Semiconductor element and preparation method thereof

A semiconductor and component technology, applied in the field of semiconductor components and their preparation, can solve the problems of inconsistent ability to release stress, deterioration of the density of the aluminum nitride layer, and damage to the performance of semiconductor devices, so as to avoid cracks and pores and reduce crystallites. The effect of reducing grid difference and reducing the leakage phenomenon of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

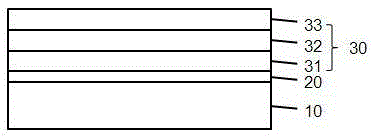

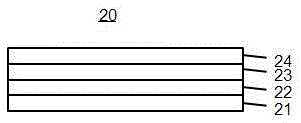

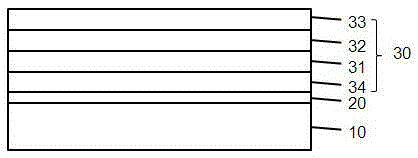

[0034] See attached Figure 1~2 , the present embodiment provides a semiconductor element, which includes: a silicon substrate 10, a multi-layer buffer structure 20 and an epitaxial functional layer 30, where the epitaxial functional layer 30 is a first semiconductor layer 31, a light emitting layer 32 and a second The light-emitting diode epitaxial layer composed of two semiconductor layers 33; the first semiconductor layer 31 and the second semiconductor layer 33 are respectively a semiconductor layer doped with donor impurities and a semiconductor layer doped with acceptor impurities. Of course, the non-doped semiconductor layer 34 can also be included in the semiconductor element of the present invention (see the attached image 3 ). The multi-layer buffer structure 20 consists of a metal protective layer 21 with a thickness of 1-100 angstroms, a metal oxide protective layer 22 with a thickness of 1-500 angstroms, a transition layer 23 with a thickness of 1-1000 nm, and a...

Embodiment 2

[0044] See attached Figure 4 The difference between this embodiment and Embodiment 1 is that a transistor epitaxial layer is deposited on the surface of the multilayer buffer structure 20 as an epitaxial functional layer 30 to form a transistor element. The preparation method and structure are as follows: deposit a metal protective layer 21, a metal oxide The substrate of the multilayer buffer structure 20 composed of the object protection layer 22, the transition layer 23 and the III-IV buffer layer 24 is transferred into the MOCVD chamber, and the AlGaN layer 35 is deposited by the MOCVD method to further buffer the multilayer buffer structure 20. Lattice stress, to avoid cracks; then another layer of gallium nitride semiconductor layer 36 that is not intentionally doped or doped with carbon or doped with iron, and then deposits an aluminum gallium nitride semiconductor layer 37, which passes through Electric field polarization generates a high-density electron gas at the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com