Automatic rubber tapping robot

A robot and rubber tapping technology, applied in the field of robots, can solve the problems of complex structure of automatic rubber tapping machine, complex cutter head structure, short motor life, etc., and achieve the effect of easy mechanical and electrical protection, high cutting speed and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

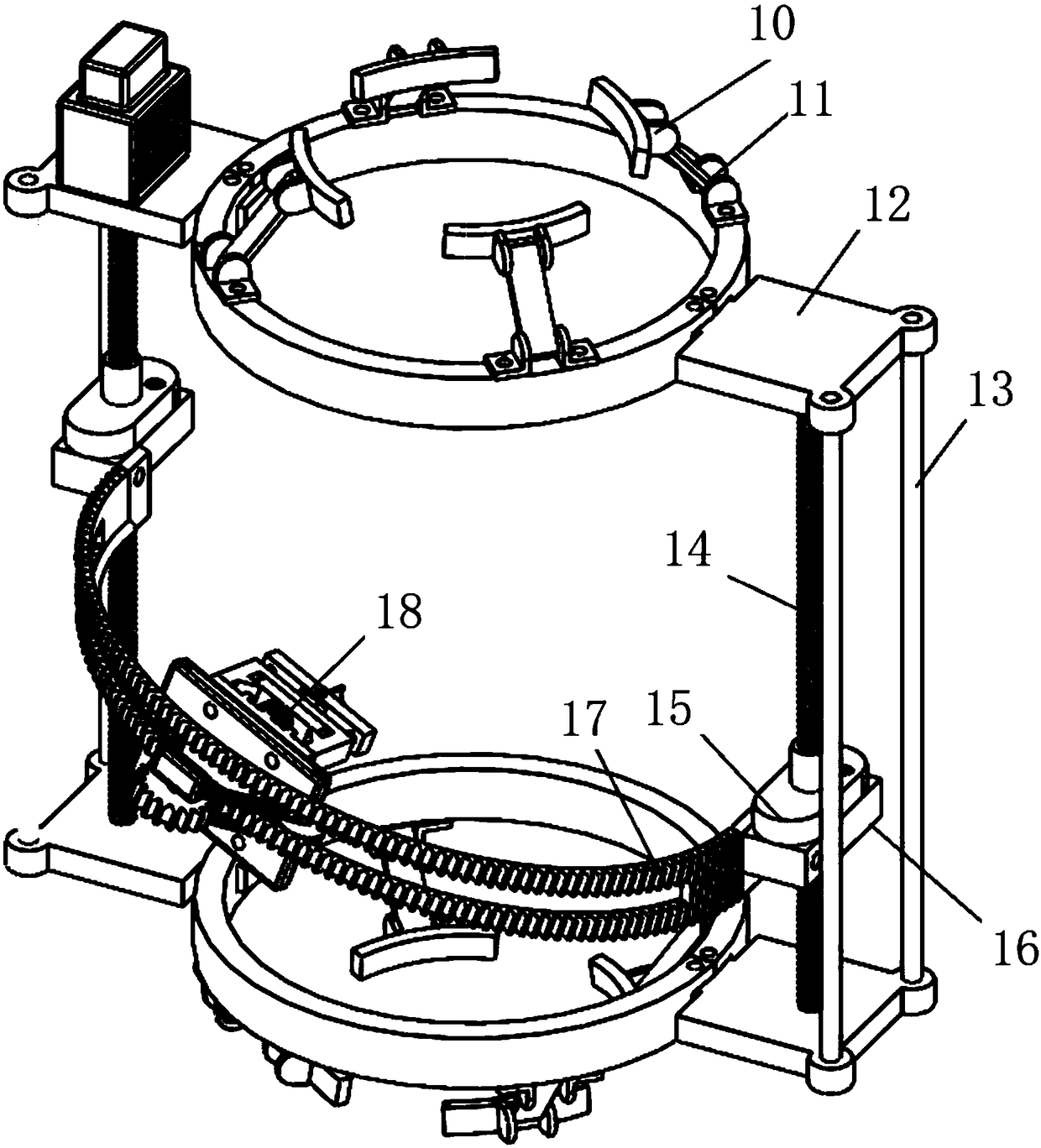

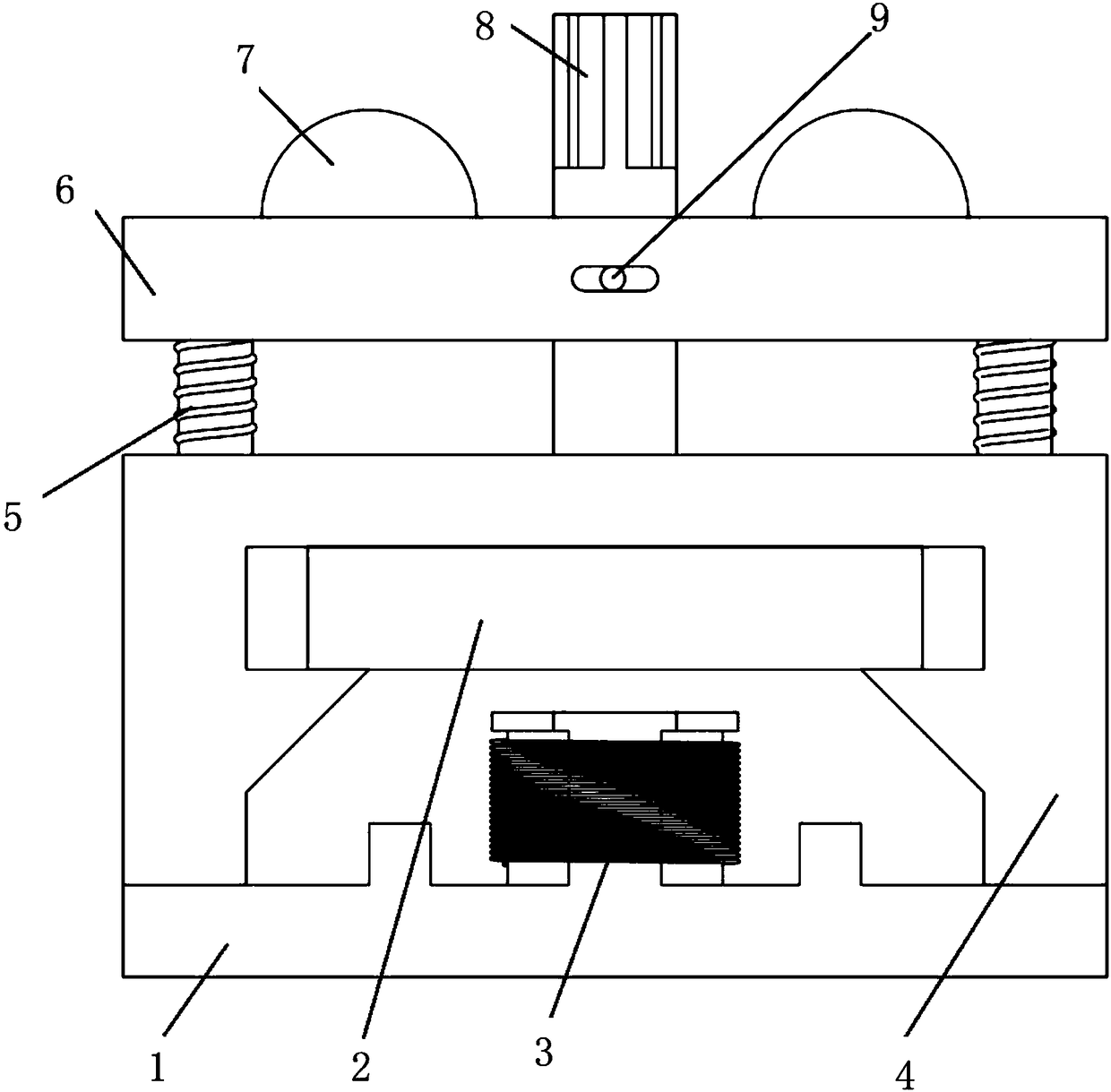

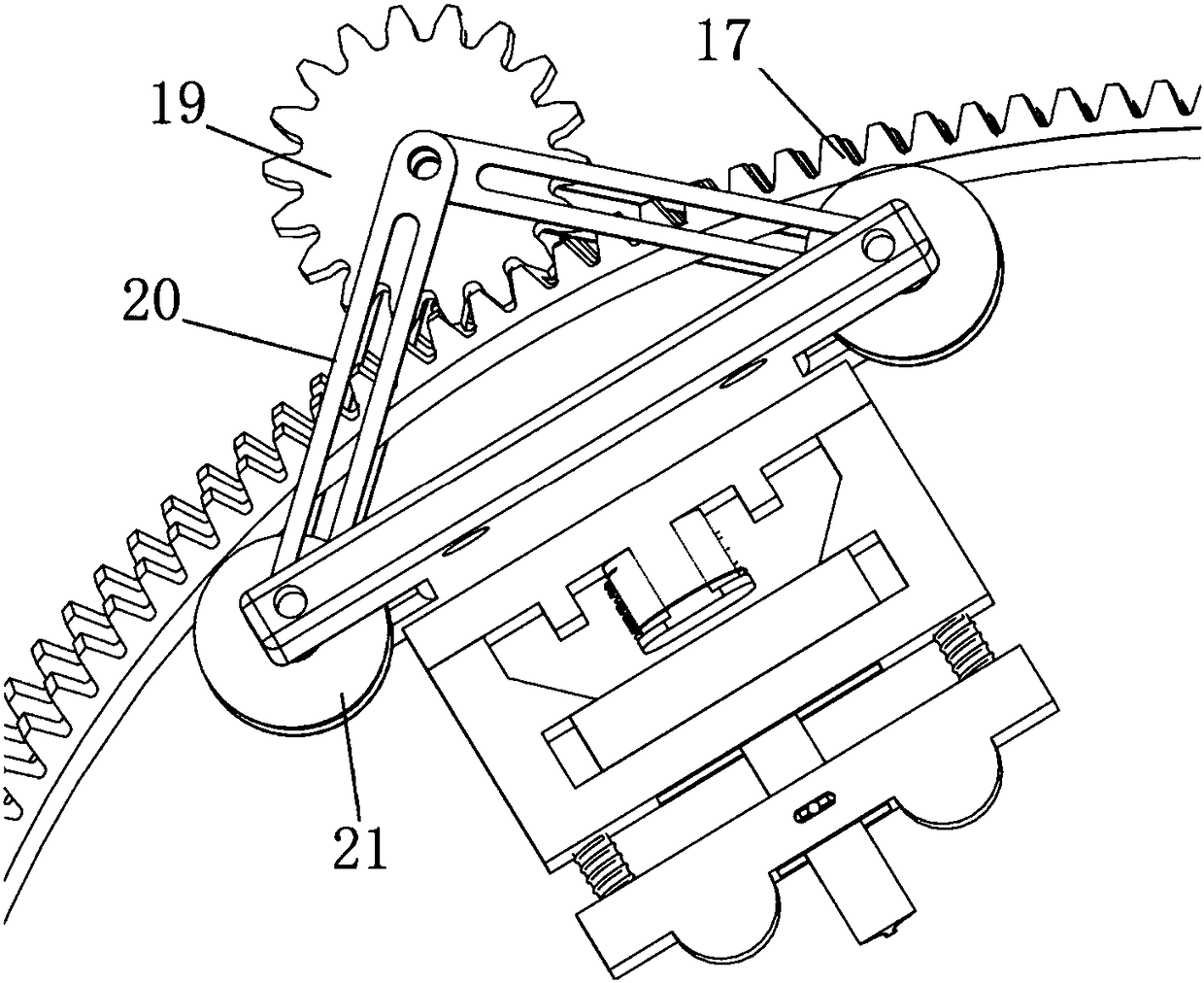

[0020] figure 1 It is an overall assembly drawing of the present invention; figure 2 It is a structural schematic diagram of the magnetic levitation cutter head 18 of the present invention; as shown in the figure: the automatic rubber tapping robot of this embodiment includes a magnetic levitation cutter head 18 and is used to attach the magnetic levitation cutter head 18 to the trunk and guide the magnetic levitation cutter head 18 A cutter head installation mechanism that moves along the trunk surface; the magnetic levitation cutter head 18 includes a base 1, a knife rest 6 elastically connected to the base 1, and a cutting knife 8 that is reciprocally slidingly fitted on the knife rest 6 with a single degree of freedom, like figure 2 As shown, the knife holder 6 is provided with a waist-shaped hole, and a cylindrical pin 9 slidingly fitted with the waist-shaped hole is fixed on the knife handle of the cutting knife 8, so that the cutting knife 8 can slide back and forth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com