Process for printing far infrared detection prevention camouflage fabric

A printing process and infrared detection technology, which is applied in dyeing, textiles, papermaking, dry-cleaning fiber products, etc., can solve the problem of losing the camouflage effect and achieve a good security camouflage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

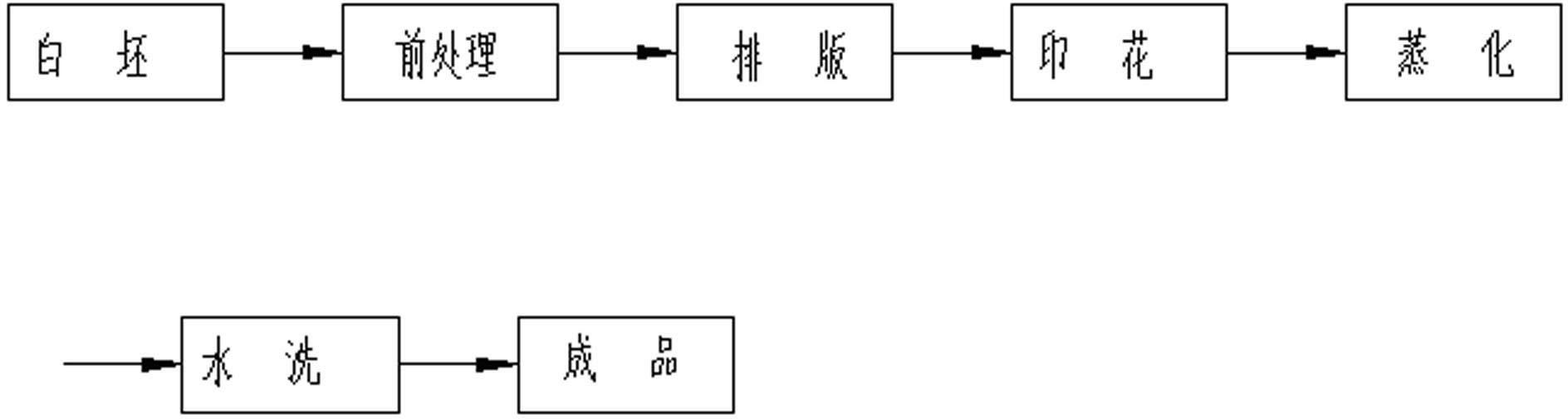

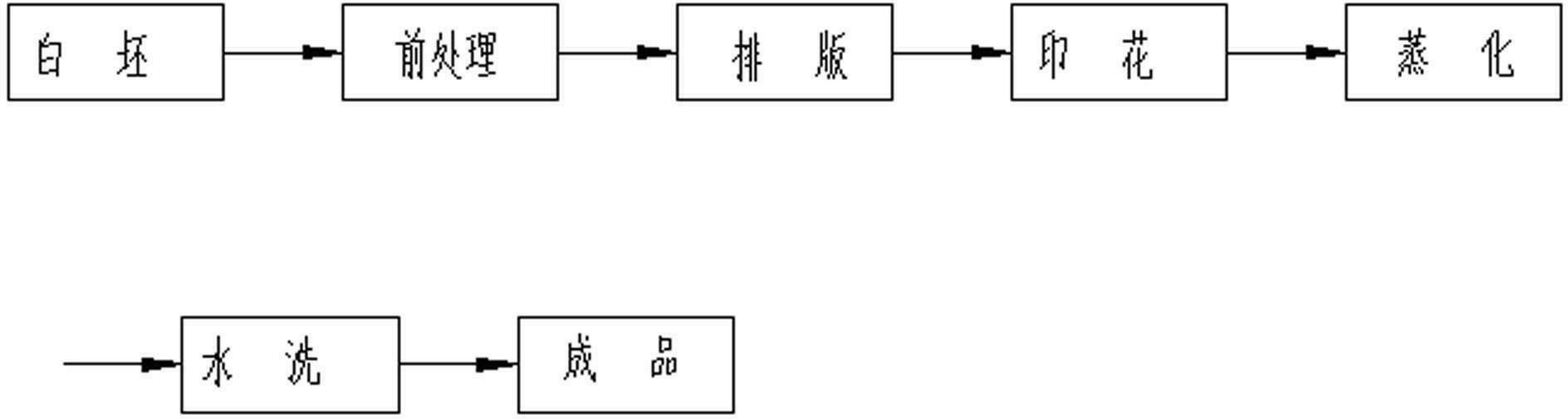

[0024] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These accompanying drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so it only shows the configuration related to the present invention.

[0025] A kind of anti-far-infrared detection camouflage cloth printing process of the present invention comprises the following processing steps:

[0026] (1) Pre-treatment: use polyester filament Oxford cloth white blank with a specification of 400D×400D at 150-180°C, bake for 30-50 seconds for high-temperature tentering, and prepare deep army green printing paste with the following ingredients:

[0027] Disperse dye 0.1-5.0 parts,

[0028] Paint 0.1-0.8 parts,

[0029] Adhesive 5-10 parts,

[0030] 1-3 parts of crosslinking agent,

[0031] 3-6 parts of urea,

[0032] Paste 50-70 parts,

[0033] 9.7-40.8 parts of water,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com