High-abrasion-resistant and environment-friendly polyvinyl chloride (PVC) modified materials and preparation method thereof

A technology of modified materials and wear-resistant modifiers, which is applied in the field of high-wear-resistant and environmentally-friendly PVC modified materials and their preparation, which can solve problems such as human health hazards, low wear-resistant coefficient, and poor wear resistance, and achieve softness. Good electrical and electrical insulation properties, improved wear resistance, and the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

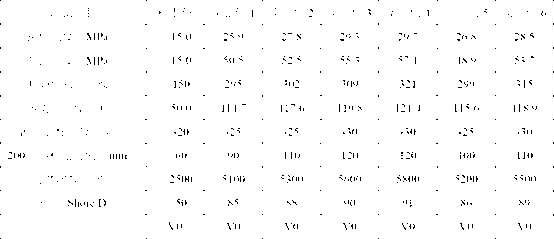

Embodiment 1

[0055] Weigh raw material SG-5 type PVC resin 80Kg, silicon dioxide 5Kg, trioctyl trimellitate 30Kg, epoxy soybean oil 1Kg, styrene-butadiene rubber 0.5Kg, natural rubber 0.5Kg, antimony trioxide 0.5Kg, boric acid 0.5Kg of zinc, 0.5Kg of dibutyltin dilaurate, 0.5Kg of rare earth stearate, 10Kg of chlorinated polyethylene with a chlorine content of 25%, 0.1Kg of paraffin wax, and 0.1Kg of stearic acid amide are mixed; into a high-speed blender, and stirred at a temperature of 100°C for 25 minutes; the stirred raw materials were extruded and granulated through a twin-screw extruder to obtain a highly wear-resistant and environmentally friendly PVC modified material; the twin-screw extruder The screw temperature is: the temperature of the first zone is 138°C, the temperature of the second zone is 135°C, the temperature of the third zone is 135°C, the temperature of the fourth zone is 132°C and the temperature of the fifth zone is 130°C. The mechanical and physical properties of t...

Embodiment 2

[0057] Weigh raw material SG-7 type PVC resin 90Kg, silicon dioxide 7Kg, trioctyl trimellitate 35Kg, epoxy soybean oil 2Kg, styrene-butadiene rubber 1Kg, natural rubber 1Kg, antimony trioxide 1Kg, zinc borate 2Kg, Di-n-octyltin dilaurate 1Kg, fatty acid rare earth 1Kg, chlorinated polyethylene 12Kg with a chlorine content of 30%, oxidized paraffin 0.3Kg, fatty acid alkanolamide 0.2Kg mixed; put the mixed raw materials into a high-speed blender , stirred at a temperature of 140°C for 15 minutes; the stirred raw materials were extruded and granulated through a twin-screw extruder to obtain a highly wear-resistant and environmentally friendly PVC modified material; the screw temperature of the twin-screw extruder was: The temperature is 140°C, the temperature in the second zone is 140°C, the temperature in the third zone is 135°C, the temperature in the fourth zone is 135°C, and the temperature in the fifth zone is 135°C. The mechanical and physical properties of the highly wear-...

Embodiment 3

[0059] Weigh raw materials SG-5 type PVC resin 100Kg, silicon dioxide 9Kg, trioctyl trimellitate 42Kg, epoxy soybean oil 4Kg, styrene-butadiene rubber 2Kg, natural rubber 2Kg, antimony trioxide 2Kg, zinc borate 3Kg, 2Kg of isooctyl tin dimethyl dimercaptoacetate, 2Kg of rare earth salicylic acid, 14Kg of chlorinated polyethylene with a chlorine content of 35%, 0.5Kg of liquid paraffin, and 0.4Kg of erucamide; put the mixed raw materials into In a high-speed blender, stir at a temperature of 120°C for 20 minutes; extrude and granulate the stirred raw materials through a twin-screw extruder to obtain a high wear-resistant and environmentally friendly PVC modified material; the screw of the twin-screw extruder The temperature is: zone 1 temperature 160°C, zone 2 temperature 160°C, zone 3 temperature 155°C, zone 4 temperature 150°C and zone 5 temperature 148°C. The mechanical and physical properties of the highly wear-resistant and environmentally friendly PVC modified material pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com