Halobacillus and method for industrially producing Ectoin by using halobacillus

A technology of bacillus and ectoine, applied in the field of microorganisms, can solve the problems of limited scope of use, high cost and high price, and achieve the effect of reducing corrosion and environmental pollution and reducing salt concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: the acquisition of bacterial strain

[0024] Dilute the sea mud samples collected in the coastal waters of Rizhao in sterile water, spread the diluted solution on medium plates containing different NaCl concentrations, and incubate at 28°C. After the colonies grow out, select a single colony and continue to separate and purify until The pure bacteria were obtained, the strains with fast growth rate and wide range of salt concentration were first screened, and the HPLC method was used to determine the yield of ectoine in the second screening, and the strain with ectoine yield of 2.4g / L was obtained through laboratory screening.

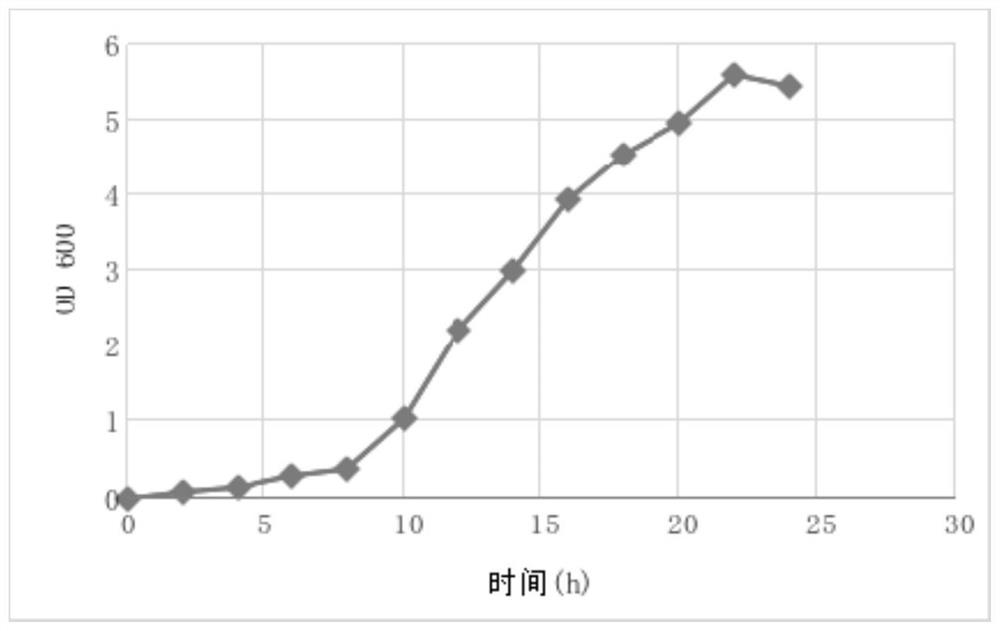

[0025] The strain was bred through chemical and physical compound mutagenesis, and was screened in a large number in the laboratory to obtain a mutant strain FL-2423 with high yield of ectoine, which has the ability of industrial production of ectoine and stable genetic characteristics. Growth curve such as figure 1 As shown, the...

Embodiment 2

[0026] Embodiment 2: Amplification, sequencing and sequence comparison of 16SrDNA of bacterial strain

[0027] Collect fresh bacteria, use the Ezup column bacterial genome DNA extraction kit to extract the total DNA template, and use universal primers to amplify the 16S rDNA gene. After the PCR product is tested and purified, it is directly sequenced. Technology Co., Ltd.

[0028] The primer sequence is as follows: 27F: 5'-AGAGTTTGATCCTGGCTCAG-3';

[0029] 1495R: 5'-GGTTACCTTGTTACGACTT-3';

[0030] The 10 μL PCR reaction system is as follows: template 1 μL; upstream primer, downstream primer 1 μL; Dream Taq GreenPCR Master Mix 5 μL; ddH 2 O 2 μL.

[0031] PCR conditions: 95°C for 5min, 94°C for 30s, 52°C for 2min, 72°C for 1min; cycle 30 times.

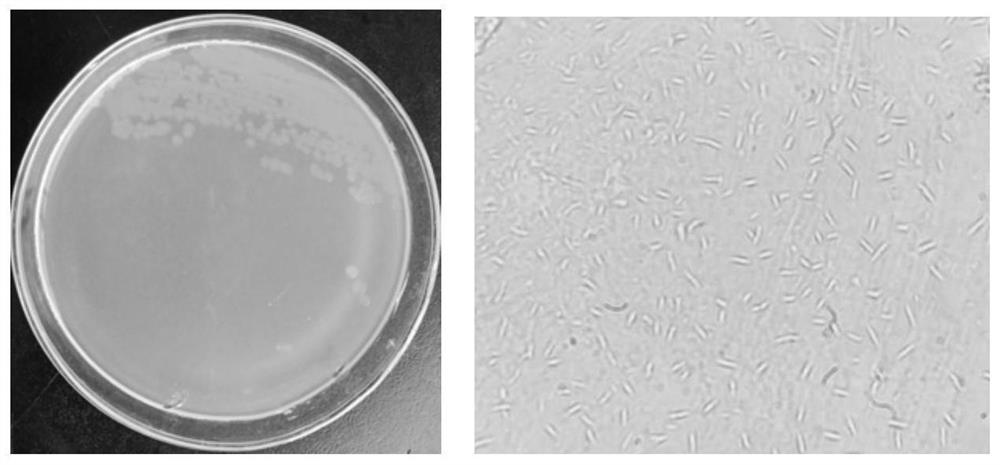

[0032] The measured full sequence results are as follows: the 16S rDNA sequence of the strain is shown in the sequence table SEQ No.1, and the colony characteristics of the mutant strain are as follows: figure 2 shown. And the o...

Embodiment 3

[0033] Embodiment 3: the culture method of halobacillus sp. FL-2423

[0034] 1) Inoculate the seed medium with Halobacillus sp. FL-2423 and culture it at 28°C for 24 hours to obtain the seed solution.

[0035] Seed medium components: monosodium glutamate 25g / L, dipotassium hydrogen phosphate 5g / L, potassium dihydrogen phosphate 3g / L, magnesium sulfate 0.4g / L, manganese sulfate 0.01g / L, yeast powder 1g / L, sodium chloride 30g / L, pH 7.0.

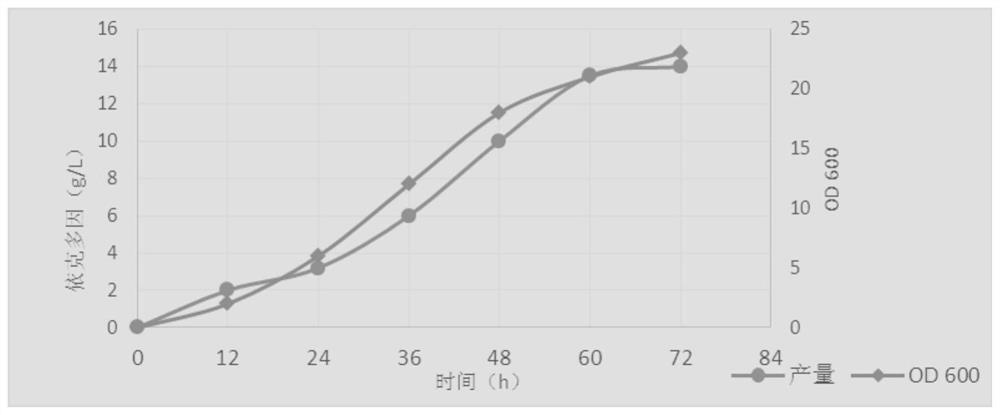

[0036] 2) The above seed solution was inoculated in a shake flask with an inoculation amount of 5%, and cultured at 28° C. for 72 hours, and the yield of ectoine in the fermentation broth was 12.5 g / L.

[0037] Fermentation medium components: sodium glutamate 40g / L, dipotassium hydrogen phosphate 8g / L, potassium dihydrogen phosphate 4g / L, magnesium sulfate 0.5g / L, manganese sulfate 0.05g / L, yeast powder 10g / L, Sodium chloride 60g / L, ammonium sulfate 10g / L, pH 7.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com