Rubber tapping robot control system and method

A control system and robot technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of low work efficiency, high cost, limited work scope, etc., and achieve stable control, complete functions, easy installation and fixation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

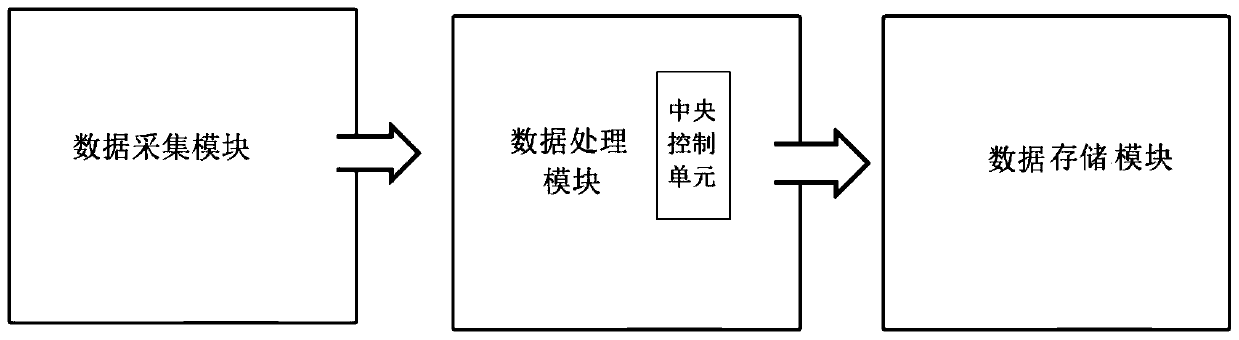

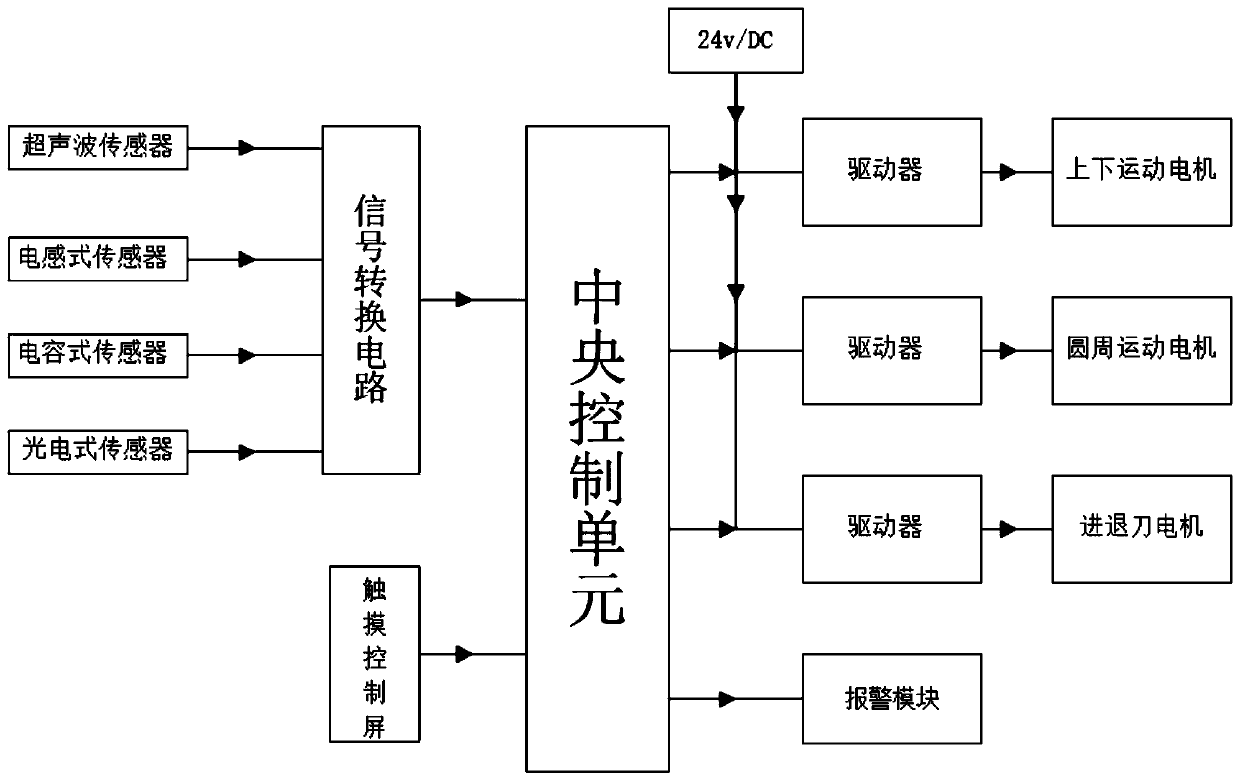

[0022] like figure 1 , figure 2 As shown, the present invention provides a rubber tapping robot control system, which includes a data acquisition module, a data processing module, a data storage module and a power supply battery, and the power supply battery is used to supply power to each module. The data acquisition module transmits the collected rubber tapping information to the data processing module, and then transmits it to the rubber tapping robot and the data storage module after being processed by the data processing module. The rubber tapping robot performs the rubber tapping operation according to the received control information, and the data storage module performs data processing storage. in:

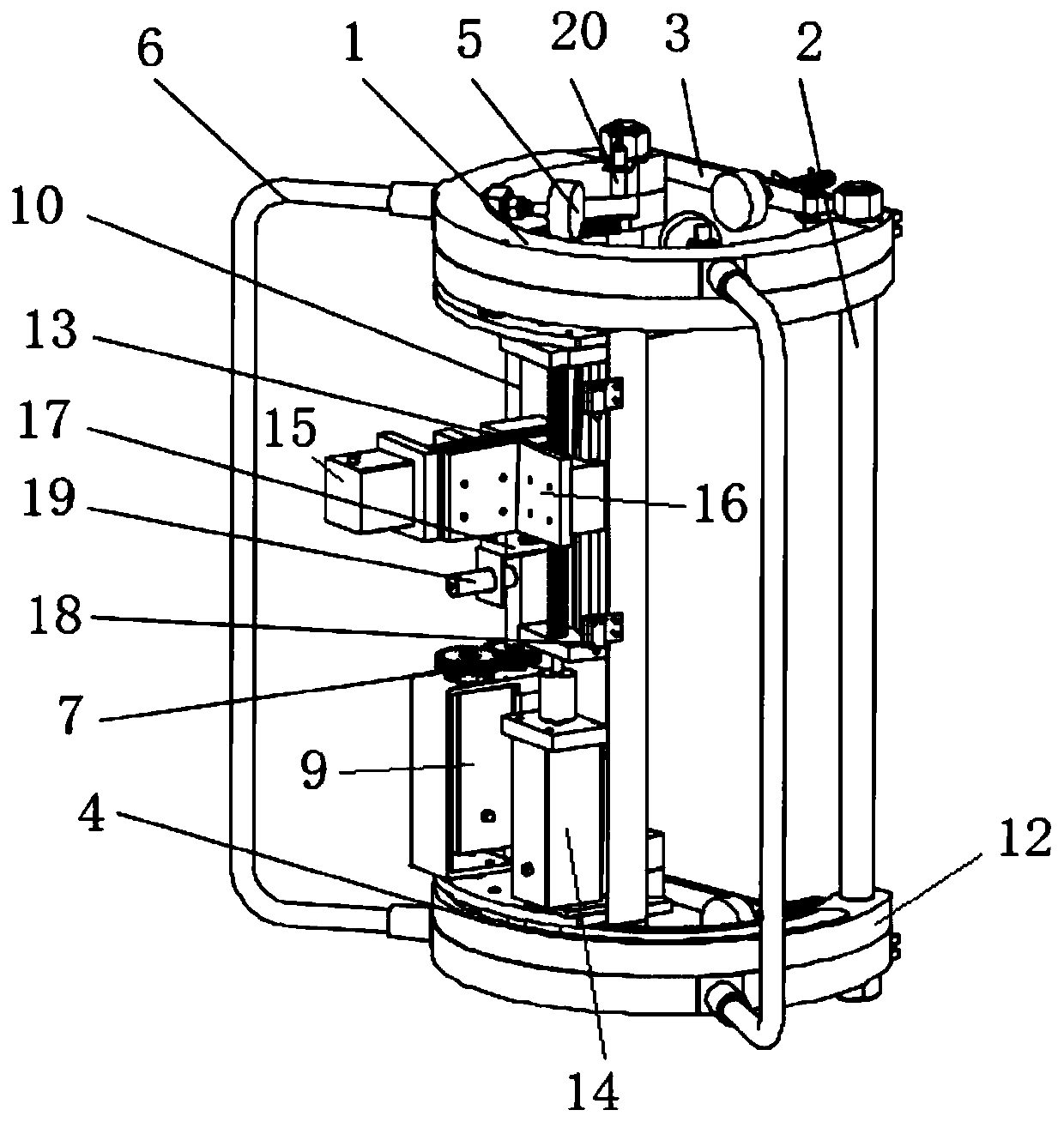

[0023] like image 3 , Figure 4 As shown, the tapping robot includes a clamping mechanism, a cutting mechanism and a moving mechanism. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com