Image Inspection Method Using Multiple Cameras

An inspection method and image technology, applied in image enhancement, image analysis, signal generator with multiple pickup devices, etc., can solve the problem of printing personnel unable to engage in printing monitoring and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

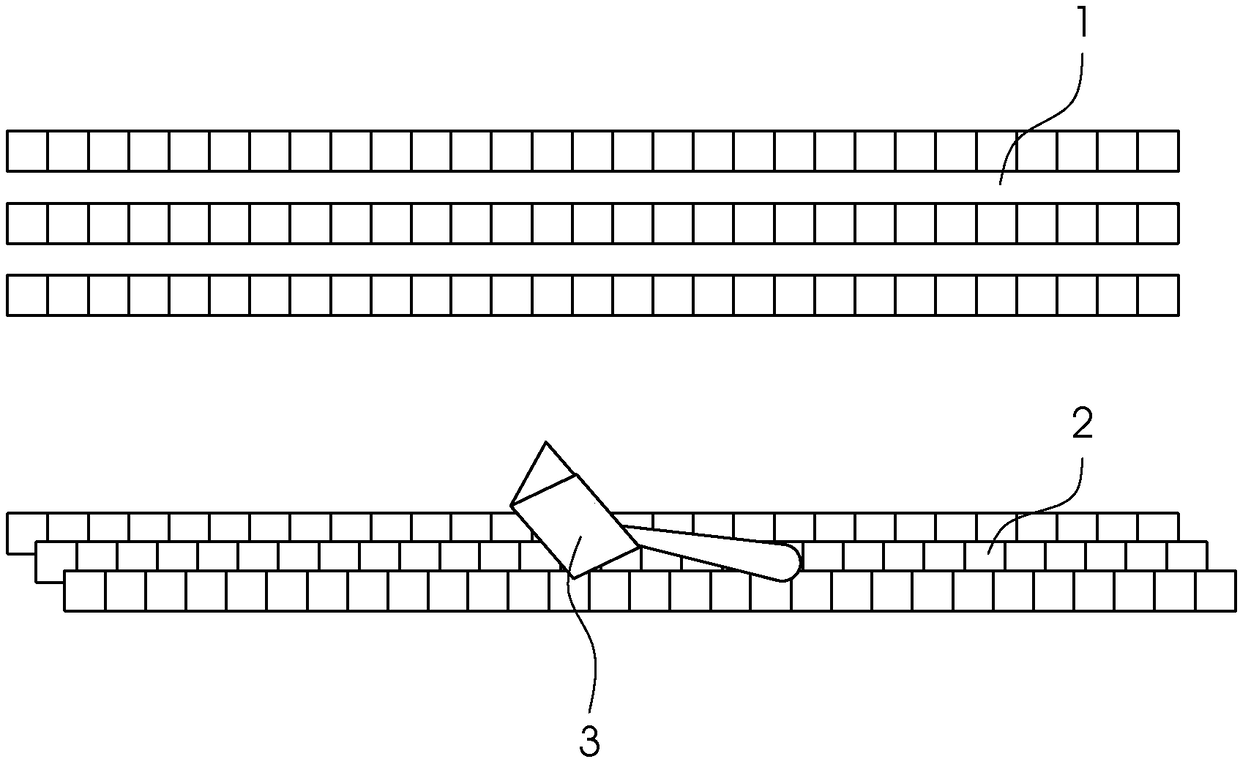

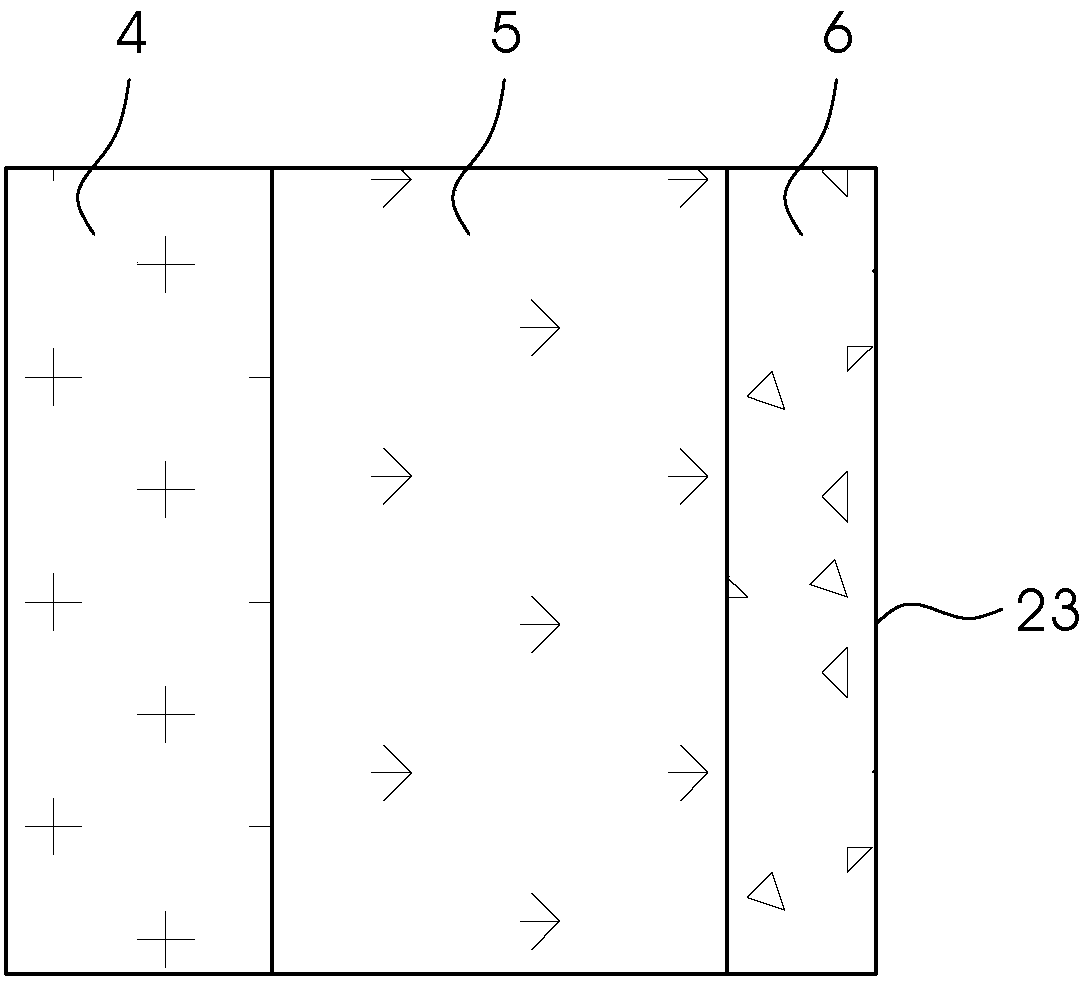

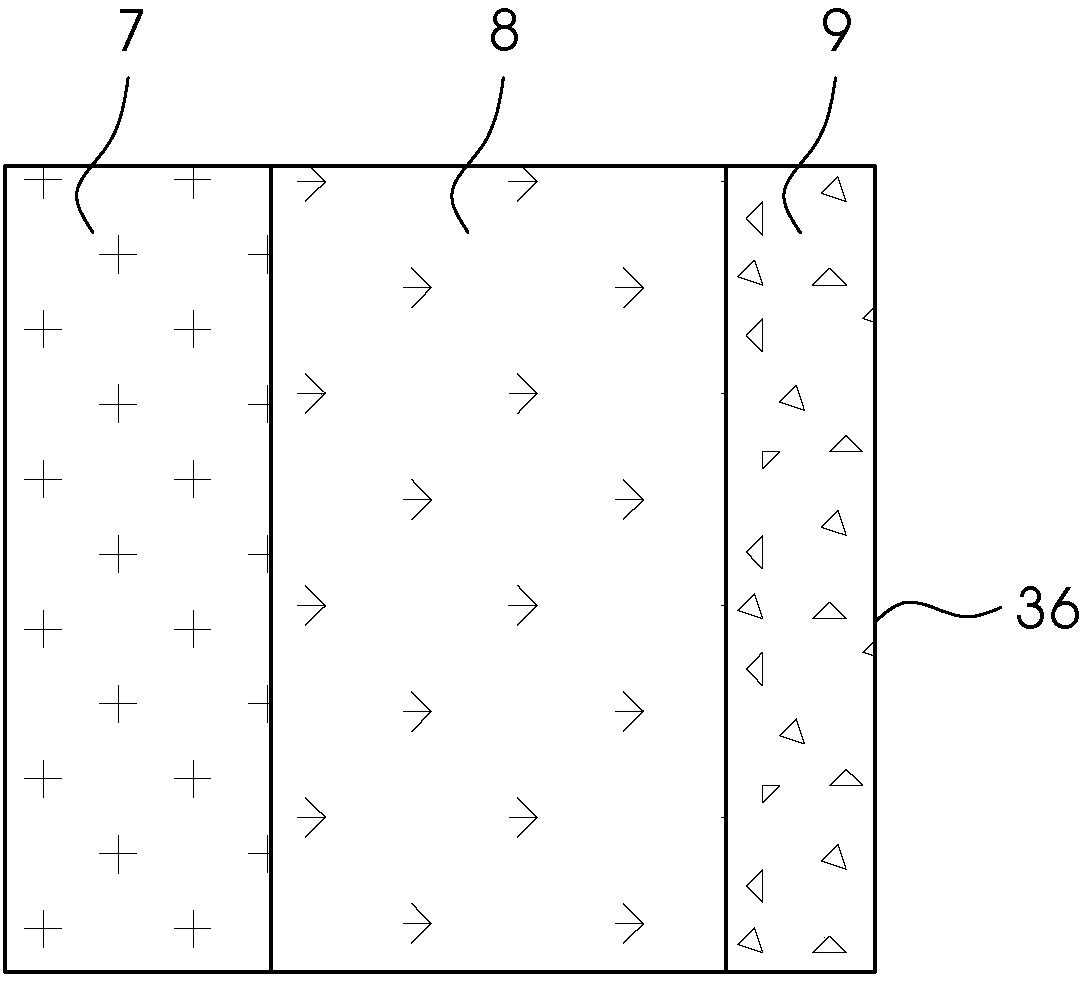

[0045] Figure 8 The flow of the method according to the invention is schematically shown. The printing job is started with the print job data and is image-captured with the camera system 32 of the image inspection system 28 during continuous printing. here, in Figure 9 An image inspection system 28 is schematically shown in . In addition to the printing press 31 itself, the image inspection system 28 includes a camera system 32 installed in the printing press 31 and an image processing computer 33 connected directly to the camera system 32 and to the control computer 29 of the printing press 31 . In this case, the control computer 29 forms the interface to the user 27 with its display 30 . The camera system 32 itself is in Figure 10 is schematically shown again. The camera system 32 is installed inside the printing press 31 (usually after the last printing unit) and comprises two digital cameras 35 arranged horizontally side by side in the form of electronic line scan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com