Liner for the protection of adhesive masses

An adhesive and anti-stick technology, applied in the direction of adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve problems such as inconvenience and increase in cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

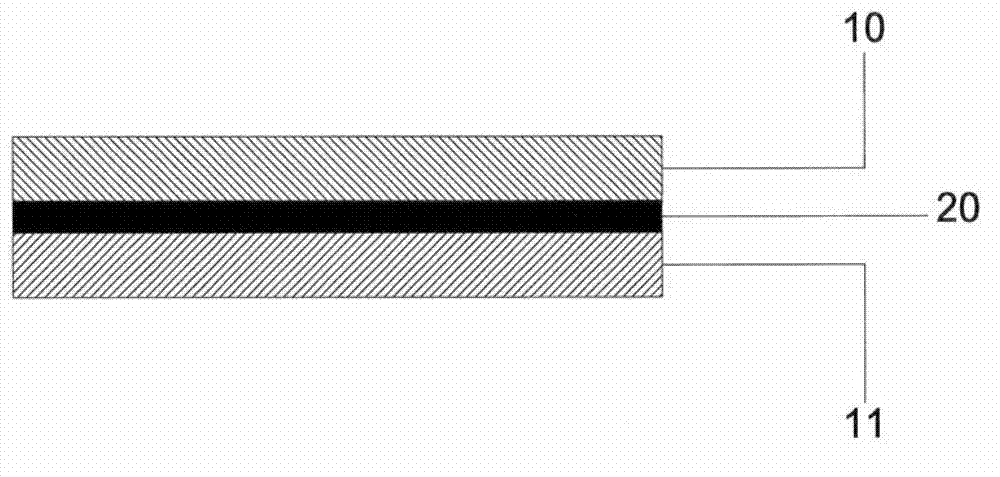

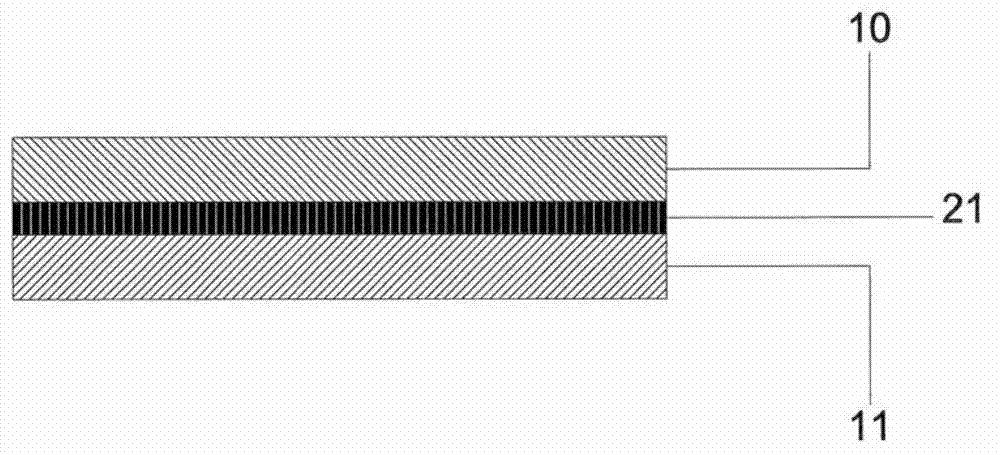

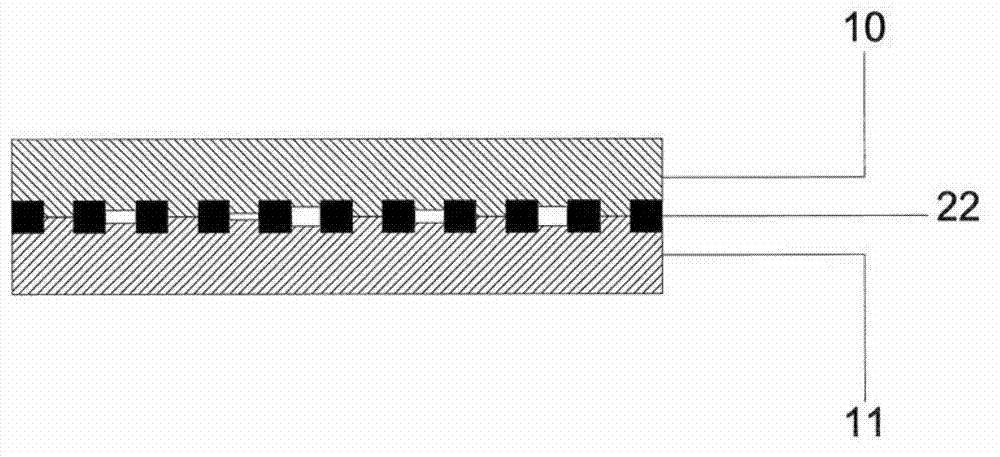

[0150] Various liners are manufactured with layers of absorbent material. And they were laminated to various adhesive tapes by a laboratory roll laminator in a controlled climate chamber at 23°C and 50% relative atmospheric humidity.

[0151] adhesive tape

[0152] For the manufacture of adhesive tapes, different pressure-sensitive adhesives (PSAs) were applied from solution to a conventional liner not according to the invention and not impeding penetration, the liner being ALU I from Mondi, using a laboratory coating apparatus, and dried Type 38UV1, includes aluminum foil carrier. The layer thickness of the adhesive after drying was in each case 25 μm. Drying was carried out in each case at 120° C. for 30 minutes in a laboratory drying cabinet.

[0153]K1: Pressure Sensitive Adhesives

[0154] 100 parts of Tuftec P 1500 with 30% by weight block polyphenylene

[0155] Ethylene content of SBBS from

[0156] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com