Pasture breaking water pressing machine

A water press and crushing technology, applied in dryers, grass drying, drying of solid materials, etc., can solve the problems of no forage crushed moisture content, inability to effectively control forage moisture content, etc., to achieve easy collection and uniform effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

[0022] Non-limiting and non-exclusive embodiments will be described with reference to the following drawings, wherein like reference numerals refer to like parts unless specifically stated otherwise.

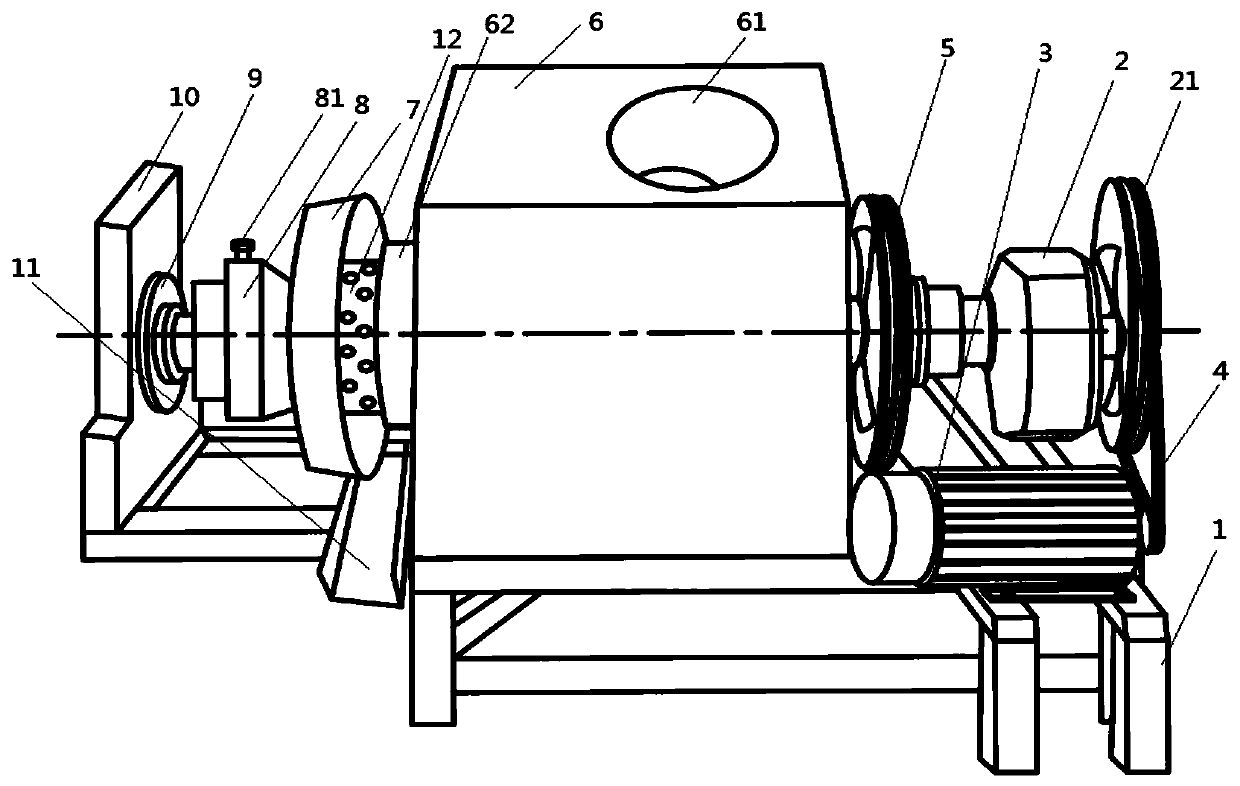

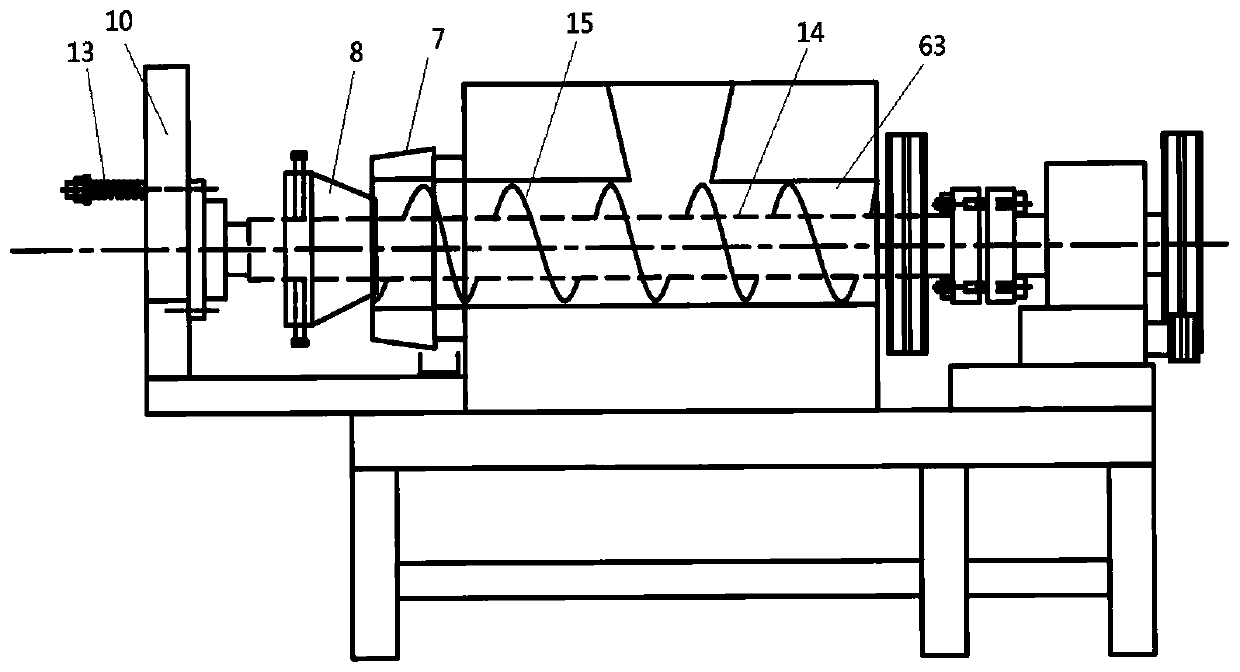

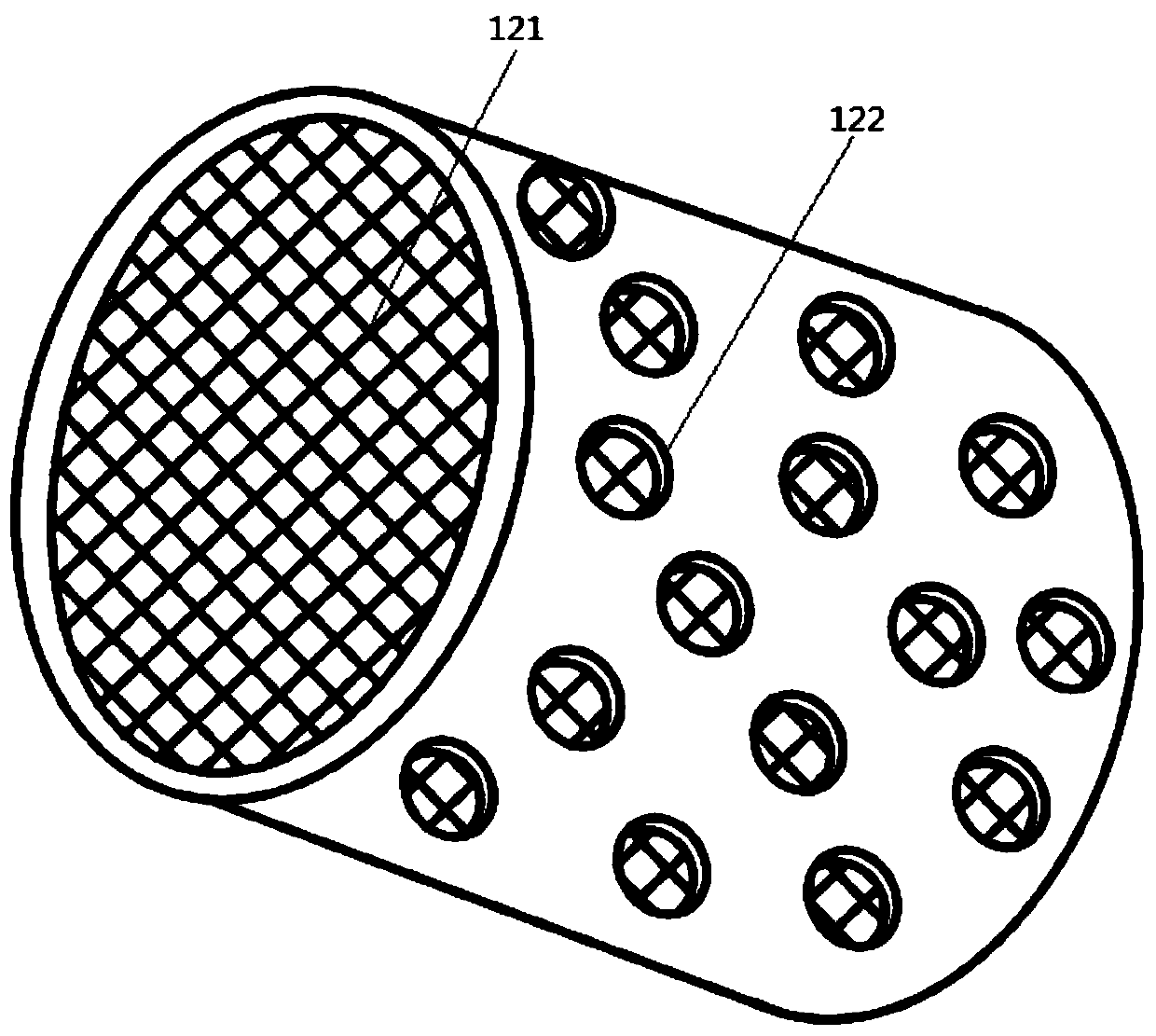

[0023] Such as Figure 1-4 A kind of pasture crushing water press shown includes a frame 1, and a motor 3 fixed on the frame 1, a speed reducer 2, and a material box 6, and the motor 1 is used as a power output and is connected to the The belt pulley 21 on the speed reducer 2 is interlocked. The left end of the frame 1 is provided with an extended extension arm 10, and the extension arm 10 is an L-shaped plate structure. The right end of the frame 1 is fixed with the redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com