A processing system for pvc film

一种加工系统、导膜的技术,应用在其他家里用具、运输和包装、卷绕条材等方向,能够解决难以实现流水化加工、PVC膜不合格、PVC膜作废等问题,达到提高液体利用率、避免褶皱和卷曲、增大接触面积的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

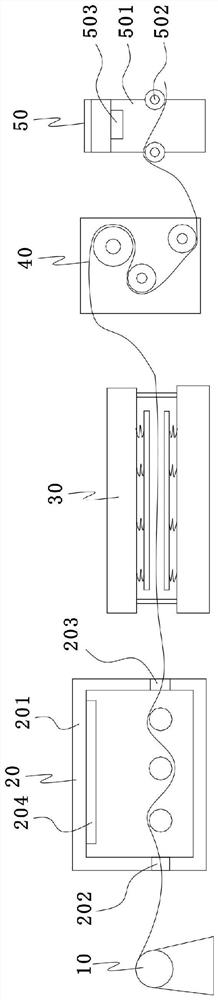

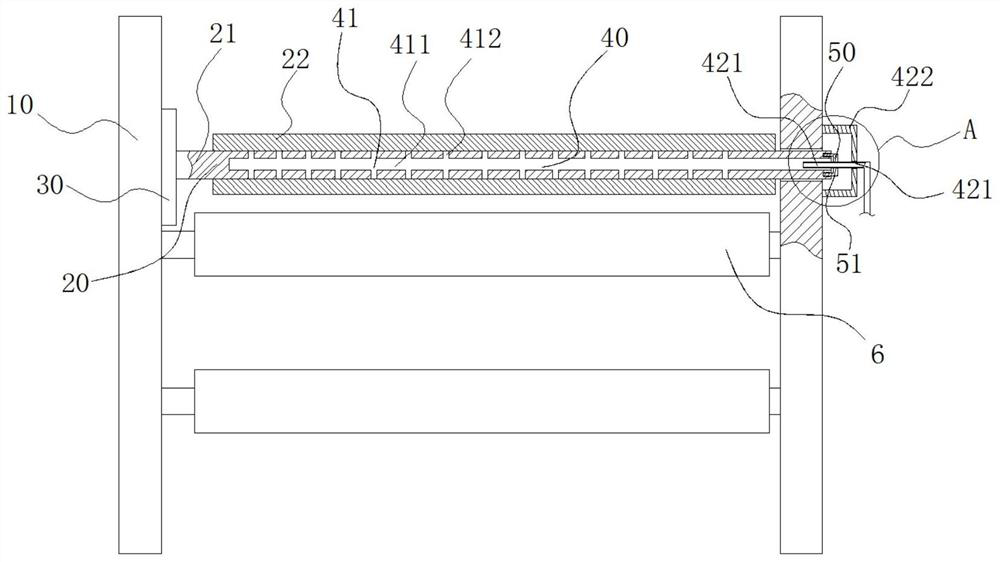

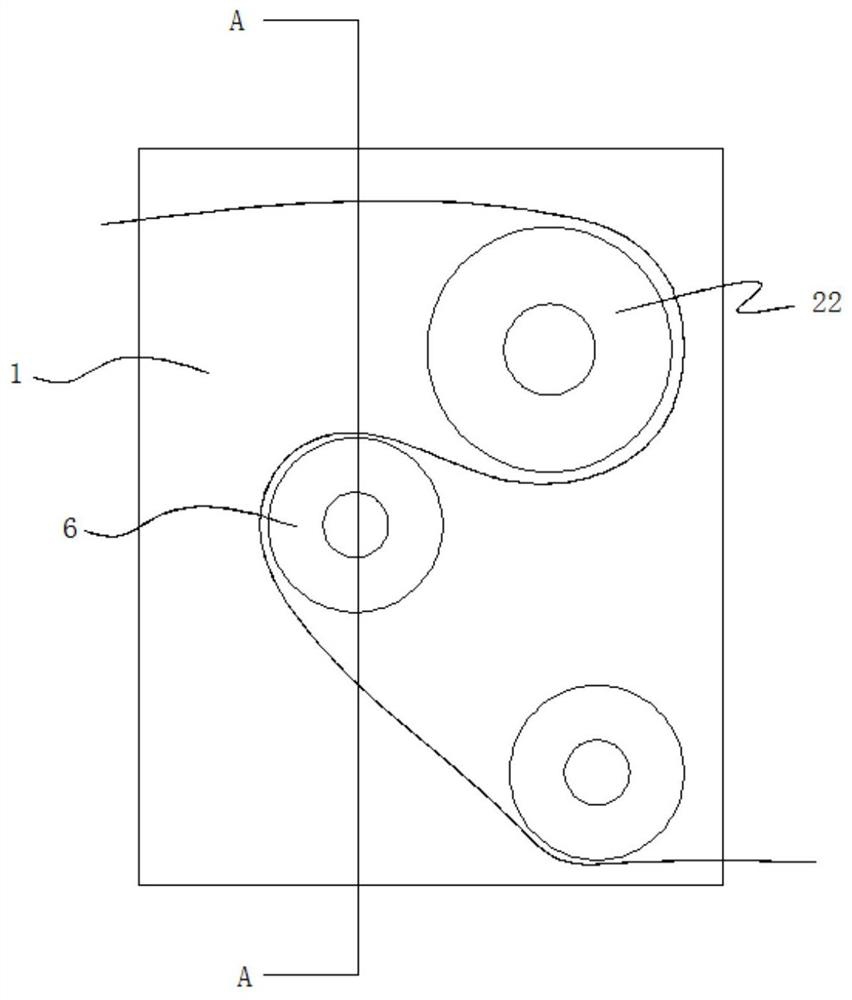

[0022] Such as Figure 1-6 Shown, a kind of processing system of PVC film comprises coil stand 10, is used for the heating device 20 that heat treatment is carried out to PVC film, is used for the corona device 30 that is carried out leveling treatment to the PVC film after heating and is used for The humidifying device 40 for the humidification and cooling treatment of PVC membrane parts; the humidifying device is arranged on the rear side of the corona device 30; the coil rack 10 is purchased directly on the market, and will not be described in detail; the corona device is purchased on the market The structure of the corona machine obtained will not be described in detail; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com