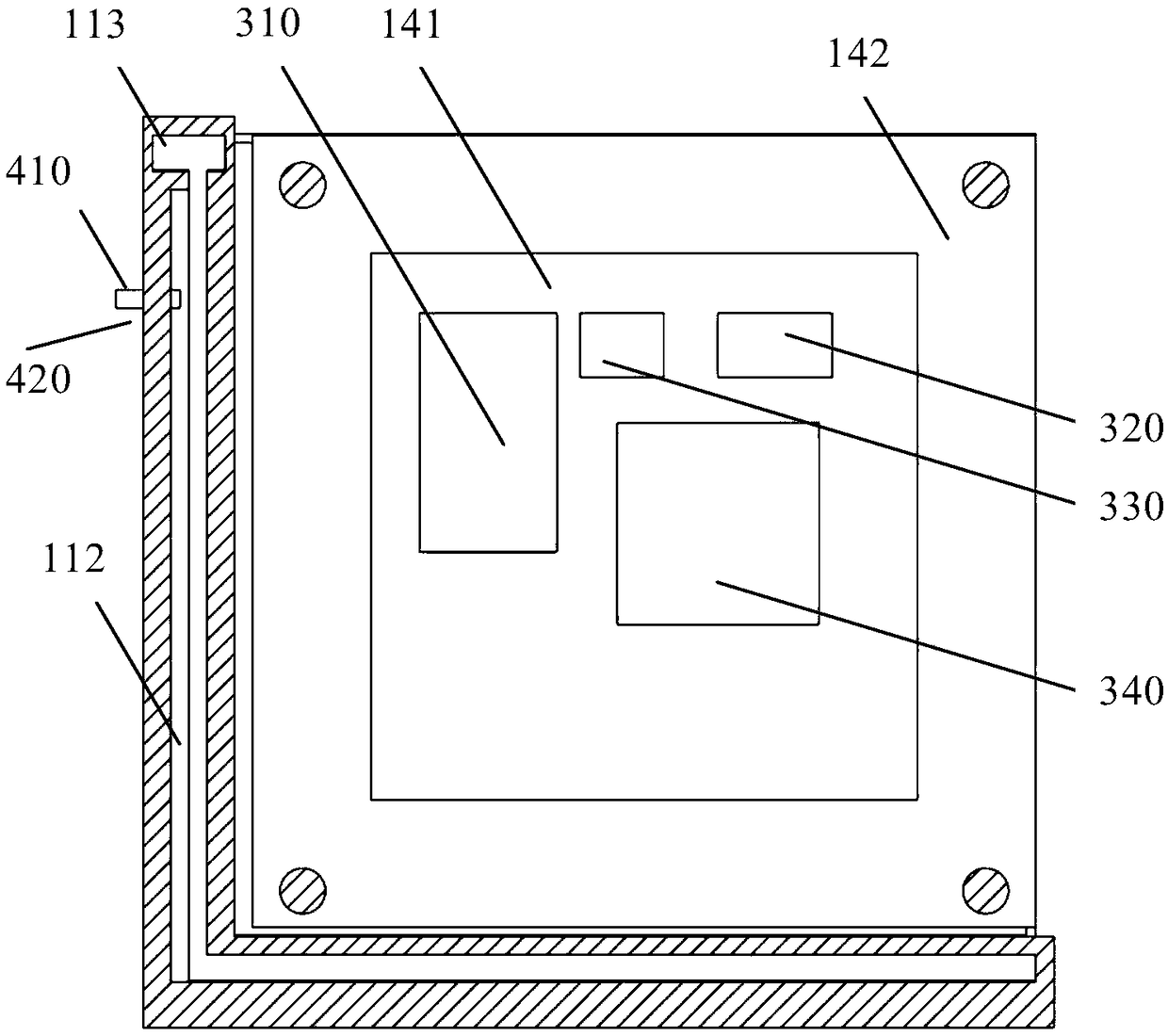

ActiveCN107155094ADamage qualityImprove qualityImage enhancementImage analysisImage InspectionImaging processing

A digital image inspection method checks printing material processing machine products by recording digital printed partial images using recording devices and combining partial images in an image processing computer forming a digital overall image causing abutment edges at an overlap. The image processing computer inspects the digital overall image and transmits a result to a machine control computer. The image processing computer creates a new image, only containing detected edges, using edge detection methods after combining partial images forming a digital overall image. The image processing computer uses known positions of abutment edges of recording devices to create a further new image only containing regions with abutment edges of recording devices. The image processing computer overlays the new images, providing a resultant image containing only edges along abutment edges of recording devices. The image processing computer applies the resultant image to the digital overall image, defining masking zones in the resultant digital overall image not being checked by image inspection.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

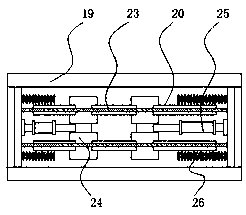

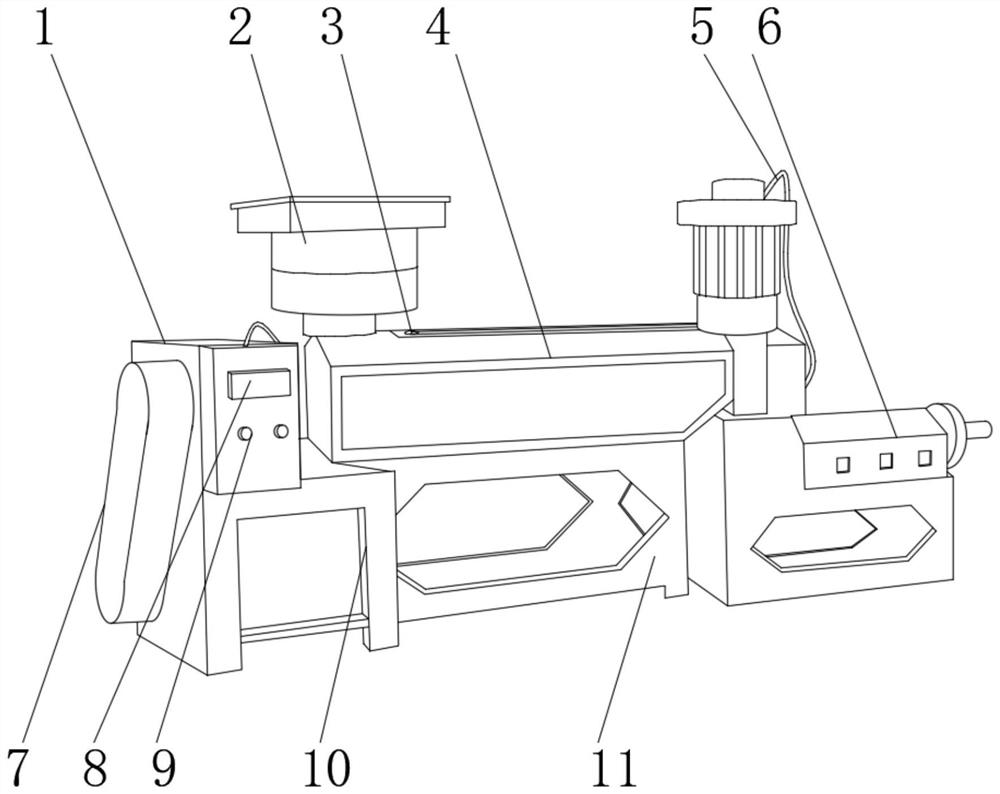

Filterable cutting type high-efficiency crushing machine for chemical processing

The invention discloses a filterable cutting type high-efficiency crushing machine for chemical processing. The crushing machine comprises a main body, a grinding chamber and a containing chamber. A funnel is fixed to the upper portion of the interior of the main body. A containing box is arranged on the left side of the main body. The funnel and the main body are fixedly welded. A cutting chamberis arranged below the funnel. A first motor is mounted on the right side of the cutting chamber. A grinding jar is arranged in the grinding chamber. The grinding chamber is located on the right sideof the main body. Through arrangement of the containing box, chemicals can be placed onto the main body conveniently; the containing box and a rotary shaft form a rotary structure; the chemicals are placed into the containing box, the containing box is turned over through the rotary shaft, and the chemicals are directly placed into the main body to protect human hands from making contact with thechemicals and prevent the quality of the chemicals from being affected; the chemicals can be cut through the cutting chamber, and the external shape of the cutting chamber is in a U shape. In this way, the chemicals are prevented from adhering to the sidewall of the cutting chamber, and the chemicals can be discharged into the containing box from a leak plate.

Owner:QINGZHOU JINGCHENG MEDICINE EQUIP MFG

Heat insulation coating filling facility

PendingCN108715433ASolve pollutionShort path of motionBarrels/casks fillingFilling device cleaningThermal insulationEngineering

The invention relates to the technical field of coating filling equipment, and discloses a heat insulation coating filling facility. The heat insulation coating filling facility comprises a machine platform. A filling position is arranged on the machine platform, a coating box is arranged above the filling position and connected with a filling pipe, and a filling valve is arranged on the filling pipe in a rotating mode. A protective mechanism is arranged on the machine platform, and comprises a rotating shaft, wherein the rotating shaft is arranged in a rotating mode. The rotating shaft is connected with a reciprocating driving mechanism, a driving gear is fixedly connected to the rotating shaft, and meshes with a driven gear, and the driven gear is fixedly connected with a lead screw which vertically penetrates through the machine platform. The lead screw and the machine platform are connected in a rotating mode, and a matched sliding sleeve is arranged on the lead screw in a sleevingmode. A stretching rod is arranged between the sliding sleeve and the machine platform, and the two ends of the stretching rod are fixedly installed on the machine platform and the sliding sleeve correspondingly. Baffles are fixedly connected to the sliding sleeve, located on the side of the filling position and used for sheltering a splashing coating. By means of the heat insulation coating filling facility, the problem that due to the fact that the coating is prone to splashing, the processing environment and filling barrels are contaminated can be solved.

Owner:重庆阿罗科技有限公司

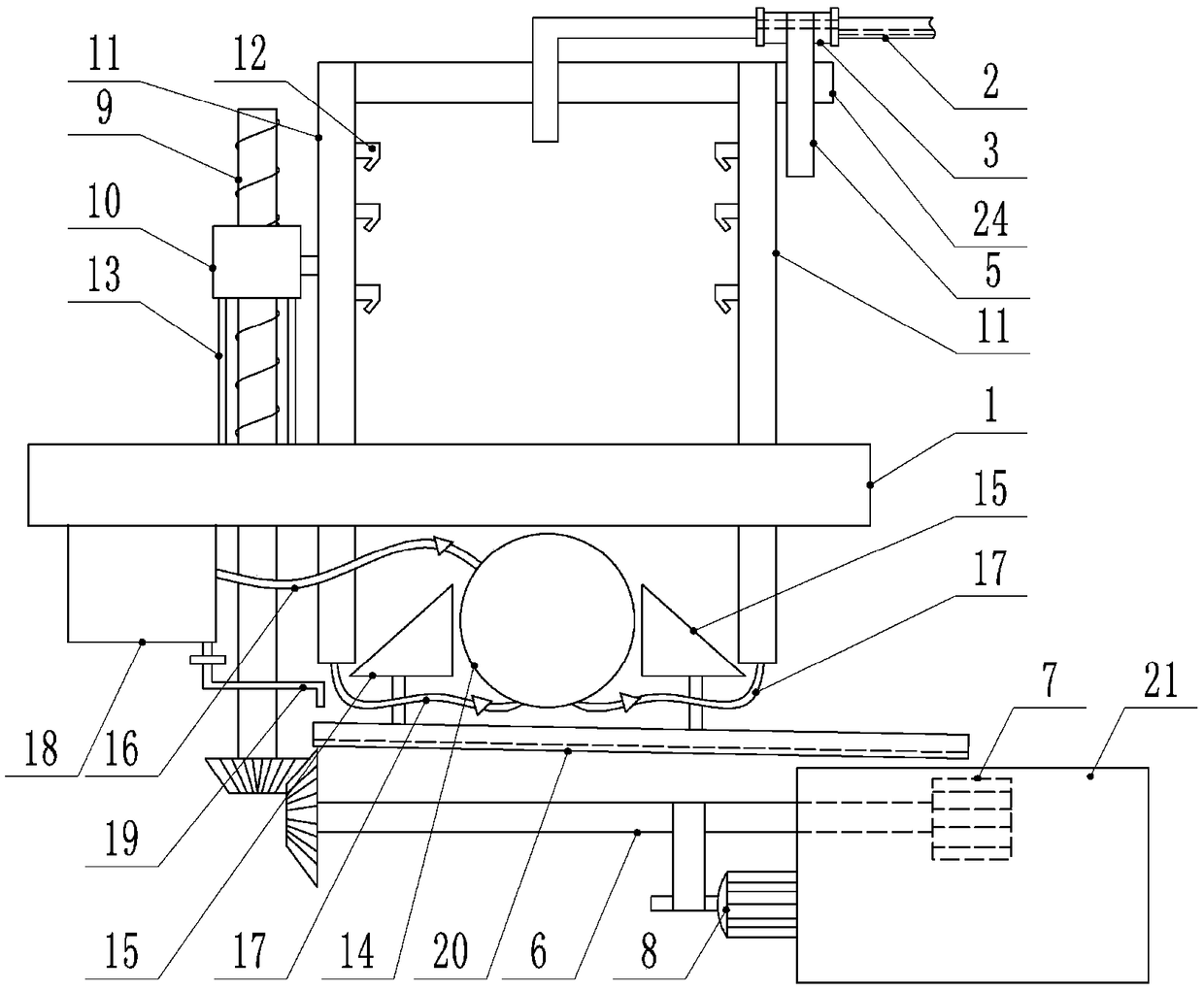

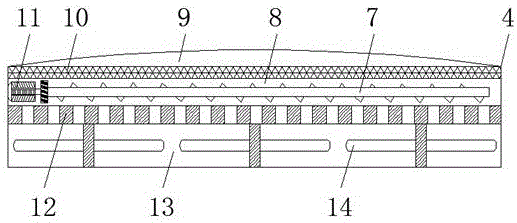

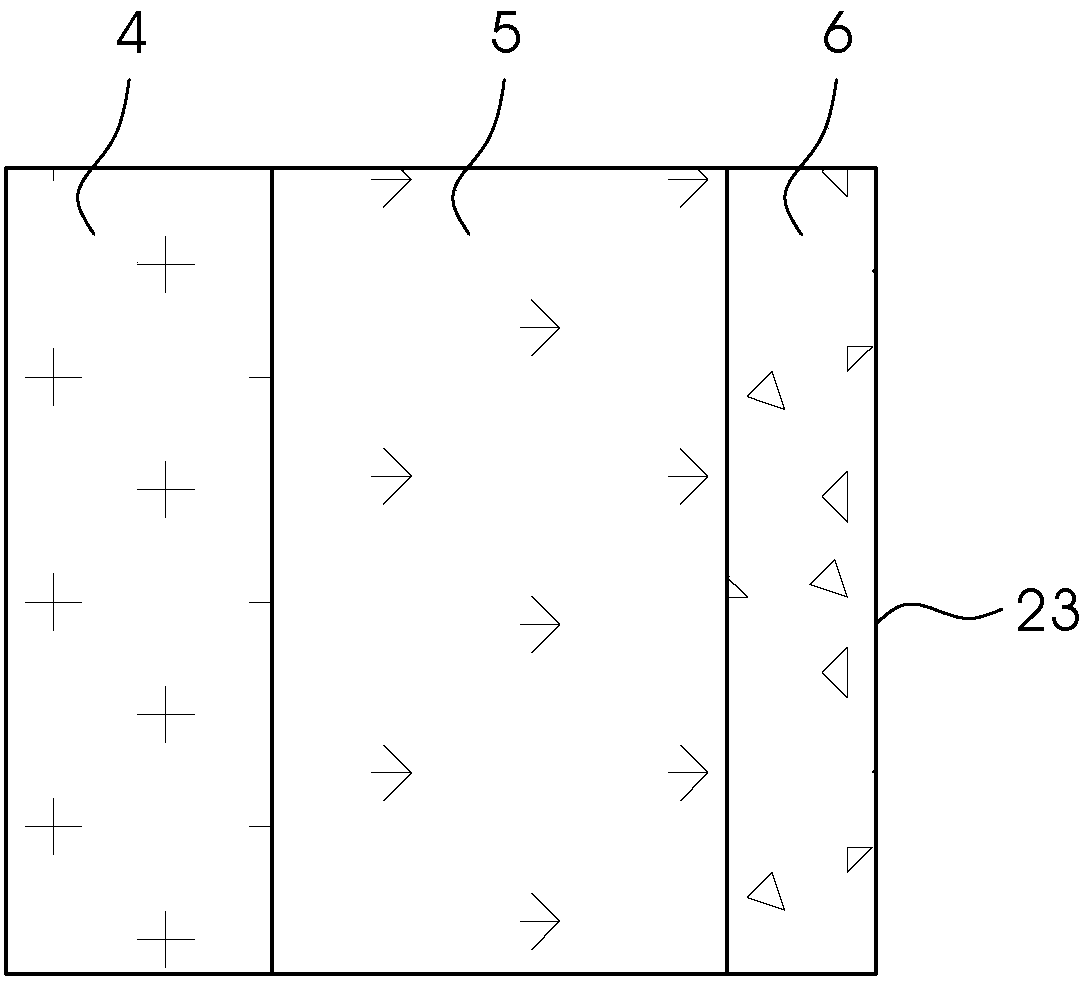

Large-batch grain drying production line

ActiveCN106595273ADamage qualityUniform qualityDrying solid materials without heatDrying gas arrangementsProduction lineEngineering

The invention discloses a large-batch drying production line which comprises a circulation conveying line which can cyclically convey grain products. A grain preheating area, a grain warming area, a grain drying area and a grain cooling area are sequentially arranged on the circulation conveying line from a grain inlet end to a grain outlet end. The grain outlet end of the circulation conveying line is provided with a grain separation and filtering area. The grain preheating area, the grain warming area and the grain drying area are provided with grain heating spaces for grain to pass. The temperatures of the grain heating spaces are sequentially increased from left to right, the highest temperature of the grain heating spaces is lower than 60 degrees, and the temperatures of the grain heating spaces of the grain preheating area, the grain warming area and the grain drying area are independently controlled.

Owner:安徽荣粮油脂有限公司

Method for the preparation of isocyanate by partially adiabatic phosgenation of the corresponding amine

PendingCN111170891ADamage qualityLess solventOrganic compound preparationIsocyanic acid derivatives purification/separationIsocyanateFluid phase

The present invention relates to a process for preparing an isocyanate by reacting a primary amine with phosgene, comprising I) providing an amine solution and adjusting its temperature in a heat exchanger, II) providing a phosgene solution and adjusting its temperature in a heat exchanger, III) mixing the amine solution with the phosgene solution in a mixing unit, followed by IV) further conversion in an adiabatically operated reaction zone and the removing of the gas phase formed as a result of the chemical reaction in a separation zone, V) expanding the remaining liquid phase, VI) further conversion of the liquid phase remaining after expansion in an indirectly heated reaction zone and VII) isolating the isocyanate from the reaction solution obtained therein, in which the temperature inthe reaction zone and separation zone is adjusted by fixing a target value within a range from 110 DEG C to 145 DEG C. for the temperature of the reaction mixture from step III) and using the actualtemperature of the reaction mixture from step III) measured continuously or at intervals for closed-loop control of the temperature of the solution of the primary amine provided in step I) and / or of the temperature of the solution of phosgene provided in step II) by means of the heat exchangers used to adjust the temperature of each of these solutions.

Owner:COVESTRO DEUTSCHLAND AG

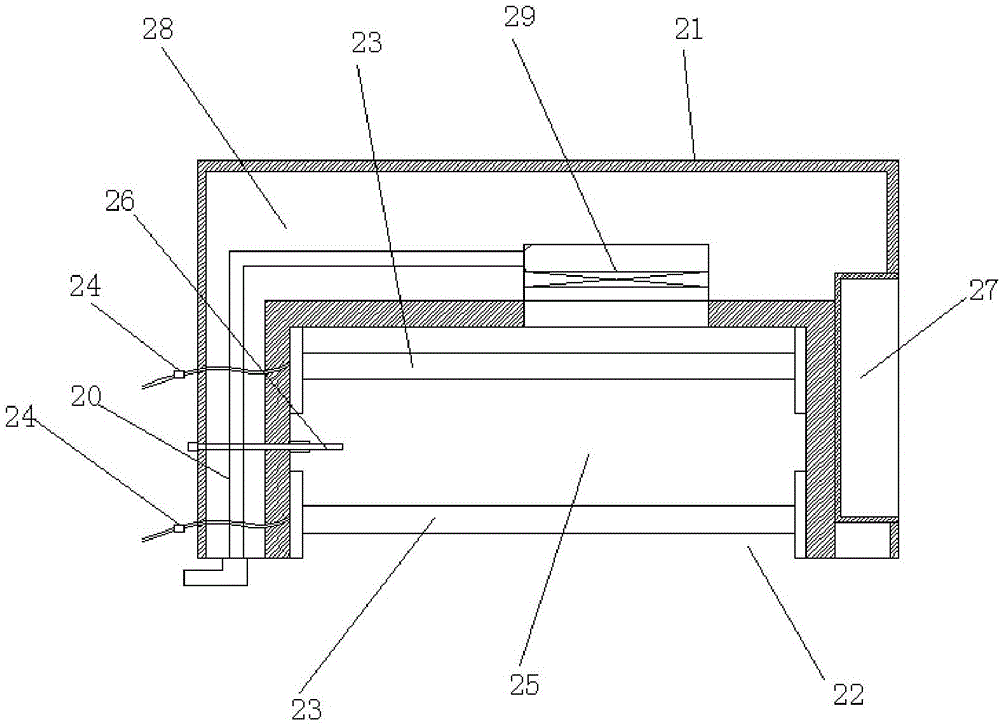

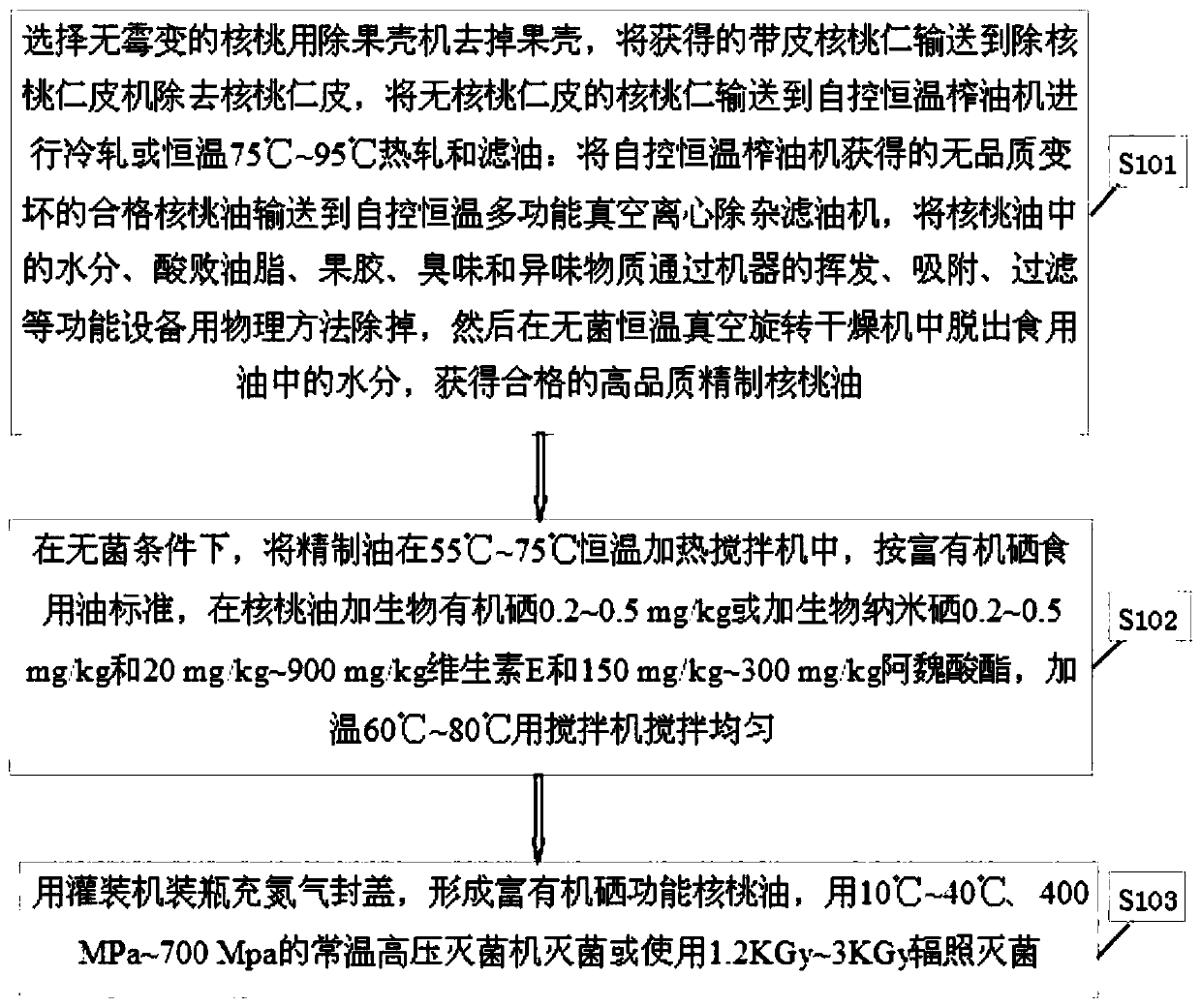

Production method of functional walnut oil rich in biological organic selenium

PendingCN111411015ANo lossRegenerative cleaning is convenient and quickFatty-oils/fats refiningFood preservationBiotechnologyWalnut Nut

The invention belongs to the technical field of fat or grease oil refining, and discloses a production method of functional walnut oil rich in biological organic selenium. The production method comprises the following steps: selecting mildew-free walnuts, removing shells of the walnuts by using a shell removing machine, conveying obtained walnut kernels with shells to a walnut kernel skin removingmachine to remove walnut kernel skins, and producing qualified high-quality refined walnut oil by using high-tech physical walnut oil squeezing equipment and high-tech physical refined oil refining equipment; under a sterile condition, adding biological organic selenium or biological nano-selenium into the refined oil in a 55-75 DEG C constant-temperature heating stirrer, and uniformly stirring;and bottling by using a filling machine, filling nitrogen and sealing to form the functional walnut oil rich in biological organic selenium. The qualified high-quality refined walnut oil is obtained,the taste and quality of the walnut oil are remarkably improved, and the impurity content of the walnut oil is greatly reduced; meanwhile, biological organic selenium or biological nano-selenium is added to form a new organic-selenium-rich functional walnut oil commodity which has market requirements and is beneficial to human health, and the quality and additional value of the walnut oil are improved.

Owner:HUBEI HUALONG XIKE BIOLOGICAL TECH CO LTD

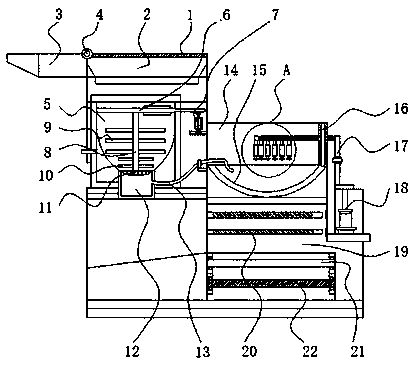

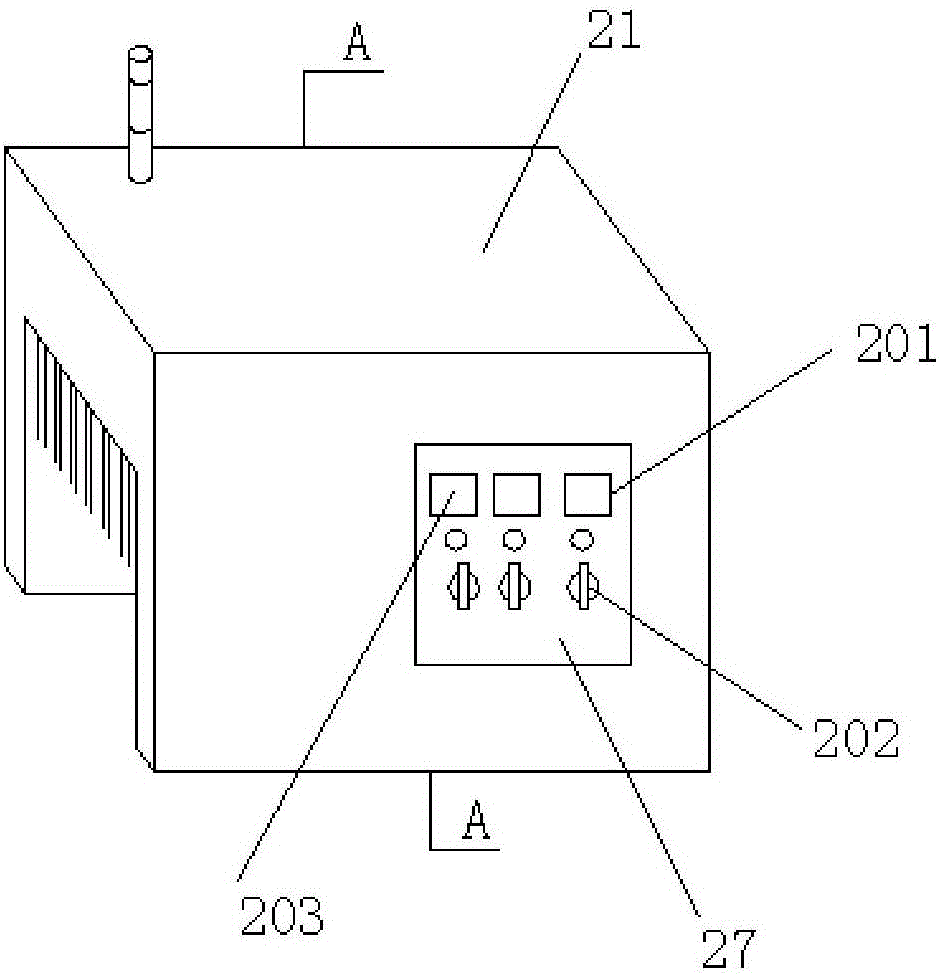

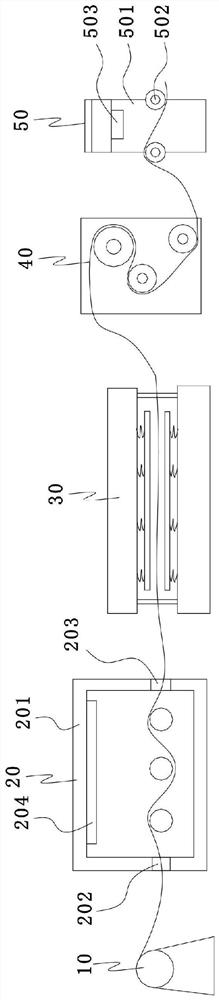

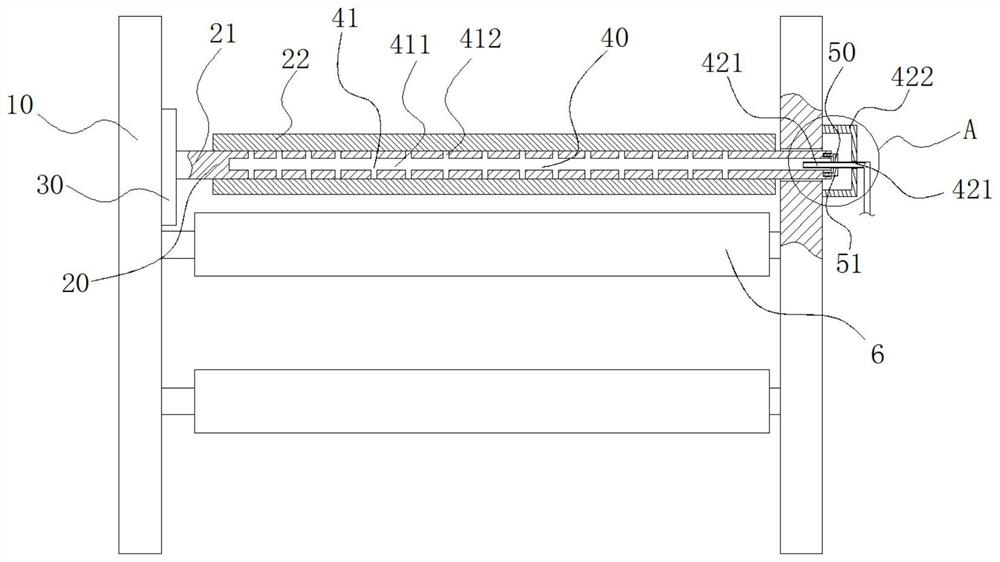

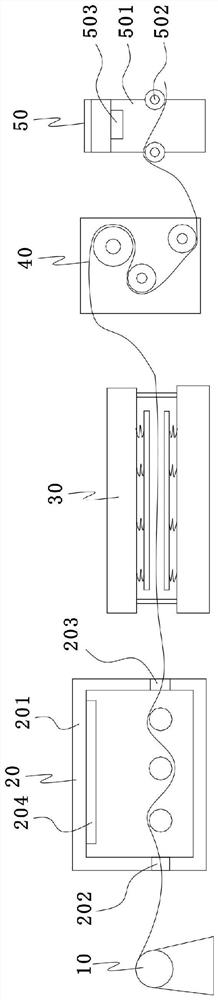

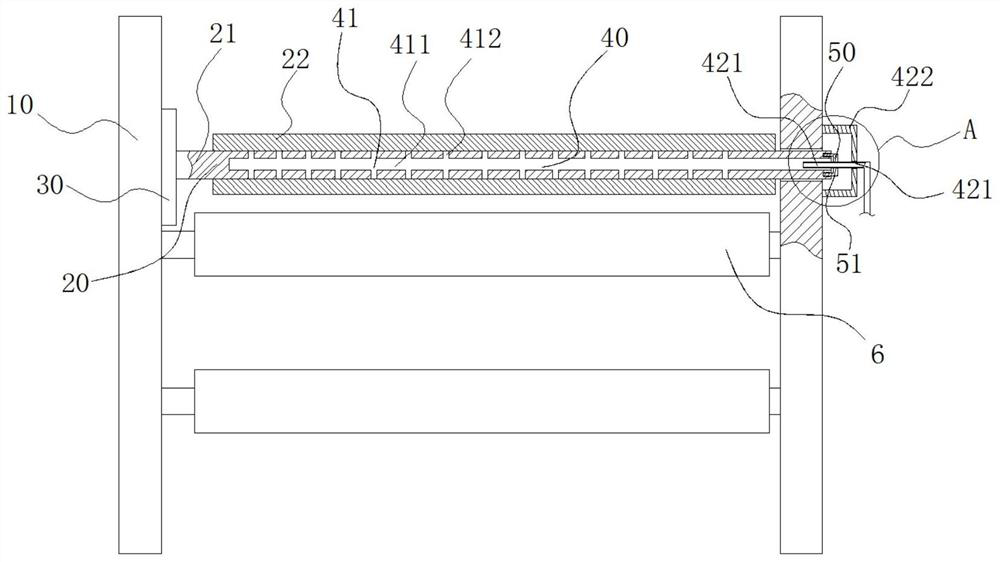

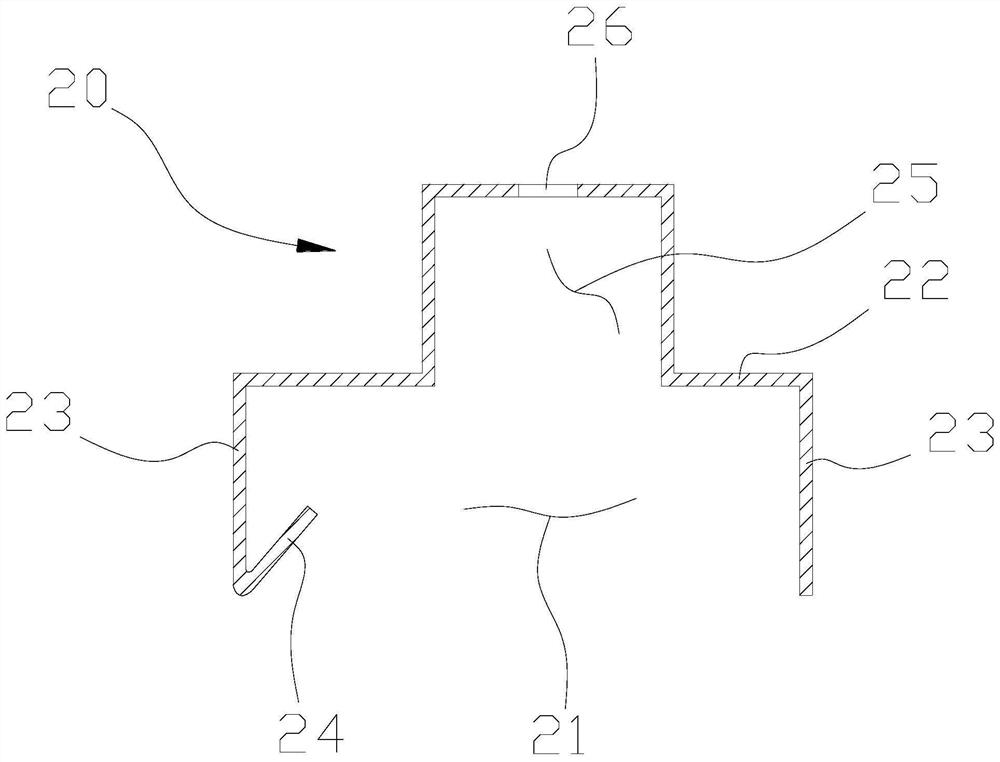

Processing system of high-quality PVC film

InactiveCN111873497AIncrease humidityReduce the temperatureFlat articlesEngineeringMechanical engineering

The invention discloses a processing system of a high-quality PVC film. The processing system comprises a material rolling frame, a heating device used for heating the PVC film, a corona device used for leveling the heated PVC film, and a humidifying device used for humidifying and cooling a PVC film piece. The humidifying device is arranged on the rear side of the corona device and comprises a frame body, a humidifying mechanism arranged on the frame body and a driving piece used for driving the humidifying mechanism to rotate. The humidifying mechanism comprises a rotating piece matched withthe driving piece and a smearing piece used for humidifying the PVC film. The frame body is further provided with a film guide roller used for guiding and conveying the PVC film, and the film guide roller is arranged on the lower portion of the front side of the smearing piece. The film guide roller is arranged on the lower position of the front side of the smearing piece, so that the smearing piece is coated with the PVC film in a large area in the conveying process of the PVC film, the contact area between the PVC film and the smearing piece is increased to a great extent, the humidifying effect is enhanced, it is guaranteed that the PVC film is well cooled, and the condition that the PVC film is wrinkled and curled in the processing process is avoided.

Owner:杨康君

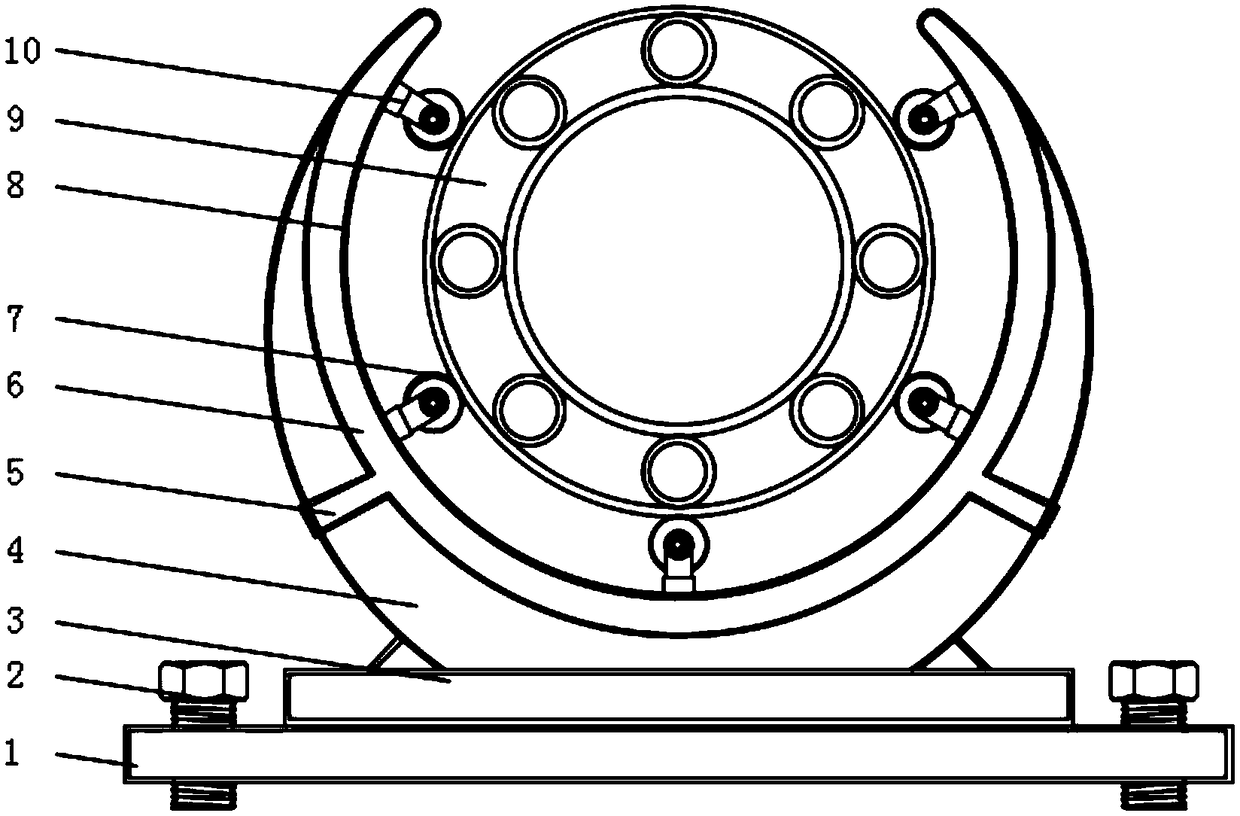

Fixing device for machining bearing

PendingCN108838722AGuaranteed stabilityInfluence structureWork holdersPositioning apparatusEngineeringOperability

The invention discloses a fixing device for machining a bearing. The fixing device comprises a mounting base plate and a bearing plate; the two ends of the mounting base plate are each provided with abolt; the bearing plate is arranged at the middle position of the top of the mounting base plate and at one side of each bolt; the middle position of the top of the bearing plate is provided with a fixing seat; an inner arc is arranged at the inner side of the fixing seat; an oil dividing pipe is arranged inside the fixing seat and is connected with oil inlets; the surface of the inner arc is provided with first hydraulic telescopic rods; and the top end of each first hydraulic telescopic rod is provided with a driving roller. In the fixing device disclosed by the invention, the bearing is bidirectionally fixed by the fixing device by virtue of the fixing seat and an inner fixing disc so as to guarantee the stability of the bearing in a machining process; meanwhile the clamping force of the fixing device can be enhanced by utilizing the first hydraulic telescopic rods and second hydraulic telescopic rods; a traditional manual fixation way is not required; and the operability of the fixing device is improved.

Owner:NANTONG LAIBITE BEARING CO LTD

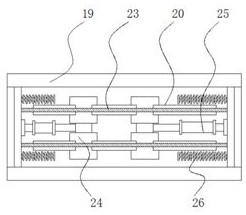

Drying box realizing uniform heating of cut tobacco

InactiveCN111678307AEvenly heatedDry evenlyTobacco preparationDrying solid materials without heatThermodynamicsElectric machinery

The invention provides a drying box realizing uniform heating of cut tobacco and relates to the technical field of tobacco processing and drying. The drying box realizing uniform heating of cut tobacco comprises a drying box body; a blower motor is fixedly installed inside the drying box body; blower blades are fixedly installed at the output end of the blower motor; a collection hood is fixedly installed at the top of the drying box body; a discharging opening is formed inside the collection hood; a leakproof cover is fixedly installed at the top of the collection hood; and a ventilation screen is fixedly installed at the top of the leakproof cover. According to the drying box realizing uniform heating of cut tobacco, the cut tobacco is pushed into the drying box body; the blower motor isused for driving the blower blades to rotate to blow up and make the cut tobacco float inside the drying box body; an electric heating wire is used for generating heat to heat the air flow passing through the electric heating wire; and the heated air flow blows the cut tobacco inside the drying box body, thereby achieving the effect of uniformly drying the cut tobacco by virtue of the high-temperature air and solving the problem about quality reduction of the cut tobacco caused by uneven drying of the cut tobacco.

Owner:李珊珊

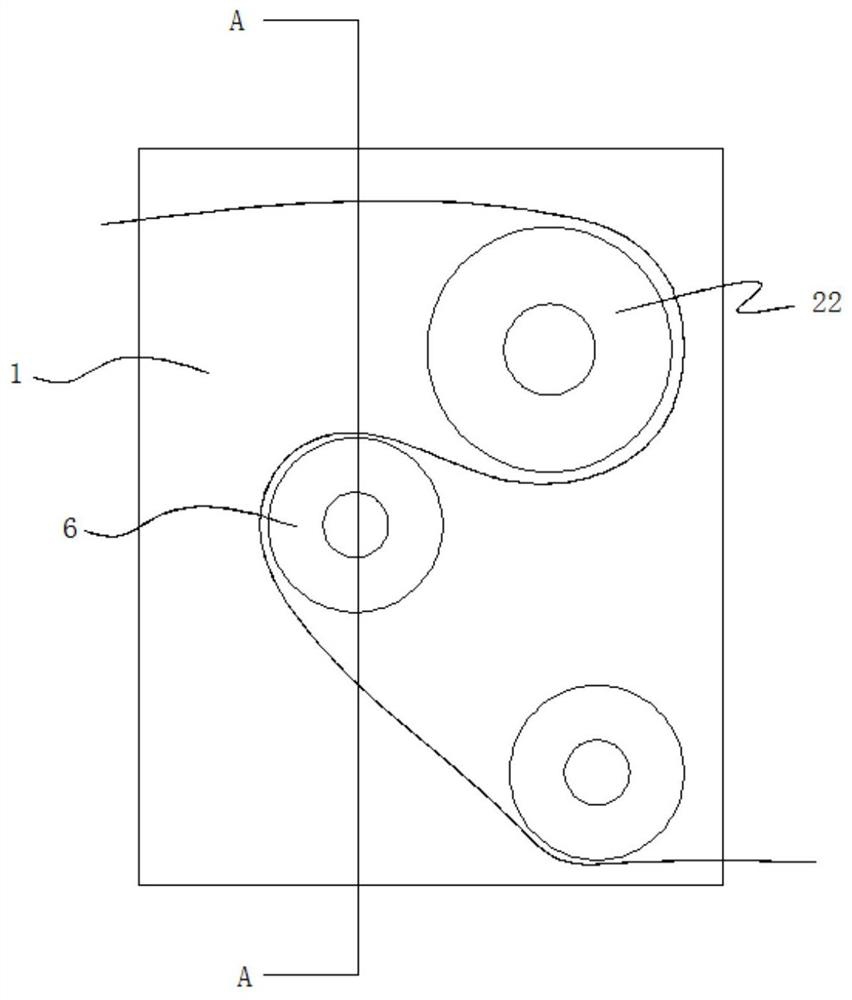

A processing system for pvc film

ActiveCN108638543BAvoid wrinklesAvoid flatnessFlat articlesWebs handlingEngineeringMechanical engineering

The invention discloses a processing system of a high-quality PVC film. The processing system comprises a material rolling frame, a heating device used for heating the PVC film, a corona device used for leveling the heated PVC film, and a humidifying device used for humidifying and cooling a PVC film piece. The humidifying device is arranged on the rear side of the corona device and comprises a frame body, a humidifying mechanism arranged on the frame body and a driving piece used for driving the humidifying mechanism to rotate. The humidifying mechanism comprises a rotating piece matched withthe driving piece and a smearing piece used for humidifying the PVC film. The frame body is further provided with a film guide roller used for guiding and conveying the PVC film, and the film guide roller is arranged on the lower portion of the front side of the smearing piece. The film guide roller is arranged on the lower position of the front side of the smearing piece, so that the smearing piece is coated with the PVC film in a large area in the conveying process of the PVC film, the contact area between the PVC film and the smearing piece is increased to a great extent, the humidifying effect is enhanced, it is guaranteed that the PVC film is well cooled, and the condition that the PVC film is wrinkled and curled in the processing process is avoided.

Owner:SHENZHEN LVYE PLASTIC CO LTD

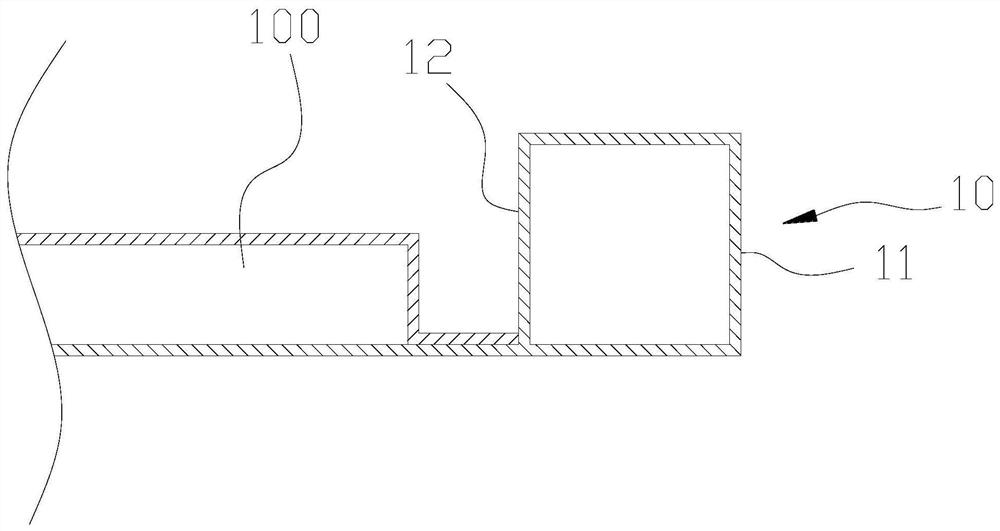

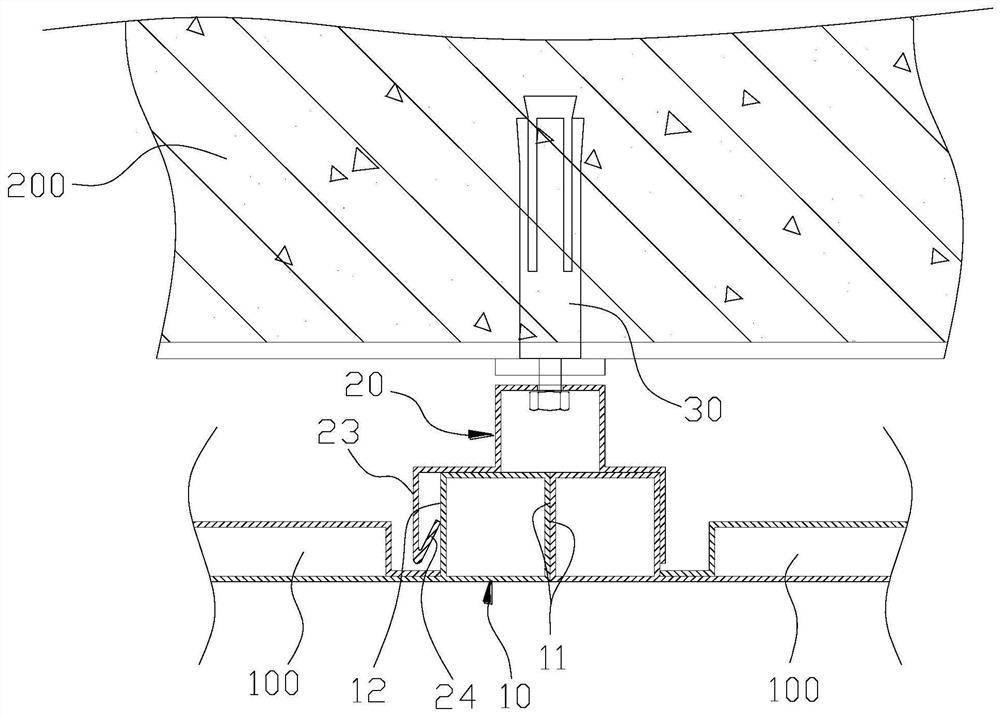

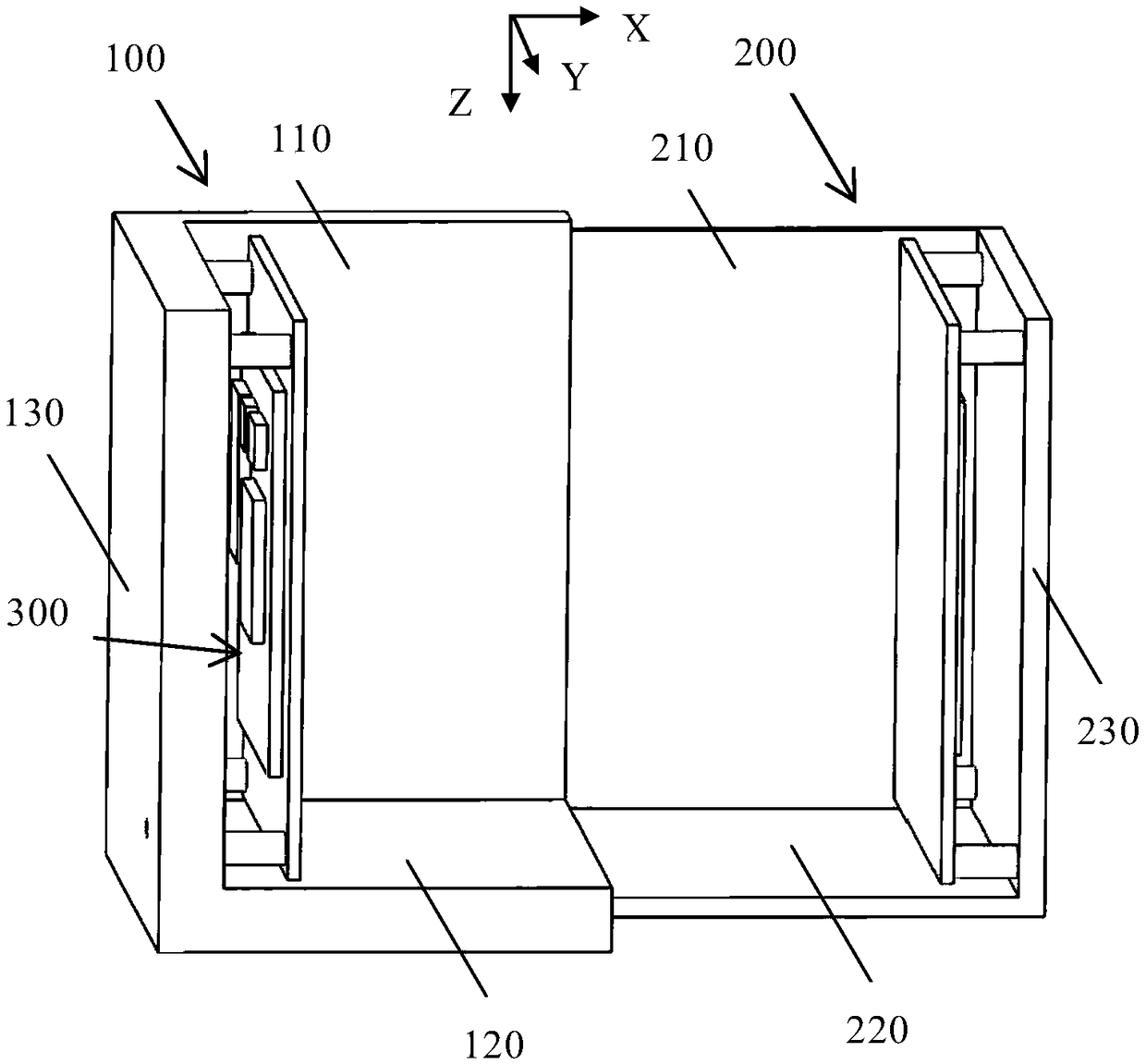

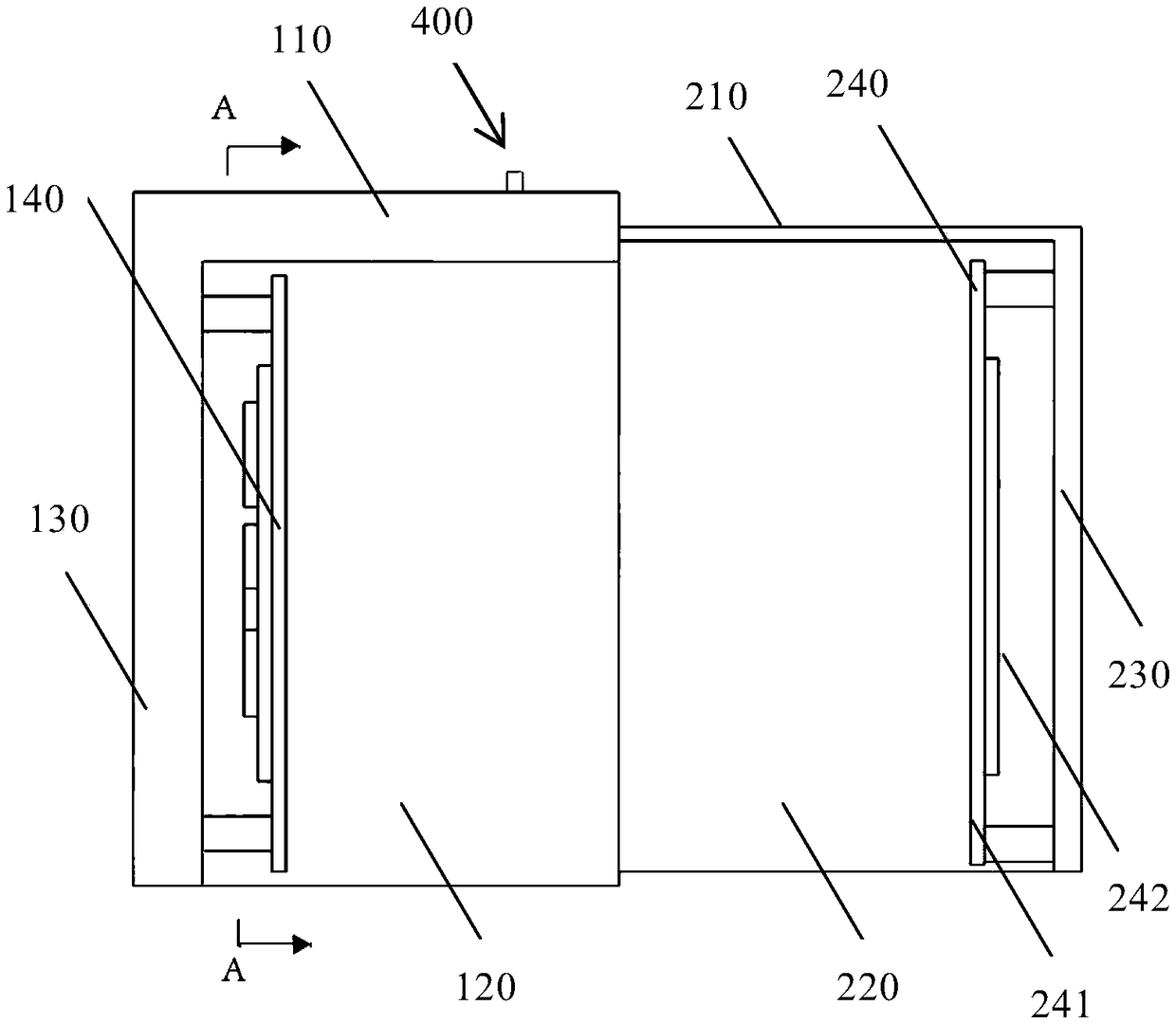

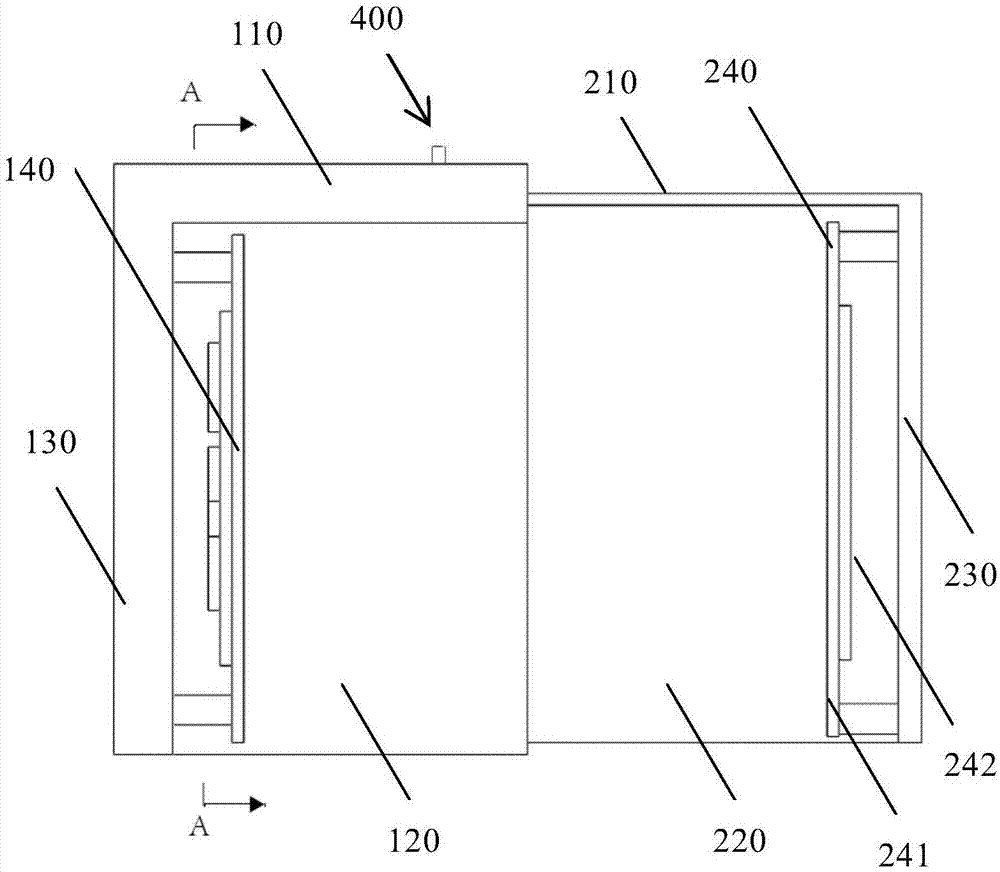

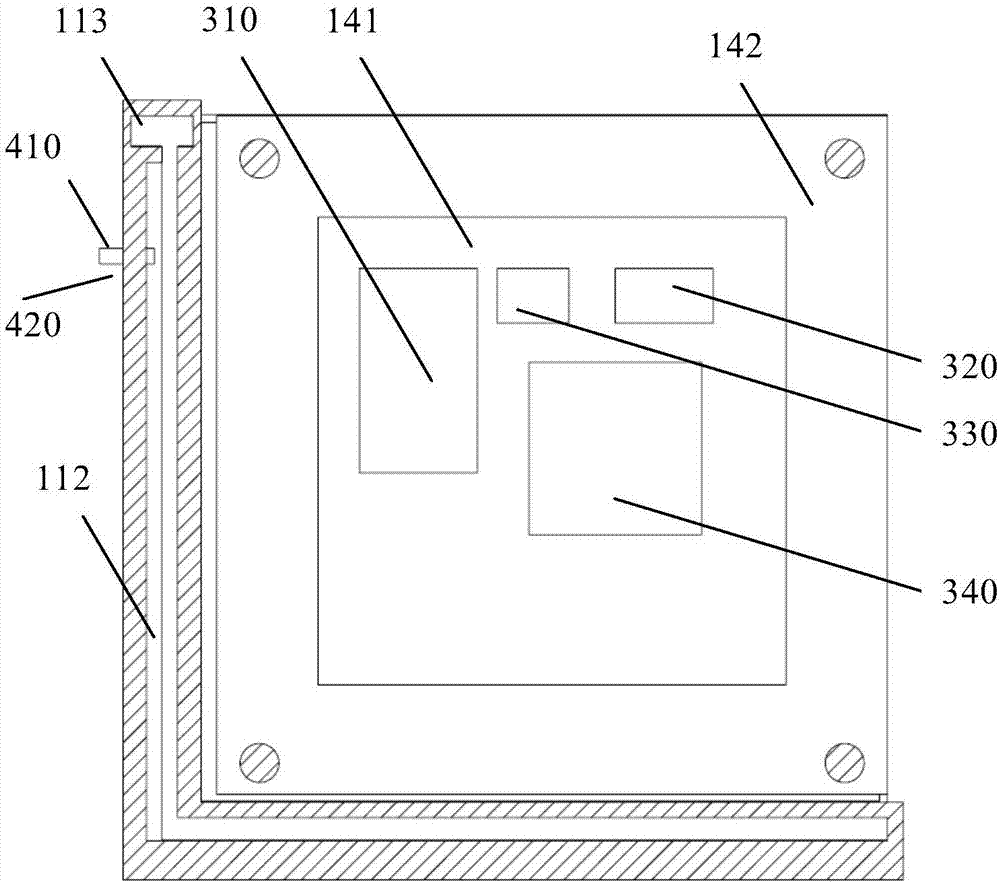

Wallboard butt joint assembly and assembly type wall surface system

The invention discloses a wallboard butt joint assembly and an assembly type wall surface system. The wallboard butt joint assembly comprises first components and at least one second component; the first components are formed on the side edges of wallboard units; each first component is provided with a butt joint face and a stress face opposite to the butt joint face; the butt joint faces of every two adjacent wallboard units are in butt joint; each second component is fixed on a structural wall body through fasteners, and the second component is provided with a slot with a notch facing the first components of the two adjacent wallboard units and at least one elastic arm inclined towards the interior of the corresponding slot, wherein in the process that two adjacent first components are jointly inserted into the slot of the corresponding second component, the elastic arms avoid the first components through the elastic arms, so that the elastic arms apply elastic force to the stress surface of at least one corresponding first component.

Owner:华耐智装科技(天津)有限公司

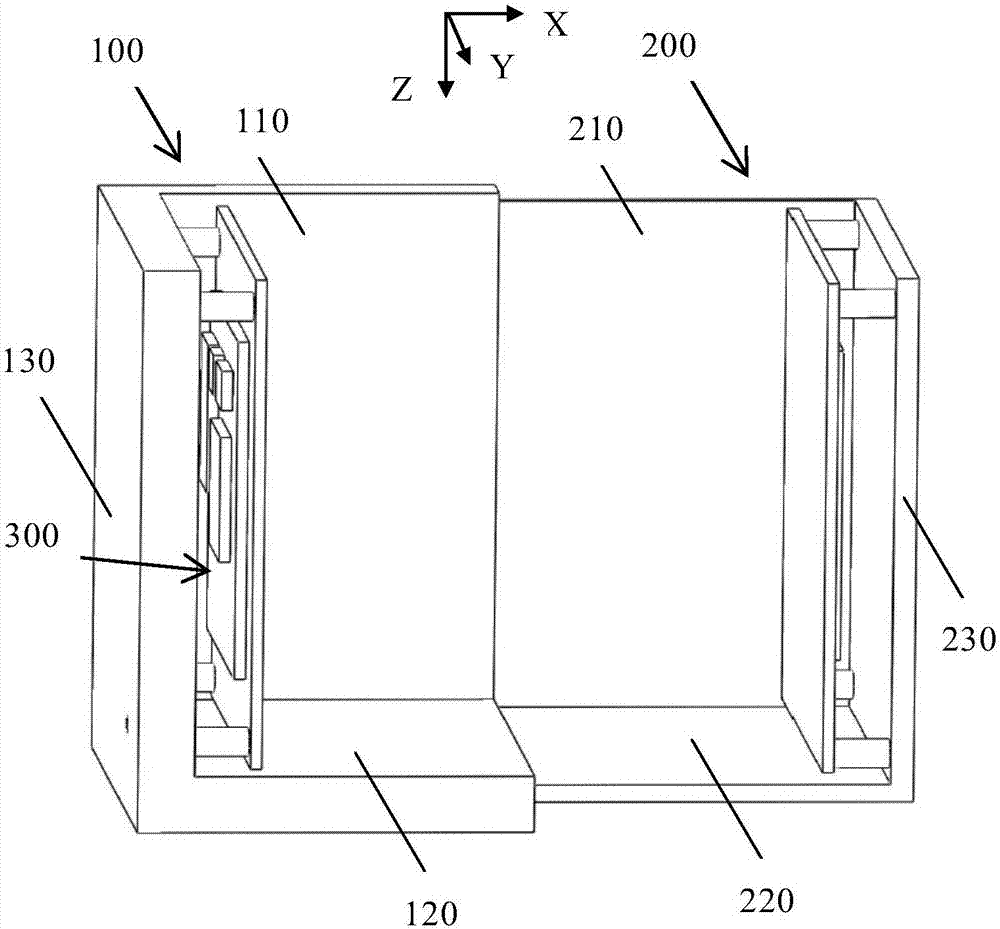

Portable Sliding Electric Hot Plate Box Beverage Warmer

Owner:SHANGHAI JIAOTONG UNIV

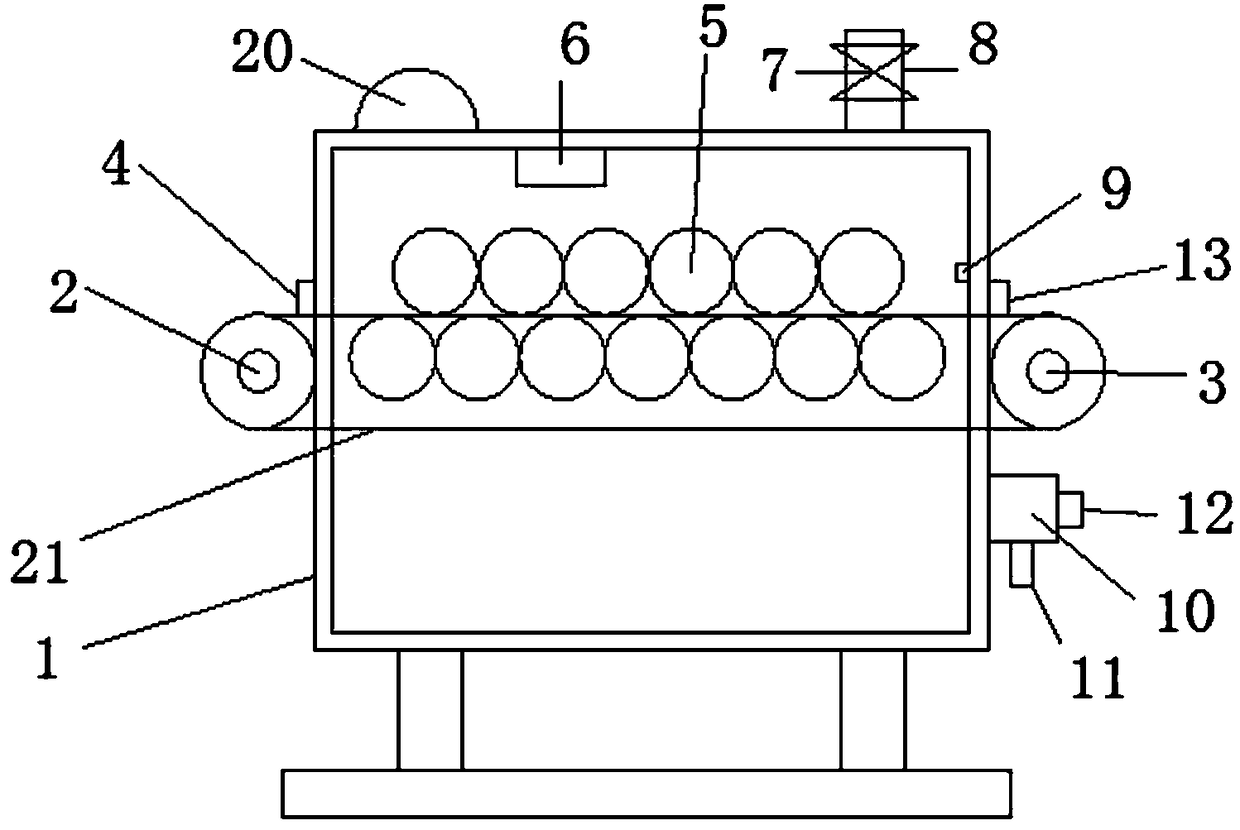

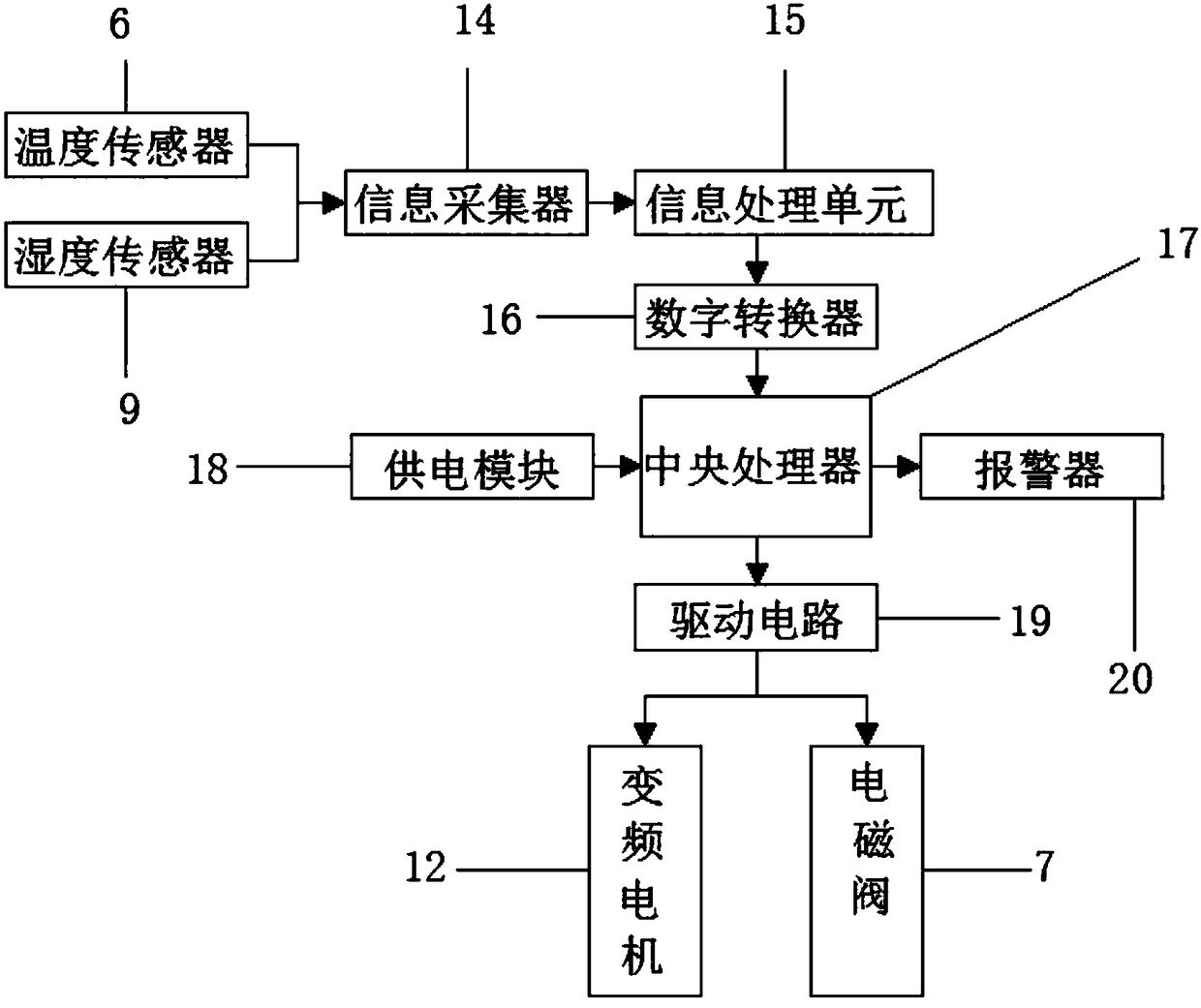

Carpet dryer control system

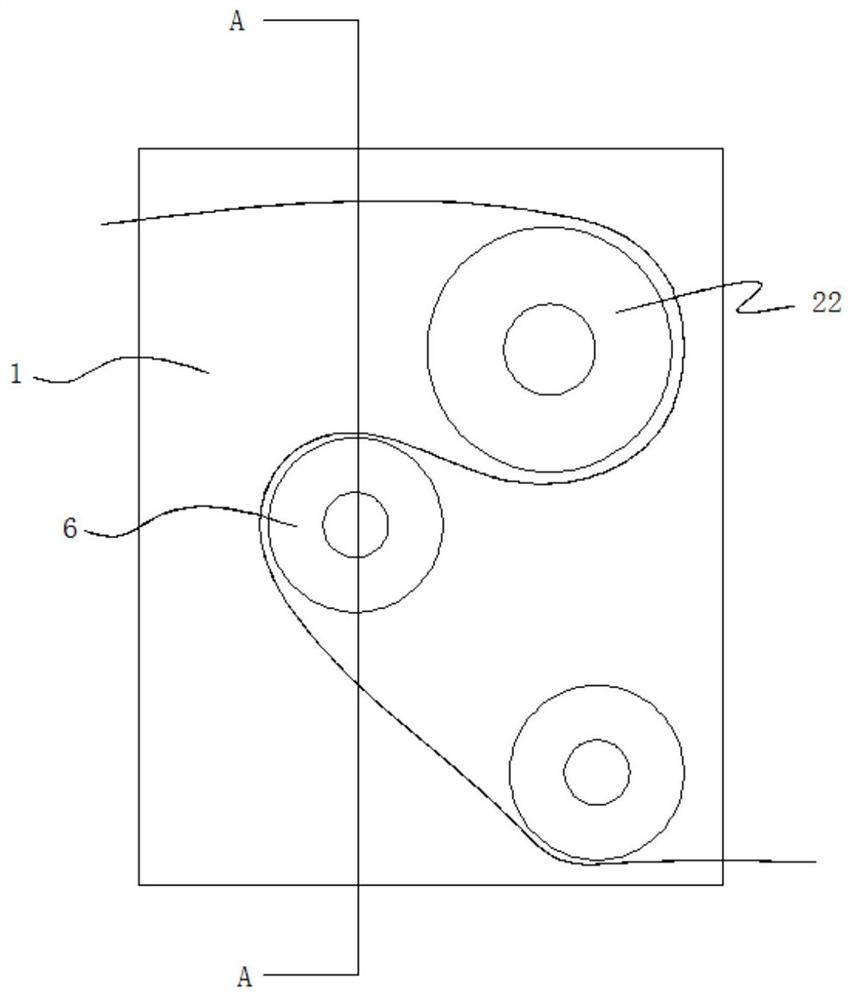

InactiveCN108626995AAccurately measure the degree of dryingAccurate control of drying degreeDrying gas arrangementsDrying machines with progressive movementsDrive wheelControl system

The invention discloses a carpet dryer control system in the technical field of drying. The carpet dryer control system comprises a box; a driving wheel and a driven wheel are arranged on the left andright sides of the box, and are connected through a belt; a hot air roller is arranged in an inner cavity of the box; a temperature sensor is arranged at the top of the inner cavity of the box; an alarm and an exhaust pipe are arranged on the left and right sides of the top of the box; an electromagnetic valve is arranged on the exhaust pipe; a humidity sensor is arranged on the right side of theinner cavity of the box; a feed port and a discharge port are formed in the left and right sides of the box; and the alarm is arranged on the left side of the top of the box. The carpet dryer controlsystem is simple in structure and convenient to operate, saves the cost, is novel in design, can accurately measure the carpet drying degree, can accurately control the drying temperature, prevents damage of the carpet quality caused by higher temperature, realizes automatic operation, and achieves higher use value.

Owner:TIANJIN SHENGFUDA TEXTILE CO LTD

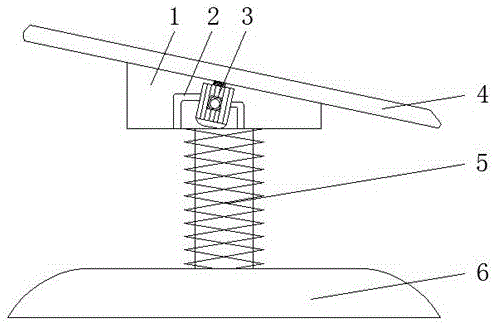

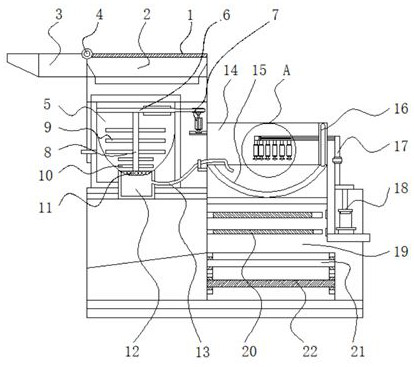

Portable heater with slide electric hot plate for packed drink

InactiveCN107260009AEasy to carry and placeLarge heating areaWarming devicesElectric heatingBackplane

The invention discloses a portable heater with slide electric hot plate for packed drink, which comprises a first heating part, a second heating part, a controlling part and a fixing part, the first heating part comprises a first rear board, a first bottom board, a first side board and a first heating unit; the second heating part comprises a second rear board, a second bottom board, a second side board and a second heating unit; the first rear board and the first bottom board possess a L-shaped hollow interlayer, the left of the hollow interlayer is closed and the right of the hollow interlayer is open, and the second heating part is on the right of the first heating part, the second rear board and the second bottom board is slidably arranged in the interior of the hollow interlayer; the volume of the heater is changeable, thereby the heater is suitable for packed drink of various sizes. The heater can be shrunk to the minimum when the heater is used, thereby the heater is convenient to place and carry.

Owner:SHANGHAI JIAO TONG UNIV

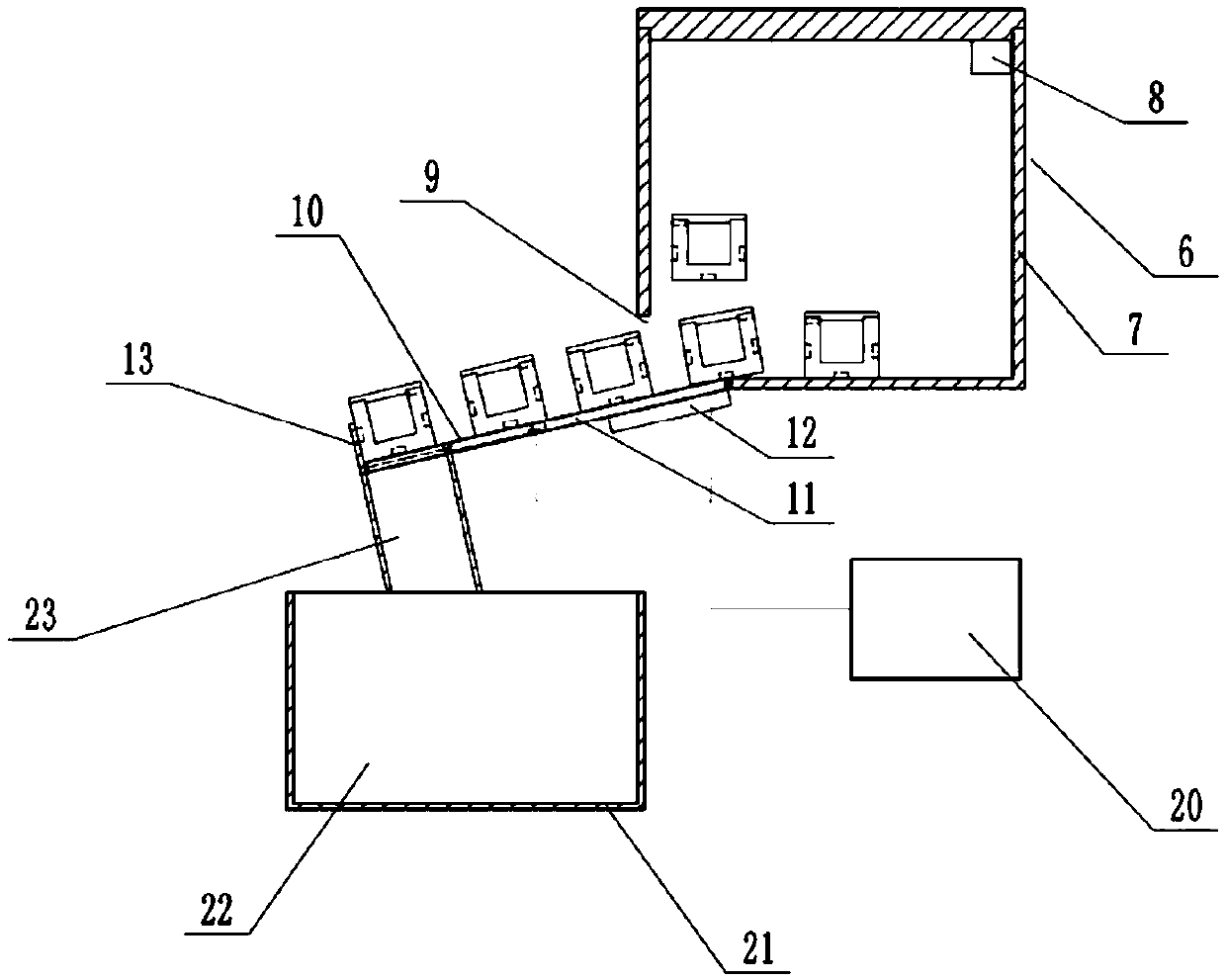

Fruit conveying and selling device

ActiveCN108033101BDamage qualityGuaranteed qualityDomestic cooling apparatusLighting and heating apparatusElectricityRefrigeration

The invention discloses a fruit conveying and selling device, and relates to the field of fruit conveying and packaging devices. The fruit conveying and selling device comprises a heat preservation box, a refrigeration device, a conveying mechanism, a controller and a recovery device, wherein the heat preservation box internally provides a cold source and magnets, the refrigeration device comprises a box body with an opening part and a refrigeration appliance, the conveying mechanism comprises an inclined sliding groove in which a through hole is formed and and a gravity sensor positioned under the sliding groove, a rail, a sliding door with a magnet piece and an electromagnetic valve are arranged in the sliding groove, the controller is electrically connected with the gravity sensor and the electromagnetic valve, and the recovery device comprises a recovery box and a recovery channel. According to the fruit conveying and selling device, the problems of extrusion and damage caused by the fact that fruits are stacked together for sales in the market are solved, the fruits can be prevented from being extruded, the fruit quality can be prevented from being damaged by a consumer when the customer turns the fruits during the selection process, and the fruits which have bad outer appearances and go bad can be automatically recovered.

Owner:张玉凯

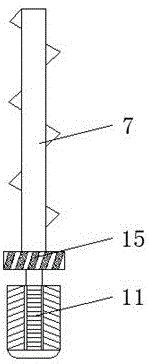

Shunt dust removal device for tea

InactiveCN106391464AEffective vibration cuttingDamage qualityGas current separationMotor driveEngineering

The invention discloses a shunt dust removal device for tea, comprising a dust removal frame; the bottom of the dust removal frame is provided with a vibration base; a vibration motor is mounted inside the vibration base; the vibration base is connected with the bottom of the dust removal frame through the vibration motor; the dust removal frame is composed of a shunt dust removal frame, a dust deposition bin, a filter screen, an air outlet housing and a fan mounting bin; the fan mounting bin communicates with the shunt dust removal frame through the air outlet housing; the shunt dust removal frame communicates with the dust deposition bin through the filter screen; the shunt dust removal frame is composed of six shunt dust removal channels; and rotating motors are mounted inside the shunt dust removal channels. A fan of the shunt dust removal device is used for blowing air to remove dust on the tea, and the rotating motors drive electromagnetic stirring shafts to rotate to sufficiently stir the tea, so that the contact area is increased, the normal operation of blowing air to remove dust is ensured, the dust removal effect is good, the quality of the tea cannot be damaged, and the work efficiency is increased.

Owner:湖南胡家园茶业有限公司

High-efficiency PVC film production humidifying equipment

ActiveCN108274783AIncrease the amount of fluidImprove humidification efficiencyFlat articlesEngineeringElectrical and Electronics engineering

The invention discloses high-efficiency PVC film production humidifying equipment. The high-efficiency PVC film production humidifying equipment comprises a frame, a second humidifying mechanism usedfor conducting primary humidifying on a PVC film, a first humidifying mechanism used for conducting secondary humidifying on the PVC film and a driving part used for driving the first humidifying mechanism to rotate. The first humidifying mechanism and the second humidifying mechanism are matched with each other. The high-efficiency PVC film production humidifying equipment achieves two-time humidifying on the PVC film through the first humidifying mechanism and the second humidifying mechanism, the humidity of the PVC film is improved, it is guaranteed than the whole PVC film is humidified completely and the PVC film is humidified uniformly; the temperature of the PVC film can be reduced, the efficiency of the subsequent cooling process is improved, and the production requirements duringthe subsequent cooling process are reduced.

Owner:ZHEJIANG HONGXIN DAMPING SYST

A screenable cutting-type high-efficiency pulverizer for chemical processing

The invention discloses a screenable cutting-type high-efficiency pulverizer for chemical medicine processing, which includes a main body, a grinding chamber and a placement chamber. A funnel is fixed inside the upper part of the main body, and a storage box is placed on the left side of the main body. There is fixed welding between the funnel and the main body, a cutting chamber is placed under the funnel, and a first motor is installed on the right side of the cutting chamber, a grinding cylinder is placed inside the grinding chamber, and the grinding chamber is located at the right side of the subject. The invention conveniently puts medicines into the interior of the main body through the setting of the storage box, and a rotating structure is formed between the storage box and the rotating shaft. By putting the medicines into the storage box, and then using the rotating shaft to turn over, the medicines are directly put into the interior of the main body , to avoid human hands touching the medicine and destroying the quality of the medicine. Through the setting of the cutting room, the medicine can be cut. Drain into the holding box in the leakage plate.

Owner:QINGZHOU JINGCHENG MEDICINE EQUIP MFG

Quantitative discharging equipment for foamed plastic production

ActiveCN112706348AImprove efficiencySo as not to damagePlastic recyclingCleaning using liquidsProcess engineeringMechanical engineering

The invention discloses quantitative discharging equipment for foamed plastic production. The quantitative discharging equipment comprises a transmission box, and a distribution box is arranged on the outer surface of the front end of the transmission box. In the foamed plastic production and transmission process, a power switch is provided through the distribution box, a worker puts a plastic raw material into a rotary closing device to enter a machine body, and the equipment can ensure that dust and insects cannot enter the machine body after being used, so that the quality of plastic foam cannot be damaged during operation; then the materials are conveyed to a quantitative discharging device through operation of the machine body, so that quantitative discharging is facilitated during use, waste outflow of the raw materials is reduced, the discharging amount can be automatically controlled, and the operation is simple; a movable cleaning device on one side can facilitate rotary movable cleaning when the operation is finished, manual cleaning is reduced, cleaning is thorough and effective, and manual operation is greatly reduced; and a rack can be effectively supported to guarantee stability, the practicability is achieved, and operation is convenient.

Owner:宿松晨辉塑料制品有限公司

A kind of semiconductor element and its preparation method

ActiveCN105336579BAvoid formingDamage qualitySemiconductor/solid-state device manufacturingSemiconductor devicesGallium nitrideLight-emitting diode

The invention provides a semiconductor element, which avoids the formation of an amorphous layer on the surface of a silicon substrate by using a metal protective layer and a metal oxide protective layer grown on a substrate; and uses a transition layer to reduce the difference between the metal oxide protective layer and the metal oxide protective layer. The crystal lattice difference of the III-IV group buffer layer improves the crystal quality of the III-IV group buffer layer. The present invention also proposes a preparation method, which can avoid the formation of an amorphous layer near the interface of the silicon substrate and avoid the generation of cracks. At the same time, the high-quality multi-layer buffer structure deposited by PVD method is fully utilized, and gallium nitride or indium gallium nitride or aluminum gallium nitride epitaxial layers are grown on it to make light-emitting diode elements or transistor elements.

Owner:ANHUI SANAN OPTOELECTRONICS CO LTD

Fruit Packing Conveyor Vending Machine

The invention discloses a fruit selling machine realizing split charging and conveying, relating to the fields of fruit conveying and packing devices. The device comprises a bracket, thermal insulation boxes, a conveying mechanism and a recycling device, wherein a sliding chute is arranged in the bracket, cold sources and magnets are arranged in the thermal insulation boxes, the conveying mechanism comprises a first gear, a second gear and a reversing gear capable of realizing meshing, and the recycling device comprises a recycling box and a recycling channel. With the fruit selling machine realizing split charging and conveying, the problem that during fruit selling on the market, squeezing and damage are easily caused when fruits are stacked together, is solved, and the invention mainlyprovides the fruit selling machine realizing split charging and conveying which can avoid fruit squeezing and can prevent the damage to the quality of the fruits since the fruits are stirred during the process that consumers select the fruits, and also can automatically recycle the fruits with poor appearance and in deterioration.

Owner:徐州宇之阳市场营销策划有限公司

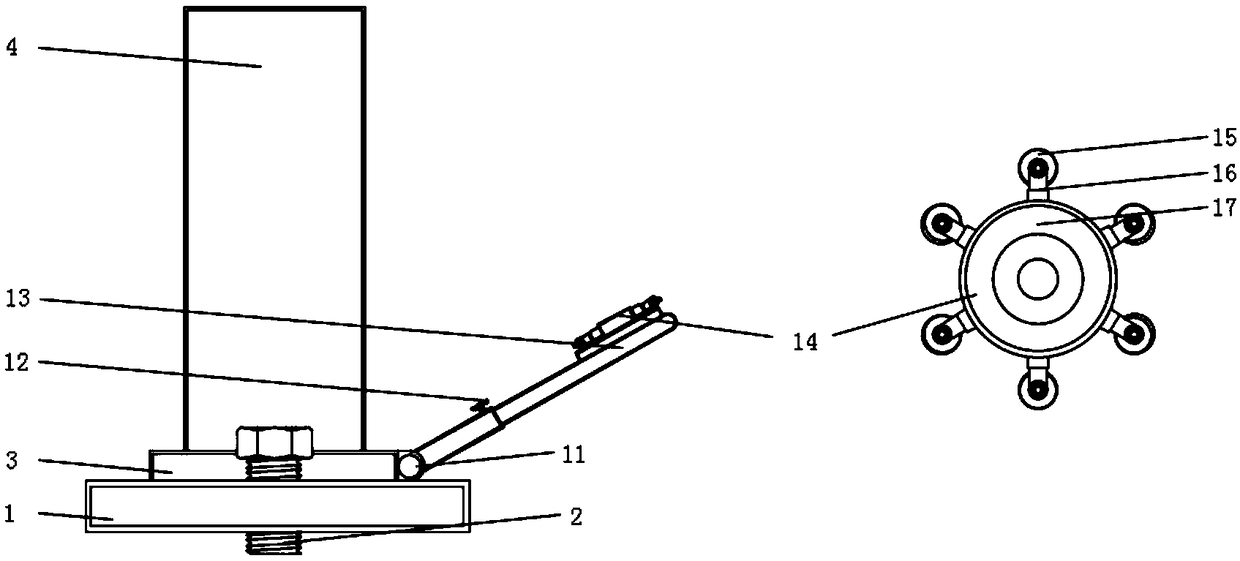

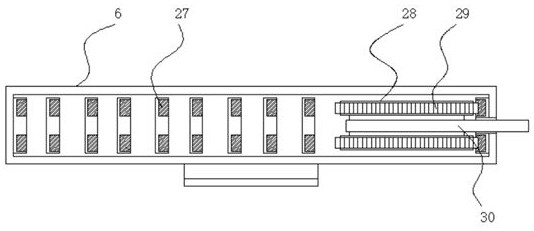

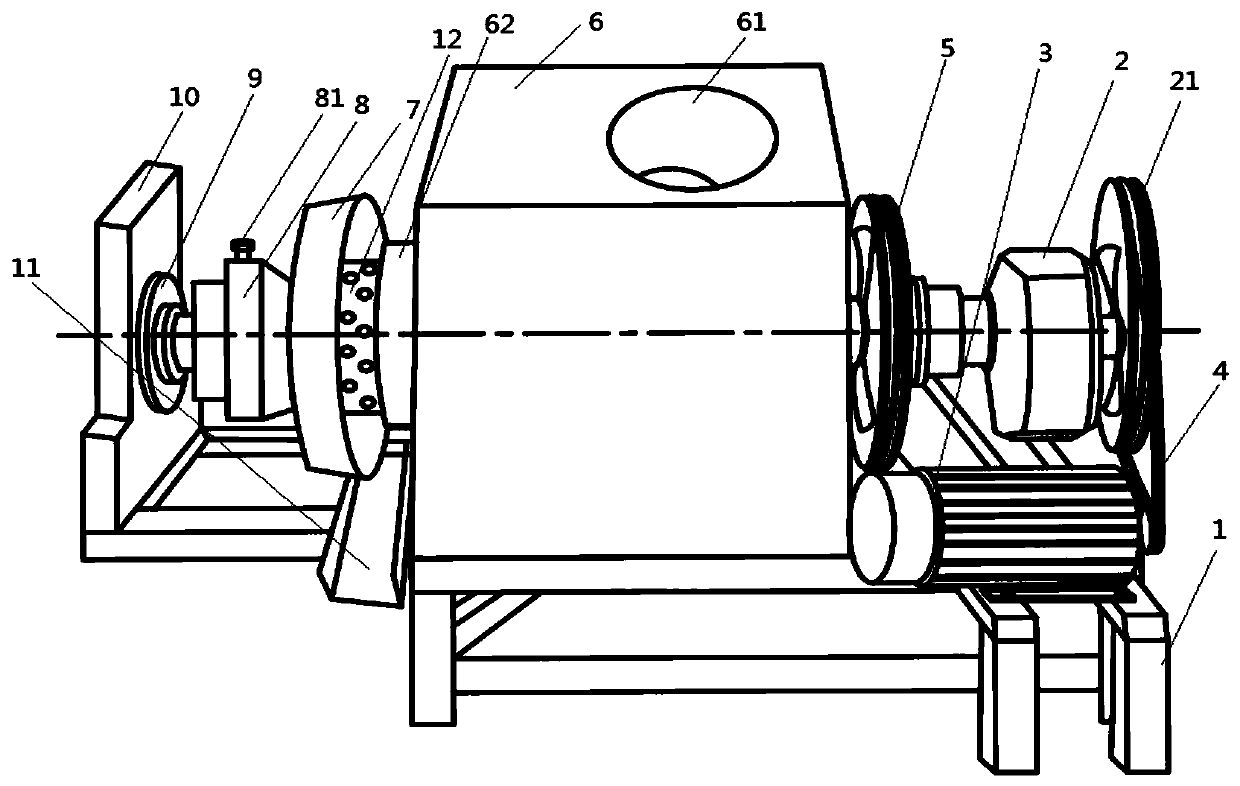

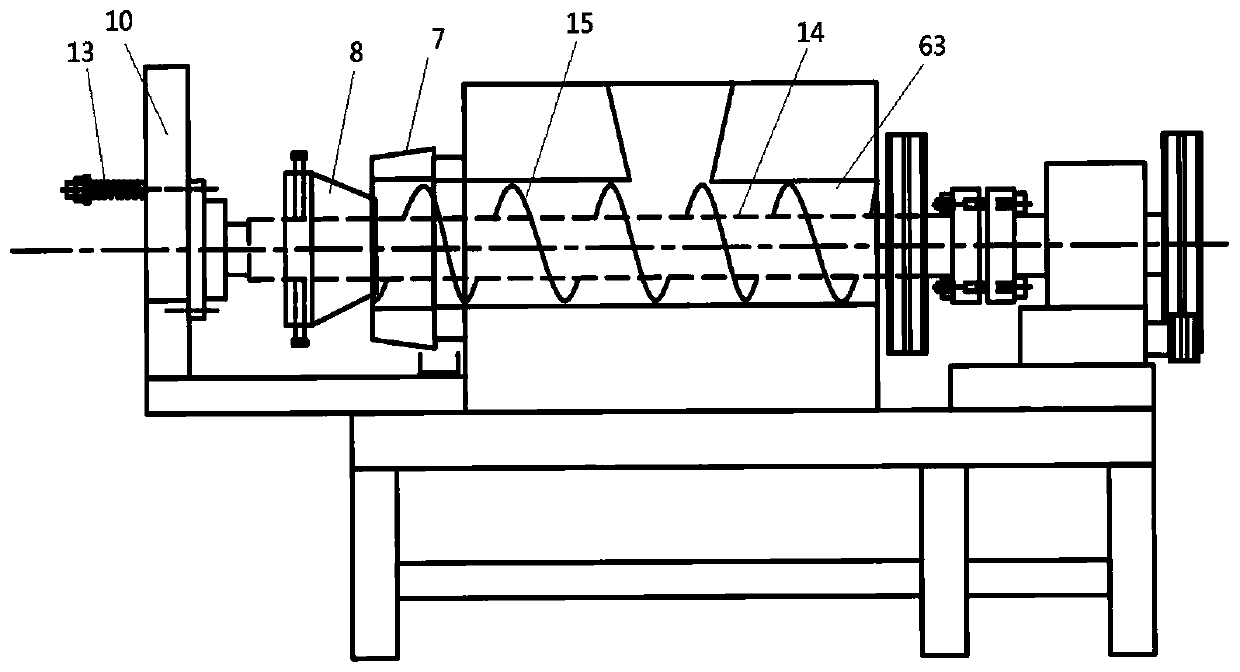

Pasture breaking water pressing machine

PendingCN110749165APrevent splashEasy to collectGrass dryingDrying solid materials without heatReduction driveSpiral blade

The invention discloses a pasture breaking water pressing machine. The machine comprises a rack, a motor, a speed reducer, a material box and a screw rod, wherein the motor, the speed reducer, the material box and the screw rod are fixed to the rack. The motor is linked with the speed reducer through a belt, an L-shaped lengthening arm is arranged on the left end of the rack, the right end of therack is fixedly provided with the speed reducer, and the square material box is fixed to the middle of the rack. A feeding cylinder is arranged in the material box, a material inlet is formed in the upper portion of the feeding cylinder, the lower end of the material inlet communicates with the feeding cylinder, the screw rod coaxial with the feeding cylinder is arranged in the feeding cylinder, the two ends of the screw rod are rotatably connected with the speed reducer and the L-shaped lengthening arm, the left end of the feeding cylinder is connected with a water partition cylinder, spiralblades of the screw rod extend to the left end of the water partition cylinder from the right end of the feeding cylinder, the left end of the screw rod is provided with a conical check block moving in the axial direction, and the check block is provided with a locking screw. The machine has the advantages of being compact in structure, efficient in work, capable of adjusting the pasture breakingwater containing rate and the like.

Owner:GUANGXI UNIV

Method for the preparation of isocyanate by partially adiabatic phosgenation of the corresponding amine

PendingCN111170890ADamage qualityAvoid foamingIsocyanic acid derivatives preparationOrganic compound preparationChemical reactionFluid phase

The present invention relates to a process for preparing an isocyanate by reacting a primary amine with phosgene, comprising I) providing an amine solution, II) providing a phosgene solution, III) mixing the amine solution with the phosgene solution in a mixing unit, followed by IV) further conversion in an adiabatically operated reaction zone and the removing of the gas phase formed as a result of the chemical reaction in a separation zone, V) expanding the remaining liquid phase in two or three stages, VI) further conversion of the liquid phase remaining after the last expansion stage in anindirectly heated reaction zone and VII) isolating the isocyanate from the reaction solution obtained therein.

Owner:COVESTRO DEUTSCHLAND AG

Image Inspection Method Using Multiple Cameras

The invention relates to a digital image inspection method. A plurality of image capturing devices respectively photograph digital sub-images of a printed image to be inspected, and the digital sub-images are combined into a digital overall image in an image processing computer, and the overlapping areas of the sub-images generate butt joint edges. Edge, the image processing computer checks the digital overall image and sends the result to the control computer of the machine processing the printing material. The image processing computer creates a new image with the help of the edge detection method: only the detected edges are included. The image processing computer uses the image capture device Create another new image with the known position of the docking edge: only include the area with the docking edge of the image capture device, and the image processing computer will overlap the two newly created images to generate a composite image: only include the edge along the image capture device docking edge The image processing computer applies the composite image to the digital ensemble image to define occluded areas in the composite digital ensemble image that are not detected by the image inspection.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com