Master batch and preparation method thereof, and vulcanized rubber and applications thereof

A technology of vulcanized rubber and masterbatch, applied in transportation and packaging, rolling resistance optimization, tire parts, etc., can solve the problems of poor dispersion of silica and montmorillonite, and achieve excellent wear resistance, low rolling resistance, the effect of reducing rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

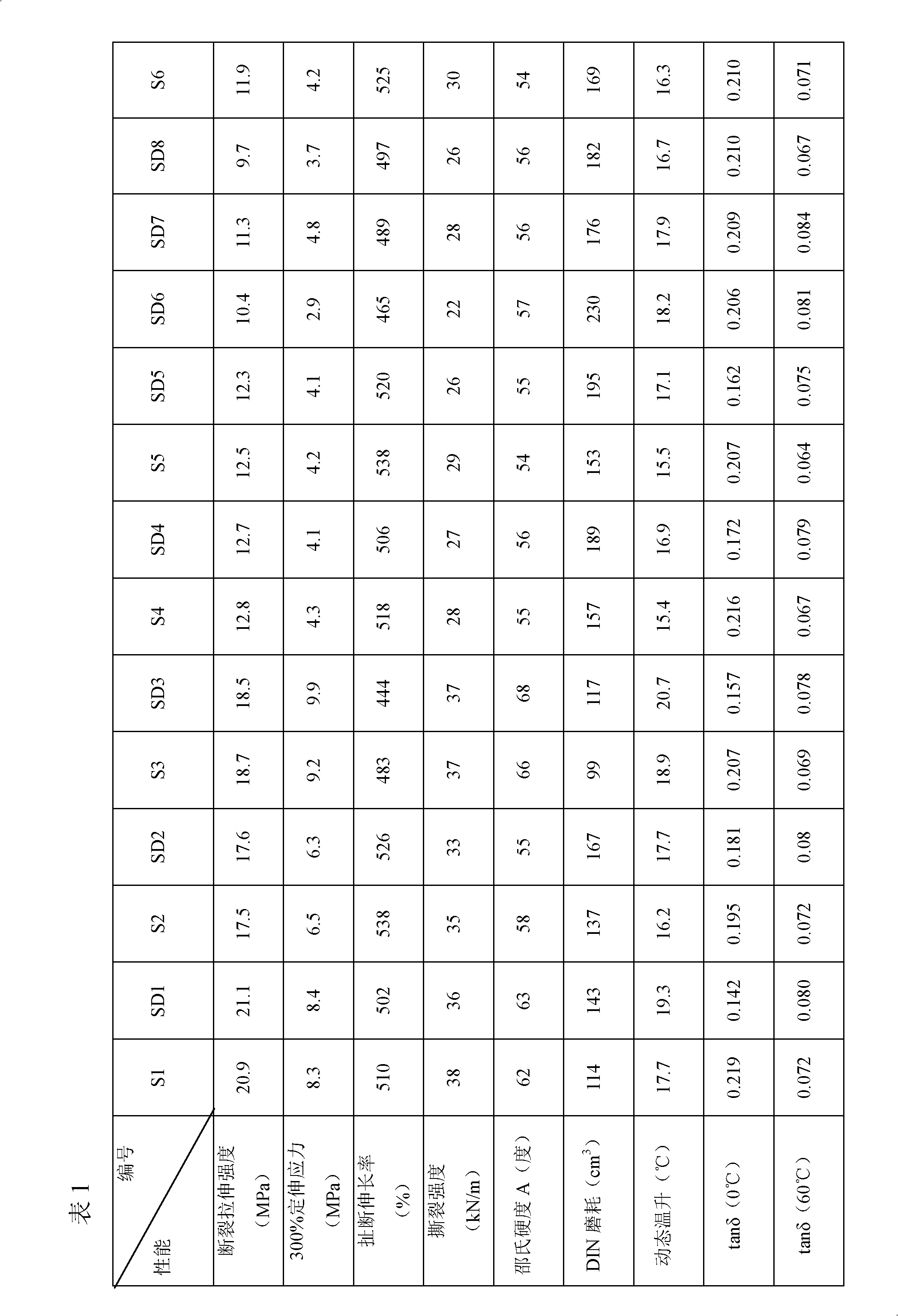

Examples

preparation example Construction

[0016] The invention provides a kind of preparation method of masterbatch, and the method comprises the following steps:

[0017] (1) Under condensation conditions, white carbon black is contacted with a silane coupling agent, and the mass ratio of the white carbon black to the silane coupling agent is 1: 0.03-0.15;

[0018] (2) mixing layered silicate minerals, quaternary ammonium salts with water, and drying;

[0019] (3) mixing the product (modified layered silicate mineral) obtained in step (2) with the rubber glue obtained by solution polymerization to obtain a suspension, the rubber glue containing a polymer and a first organic solvent, Based on the total weight of the rubber glue, the content of the polymer is 0.6-8% by weight; relative to 100 parts by weight of the polymer, the product obtained in the step (2) is 3-15 parts by weight;

[0020] (4) Mix and dry the contacted product (modified white carbon black) described in step (1) with the suspension obtained in step...

Embodiment 1

[0043] (1) 40g white carbon black (the specific surface area value is 115-175 square meters / gram, manufacturer: French Rhodia Company, the same below), 2g bis-(γ-triethoxysilylpropyl)-tetrafluoroethylene The sulfide and 157.8 g of ethanol were stirred and mixed at 25° C. for 4 hours, and then heated at 100° C. for 2.5 hours to remove volatile matter therein to obtain 37 g of modified white carbon black.

[0044] (2) Stir 7g montmorillonite (average lamellar spacing 1.3nm, manufacturer: Zhejiang Fenghong Clay Chemical Co., Ltd., the same below), 2.1g octadecyltrimethylammonium chloride and 350g water at 65°C Mixed for 4 hours, and then dried to obtain 7 g of modified montmorillonite, the average interlamellar distance of the modified montmorillonite measured by X-ray diffraction was 2.8 nm.

[0045] (3) 7 g of the modified montmorillonite obtained in step (2) and 350 g of cyclohexane were stirred and mixed at 70° C. for 4 hours. The copolymer glue (solvent is cyclohexane; soli...

Embodiment 2

[0051] (1) 31g of white carbon black, 2.48g of bis-(γ-triethoxysilylpropyl)-tetrasulfide and 98.2g of methanol were stirred and mixed at 10°C for 8 hours, and then heated at 95°C for 3 hours to Remove volatile matter wherein, obtain 30g modified white carbon black.

[0052](2) 3g montmorillonite, 0.3g dodecyltrimethylammonium chloride and 90g water were stirred and mixed at 50°C for 1 hour, then dried to obtain 3g modified montmorillonite, which was measured by X-ray diffraction The average interlamellar spacing of the modified montmorillonite is 3.2 nanometers.

[0053] (3) 3 g of modified montmorillonite obtained in step (2) and 90 g of benzene were stirred and mixed at 55° C. for 1 hour. The glue solution of the butadiene-styrene copolymer obtained by this mixture and 5L solution polymerization (solvent is cyclohexane; Solid content is 20g / L, and the weight-average molecular weight of butadiene-styrene copolymer is 240,000, It is obtained by polymerizing butadiene and sty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Solid content | aaaaa | aaaaa |

| Solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com