Method for recycling residues of sodium dithionite

A technology of sodium hydrosulfite and residue, which is applied in the direction of thiosulfate/dithionite/polythionate, etc., can solve problems such as environmental pollution and waste of resources, and achieve reduction in production costs, energy consumption and material consumption, and good The effect of economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

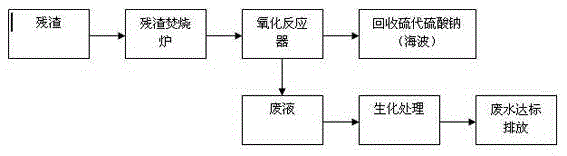

[0024] A method for recovering and reusing sodium hydrosulfite residue, comprising the following steps:

[0025] 1) Put the residue into the incinerator for incineration at 700-900°C to remove the organic salts;

[0026] 2) Send the residue of the material to the reactor in a stirring state, and heat it to boiling; then add sulfur with 5% weight of the residue, continue heating at 90-100°C, and stir for 1 hour;

[0027] 3) Put the solution obtained in step 2) into the oxidation reactor, and oxidize it with air at 70-80°C until the reaction solution changes from brownish-yellow or yellow to white, and the pH value is 7-8, which is regarded as the oxidation end point ;

[0028] 4) The reaction solution after oxidation is vacuum evaporated, decolorized by activated carbon, pressure filtered, cooled, crystallized, centrifuged and sieved to obtain industrial-grade sodium thiosulfate product (big soda); the mother liquor after crystallization and separation is returned to the oxida...

Embodiment 2

[0031] A method for recovering and reusing sodium hydrosulfite residue, comprising the following steps:

[0032] 1) Put the residue into the incinerator for incineration at 700-800°C to remove the organic salts;

[0033] 2) Send the material residue to the reactor under stirring state, heat to boiling; then add 8% sulfur by weight of the residue, continue heating at 90-100°C, and stir for 2 hours;

[0034] 3) Put the solution obtained in step 2) into the oxidation reactor, and oxidize it with air at 70-80°C until the reaction solution changes from brownish-yellow or yellow to white, and the pH value is 7-8, which is regarded as the oxidation end point ;

[0035] 4) The reaction solution after oxidation is vacuum evaporated, decolorized by activated carbon, pressure filtered, cooled, crystallized, centrifuged and sieved to obtain industrial-grade sodium thiosulfate product (big soda); the mother liquor after crystallization and separation is returned to the oxidation reaction ...

Embodiment 3

[0037] A method for recovering and reusing sodium hydrosulfite residue, comprising the following steps:

[0038] 1) Put the residue into the incinerator for incineration at 800-900°C to remove the organic salts;

[0039] 2) Send the material residue to the reactor under stirring state, heat to boiling; then add sulfur with 12% weight of the residue, continue heating at 90-100°C, and stir for 1.5h;

[0040] 3) Put the solution obtained in step 2) into the oxidation reactor, and oxidize it with air at 70-80°C until the reaction solution changes from brownish-yellow or yellow to white, and the pH value is 7-8, which is regarded as the oxidation end point ;

[0041] 4) The reaction solution after oxidation is vacuum evaporated, decolorized by activated carbon, pressure filtered, cooled, crystallized, centrifuged and sieved to obtain industrial-grade sodium thiosulfate product (big soda); the mother liquor after crystallization and separation is returned to the oxidation reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com