Comprehensive utilization method of desulfurization waste liquid

A technology for desulfurization waste liquid and waste liquid, which is applied in chemical instruments and methods, thiocyanic acid, flocculation/sedimentation water/sewage treatment, etc., can solve energy consumption or complex operation, cumbersome follow-up step recycling, and is not suitable for industrial applications and other problems, to achieve the effect of reducing salt concentration and reducing efflux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

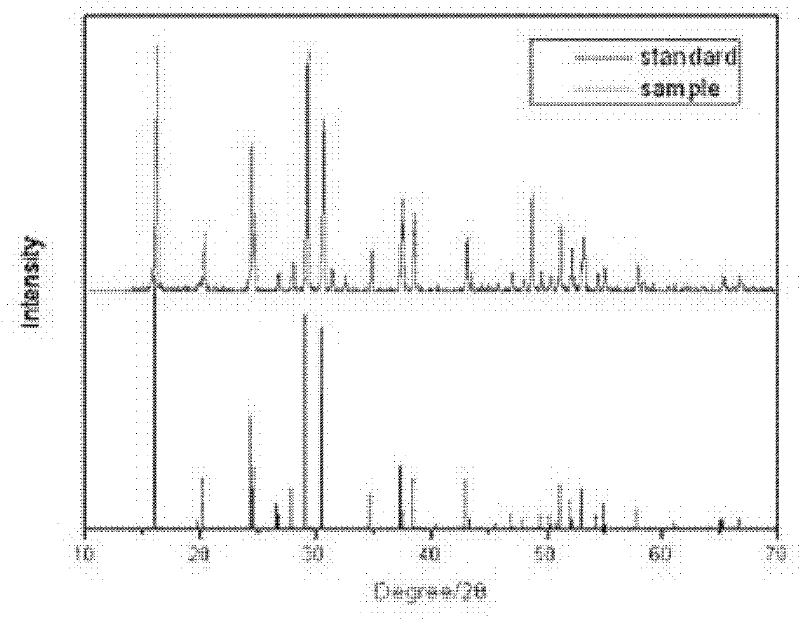

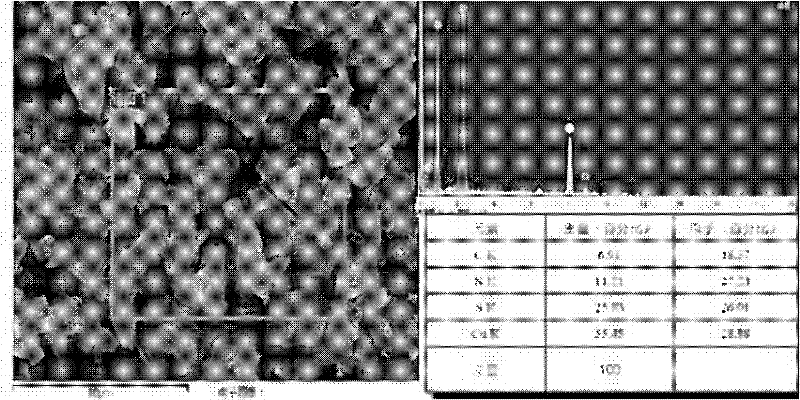

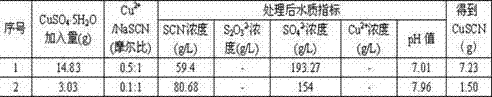

[0020] Laboratory preparation containing NaSCN and Na 2 S 2 o 3 Simulated desulfurization waste liquid, which contains NaSCN 100g / L, Na 2 S 2 o 3 100g / L, Na 2 CO 3 2g / L, NaHCO 3 It is 20g / L, and the pH is 8.58. Take 100ml of the solution to react, the reaction temperature is normal temperature, add CuSO of different quality in small amounts and several times under the condition of stirring 4 ×5H 2 O, after separating the precipitate, measure the pH value and SCN of the solution after the reaction - , S 2 o 3 - 2- , SO 4 2- 、Cu 2+ The concentration and the amount and phase composition of the precipitate. The determination methods refer to national standards, and the results are shown in Table 1.

[0021] Table 1 Addition of CuSO to simulated desulfurization waste liquid 4 ·5H 2 O and its purification effect

[0022] (Composition of simulated desulfurization waste liquid: NaSCN 100g / L, Na 2 S 2 o 3 100g / L, Na 2 CO3 2g / L, NaHCO 3 20g / L, pH 8.58)

[0...

Embodiment 2

[0026] Laboratory preparation containing NaSCN, Na 2 S 2 o 3 and Na 2 SO 4 Simulated desulfurization waste liquid, which contains NaSCN 100g / L, Na 2 SO 4 40g / L, Na 2 S 2 o 3 100g / L, Na 2 CO 3 2g / L, NaHCO 3 It is 20g / L, and the pH is 8.58. Take 100ml of the solution to react, the reaction temperature is normal temperature, add CuSO of different quality in small amounts and several times under the condition of stirring 4 ×5H 2 O, after separating the precipitate, measure the pH value and SCN of the solution after the reaction - , S 2 o 3 - 2- , SO 4 2- 、Cu 2+ The concentration and the amount and phase composition of the precipitate. The determination methods refer to national standards, and the results are shown in Table 2.

[0027] Table 2 Adding CuSO to simulated desulfurization waste liquid 4 ·5H 2 O and its purification effect

[0028] (Composition of simulated desulfurization waste liquid: NaSCN 100g / L, Na 2 SO 4 40g / L, Na 2 S 2 o 3 100g / L,...

Embodiment 3

[0033] The actual desulfurization waste liquid was determined from a fertilizer factory, and the composition of the tested solution was: NaSCN 125g / L, NaSCN 2 S 2 o 3 83.8g / L, Na 2 SO 4 43g / L, Na 2 CO 3 2.18g / L, NaHCO 3 21.9g / L, pH 8.46. Take 100ml solution to react, the reaction temperature is normal temperature, by adding different quality CuSO 4 ·5H 2 O, after separating the precipitate, measure the pH value and SCN of the solution after the reaction - , S 2 o 3 - 2- , SO 4 2- 、Cu 2+ The concentration and the amount and phase composition of the precipitate. The determination methods refer to national standards, and the results are shown in Table 3.

[0034] Table 3 CuSO was added to the actual desulfurization waste liquid of a fertilizer plant 4 ·5H 2 O and its purification effect

[0035] (The actual desulfurization waste liquid composition of a chemical fertilizer plant: NaSCN 125g / L, Na 2 SO 4 43g / L, Na 2 S 2 o 3 83.3g / L, Na 2 CO 3 2.18g / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com