Large-batch grain drying production line

A production line and mass-batch technology, applied in drying, dryers, grain drying, etc., can solve the problems of large heat loss, long time, and decline in grain quality, and achieve uniform heating, long storage time, and clean grain. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below according to the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

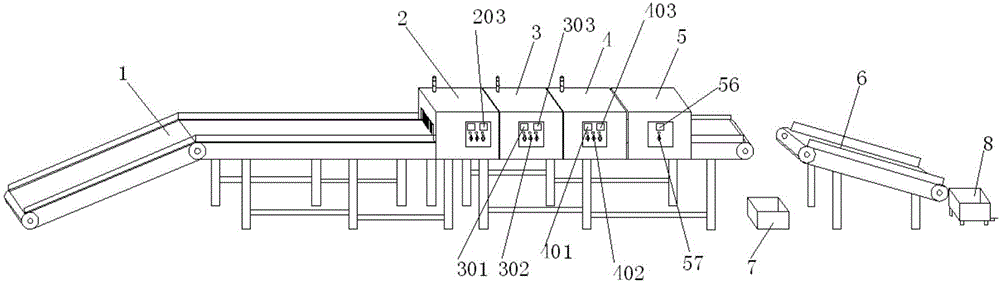

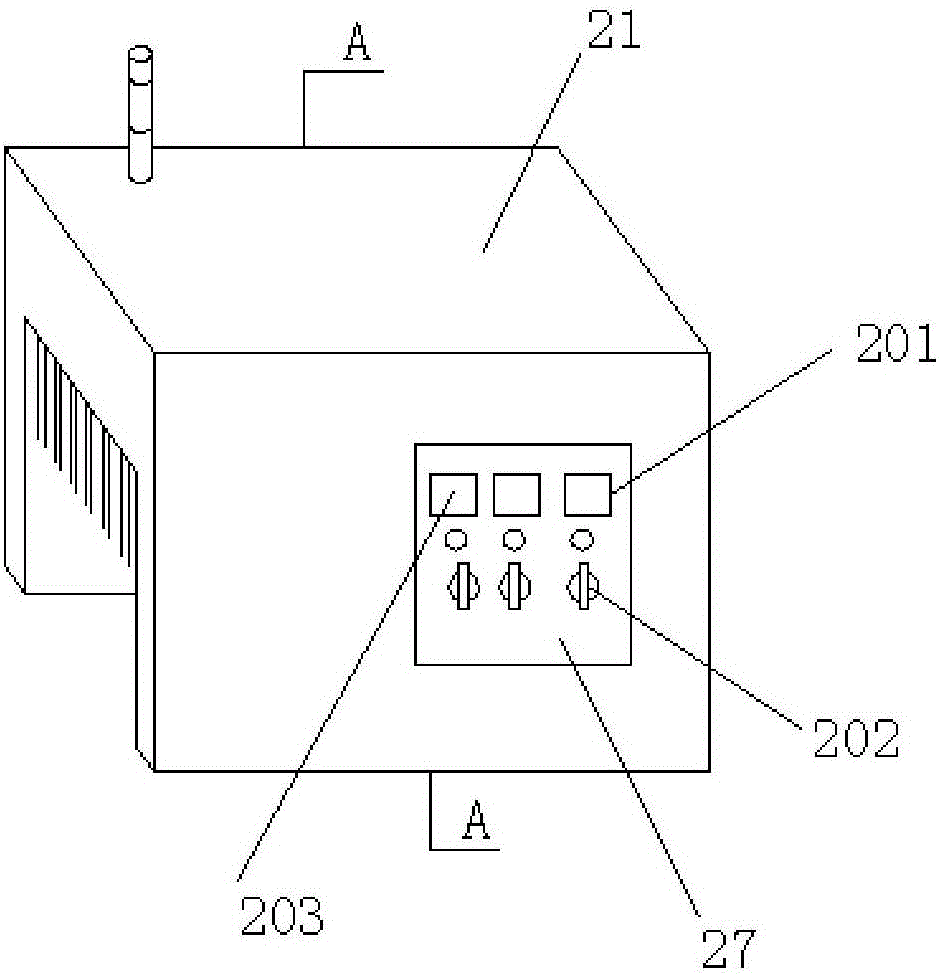

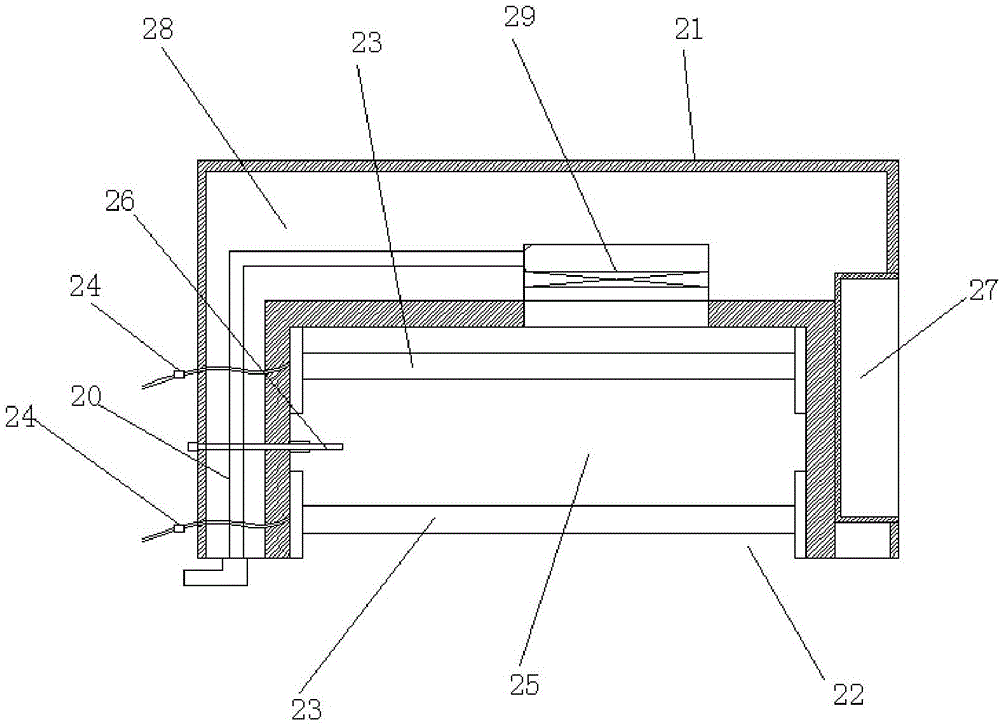

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, a large-scale grain drying production line includes a circular conveying line 1 capable of circularly transporting grain products, and a grain preheating zone 2 and a grain heating zone are sequentially arranged on the circular conveying line 1 from the grain inlet end to the grain outlet end 3. Grain drying area 4 and grain cooling area 5, grain sorting and filtering area 6 is provided at the grain output end of circulation conveying line 1, grain preheating area 2, grain heating area 3 and grain drying area 4 all have grain supply The temperature of the grain heating space that passes through the grain heating space increases sequentially from left to right, and the maximum temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com